4WD MAZDA MX-5 1997 Factory Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1997, Model line: MX-5, Model: MAZDA MX-5 1997Pages: 514, PDF Size: 17.89 MB

Page 110 of 514

openings. Remove front disc brake pads. See FRONT DISC BRAKE PADS. Remove remaining mounting

bolt(s). Remove caliper from vehicle. To install, reverse removal procedure. Bleed air from system.

FRONT BRAKE ROTOR

Removal & Installation (B2300, B3000 & B4000 2WD)

1. Raise and support vehicle. Remove front wheel assemblies and brake caliper. See FRONT DISC

BRAKE PADS . Remove grease cap, cotter pin, retainer, adjusting nut, washer and outer bearing.

Carefully remove hub and rotor assembly. Remove inner bearing and seal.

2. To install, reverse removal procedure. Adjust front wheel bearings. While rotating rotor, tighten adjusting

nut 17-25 ft. lbs. (23-34 N.m) to seat bearings. Back off adjusting nut 1/2 turn. Tighten adjusting nut to

18-20 INCH lbs. (2.0-2.3 N.m). Install bearing retainer and NEW cotter pin. DO NOT turn adjusting nut

to align cotter pin.

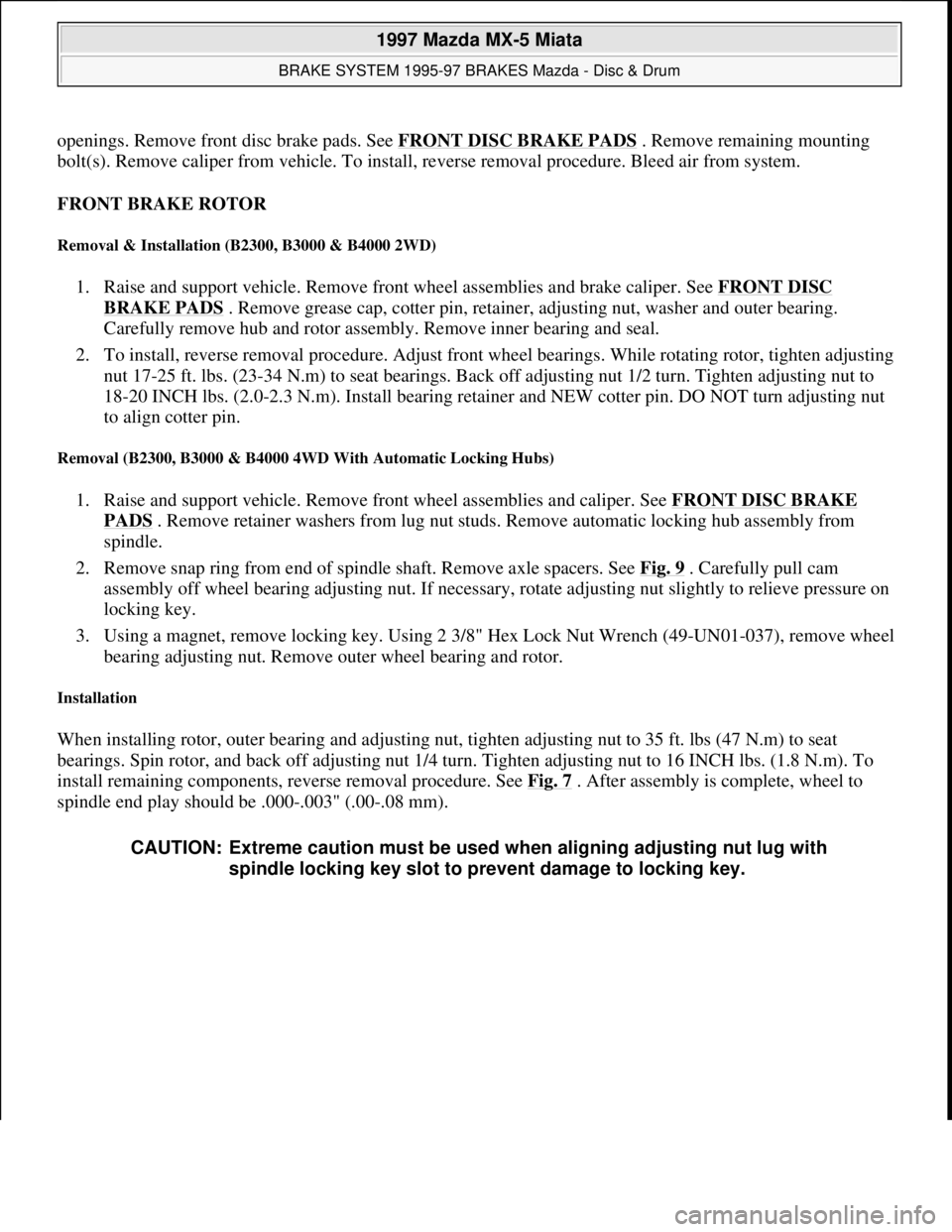

Removal (B2300, B3000 & B4000 4WD With Automatic Locking Hubs)

1. Raise and support vehicle. Remove front wheel assemblies and caliper. See FRONT DISC BRAKE

PADS . Remove retainer washers from lug nut studs. Remove automatic locking hub assembly from

spindle.

