clock MERCEDES-BENZ AMG GT ROADSTER 2018 Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2018, Model line: AMG GT ROADSTER, Model: MERCEDES-BENZ AMG GT ROADSTER 2018Pages: 294, PDF Size: 4.8 MB

Page 75 of 294

The vehicle is locked automatically when the

ignition is switched on and the wheels are turn-

ing.

You could therefore be locked out if:

Rthe vehicle is being pushed

Rthe vehicle is being towed

Rthe vehicle is on a roller dynamometer

iYou can activate and deactivate the auto-

matic locking mechanism via the multimedia

system (see the Digital Operator's Manual).

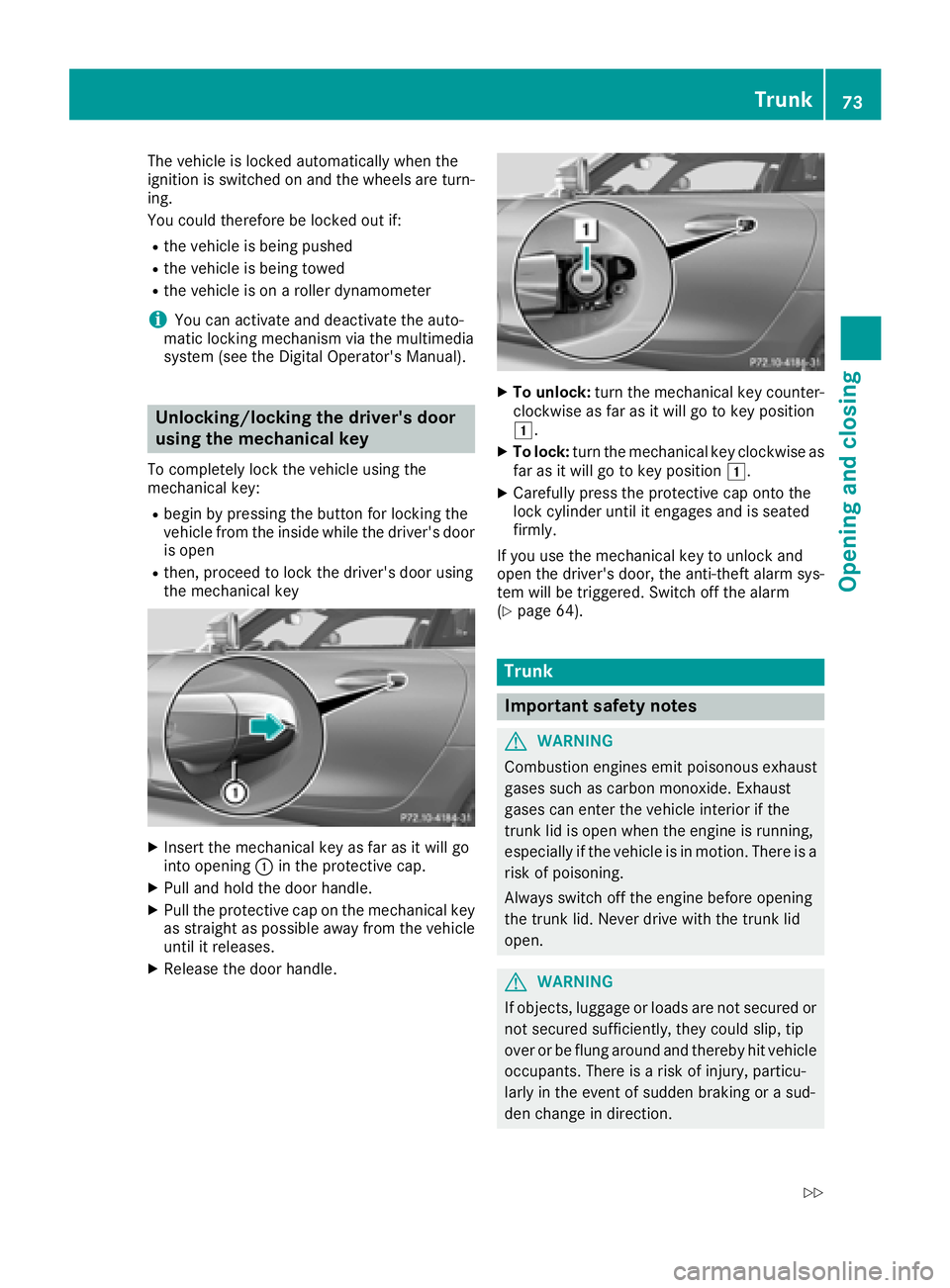

Unlocking/locking the driver's door

using the mechanical key

To completely lock the vehicle using the

mechanical key:

Rbegin by pressing the button for locking the

vehicle from the inside while the driver's door

is open

Rthen, proceed to lock the driver's door using

the mechanical key

XInsert the mechanical key as far as it will go

into opening :in the protective cap.

XPull and hold the door handle.

XPull the protective cap on the mechanical key

as straight as possible away from the vehicle

until it releases.

XRelease the door handle.

XTo unlock: turn the mechanical key counter-

clockwise as far as it will go to key position

1.

XTo lock: turn the mechanical key clockwise as

far as it will go to key position 1.

XCarefully press the protective cap onto the

lock cylinder until it engages and is seated

firmly.

If you use the mechanical key to unlock and

open the driver's door, the anti-theft alarm sys-

tem will be triggered. Switch off the alarm

(

Ypage 64).

