power steering fluid MAZDA 6 2002 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 20 of 909

GI–16

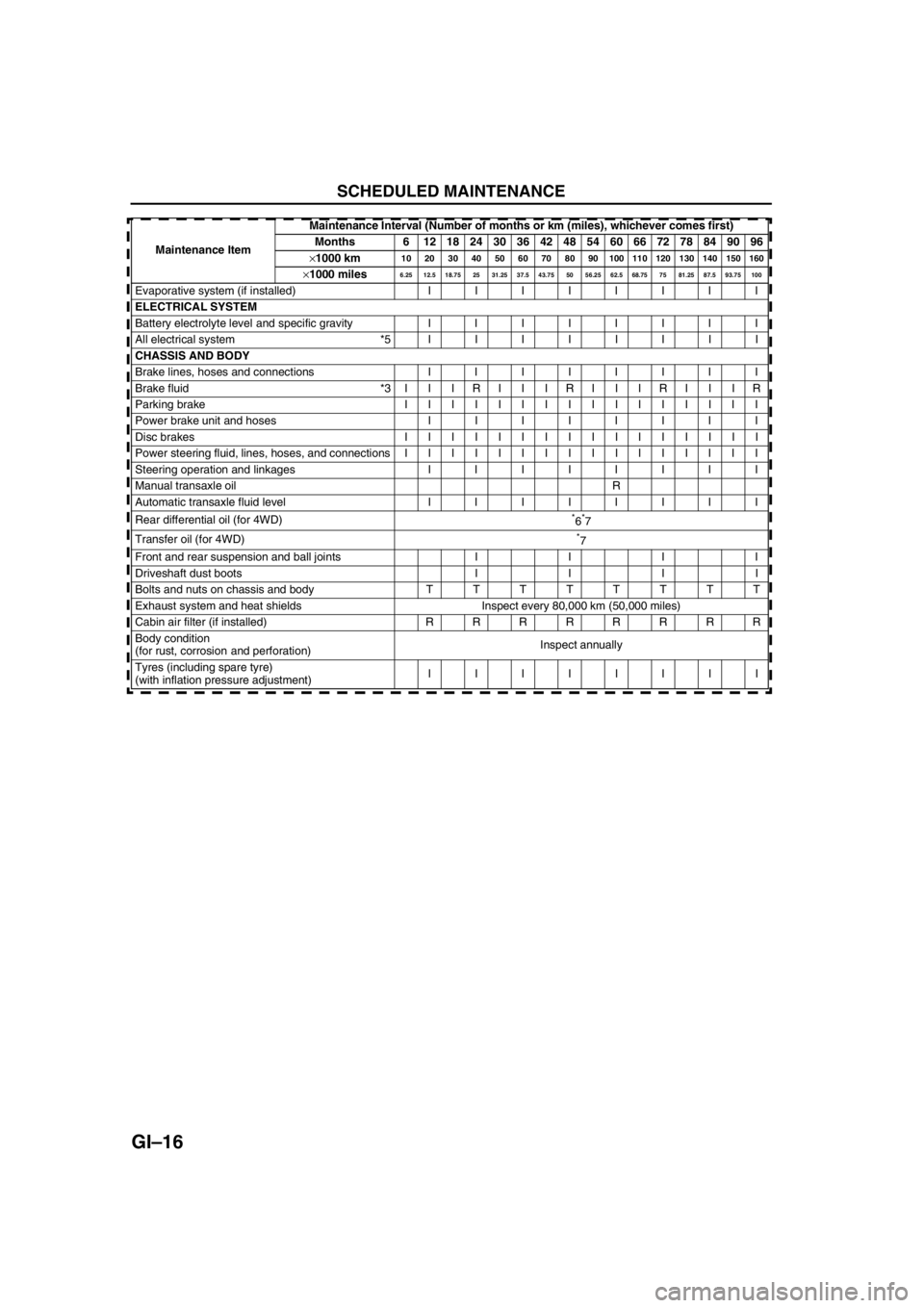

SCHEDULED MAINTENANCE

Evaporative system (if installed) IIIIIIII

ELECTRICAL SYSTEM

Battery electrolyte level and specific gravity IIIIIIII

All electrical system *5IIIIIIII

CHASSIS AND BODY

Brake lines, hoses and connections IIIIIIII

Brake fluid *3IIIRIIIRIIIRIIIR

Parking brake IIIIIIIIIIIIIIII

Power brake unit and hoses IIIIIIII

Disc brakes IIIIIIIIIIIIIIII

Power steering fluid, lines, hoses, and connections I I I I I I I I I I I I I I I I

Steering operation and linkages IIIIIIII

Manual transaxle oilR

Automatic transaxle fluid level IIIIIIII

Rear differential oil (for 4WD)

*6*7

Transfer oil (for 4WD)

*7

Front and rear suspension and ball joints I I I I

Driveshaft dust boots I I I I

Bolts and nuts on chassis and body TTTTTTTT

Exhaust system and heat shields Inspect every 80,000 km (50,000 miles)

Cabin air filter (if installed) RRRRRRRR

Body condition

(for rust, corrosion and perforation)Inspect annually

Tyres (including spare tyre)

(with inflation pressure adjustment)IIIIIIII Maintenance ItemMaintenance Interval (Number of months or km (miles), whichever comes first)

Months 6 121824303642485460667278849096

×1000 km

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160

×1000 miles6.25 12.5 18.75 25 31.25 37.5 43.75 50 56.25 62.5 68.75 75 81.25 87.5 93.75 100