2. Remove snap ring from end of spindle shaft. Remove axle spacers. See Fig. 9

. Carefully pull cam

assembly off wheel bearing adjusting nut. If necessary, rotate adjusting nut slightly to relieve pressure on

locking key.

3. Using a magnet, remove locking key. Using 2 3/8" Hex Lock Nut Wrench (49-UN01-037), remove wheel

bearing adjusting nut. Remove outer wheel bearing and rotor.

Installation

When installing rotor, outer bearing and adjusting nut, tighten adjusting nut to 35 ft. lbs (47 N.m) to seat

bearings. Spin rotor, and back off adjusting nut 1/4 turn. Tighten adjusting nut to 16 INCH lbs. (1.8 N.m). To

install remaining components, reverse removal procedure. See Fig. 7

. After assembly is complete, wheel to

spindle end play should be .000-.003" (.00-.08 mm).

CAUTION: Extreme caution must be used when aligning adjusting nut lug with

spindle locking key slot to prevent damage to locking key.

1997 Mazda MX-5 Miata

BRAKE SYSTEM 1995-97 BRAKES Mazda - Disc & Drum

Microsoft

Sunday, July 05, 2009 1:51:03 PMPage 16 © 2005 Mitchell Repair Information Company, LLC.

Page 111 of 514

Fig. 9: Removing Front Rotor (B2300, B3000 & B4000 With Automatic Locking Hubs)

Courtesy of FORD MOTOR CO.

Removal (B2300, B3000 & B4000 4WD With Manual Locking Hubs)

1. Raise and support vehicle. Remove front wheel assemblies and caliper. See FRONT DISC BRAKE

PADS . Remove retainer washers from lug nut studs. Remove manual locking hub assembly from

spindle.

2. Remove snap ring from end of spindle shaft. Remove axle spacers. See Fig. 10

. Using Lock Nut Wrench

(49-UN01-042), remove outer wheel bearing lock nut. Remove lock washer. Using lock nut wrench,

remove inner wheel bearing lock nut. Remove outer wheel bearing, cup and rotor.

Installation

When installing rotor, outer bearing and inner lock nut, tighten inner lock nut to 35 ft. lbs. (47 N.m) to seat

bearings. Spin rotor, and back off inner lock nut 1/4 turn. Tighten inner lock nut to 16 INCH lbs. (1.8 N.m). To

install remaining components, reverse removal procedure. See Fig. 10

. After assembly is complete, wheel to

spindle end pla

y should be .000-.003" (.00-.08 mm).

1997 Mazda MX-5 Miata

BRAKE SYSTEM 1995-97 BRAKES Mazda - Disc & Drum

Microsoft

Sunday, July 05, 2009 1:51:03 PMPage 17 © 2005 Mitchell Repair Information Company, LLC.

Page 160 of 514

Submerge other end of hose in container of brake fluid.

2. Fill reservoir with DOT 3 brake fluid. Have an assistant press and release clutch pedal several times, then

hold pedal down. With pedal pressed, loosen bleeder screw to let air and fluid escape.

3. Repeat step 2) until no more air bubbles emerge from hose. Tighten bleeder screw. Fill reservoir. Operate

clutch while inspecting for leaks. Check clutch and brake operation.

REMOVAL & INSTALLATION

CLUTCH ASSEMBLY

Removal (B2300, B2500, B3000 & B4000)

1. Disconnect negative battery cable. Shift transmission into Neutral. Remove gearshift lever. Raise and

support vehicle. Mark drive shaft flanges for installation reference. Remove drive shaft. Using Clutch

Disconnect Tool (T88T-70522-A), disconnect hydraulic line at transmission. See Fig. 2

. Plug hydraulic

line to prevent contamination. Disconnect wiring at transmission.

2. Remove starter. Remove exhaust components as necessary for clearance. On 4WD models, remove skid

plate and transfer case. On all models, secure transmission jack under transmission. Remove transmission

mount-to-crossmember nuts and bolts.

3. Remove nuts securing crossmember to frame side rails, and remove crossmember. Lower transmission

enough to gain access to transmission-to-engine block bolts. Remove transmission-to-engine block bolts.

