compression ratio MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 38 of 1708

Before beginning any service procedure. refer to section T of this manual for air bag system service warnings and audio antitheft system alarm conditions . ENGINE INDEX ............................. B- 2 OUTLINE .......................... B- 3 SPECIFICATIONS ................ B- 3 TROUBLESHOOTING GUIDE ........ B- 3 ENGINE TUNE-UP .................. 8- 5 PREPARATION ................... B- 5 ENGINE OIL ..................... B- 5 ENGINE COOLANT ............... B- 5 DRIVE BELT ..................... 8- 6 HLA TROUBLESHOOTING GUIDE . 8- 8 IGNITION TIMING. IDLE SPEED .... B- 8 COMPRESSION .................... 8-10 INSPECTION ..................... B-10 ON-VEHICLE MAINTENANCE ....... B-11 PREPARATION ................... B-11 TIMING BELT ..................... 8-12 CYLINDER HEAD GASKET ........ B-16 H LA ............................. 8-20 FRONT OIL SEAL ................. 8-24 REAR OIL SEAL .................. 8-26 REMOVAL ......................... 8-28 PROCEDURE .................... B-28 ENGINE STAND MOUNTING ......... 8-32 PREPARATION ................... 8-32 PROCEDURE .................... B-33 DISASSEMBLY ..................... B-35 PREPARATION ................... 8-35 AUXILIARY PARTS ............... 8-36 TIMING BELT ..................... 8-37 CYLINDER HEAD ................. 8-39 CYLINDER BLOCK (EXTERNAL PARTS) ............. 8-42 CYLINDER BLOCK .............. (INTERNAL PARTS) 8-44 .............. INSPECTION I REPAIR 8-47 ................... PREPARATION 8-47 ................. CYLINDER HEAD 8-47 .............. VALVE MECHANISM 8-48 ...................... CAMSHAFT B-51 HLA ............................. 8-53 ............... CYLINDER BLOCK B-53 .......................... OIL JET B-54 PISTON. PISTON RING. AND ..................... PISTON PIN 8-55 CONNECTING ROD .............. B-56 ................... CRANKSHAFT 8-57 BEARING ........................ 8-57 TIMING BELT ..................... 8-58 TENSIONER. IDLER .............. 8-58 TENSIONER SPRING ............. 8-58 PULLEY ......................... 8-58 ........................ ASSEMBLY 8-59 ................... PREPARATION 8-59 CYLINDER BLOCK (INTERNAL PARTS) .............. B-60 CYLINDER BLOCK (EXTERNAL PARTS) ............. B-65 CYLINDER HEAD ................. B-69 TIMING BELT ..................... 8-73 ............... AUXILIARY PARTS 8-77 ..... ENGINE STAND DISMOUNTING 8-81 .................... PROCEDURE 8-81 INSTALLATION ..................... 8-83 .................... PROCEDURE 843 45UOBX-001 Gartner Banana