Trunk

Important safety notes

GWARNING

Combustion engines emit poisonous exhaust

gases such as carbon monoxide. Exhaust

gases can enter the vehicle interior if the

trunk lid is open when the engine is running,

especially if the vehicle is in motion. There is a

risk of poisoning.

Always switch off the engine before opening

the trunk lid. Never drive with the trunk lid

open.

GWARNING

If objects, luggage or loads are not secured or

not secured sufficiently, they could slip, tip

over or be flung around and thereby hit vehicle

occupants. There is a risk of injury, particu-

larly in the event of sudden braking or a sud-

den change in direction.

Trunk73

Opening and closing

Z

Page 128 of 294

!Use a filter when adding fuel from a fuel can.

The fuel lines and/or the fuel injection system

could otherwise be blocked by particles from

the fuel can.

If you overfill the fuel tank, fuel could spray out

when the fuel pump nozzle is removed.

For further information on fuel and fuel quality

(

Ypage 286).

Refueling

General information

Pay attention to the important safety notes

(Ypage 125).

If you unlock/lock the vehicle from the outside, the fuel filler flap also unlocks/locks.

The position of the fuel filler cap is displayed

8 in the instrument cluster. The arrow next

to the filling pump indicates the side of the vehi-

cle.

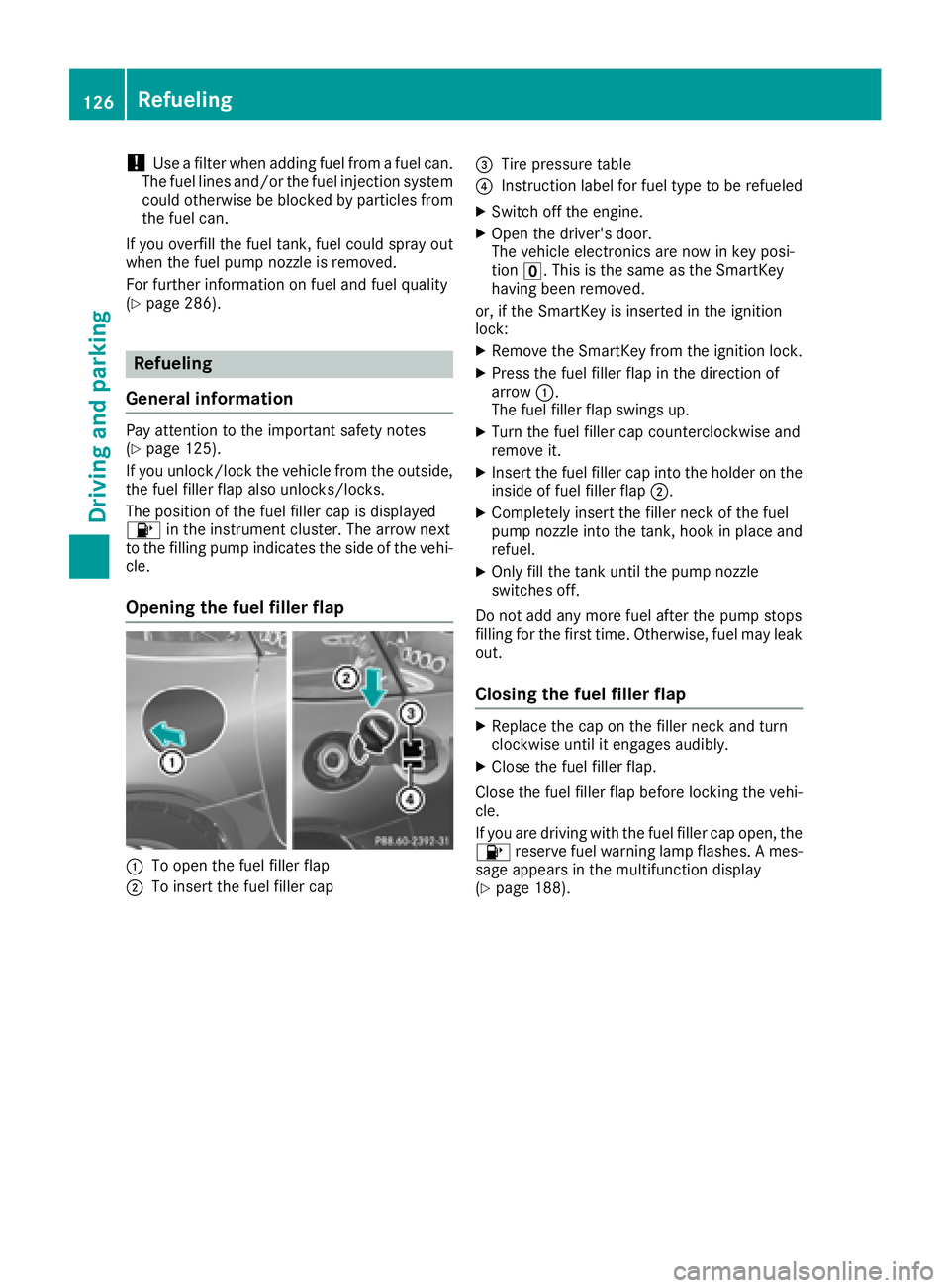

Opening the fuel filler flap

:To open the fuel filler flap

;To insert the fuel filler cap

=Tire pressure table

?Instruction label for fuel type to be refueled

XSwitch off the engine.

XOpen the driver's door.

The vehicle electronics are now in key posi-

tion u. This is the same as the SmartKey

having been removed.

or, if the SmartKey is inserted in the ignition

lock:

XRemove the SmartKey from the ignition lock.

XPress the fuel filler flap in the direction of

arrow :.

The fuel filler flap swings up.