Page 21 of 909

SCHEDULED MAINTENANCE

GI–17

GI

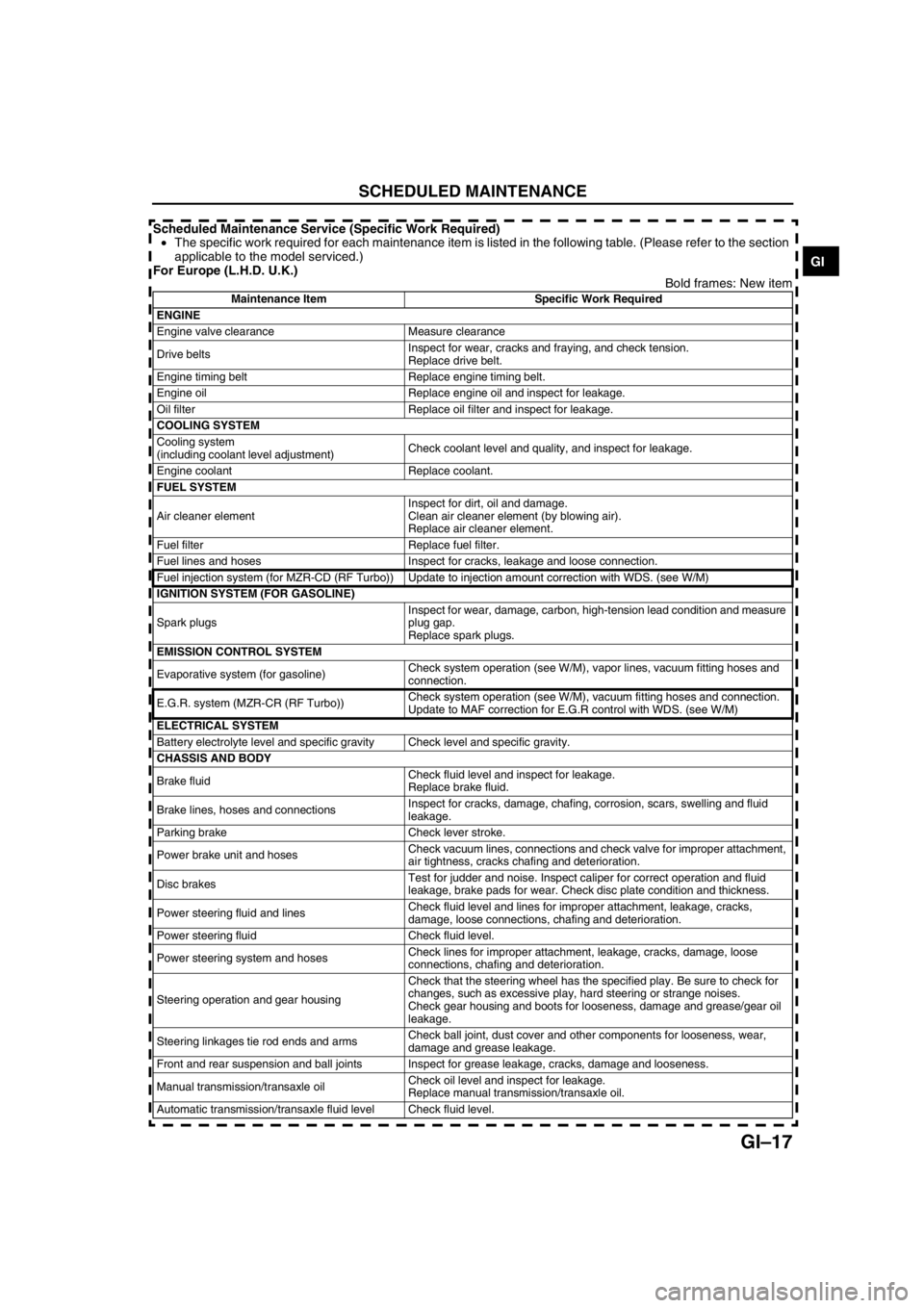

Scheduled Maintenance Service (Specific Work Required)

•The specific work required for each maintenance item is listed in the following table. (Please refer to the section

applicable to the model serviced.)

For Europe (L.H.D. U.K.)

Bold frames: New item

Maintenance Item Specific Work Required

ENGINE

Engine valve clearance Measure clearance

Drive beltsInspect for wear, cracks and fraying, and check tension.

Replace drive belt.

Engine timing belt Replace engine timing belt.

Engine oil Replace engine oil and inspect for leakage.

Oil filter Replace oil filter and inspect for leakage.

COOLING SYSTEM

Cooling system

(including coolant level adjustment)Check coolant level and quality, and inspect for leakage.

Engine coolant Replace coolant.

FUEL SYSTEM

Air cleaner elementInspect for dirt, oil and damage.

Clean air cleaner element (by blowing air).

Replace air cleaner element.

Fuel filter Replace fuel filter.

Fuel lines and hoses Inspect for cracks, leakage and loose connection.

Fuel injection system (for MZR-CD (RF Turbo)) Update to injection amount correction with WDS. (see W/M)

IGNITION SYSTEM (FOR GASOLINE)

Spark plugsInspect for wear, damage, carbon, high-tension lead condition and measure

plug gap.

Replace spark plugs.

EMISSION CONTROL SYSTEM

Evaporative system (for gasoline)Check system operation (see W/M), vapor lines, vacuum fitting hoses and

connection.

E.G.R. system (MZR-CR (RF Turbo))Check system operation (see W/M), vacuum fitting hoses and connection.

Update to MAF correction for E.G.R control with WDS. (see W/M)

ELECTRICAL SYSTEM

Battery electrolyte level and specific gravity Check level and specific gravity.

CHASSIS AND BODY

Brake fluidCheck fluid level and inspect for leakage.

Replace brake fluid.

Brake lines, hoses and connectionsInspect for cracks, damage, chafing, corrosion, scars, swelling and fluid

leakage.

Parking brake Check lever stroke.

Power brake unit and hosesCheck vacuum lines, connections and check valve for improper attachment,

air tightness, cracks chafing and deterioration.