Remove transmission.

4. If clutch parts are going to be reused, mark clutch cover and flywheel for reassembly reference. Loosen

pressure plate bolts evenly in crisscross pattern until springs are not under tension. Remove clutch cover

and clutch disc.

Inspection (B2300, B2500, B3000 & B4000)

1. Inspect disc for loose rivets, worn or defective springs, excessive wear, or oil contamination. Inspect

flywheel and clutch cover for burns, scoring, or grooves.

2. Measure flywheel and clutch cover runout. Resurface or replace flywheel and clutch cover if beyond

specification. See CLUTCH RUNOUT (MAXIMUM)

table.

3. Measure clutch disc runout. Replace disc if it is not to specification. See CLUTCH RUNOUT

(MAXIMUM) table. Inspect disc hub and input shaft splines for excessive wear. Hub must slide

smoothly on input shaft splines.

4. Inspect pilot bearing for wear. Apply inward pressure while rotating pilot bearing. If bearing sticks or has

excessive resistance, replace bearing. Check for tight fit in crankshaft. Replace as necessary. Inspect

release bearing for smooth operation, wear, damage, or looseness. Replace bearing as necessary.

CLUTCH RUNOUT (MAXIMUM)

ApplicationIn. (mm)

Disc0.028 (0.7)

Flywheel0.008 (0.20)

1997 Mazda MX-5 Miata

CLUTCH 1997-98 CLUTCHES Mazda - RWD

Microsoft

Sunday, July 05, 2009 1:36:47 PMPage 4 © 2005 Mitchell Repair Information Company, LLC.

Page 161 of 514

Installation (B2300, B2500, B3000 & B4000)

1. Lightly coat input shaft splines, release bearing, and fork contact areas with molybdenum disulfide

grease. Align clutch cover dowel holes with flywheel dowels. Tighten clutch cover bolts evenly in a

crisscross pattern to specification. See TORQUE SPECIFICATIONS

.

2. Raise transmission into position. Install and tighten transmission-to-engine block bolts. See TORQUE

SPECIFICATIONS . Install crossmember.

3. On 4WD models, install NEW transfer case gasket. Install transfer case. Tighten transfer case bolts to

specification is sequence. See Fig. 3

. See TORQUE SPECIFICATIONS .

4. On all models, to complete installation, reverse removal procedure. Bleed hydraulic clutch system. See

HYDRAULIC SYSTEM BLEEDING

under ADJUSTMENTS.

Fig. 3: Tightening Transfer Case Bolts (B2300, B2500, B3000 & B4000)

Courtesy of MAZDA MOTORS CORP.

Removal (Miata)

1. Disconnect negative battery cable. Remove gearshift knob, console, and shift lever. See Fig. 4. Raise and

support vehicle. Remove engine undercover. Disconnect exhaust pipe from manifold. Mark drive shaft

flanges for installation reference. Remove drive shaft.

1997 Mazda MX-5 Miata

CLUTCH 1997-98 CLUTCHES Mazda - RWD

Microsoft

Sunday, July 05, 2009 1:36:47 PMPage 5 © 2005 Mitchell Repair Information Company, LLC.