XTurn the fuel filler cap counterclockwise and

remove it.

XInsert the fuel filler cap into the holder on the

inside of fuel filler flap ;.

XCompletely insert the filler neck of the fuel

pump nozzle into the tank, hook in place and

refuel.

XOnly fill the tank until the pump nozzle

switches off.

Do not add any more fuel after the pump stops

filling for the first time. Otherwise, fuel may leak

out.

Closing the fuel filler flap

XReplace the cap on the filler neck and turn

clockwise until it engages audibly.

XClose the fuel filler flap.

Close the fuel filler flap before locking the vehi-

cle.

If you are driving with the fuel filler cap open, the 8 reserve fuel warning lamp flashes. A mes-

sage appears in the multifunction display

(

Ypage 188).

126Refueling

Driving and parking

Page 239 of 294

Display messagesPossible causes/consequences andMSolutions

Engine Oil LevelCorrectMeasurementOnlyif Vehicl eIson Level Ground

The vehicl eis no tparked on alevel surface.

XPark th evehicl eon alevel surface.

Engine Oil LevelNot Measurabl e

Oil level measuremen twit hth eoil dipstick is possible. The measurin g

system is malfunctioning .

XVisitaqualified specialist workshop .

Adding engine oil

GWARNING

Certain component sin th eengin ecompart-

ment, suc has th eengine, radiato rand part s

of th eexhaust system, can become ver yhot .

Working in th eengin ecompartmen tposes a

ris kof injury.

Where possible, let th eengin ecool down and

touch only th ecomponent sdescribed in th e

following.

GWARNIN G

If engin eoil comes int ocontact wit hhot com-

ponents in th eengin ecompartment, it may

ignite. There is aris kof fir eand injury.

Mak esur ethat engin eoil is no tspilled next to

th efiller neck .Let th eengin ecool down and

thoroughly clean th eengin eoil off th ecom-

ponents before starting th eengine.

HEnvironmenta lnot e

Whe naddin goil, tak ecar eno tto spil lany. If

oil enters th esoil or waterways, it is harmful to

th eenvironment.

!Use only engin eoils and oil filters that are

approve dfor vehicles wit h aservic esystem. A

list of th eengin eoils and oil filters that hav e

been tested and approve din accordanc ewit h

Mercedes-Ben zSpecification sfor Service

Products is available at any authorize d

Mercedes-Ben zCenter. The followin

gcaus eengin efailure or damag e

to th eexhaust system:

RUse of engin eoils and oil filters that hav e

no tbeen expressl yapprove dfor th eservic e

system

RReplacement of engin eoil and oil filter after

th ereplacemen tinterval specified by th e

servic esystem has expired

RUse of engin eoil additive s

!Do notadd to omuc hoil. If th eoil level is

abov eth e"max "mar kon th edipstick ,to o

muc hoil has been added .This can lead to

damag eto th eengin eor th ecatalytic con-

verter. Hav eexcess oil siphoned off .