Disc brakesTest for judder and noise. Inspect caliper for correct operation and fluid

leakage, brake pads for wear. Check disc plate condition and thickness.

Power steering fluid and linesCheck fluid level and lines for improper attachment, leakage, cracks,

damage, loose connections, chafing and deterioration.

Power steering fluid Check fluid level.

Power steering system and hosesCheck lines for improper attachment, leakage, cracks, damage, loose

connections, chafing and deterioration.

Steering operation and gear housingCheck that the steering wheel has the specified play. Be sure to check for

changes, such as excessive play, hard steering or strange noises.

Check gear housing and boots for looseness, damage and grease/gear oil

leakage.

Steering linkages tie rod ends and armsCheck ball joint, dust cover and other components for looseness, wear,

damage and grease leakage.

Front and rear suspension and ball joints Inspect for grease leakage, cracks, damage and looseness.

Manual transmission/transaxle oilCheck oil level and inspect for leakage.

Replace manual transmission/transaxle oil.

Automatic transmission/transaxle fluid level Check fluid level.

Page 58 of 909

ENGINE

B2–27

B2

ENGINE REMOVAL/INSTALLATIONA6E232401001201

Warning

•Fuel vapor is hazardous. It can very easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injures or death and

damage. Fuel can also irritate skin and eyes. To prevent this, always complete the “Fuel Line

Safety Procedure”. (See F2–45 Fuel Line Safety Procedures.)

1. Disconnect the negative battery cable.

2. Drain the engine coolant, engine oil, and transaxle oil.

3. Remove the radiator.

4. Remove the engine cover. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

5. Remove the air cleaner and air hose. (See F2–36 INTAKE-AIR SYSTEM REMOVAL/INSTALLATION.)

6. Disconnect the fuel hose. (See F2–45 BEFORE REPAIR PROCEDURE.)

7. Remove the front pipe. (See F2–57 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

8. Remove the battery and tray. (See G–5 BATTERY REMOVAL/INSTALLATION.)

9. Remove the shift cable, select cable and clutch release cylinder related to the transaxle. (See J2–7 MANUAL

TRANSAXLE REMOVAL/INSTALLATION.)

10. Remove the clutch release cylinder.

11. Remove the vacuum hose and the heater hose.

12. Disconnect the P/S oil pump pressure pipe and P/S oil pump relief hose from the P/S oil pump side. (See N–16

POWER STEERING OIL PUMP (MZR-CD (RF Turbo)) REMOVAL/INSTALLATION.)

Note

•The P/S oil pump will not be removed from the engine.

13. Remove the A/C compressor with the pipe still connected. Position the A/C compressor so that it is out of the

way. Use wire or rope to secure it. (See U–11 A/C COMPRESSOR REMOVAL/INSTALLATION.)

14. Remove the joint shaft.

15. Remove the front drive shaft (LH) from the transaxle.

16. Remove in the order indicated in the table.

17. Install in the reverse order of removal.

18. Fill the engine coolant, engine oil, and transaxle oil.

19. Bleed the air from the fuel line. (See F2–45 AFTER REPAIR PROCEDURE.)

20. Start the engine and:

•Inspect the pulleys and the drive belt for runout and contact.

•Inspect the engine oil, engine coolant transaxle oil, P/S fluid, and fuel for leakage.

•Inspect the idle speed. (See F2–34 IDLE SPEED INSPECTION.)