Page 171 of 514

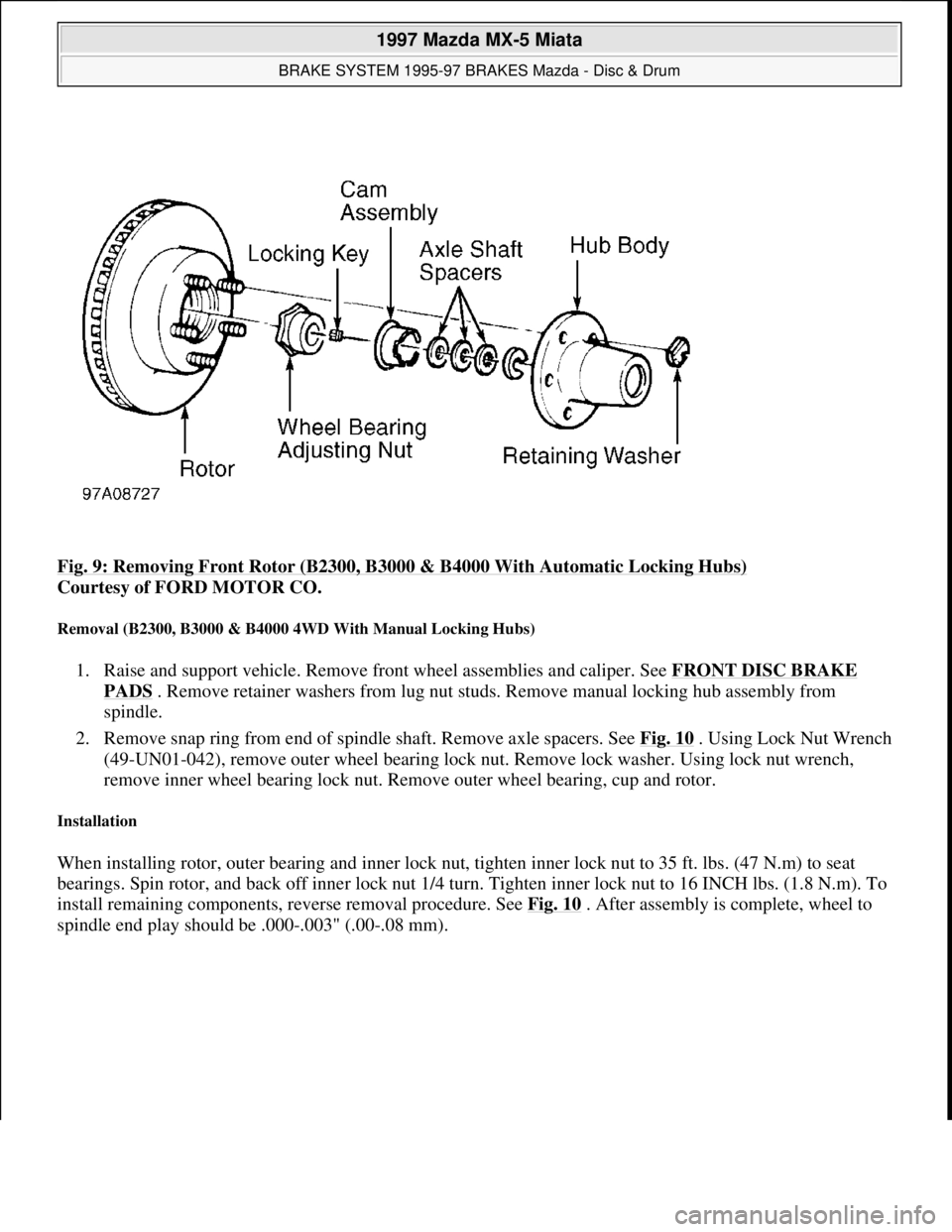

Fig. 11: Exploded View Of Clutch Release Cylinder (Miata)

Courtesy of MAZDA MOTORS CORP.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS NOTE: Use exploded view of clutch release cylinder for overhaul procedure. See Fig.

11 .

ApplicationFt. Lbs. (N.m)

B2300, B2500, B3000 & B4000

Clutch Cover Bolts (1) 17-24 (23-32)

Crossmember Nuts39-53 (53-72)

Drive Shaft Bolts65-87 (88-119)

Flywheel-To-Crankshaft Nuts54-67 (73-91)

Gearshift Lever Bolt20-30 (27-40)

Starter Mounting Bolts17-20 (23-27)

Transfer Case Bolts (4WD) (2) 35-46 (47-62)

Transmission-To-Engine Block Bolts37-50 (50-68)

Miata

Clutch Cover Bolts (1) 13-19 (18-26)

Drive Shaft Nuts37-43 (50-58)

Flywheel-To-Crankshaft Bolts71-76 (96-103)

PPF-To-Differential Mounting Spacer Bolt (Short)27-38 (37-51)

PPF-To-Differential Side Mounting Bolts (Long)77-91 (104-123)

PPF-To-PPF Bracket Bolt27-40 (37-54)

1997 Mazda MX-5 Miata

CLUTCH 1997-98 CLUTCHES Mazda - RWD

Microsoft

Sunday, July 05, 2009 1:36:47 PMPage 15 © 2005 Mitchell Repair Information Company, LLC.

Page 175 of 514

1997-98 DRIVE AXLES

Differentials & Drive Axles - MPV & MX-5 Miata

AXLE RATIO & IDENTIFICATION

See AXLE RATIO SPECIFICATIONS table. To determine axle ratio, divide number of ring gear teeth by

number of pinion teeth.

AXLE RATIO SPECIFICATIONS

DESCRIPTION

A Limited Slip Differential (LSD) is optional on Miata. On MPV, rear axle bearings are held in place by a

pressed-on collar. Front axle on MPV 4WD and rear axle on Miata use CV joints to connect differential to axle

hubs.

LUBRICATION

CAPACITY

DIFFERENTIAL CAPACITY SPECIFICATIONS

FLUID TYPE

Application

Number Of Teeth Pinion/Ring

Gear

Ratio

Miata

A/TN/A4.10:1

M/TN/A4.30:1

MPV

2WD11/433.91:1

4WD (Front & Rear)10/414.10:1

NOTE: For models with independent suspension, see AXLE SHAFTS - REAR or AXLE

SHAFTS - FRONT article for axle shaft overhaul.