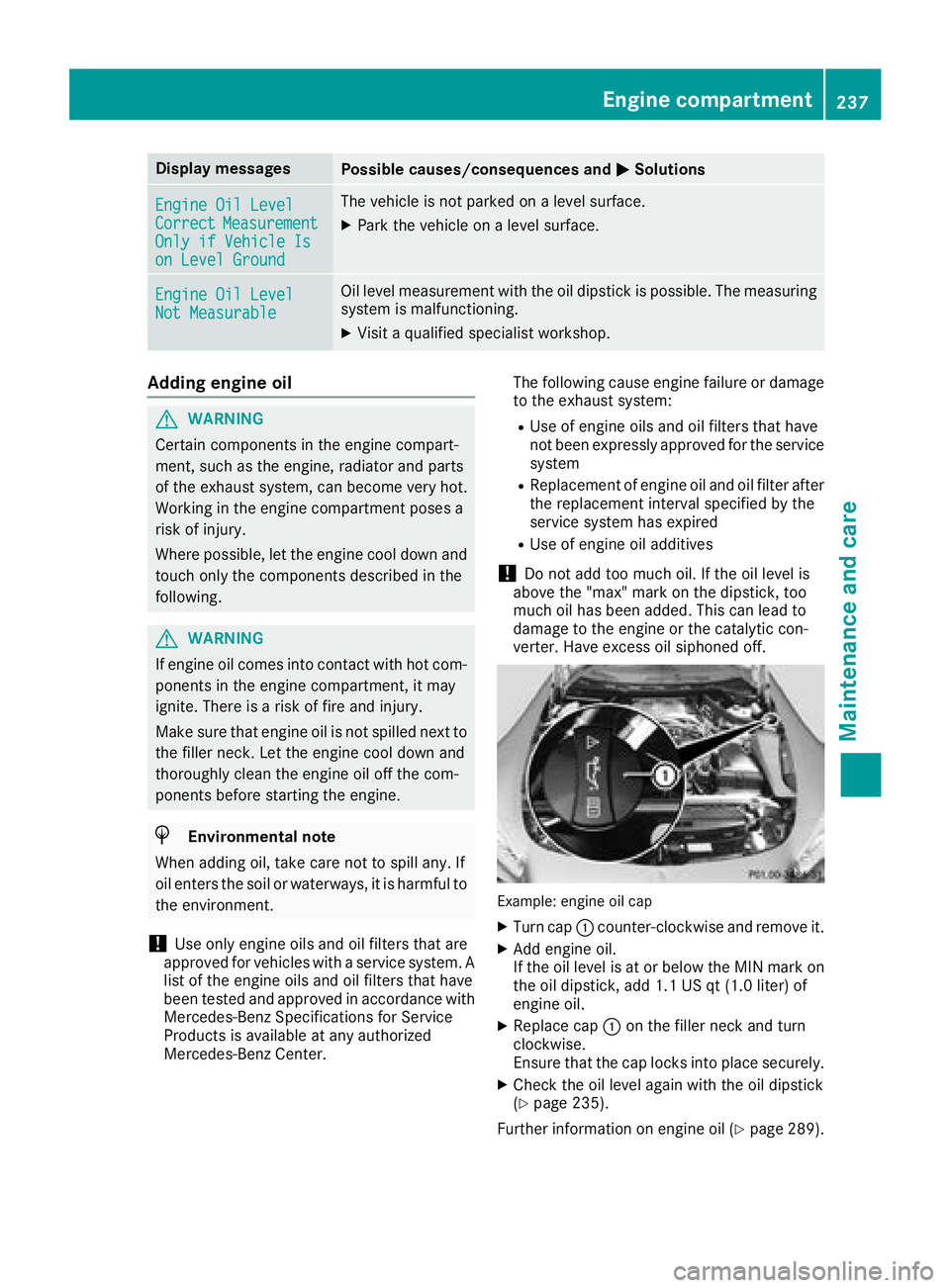

Example: engineoil cap

XTurn cap :counter-clockwise and remove it .

XAddengin eoil.

If th eoil level is at or belo wtheMIN mar kon

th eoil dipstick ,add 1. 1US qt (1. 0liter) of

engin eoil.

XReplac ecap :on th efiller neck and tur n

clockwise .

Ensur ethat th ecap locks int oplac esecurely.

XChec kth eoil level again wit hth eoil dipstick

(Ypage 235).

Further information on engin eoil (

Ypage 289).

Engine compartment237

Maintenance and care

Z

Page 240 of 294

Additional service products

Checking coolant level

GWARNIN G

Certain component sin th eengin ecompart-

ment, suc has th eengine, radiato rand part s

of th eexhaust system, can become ver yhot .

Working in th eengin ecompartmen tposes a

ris kof injury.

Wher epossible, let th eengin ecool down and

touch only th ecomponent sdescribed in th e

following.

GWARNIN G

Opening th ehoo dwhen th eengin eis over-

heated or when there is afir ein th eengin e

compartmen tcould expos eyou to hot gase s

or other servic eproducts .There is aris kof

injury.

Let an overheate dengin ecool down before

opening th ehood. If there is afir ein th e

engin ecompartment, keep th ehoo dclosed

and contact th efir edepartment.

GWARNIN G

The coolin gsystem is pressurized, particularly

when th emotor is warm .If you open th ecap ,

you could be scalded if hot coolan tsprays out .

There is aris kof injury.

Let th eengin ecool down before you open th e

cap .Wear gloves and eye protection .Slowly

open th ecap to reliev epressure.

!Befor estarting your journey, mak esur ethat

all engin ecover sare installed. Otherwise ,th e

engin ecan be damaged, e.g. throug hover-

heating .