21. Perform a road test.

22. Reinspect the engine oil, engine coolant, transaxle oil, and P/S fluid levels.

ENGINE

Page 369 of 909

TROUBLESHOOTING

F2–217

F2

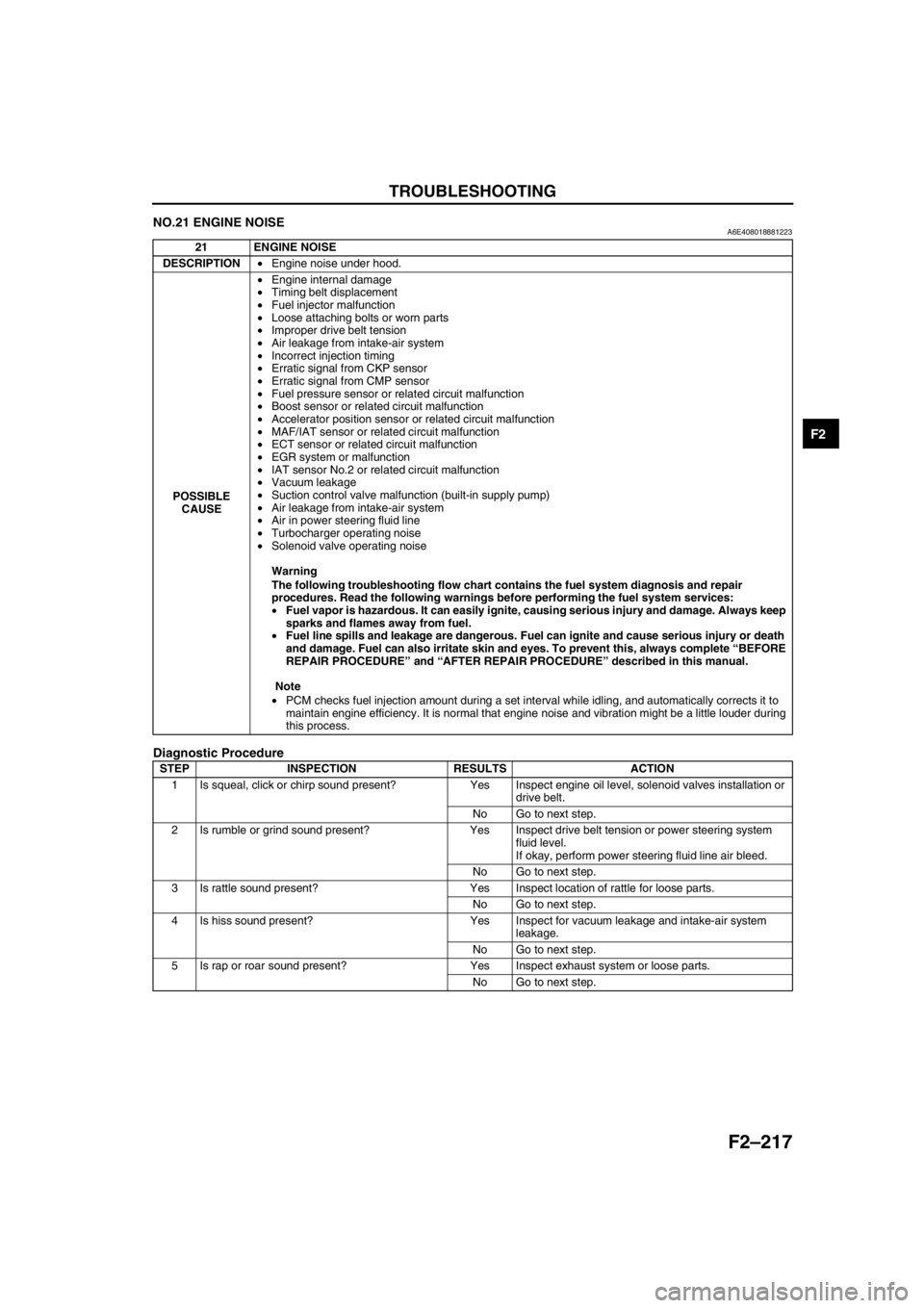

NO.21 ENGINE NOISEA6E408018881223

Diagnostic Procedure

21 ENGINE NOISE

DESCRIPTION•Engine noise under hood.