Application(1) Qts. (L)

Miata1.06 (1.00)

MPV 2WD1.60 (1.50)

MPV 4WD

Front1.80 (1.70)

Rear1.60 (1.50)

(1)Fill to lower edge of filler plug hole.

1997 Mazda MX-5 Miata

1997-98 DRIVE AXLES Differentials & Drive Axles - MPV & MX-5 Miata

1997 Mazda MX-5 Miata

1997-98 DRIVE AXLES Differentials & Drive Axles - MPV & MX-5 Miata

Microsoft

Sunday, July 05, 2009 1:52:42 PMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Microsoft

Sunday, July 05, 2009 1:52:46 PMPage 1 © 2005 Mitchell Repair Information Company, LLC.

Page 183 of 514

Fig. 5: Exploded View Of Rear Axle Shaft (MPV)

Courtesy of MAZDA MOTORS CORP.

DIFFERENTIAL ASSEMBLY

Removal (Front MPV 4WD)

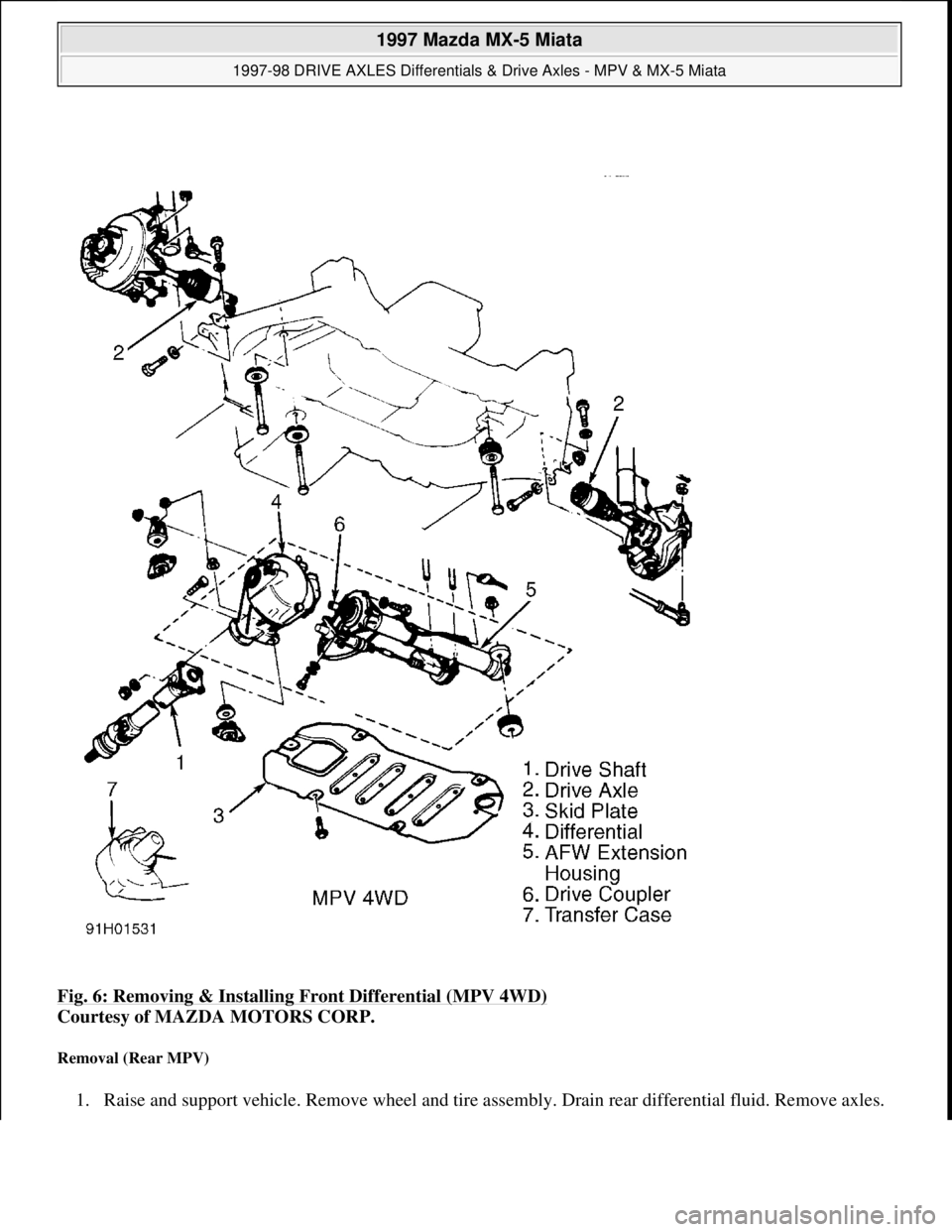

1. Raise and support vehicle. Remove engine skid plate. See Fig. 6 . Drain front differential fluid. Remove

tie rod ends and lower control arms. Remove front axle shafts. See AXLE SHAFTS

- FRONT article.