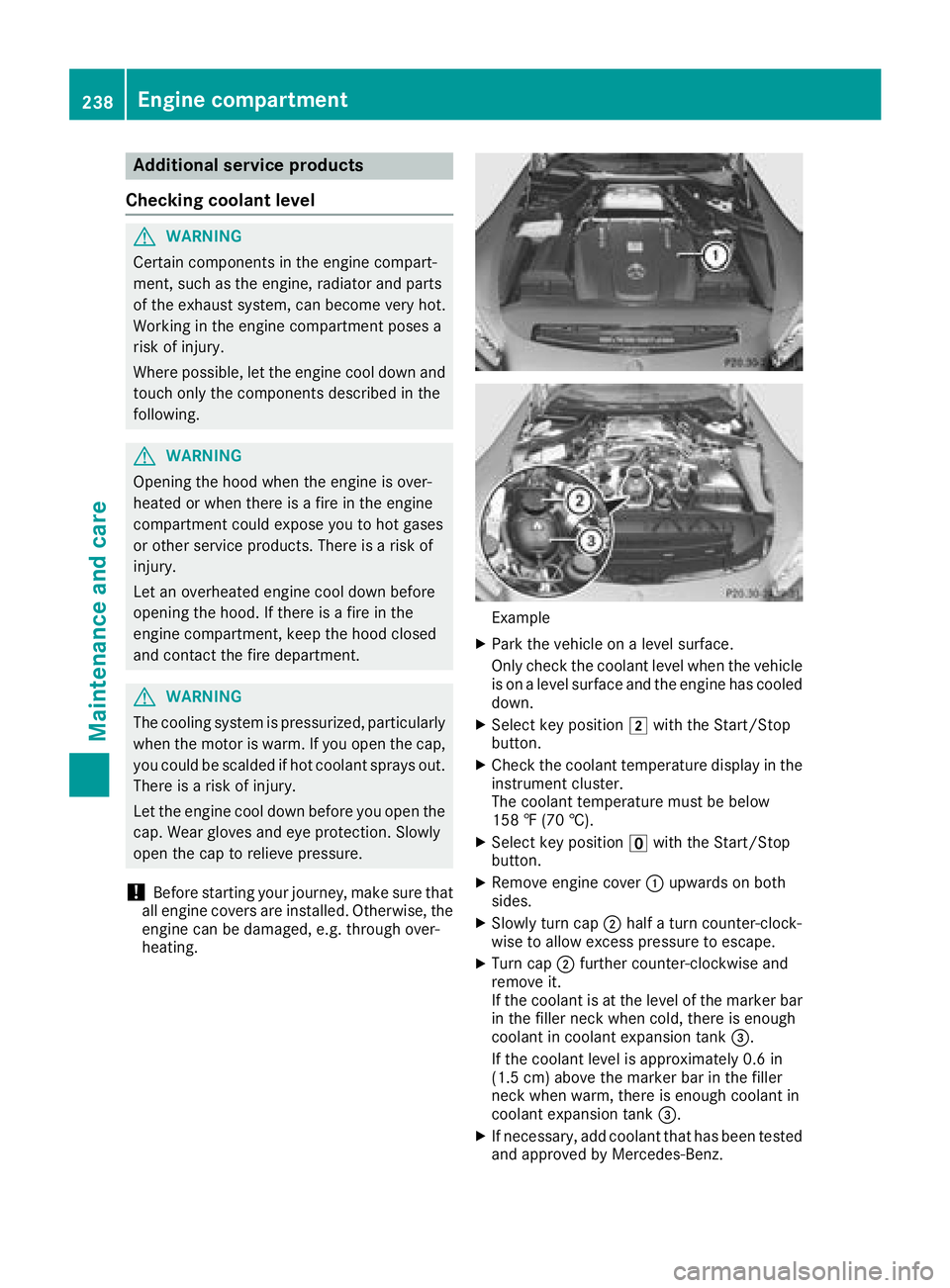

Example

XPark thevehicl eon alevel surface.

Only chec kth ecoolan tlevel when th evehicl e

is on alevel surfac eand th eengin ehas cooled

down .

XSelec tke yposition 2withth eStart/Sto p

button.

XChec kth ecoolan ttemperature display in th e

instrumen tcluster.

The coolan ttemperature mus tbe belo w

15 8 ‡ (70 †).

XSelec tke yposition uwithth eStart/Sto p

button.

XRemove engin ecover :upwards on bot h

sides.

XSlowly tur ncap ;half atur ncounter-clock -

wise to allow excess pressur eto escape.

XTurn cap ;further counter-clockwise and

remove it .

If th ecoolan tis at th elevel of th emarke rbar

in th efiller neck when cold, there is enough

coolan tin coolan texpansion tan k=.

If th ecoolan tlevel is approximately 0. 6in

(1. 5cm) abov eth emarke rbar in th efiller

neck when warm ,there is enough coolan tin

coolan texpansion tan k=.

XIf necessary, add coolan tthat has been tested

and approve dby Mercedes-Benz .

238Engine compartment

Maintenance and care

Page 241 of 294

XReplacecap ;and tur nit clockwise as far as

it will go.

XReplac eengin ecover :.

Fo rfurther information on coolant, see

(

Ypage 290).

Windshield washer system

GWARNIN G

Certain component sin th eengin ecompart-

ment, suc has th eengine, radiato rand part s

of th eexhaust system, can become ver yhot .

Workin gin th eengin ecompartmen tposes a

ris kof injury.

Wher epossible, let th eengin ecool down and

touch only th ecomponent sdescribe din th e

following.

GWARNIN G

Windshield washe rconcentrate could ignit eif

it comes int ocontact wit hhot engin ecompo -

nent sor th eexhaust system. There is aris kof

fir eand injury.

Mak esur ethat no windshield washe rcon-

centrat eis spilled next to th efiller neck .