POSSIBLE

CAUSE•Engine internal damage

•Timing belt displacement

•Fuel injector malfunction

•Loose attaching bolts or worn parts

•Improper drive belt tension

•Air leakage from intake-air system

•Incorrect injection timing

•Erratic signal from CKP sensor

•Erratic signal from CMP sensor

•Fuel pressure sensor or related circuit malfunction

•Boost sensor or related circuit malfunction

•Accelerator position sensor or related circuit malfunction

•MAF/IAT sensor or related circuit malfunction

•ECT sensor or related circuit malfunction

•EGR system or malfunction

•IAT sensor No.2 or related circuit malfunction

•Vacuum leakage

•Suction control valve malfunction (built-in supply pump)

•Air leakage from intake-air system

•Air in power steering fluid line

•Turbocharger operating noise

•Solenoid valve operating noise

Warning

The following troubleshooting flow chart contains the fuel system diagnosis and repair

procedures. Read the following warnings before performing the fuel system services:

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always keep

sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injury or death

and damage. Fuel can also irritate skin and eyes. To prevent this, always complete “BEFORE

REPAIR PROCEDURE” and “AFTER REPAIR PROCEDURE” described in this manual.

Note

•PCM checks fuel injection amount during a set interval while idling, and automatically corrects it to

maintain engine efficiency. It is normal that engine noise and vibration might be a little louder during

this process.

STEP INSPECTION RESULTS ACTION

1 Is squeal, click or chirp sound present? Yes Inspect engine oil level, solenoid valves installation or

drive belt.

No Go to next step.

2 Is rumble or grind sound present? Yes Inspect drive belt tension or power steering system

fluid level.

If okay, perform power steering fluid line air bleed.

No Go to next step.

3 Is rattle sound present? Yes Inspect location of rattle for loose parts.

No Go to next step.

4 Is hiss sound present? Yes Inspect for vacuum leakage and intake-air system

leakage.

No Go to next step.

5 Is rap or roar sound present? Yes Inspect exhaust system or loose parts.

No Go to next step.

Page 715 of 909

N–1

N

NSTEERING SYSTEM

OUTLINE................................................................ N-2

OUTLINE OF CONSTRUCTION.......................... N-2

FEATURES .......................................................... N-2

SPECIFICATIONS ............................................... N-2

STRUCTURAL VIEW ...........................................N-3

OUTLINE................................................................ N-5

SUPPLEMENTAL SERVICE

INFORMATION .................................................N-5

ENGINE SPEED SENSING POWER

STEERING........................................................... N-6

POWER STEERING FLUID INSPECTION ..........N-6

STEERING GEAR AND LINKAGE

(MZR-CD (RF TURBO))

REMOVAL/INSTALLATION ..............................N-8

STEERING GEAR AND LINKAGE (4WD)

REMOVAL/INSTALLATION ............................N-13

POWER STEERING OIL PUMP

(MZR-CD (RF TURBO))

REMOVAL/INSTALLATION ............................N-16

POWER STEERING OIL PUMP

(MZR-CD (RF TURBO))

DISASSEMBLY/ASSEMBLY .......................... N-17 FEATURES

SERVICE

Page 716 of 909

N–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E660201036201•The construction and operation of the steering system is essentially carried over from that of the current

Mazda6 (GG), except for the following features. (See Mazda6 Training Manual 3359-1*-02C.)

• Due to the addition of the MZR-CD (RF Turbo) engine, a gear-driven power steering oil pump has been

adopted. The operation of the oil pump is the same as that of the current Mazda6 (GG).

• The disassembly/assembly procedures for the steering gear and linkage of the newly equipped MZR-CD (RF

Turbo) engine, wagon and 4WD models are the same as that of the current Mazda6 (GG).

End Of Sie

FEATURESA6E660201036202Improved Steering Feel

• The fluid pressure characteristics of the power steering system has been optimized (MZR-CD (RF Turbo) and

4WD models).