2. Mark drive shaft and differential carrier flanges for reassembly reference, and remove drive shaft from

differential carrier. See Fig. 6

. Disconnect Automatic Free Wheel (AFW) vacuum hoses and electrical

connector.

3. Place floor jack under differential assembly. Remove differential-to-chassis mounting bolts and AFW

extension housing mounting nuts. Remove differential and AFW extension housing from vehicle.

Remove AFW assembly from left side of differential housing. Pull drive coupler from carrier. Remove

differential carrier-to-housing bolts. Remove differential carrier.

Installation

To install, reverse removal procedure. Apply sealant to carrier mating flange. Align marks made during

removal. Refill differential with lubricant. Tighten all nuts and bolts to specification. See TORQUE

SPECIFICATIONS.

1997 Mazda MX-5 Miata

1997-98 DRIVE AXLES Differentials & Drive Axles - MPV & MX-5 Miata

Microsoft

Sunday, July 05, 2009 1:52:42 PMPage 9 © 2005 Mitchell Repair Information Company, LLC.

Page 184 of 514

Fig. 6: Removing & Installing Front Differential (MPV 4WD)

Courtesy of MAZDA MOTORS CORP.

Removal (Rear MPV)

1. Raise and support vehicle. Remove wheel and tire assembly. Drain rear differential fluid. Remove axles.

1997 Mazda MX-5 Miata

1997-98 DRIVE AXLES Differentials & Drive Axles - MPV & MX-5 Miata

Microsoft

Sunday, July 05, 2009 1:52:42 PMPage 10 © 2005 Mitchell Repair Information Company, LLC.