Page 40 of 1708

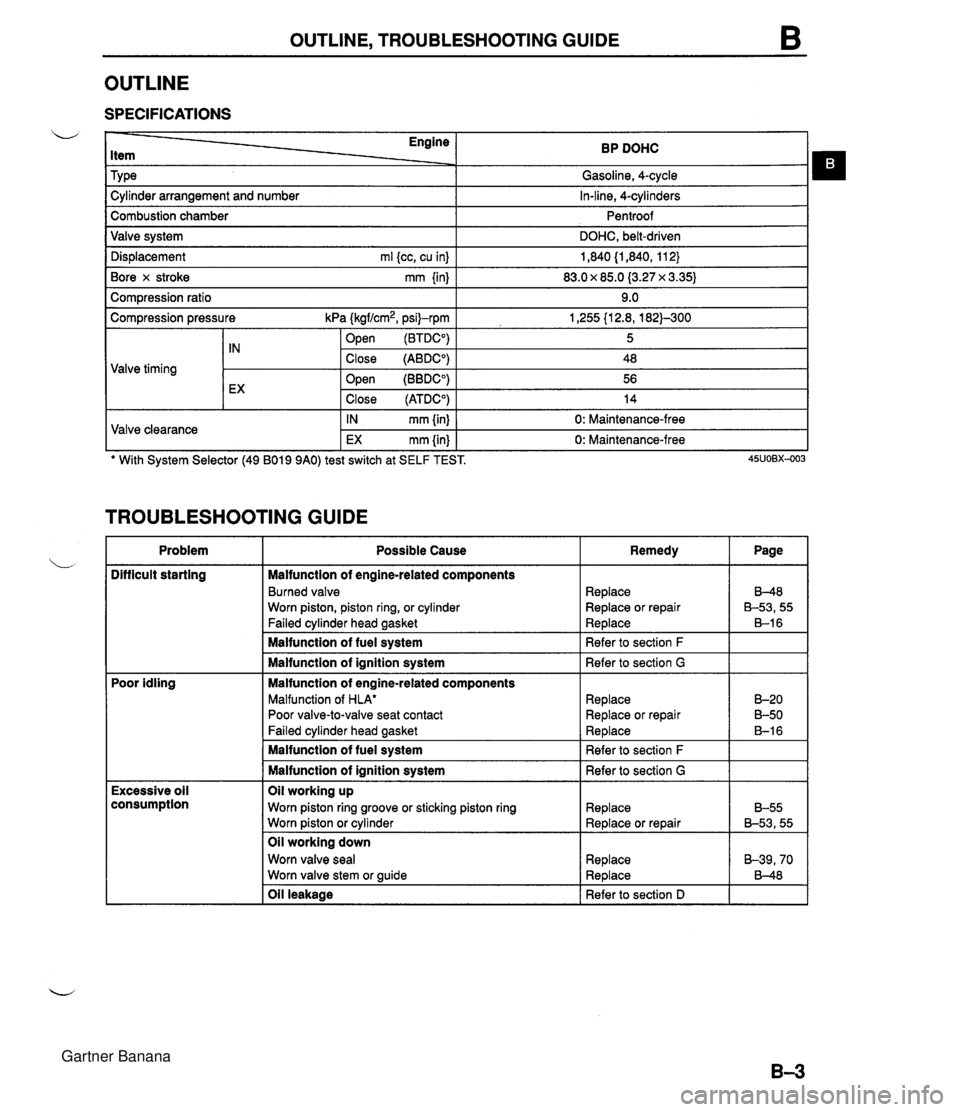

OUTLINE, TROUBLESHOOTING GUIDE OUTLINE SPECIFICATIONS Engine Item Tv~e BP DOHC Gasoline, 4-cvcle . . I -, Dis~lacement ml kc. cu inl I 1.840 (1.840. 11 2) I Cylinder arrangement and number Combustion chamber Valve system Bore x stroke mm {in) I 83.0 x 85.0 (3.27 x 3.35) I In-line, 4-cylinders Pentroof DOHC, belt-driven Com~ression ratio I 9.0 I Compression pressure kPa (kgf/cm2, psi)-rpm .- . 1 open (BTDCO) 1,255 {I 2.8, 182)-300 5 Valve timing TROUBLESHOOTING GUIDE tX Valve clearance Problem .. . -. . Difficult starting ' With System Selector (49 B019 9AO) test switch at SELF TEST. 45uo~x-003 Close (ATDCO) IN mm {in) EX mm {in) Poor idling Close (ABDCO) Open (BBDCO) 14 0: Maintenance-free 0: Maintenance-free Excessive oil consumption 48 56 Possible Cause Malfunction of engine-related components Burned valve Worn piston, piston ring, or cylinder Failed cylinder head gasket Malfunction of fuel system Malfunction of ignition system Malfunction of engine-related components Malfunction of HLA' Poor valve-to-valve seat contact Failed cvlinder head aasket Oil leakage I Refer to section D I I Remedy Malfunction of fuel system Malfunction of ignition system Oil working up Worn piston ring groove or sticking piston ring Worn piston or cylinder Oil working down Worn valve seal Worn valve stem or guide Page Replace Replace or repair Replace Refer to section F Refer to section G Replace Replace or repair Re~lace 8-48 B-53,55 B-1 6 B-20 B-50 B-1 6 Refer to section F Refer to section G Replace Replace or repair Replace Replace B-55 B-53,55 B-39,70 8-48 Gartner Banana