End Of Sie

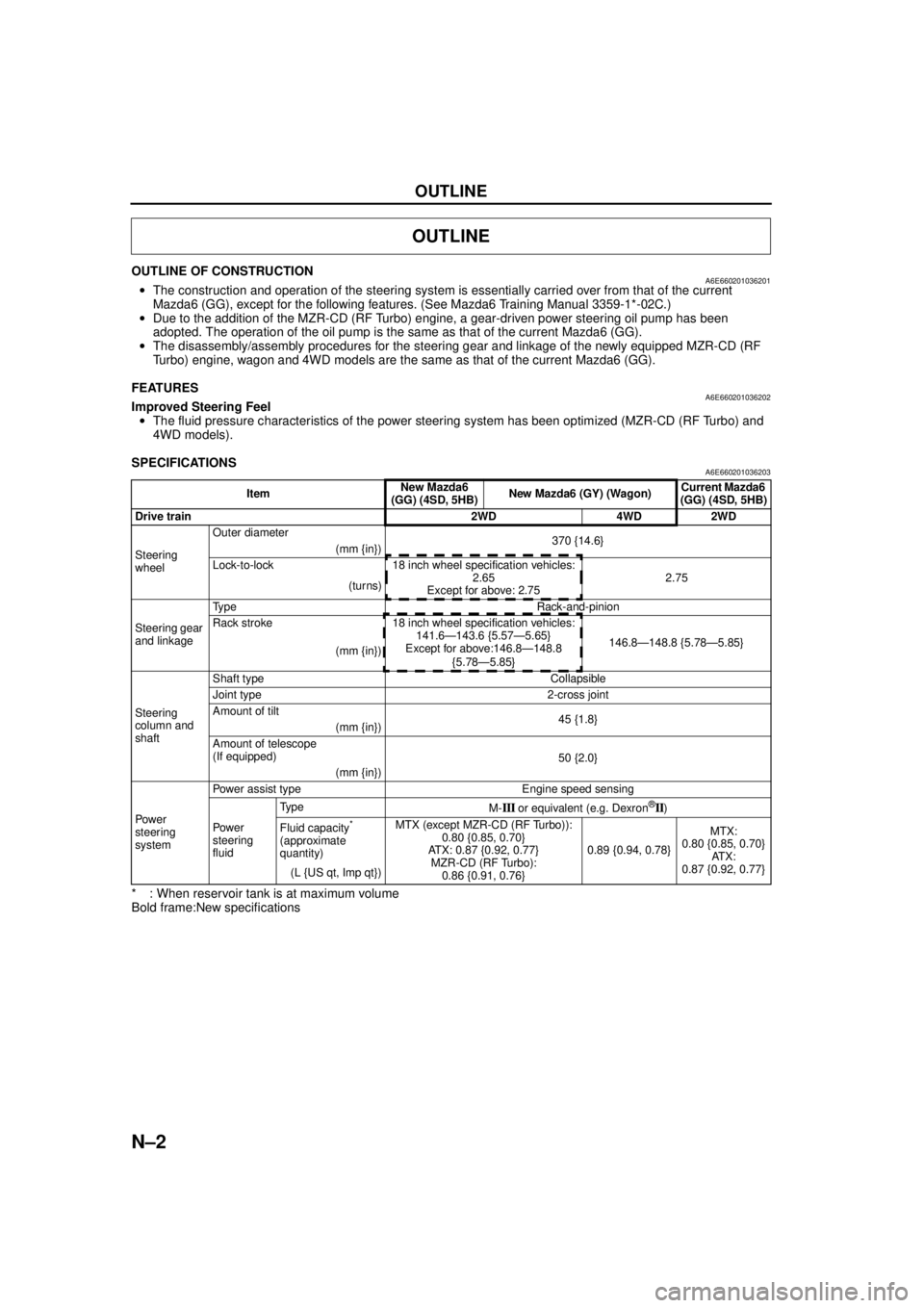

SPECIFICATIONSA6E660201036203

* : When reservoir tank is at maximum volume

Bold frame:New specifications

End Of Sie

OUTLINE

Item New Mazda6

(GG) (4SD, 5HB) New Mazda6 (GY) (Wagon) Current Mazda6

(GG) (4SD, 5HB)