Page 194 of 514

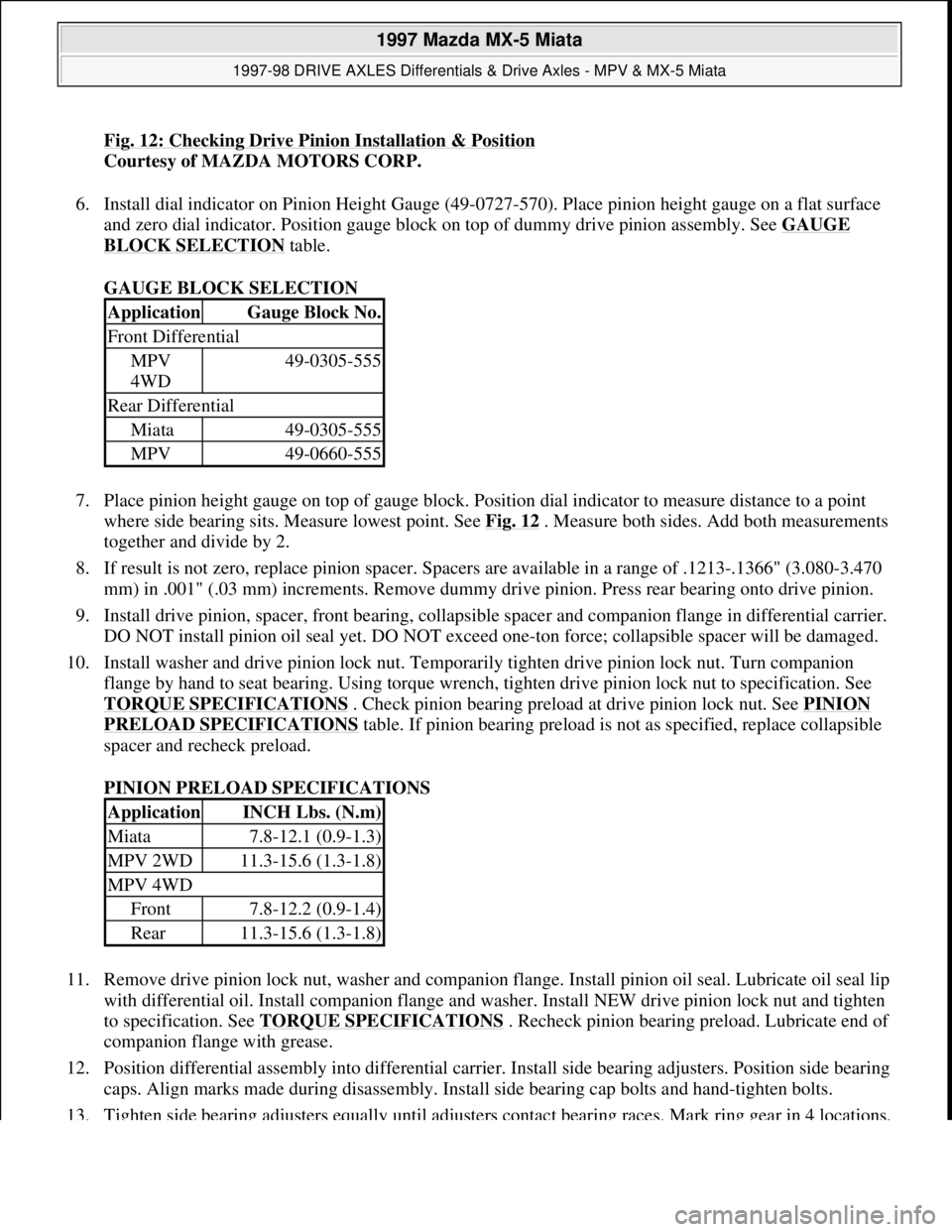

Fig. 12: Checking Drive Pinion Installation & Position

Courtesy of MAZDA MOTORS CORP.

6. Install dial indicator on Pinion Height Gauge (49-0727-570). Place pinion height gauge on a flat surface

and zero dial indicator. Position gauge block on top of dummy drive pinion assembly. See GAUGE

BLOCK SELECTION table.

GAUGE BLOCK SELECTION

7. Place pinion height gauge on top of gauge block. Position dial indicator to measure distance to a point

where side bearing sits. Measure lowest point. See Fig. 12

. Measure both sides. Add both measurements

together and divide by 2.

8. If result is not zero, replace pinion spacer. Spacers are available in a range of .1213-.1366" (3.080-3.470

mm) in .001" (.03 mm) increments. Remove dummy drive pinion. Press rear bearing onto drive pinion.

9. Install drive pinion, spacer, front bearing, collapsible spacer and companion flange in differential carrier.

DO NOT install pinion oil seal yet. DO NOT exceed one-ton force; collapsible spacer will be damaged.

10. Install washer and drive pinion lock nut. Temporarily tighten drive pinion lock nut. Turn companion

flange by hand to seat bearing. Using torque wrench, tighten drive pinion lock nut to specification. See

TORQUE SPECIFICATIONS

. Check pinion bearing preload at drive pinion lock nut. See PINION

PRELOAD SPECIFICATIONS table. If pinion bearing preload is not as specified, replace collapsible

spacer and recheck preload.

PINION PRELOAD SPECIFICATIONS

11. Remove drive pinion lock nut, washer and companion flange. Install pinion oil seal. Lubricate oil seal lip

with differential oil. Install companion flange and washer. Install NEW drive pinion lock nut and tighten

to specification. See TORQUE SPECIFICATIONS

. Recheck pinion bearing preload. Lubricate end of

companion flange with grease.

12. Position differential assembly into differential carrier. Install side bearing adjusters. Position side bearing

caps. Align marks made during disassembly. Install side bearing cap bolts and hand-tighten bolts.

13. Ti

ghten side bearing adjusters equally until adjusters contact bearing races. Mark ring gear in 4 locations,

ApplicationGauge Block No.

Front Differential

MPV

4WD49-0305-555

Rear Differential

Miata49-0305-555

MPV49-0660-555

ApplicationINCH Lbs. (N.m)

Miata7.8-12.1 (0.9-1.3)

MPV 2WD11.3-15.6 (1.3-1.8)

MPV 4WD

Front7.8-12.2 (0.9-1.4)

Rear11.3-15.6 (1.3-1.8)

1997 Mazda MX-5 Miata

1997-98 DRIVE AXLES Differentials & Drive Axles - MPV & MX-5 Miata

Microsoft

Sunday, July 05, 2009 1:52:42 PMPage 20 © 2005 Mitchell Repair Information Company, LLC.

Page 195 of 514

90 degrees apart. Position dial indicator against ring gear to check ring gear backlash.