Page 167 of 1708

F TROUBLESHOOTING GUIDE INSPECTION Check if battery positive voltage exists at fuel pump connector fuel pump positive terminal with jumper wire connected.(~tep 3 Check for fuel injector operating sound while crank- ing engine Check if battery positive voltage exists at fuel injector connector B terminal wire with ignition switch ON Connect data link connector terminals F/P and GND with jumper wire and check for correct fuel line pres- sure with ignition switch ON page F-110 Fuel Line pressure: 265--314 kPa f2.7-3.2 kgf/crn2, 38-46 psi) Check for correct engine compression Section B Engine compression: 1,255--883 kPa {12.&9.0 kgf/crn2, 182-1 28 psi)-300 rpm Check if spark plugs are OK WEAR AND CARBON BUILDUP BURNS PLUG GAP 1.0-l.lmm DAMAGE AND (0.040-0.043 in) DETERIORATION DAMAGE Try known good PCME and check if condition im- proves page F-144 - Yes - No Yes Yes - No Yes Yes - No - Yes ACTION Check continuity of fuel pump page F-114 Check fuel pump relay page F-117 Go to Step 7 Go to Step 6 Check PCME terminals 2A, 2U, 2V, 2Y and 22 voltages @3F page F-147 Check for open circuit in wiring between main relay and fuel injector page F-7 Go to next step Low pressure Check fuel line pressure while pinching fuel return hose 0 If fuel line pressure quickly increases, check pressure regulator page F-118 0 If fuel line pressure gradually increases, check for clog- ging between fuel pump and pressure regulator If not clogged, check fuel pump maximum pressure page F-115 Go to next step Check engine condition @3F Section B w Worn piston, piston rings or cylinder wall Defective cylinder head gasket w Distorted cylinder head Improper valve seating w Valve sticking in guide Go to next step Repair, clean, or replace Section G Gartner Banana

Page 169 of 1708

TROUBLESHOOTING GUIDE INSPECTION Check if PCME terminal voltages are OK (IC, 1 R, IT, 2D, 20 and 2Q) page F-146 :heck for air leakage of intake air system malfunction page F-100 :heck for EGR system malfunction page F-124 Check if mass airflow sensor US page F-152 Check for correct engine compression Section B Engine compression: 1,255-883 kPa j12.8-9.0 kgf/cm2, 182-128 psil-300 rpm Check if spark plugs are OK WEAR AND CARB/ON BUILDUP BURNS PLUG GAP 1 .O-1 .l mm (0.040-4.043 in) DAMAGE AND DETERIORATION DAMAGE - Yes Yes - No Yes - No Yes - No Yes No - Yes - No - ACTION Go to next step Check for cause (Refer to "Check Point for Each Terminal") page F-148 Repair or replace Go to next step Repair or replace Go to next step Go to next step Repair or replace page F-99 Go to next step Check engine condition Section B Worn piston, piston rings or cylinder wall Defective cylinder head gasket Distorted cylinder head Improper valve seating a Valve sticking in guide Go to next step Repair, clean, or replace @a Section G Try known good PCME and check if condition im- 3rOVeS page F-144 Gartner Banana