Drive train 2WD 4WD 2WD

Steering

wheel Outer diameter

370 {14.6}

(mm {in})

Lock-to-lock 18 inch wheel specification vehicles: 2.65

Except for above: 2.75 2.75

(turns)

Steering gear

and linkage Type Rack-and-pinion

Rack stroke 18 inch wheel specification vehicles:

141.6—143.6 {5.57—5.65}

Except for above:146.8—148.8

{5.78—5.85} 146.8—148.8 {5.78—5.85}

(mm {in})

Steering

column and

shaft Shaft type Collapsible

Joint type 2-cross joint

Amount of tilt

45 {1.8}

(mm {in})

Amount of telescope

(If equipped) 50 {2.0}

(mm {in})

Powe r

steering

system Power assist type Engine speed sensing

Pow er

steering

fluid

Ty p e

M-

III or equivalent (e.g. Dexron®II)

Fluid capacity

*

(approximate

quantity) MTX (except MZR-CD (RF Turbo)):

0.80 {0.85, 0.70}

ATX: 0.87 {0.92, 0.77} MZR-CD (RF Turbo):

0.86 {0.91, 0.76} 0.89 {0.94, 0.78}

MTX:

0.80 {0.85, 0.70}

AT X :

0.87 {0.92, 0.77}

(L {US qt, Imp qt})

Page 717 of 909

OUTLINE

N–3

N

STRUCTURAL VIEWA6E660201036204MZR-CD (RF Turbo)

.

7

6

7

6

5

5

3

1

2

4

A6E63162001

1L.H.D.

2 R.H.D.

3 Steering wheel

4 Steering column and shaft5 Steering gear

6 Power steering oil pump

7 Fluid reservoir

Page 718 of 909

N–4

OUTLINE

4WD

.

End Of Sie

8

7

5

4

3

1

2

6

5

6

8

7

A6E63162002

1 L.H.D.

2 R.H.D.

3 Steering wheel

4 Steering column and shaft5 Steering gear

6 Power steering oil pump

7 Fluid reservoir

8 Cooling pipe

Page 719 of 909

OUTLINE

N–5

N

SUPPLEMENTAL SERVICE INFORMATIONA6E660201034201•The following changes have been made since publication of the Mazda6 Workshop Manual (1730-1*-02C).

Power steering fluid

•Inspection procedure has been modified.

Steering gear and linkage (MZR-CD (RF Turbo))

•Removal/installation procedure has been added.

Steering gear and linkage (4WD)

•Removal/installation procedure has been added.

Power steering oil pump (MZR-CD (RF Turbo))

•Removal/installation procedure has been added.

•Disassembly/assembly procedure has been added.

End Of Sie

OUTLINE

Page 720 of 909

N–6

ENGINE SPEED SENSING POWER STEERING

POWER STEERING FLUID INSPECTIONA6E661432040201Fluid Level Inspection

1. Inspect the power steering fluid level.

•Add fluid to the specified level as necessary.

Fluid specification

ATF M-III or equivalent (e.g. Dexron

®II)

Fluid Leakage Inspection

Caution

•If the steering wheel is kept in the fully turned position for more than 5 seconds, the fluid

temperature will rise excessively and adversely affect the oil pump.

1. Start the engine and let it idle.

2. Turn the steering wheel fully to the left and right to apply fluid pressure.

Note

•The points where fluid leakage may occur are indicated in the figure.

3. Inspect for fluid leakage.

•If fluid leakage is found, replace the related pipe or hose.

ENGINE SPEED SENSING POWER STEERING

L.H.D.

ATX

MTX

R.H.D.

ATX

MTX MZR-CD (RF Turbo)

EXCEPT MZR-CD (RF Turbo)L.H.D

R.H.D

A6E66142001