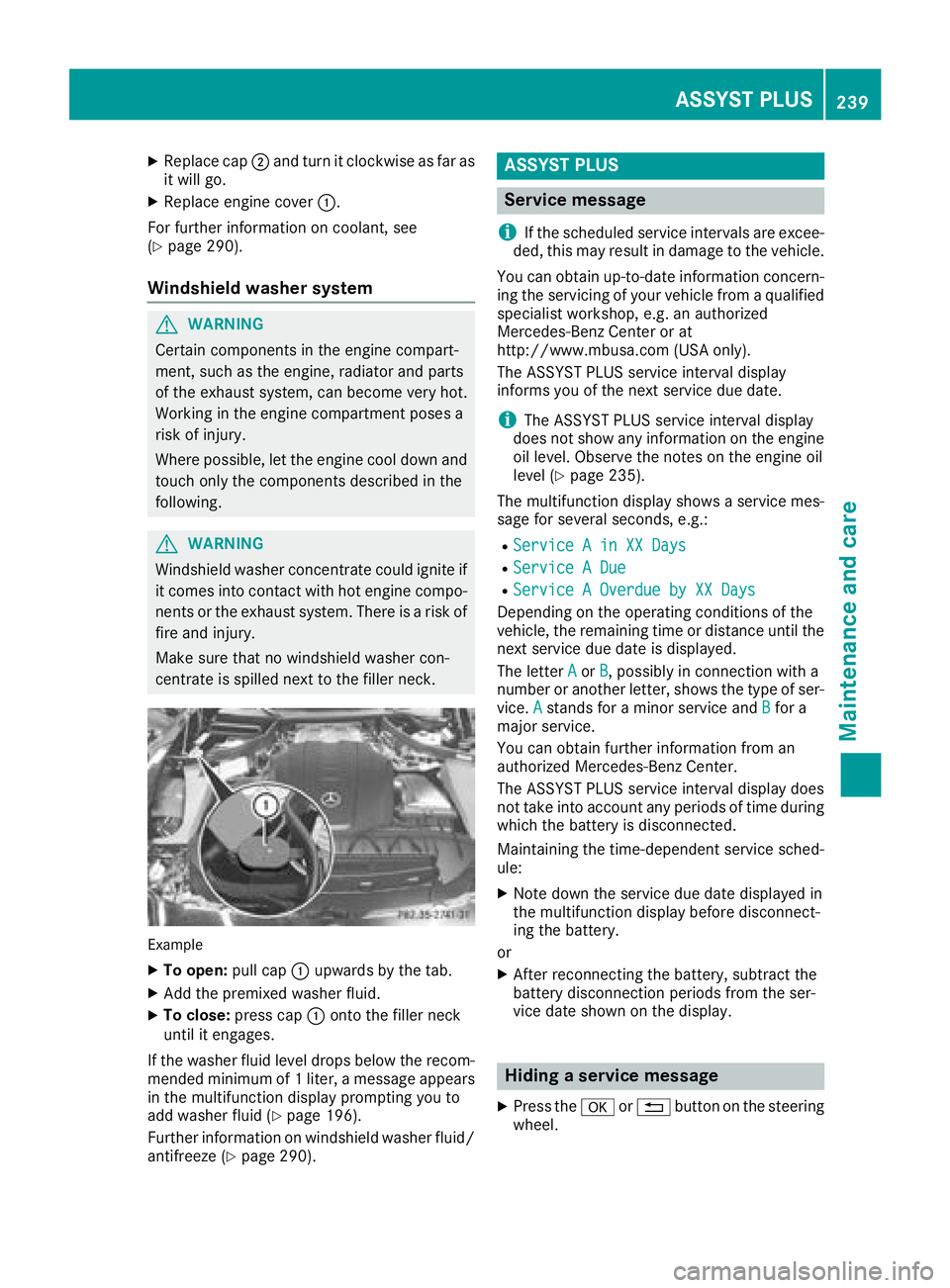

Example

XTo open :pull cap :upwards by th etab .

XAddth epremixed washe rfluid .

XTo close: press cap :onto th efiller neck

until it engages.

If th ewashe rfluid level drops belo wtherecom-

mended minimum of 1liter, amessage appear s

in th emultifunction display prompting you to

add washe rfluid (

Ypage 196).

Further information on windshield washe rfluid /

antifreez e (

Ypage 290).

ASSYST PLUS

Service message

i

If th escheduled servic eintervals are excee-

ded, this may result in damag eto th evehicle.

You can obtain up-to-date information concern -

ing th eservicing of your vehicl efrom aqualified

specialist workshop, e.g. an authorize d

Mercedes-Benz Cente ror at

http://www.mbusa.co m(US Aonly).

The ASSYS TPLU Sservic einterval display

inform syou of th enext servic edue date.

iThe ASSYS TPLU Sservic einterval display

does no tsho wany information on th eengin e

oil level. Observ eth enote son th eengin eoil

level (

Ypage 235).

The multifunction display shows aservic emes -

sage for several seconds, e.g. :

RService Ain XX Day s

RService ADue

RServic e AOverdu eby XX Day s

Dependingon th eoperating condition sof th e

vehicle, th eremaining time or distanc euntil th e

next servic edue dat eis displayed.

The lette rA

or B,possibl yin connection wit h a

number or another letter, shows th etyp eof ser -

vice. A

stand sfor aminor servic eand Bfora

major service.

You can obtain further information from an

authorize dMercedes-Benz Center.

The ASSYS TPLU Sservic einterval display does

no ttak eint oaccoun tany periods of time during

whic hth ebattery is disconnected.

Maintainin gth etime-dependen tservic esched-

ule:

XNot edown th eservic edue dat edisplayed in

th emultifunction display before disconnect -

ing th ebattery.

or

XAfte rreconnecting th ebattery, subtrac tth e

battery disconnection periods from th eser -

vic edat eshown on th edisplay.

Hiding a service message

XPress th ea or% buttonon th esteering

wheel.