Page 173 of 1708

TROUBLESHOOTING GUIDE INSPECTION ACTION Check if PCME terminal voltages are OK (1 R, 1 T, ZD, 20 and 20) us page F-146 Yes Go to next step Check for cause (Refer to "Check Point for Each Termi- nal") Djp paae F-148 Check if strong blue spark is visible at each discon. nected high-tension lead while cranking engine Yes - No Go to next step Check ignition system (Refer to Troubleshooting "Misfire") Section G Check for EGR system malfunction page F-124 Yes - No Repair or replace Go to next step Check for fuel injector operating sound at each in- Yes Go to Step 10 jector at idle No - Yes Go to Step 9 Check if battery positive voltage exists at fuel injec- tor connector B terminal with ignition switch ON Check if fuel injector resistance is OK page F-119 Resistance: 12-1 6R G If OK, check wiring between injector and PCME page F-7 o If not OK, replace injector L@? page F-119 No - Yes Check wiring between main relay and fuel injector page F-7 Go to next step Check for correct engine compression Section B Engine compression: 1,255-883 kPa I12.8-9.0 kgflcm2, 182-1 28 psi)-300 rpm Check engine condition Section B I Worn piston, piston rings or cylinder wall r Defective cylinder head gasket r Distorted cylinder head r Improper valve seating Valve sticking in guide No - Yes :heck if spark plugs PLUG GAP 1 .O-1 .l mm (0.04+0.043 in} DETERIORATION 30 to next step qepair, clean, or replace Section G Try known good PCME and check if condition im- roves @r page F-144 Gartner Banana

Page 176 of 1708

![MAZDA MX-5 1994 Workshop Manual TROUBLESHOOTING GUIDE B ROUGH IDLE - ALWAYS JCRIPTION I Engine vibrates excessively at idle in every condition ROUBLESHOOTING HINTS] AirIFuel mixture too lean Air leakage Fuel injection control malfu MAZDA MX-5 1994 Workshop Manual TROUBLESHOOTING GUIDE B ROUGH IDLE - ALWAYS JCRIPTION I Engine vibrates excessively at idle in every condition ROUBLESHOOTING HINTS] AirIFuel mixture too lean Air leakage Fuel injection control malfu](/img/28/57072/w960_57072-175.png)

TROUBLESHOOTING GUIDE B ROUGH IDLE - ALWAYS JCRIPTION I Engine vibrates excessively at idle in every condition 'ROUBLESHOOTING HINTS] AirIFuel mixture too lean Air leakage Fuel injection control malfunction Low fuel line pressure Q One or more injectors not operating or clogged O One or more spark plugs not sparking @ Injection timing misadjustment O Low engine compression INSPECTION >heck for correct intake manifold vacuum at idle tacuum: More than 450 mmHg f17.7 inHg} VACUUM GAUGE =heck if air cleaner element is clean page F-76 :heck if "00" is displayed on Self-Diagnosis Check- 3r with ignition switch ON page F-79 SELECTSWA SYSTEM SELECT 1 Sheck switches for correct operation with Self- Diagnosis Checker Monitor Lamp and ignition switch ON SELECT SW A page F-95 Sheck if PCME terminal voltages are OK MONITOR . Sheck i (1 R, IT, 2D, 20 and 2Q) page F-146 - Yes Yes - No - Yes Yes - No - Yes ACTION Go to next step Check for air leakage of intake air system components page F-100 Go to next step Replace air cleaner element page F-99 Go to next step Diagnostic Trouble Code No. displayed Check for cause (Refer to specified check sequence) page F-81 "88" flashes Check PCME terminal 1 E voltage page F-136 Specification: Battery positive voltage (Ignition switch ON) e If OK, replace PCME page F-143 Q If not OK, check wiring between PCME and Self-Diagno- sis Checker page F-7 Go to next step Lamp not ONlOFF with specified switch Check for cause (Refer to specified check sequence) page F-96 Lamp always ON Check wiring between PCME terminal 1 D and Self-Diag- nosis Checker as? page F-7 Go to next step Check for cause (Refer to "Check Point for Each Termi- nal") us ~aae F-148 Gartner Banana