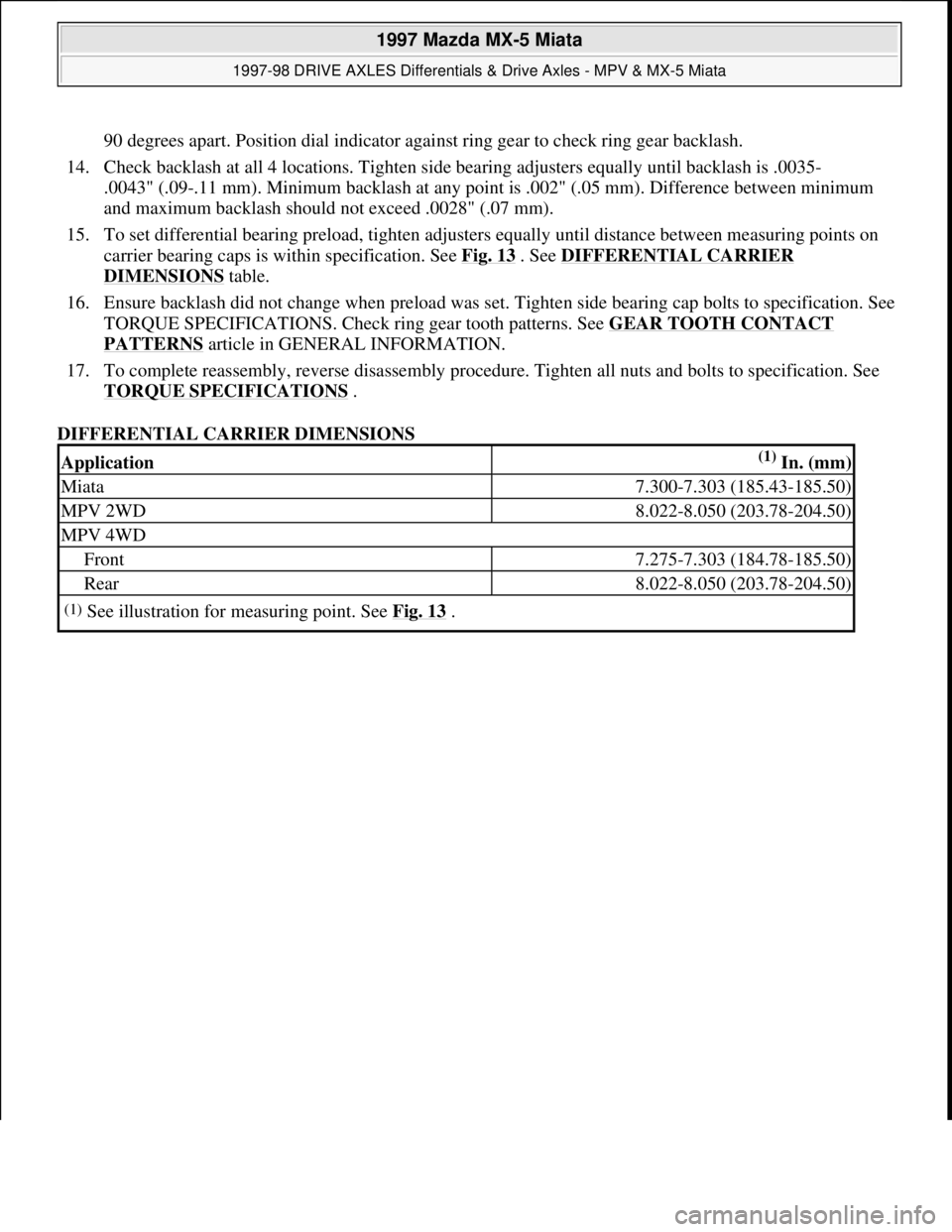

14. Check backlash at all 4 locations. Tighten side bearing adjusters equally until backlash is .0035-

.0043" (.09-.11 mm). Minimum backlash at any point is .002" (.05 mm). Difference between minimum

and maximum backlash should not exceed .0028" (.07 mm).

15. To set differential bearing preload, tighten adjusters equally until distance between measuring points on

carrier bearing caps is within specification. See Fig. 13

. See DIFFERENTIAL CARRIER

DIMENSIONS table.

16. Ensure backlash did not change when preload was set. Tighten side bearing cap bolts to specification. See

TORQUE SPECIFICATIONS. Check ring gear tooth patterns. See GEAR TOOTH CONTACT

PATTERNS article in GENERAL INFORMATION.

17. To complete reassembly, reverse disassembly procedure. Tighten all nuts and bolts to specification. See

TORQUE SPECIFICATIONS

.

DIFFERENTIAL CARRIER DIMENSIONS

Application(1) In. (mm)

Miata7.300-7.303 (185.43-185.50)

MPV 2WD8.022-8.050 (203.78-204.50)

MPV 4WD

Front7.275-7.303 (184.78-185.50)

Rear8.022-8.050 (203.78-204.50)

(1)See illustration for measuring point. See Fig. 13 .

1997 Mazda MX-5 Miata

1997-98 DRIVE AXLES Differentials & Drive Axles - MPV & MX-5 Miata

Microsoft

Sunday, July 05, 2009 1:52:42 PMPage 21 © 2005 Mitchell Repair Information Company, LLC.