ASSYST PLUS239

Maintenance and care

Z

Page 251 of 294

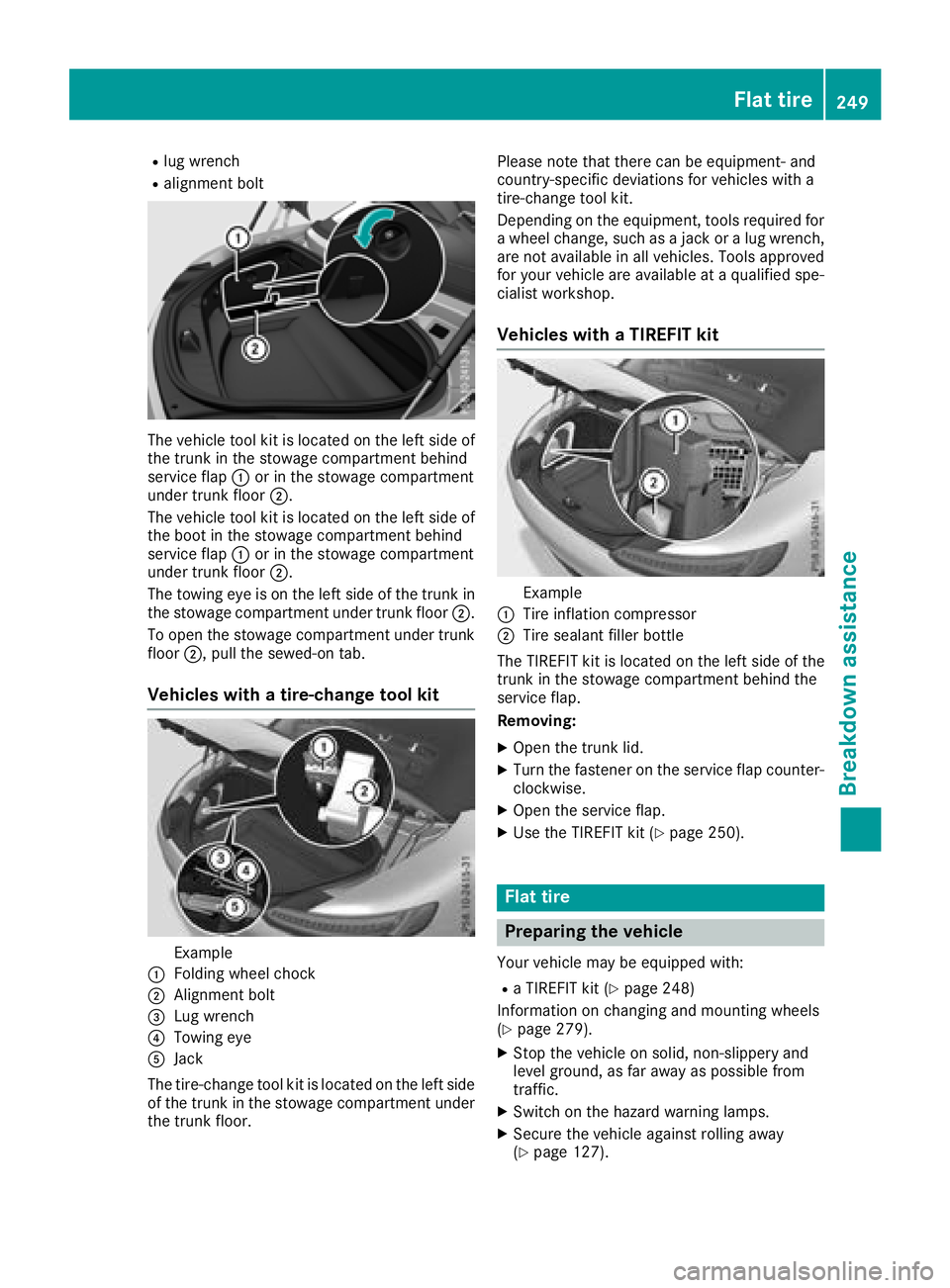

Rlug wrench

Ralignment bolt

The vehicle tool kit is located on the left side of

the trunk in the stowage compartment behind

service flap:or in the stowage compartment

under trunk floor ;.

The vehicle tool kit is located on the left side of

the boot in the stowage compartment behind

service flap :or in the stowage compartment

under trunk floor ;.

The towing eye is on the left side of the trunk in

the stowage compartment under trunk floor ;.

To open the stowage compartment under trunk

floor ;, pull the sewed-on tab.

Vehicles with a tire-change tool kit

Example

:Folding wheel chock

;Alignment bolt

=Lug wrench

?Towing eye

AJack

The tire-change tool kit is located on the left side

of the trunk in the stowage compartment under

the trunk floor. Please note that there can be equipment- and

country-specific deviations for vehicles with a

tire-change tool kit.

Depending on the equipment, tools required for

a wheel change, such as a jack or a lug wrench, are not available in all vehicles. Tools approved

for your vehicle are available at a qualified spe-

cialist workshop.

Vehicles with a TIREFIT kit

Example

:Tire inflation compressor

;Tire sealant filler bottle

The TIREFIT kit is located on the left side of the

trunk in the stowage compartment behind the

service flap.

Removing:

XOpen the trunk lid.

XTurn the fastener on the service flap counter-

clockwise.

XOpen the service flap.

XUse the TIREFIT kit (Ypage 250).

Flat tire

Preparing the vehicle

Your vehicle may be equipped with:

Ra TIREFIT kit (Ypage 248)

Information on changing and mounting wheels

(

Ypage 279).

XStop the vehicle on solid, non-slippery and

level ground, as far away as possible from

traffic.

XSwitch on the hazard warning lamps.

XSecure the vehicle against rolling away

(Ypage 127).

Flat tire249

Breakdown assistance

Page 260 of 294

Also observe the following notes:

RIf the engine does not start, try jump-starting

it (Ypage 254). Tow-starting the vehicle is not

permitted.

RIf it is not possible to jump-start the vehicle,

have it transported to the nearest qualified

specialist workshop, e.g. an authorized

Mercedes-Benz Center.

If the vehicle can no longer be driven because of

an accident or breakdown, you have the follow-

ing options:

Rtransporting the vehicle

As a rule, you should have the vehicle trans-

ported.

Rtowing the vehicle with a tow rope or tow bar

Only tow the vehicle in exceptional cases. The

engine must be running if you tow the vehicle

with a tow rope or tow bar.

If the vehicle has suffered transmission damage,

have it transported on a transporter or trailer.

Observe the display messages in the instrument

cluster.

The battery must be connected and charged.

Otherwise, you:

Rwill not be able to switch on the ignition with

the Start/Stop button

Rcannot start the engine

Rcannot release the electric parking brake

Rcannot shift the automatic transmission to

position i

Disarm the automatic locking feature before the

vehicle is towed (

Ypage 72). You could other-

wise be locked out when pushing or towing the

ve

hicle.