Page 177 of 1708

TROUBLESHOOTING GUIDE INSPECTION Check for fuel injector operating sound at idle with sound scope or screwdriver Check if battery positive voltage exists at fuel injec- tor connector 6 terminal Disconnect each high-tension lead at idle and check if engine speed decreases equally each time - - - Check if spark plu CARBON BUILDUP PLUG GAP 1.0-1 .l mm (0.040-0.043 in) DAMAGE AND DETERIORATION Check for correct ignition timing at idle page F-76 Ignition timing: 10" +. lo BTDC Check for EGR system malfunction w page F-124 Check for correct fuel line pressure at idle * page F-110 Fuel line pressure: 26-14 kPa f2.7-3.2 kgflcm2, 38-46 psi} (Vacuum hose to pressure reaulator discon- - Yes - No - Yes No - Yes - No - Yes - No Yes No - Yes ACTION Yes - No - Go to Step 8 Go to Step 7 Check if fuel injector resistance is OK page F-119 Resistance: 12-1 632 0 If OK, check wiring between PCME and fuel injector @r page F-7 Q If not OK, replace fuel injector page F-119 Check wiring between PCME and fuel injector page F-7 Disconnect each fuel injector connector at idle and check if engine speed decreases equally each time 0 If OK, go to Step 10 o If not OK, check fuel injector for fuel leakage G= pane F-120 Go to step 9 Check for correct engine compression t@ Section B Q if OK, replace fuel injector t@ page F-119 o If not OK, check for cause (Refer to Section 6) U=S Section B Repair, clean, or replace Section G Check for correct idle speed @ page F-77 Idle speed: 850 -c 50 rpm (MT) 800 2 50 rpm (AT) 0 If OK, go to next step 0 If not OK, adjust idle speed w page F-77 Adjust page F-72 Repair or replace Go to next step Go to next step Low pressure Check fuel line pressure while pinching fuel return hose 3 If fuel line pressure quickly increases, check pressure regulator US= page F-118 3 If fuel line pressure gradually increases, check for clog- ging between fuel pump and pressure regulator If not clogged, check fuel pump maximum pressure E+T page F-115 Try known good PCME and check if condition im- proves w Daae F-144 Gartner Banana

Page 180 of 1708

![MAZDA MX-5 1994 Workshop Manual TROUBLESHOOTING GUIDE lo 1 LOW IDLE SPEEDIROUGH IDLE - AFTER WARM-UP 3ESCRIPTION I Engine runs normally at idle during warm-up but vibrates excessively after warm-up ;TROUBLESHOOTING HINTS] I> Idle sp MAZDA MX-5 1994 Workshop Manual TROUBLESHOOTING GUIDE lo 1 LOW IDLE SPEEDIROUGH IDLE - AFTER WARM-UP 3ESCRIPTION I Engine runs normally at idle during warm-up but vibrates excessively after warm-up ;TROUBLESHOOTING HINTS] I> Idle sp](/img/28/57072/w960_57072-179.png)

TROUBLESHOOTING GUIDE lo 1 LOW IDLE SPEEDIROUGH IDLE - AFTER WARM-UP 3ESCRIPTION I Engine runs normally at idle during warm-up but vibrates excessively after warm-up ;TROUBLESHOOTING HINTS] I> Idle speed control malfunction b AirlFuel mixture too lean Air leakage of intake air system Low fuel line pressure INSPECTION Check if "00" is displayed on Self-Diagnosis Check- er with ignition switch ON m? page F-79 Check switches for correct operation with Self- Diagnosis Checker Monitor Lamp and ignition switch ON page F-95 SELECT SW A Disconnect idle air control valve connector at idle and check if engine condition is charged IAC VALVE - Yes No - Yes - No Yes O Air/Fuel mixture too rich Fuel injection control malfunction (Correction for coolant temperature) @ Poor ignition spark Q Low engine compression ACTION Go to next step Diagnostic Trouble Code No. displayed Check for cause (Refer to specified check sequence) page F-81 "88" flashes Check PCME terminal 1 E voltage page F-145 Specification: Battery positive voltage (Ignition switch ON) 6 If OK, replace PCME page F-143 Q If not OK, check wiring between PCME and Self-Diagno- sis Checker page F-7 Go to next step Lamp not ONIOFF with specified switch Check for cause (Refer to specified check sequence) page F-96 Lamp always ON Check wiring between PCME terminal 1 D and Self-Diag- nosis Checker page F-7 Go to next step Check idle air control valve page F-106 Gartner Banana

Page 188 of 1708

TROUBLESHOOTING GUIDE - TEP - 4 INSPECTION ACTION ;heck for correct intake manifold vacuum at idle Yes - No - Yes Go to next step Intake manifold vacuum: More than 450 mmHg I17.7 InHg} ,VACUUM GAUGE Low vacuum Check for air leakage of intake air system page F-100 Zheck for fuel injector operating sound at idle with sound scope or screwdriver Go to Step 7 Go to Step 6 Check if fuel injector resistance is OK us page F-119 Check if battery positive voltage exists at fuel injec- tor connector B terminal Yes - No - Yes - No Resistance: 12-1 6R e If OK, check wiring between PCME and fuel injector page F-7 Q If not OK, replace fuel injector us page F-119 Check wiring between PCME and fuel injector page F-7 Disconnect each fuel injector connector at idle and check if engine speed decreases equally each time Disconnect each high-tension lead at idle and :heck if engine speed decreases equally each time Q If OK, go to Step 9 Q If not OK, check fuel injector for fuel leakage page F-120 Go to step 8 Zheck if spark plugs are OK ILDUP PLUG GAP 1.0-l.lmrn [0.04-.043 in) DAMAGE AND DETERIORATION Check if PCME terminal voltages are OK (1 R, IT, 2Q2Q and 2X) page F-146 Yes - No - Yes Check for correct engine compression Section B + If OK, replace fuel injector page F-119 Q If not OK, check for cause (Refer to Section 6) Section B Repair, clean, or replace Go to next step No - Yes Check for cause (Refer to "Check Point for Each Termi- nal") page F-148 Check purge solenoid valve = page F-132 - - Check if vacuum is felt at purge solenoid valveat Go to next step Try known good PCME and check if condition im- proves page F-144 Gartner Banana

Page 206 of 1708

TROUBLESHOOTING GUIDE F 24 Overloaded ) Low intake air amount Throttle valve not oDen fully LACK OF POWER ESCRIPmH - TEP - 1 - 2 : Performance poor under load Reduced maximum speed :heck factors other than engine Clutch slipping as Section H Brake dragging Section P Low tire pressure as Section Q Unrecommended tire size Section Q ;heck if throttle valve wide open throttles when lepressing accelerator fully rROUBLESHOOTlNG HINTS] Factors other than engine malfunction O AirlFuel mixture too lean or too rich Clutch slipping Fuel line pressure low or high Brake dragging Insufficient fuel injection Low tire pressure @ Poor ignition Unrecommended tire size 8 Low engine compression >heck if "00 is displayed on Self-Diagnosis Check- !r with ignition switch ON page F-79 :heck switches for correct operation with Self- Diagnosis Checker Monitor Lamp and ignition switch ON as page F-95 SELECT SW A YSTEM SELECT 1 - Yes Yes Clogged intake air system - INSPECTION I - C 0 0 0 0 - c C - ( E -- I I i I I No - Yes No - Yes - No ACTION %to next step 20 to next step Sheck if accelerator cable is correctly installed page F-103 3 If OK, check throttle body @r page F-101 3 If not OK, install accelerator cable correctly page F-103 - 30 to next step Diagnostic Trouble Code No. displayed Check for cause (Refer to specified check sequence) page F-81 "88" flashes Check PCME terminal 1 E voltage @r page F-145 Specification: Battery positive voltage (Ignition switch ON) o If OK, replace PCME page F-143 O If not OK, check wiring between PCME and Self-Diagno- sis Checker E+T page F-7 Go to next step -- Lamp not ONlOFF with specified switch Check for cause (Refer to specified check sequence) page F-96 Lamp always ON Check wiring between PCME terminal 1 D and Self-Diag- nosis Checker @r page F-7 Gartner Banana