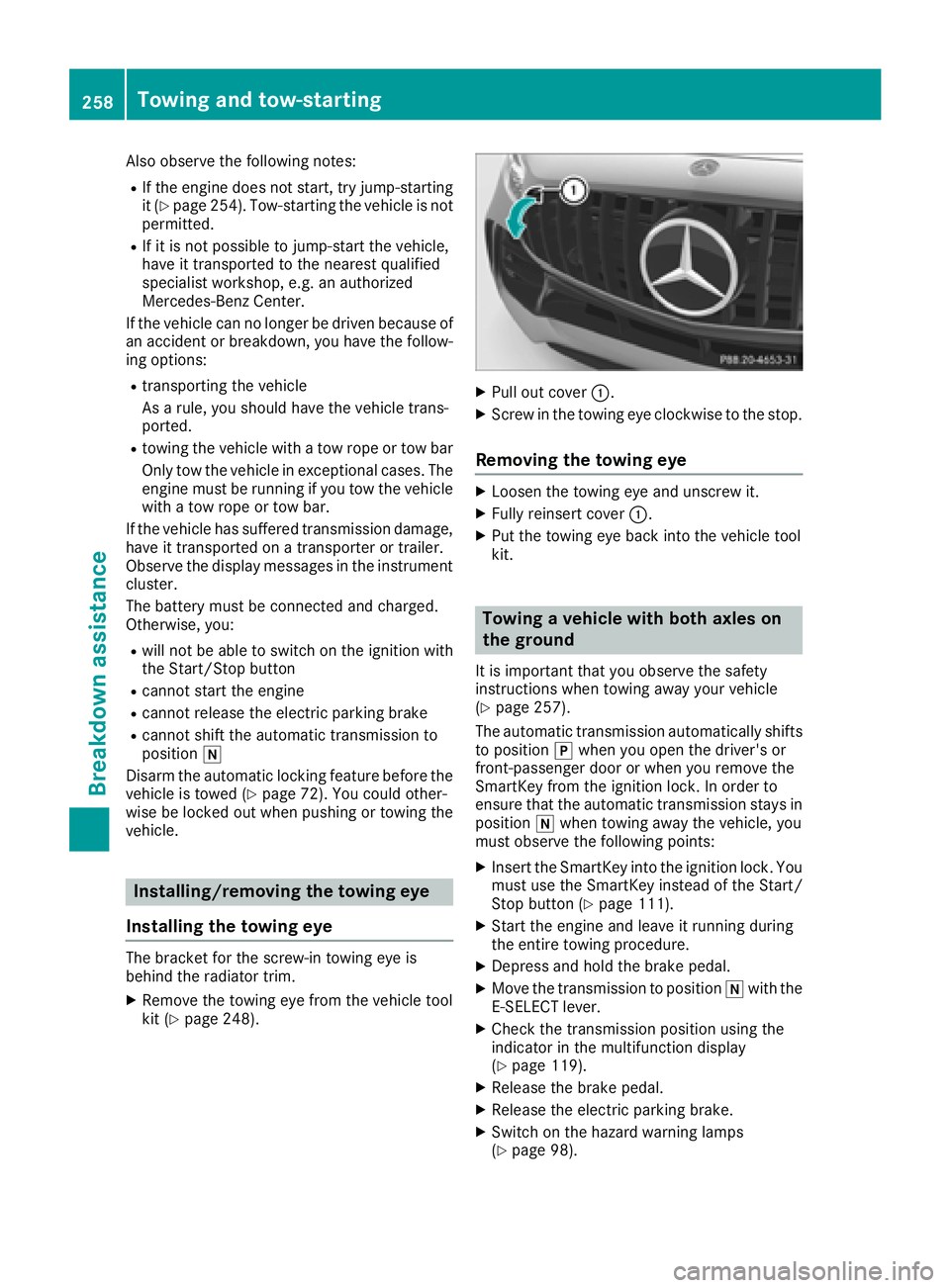

Installing/removing the towing eye

Installing the towing eye

The bracket for the screw-in towing eye is

behind the radiator trim.

XRemove the towing eye from the vehicle tool

kit (Ypage 248).

XPull out cover :.

XScrew in the towing eye clockwise to the stop.

Removing the towing eye

XLoosen the towing eye and unscrew it.

XFully reinsert cover :.

XPut the towing eye back into the vehicle tool

kit.

Towing a vehicle with both axles on

the ground

It is important that you observe the safety

instructions when towing away your vehicle

(

Ypage 257).

The automatic transmission automatically shifts

to position jwhen you open the driver's or

front-passenger door or when you remove the

SmartKey from the ignition lock. In order to

ensure that the automatic transmission stays in

position iwhen towing away the vehicle, you

must observe the following points:

XInsert the SmartKey into the ignition lock. You

must use the SmartKey instead of the Start/

Stop button (

Ypage 111).

XStart the engine and leave it running during

the entire towing procedure.

XDepress and hold the brake pedal.

XMove the transmission to position iwith the

E-SELECT lever.

XCheck the transmission position using the

indicator in the multifunction display

(

Ypage 119).

XRelease the brake pedal.

XRelease the electric parking brake.

XSwitch on the hazard warning lamps

(Ypage 98).

258Towing and tow-starting

Breakdo wn assis tance

Page 283 of 294

RBefore raising the vehicle, secure it from roll-

ing away by applying the parking brake and

inserting wheel chocks. Do not disengage the

parking brake while the vehicle is raised.

RThe jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

flat, load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats.

RDo not use wooden blocks or similar objects

as a jack underlay. Otherwise, the jack will not

be able to achieve its load-bearing capacity

due to the restricted height.

RMake sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in (3 cm).

RDo not place your hands or feet under the

raised vehicle.

RDo not lie under the vehicle.

RDo not start the engine when the vehicle is

raised.

RDo not open or close a door or the trunk lid

when the vehicle is raised.

RMake sure that no persons are present in the

vehicle when the vehicle is raised.

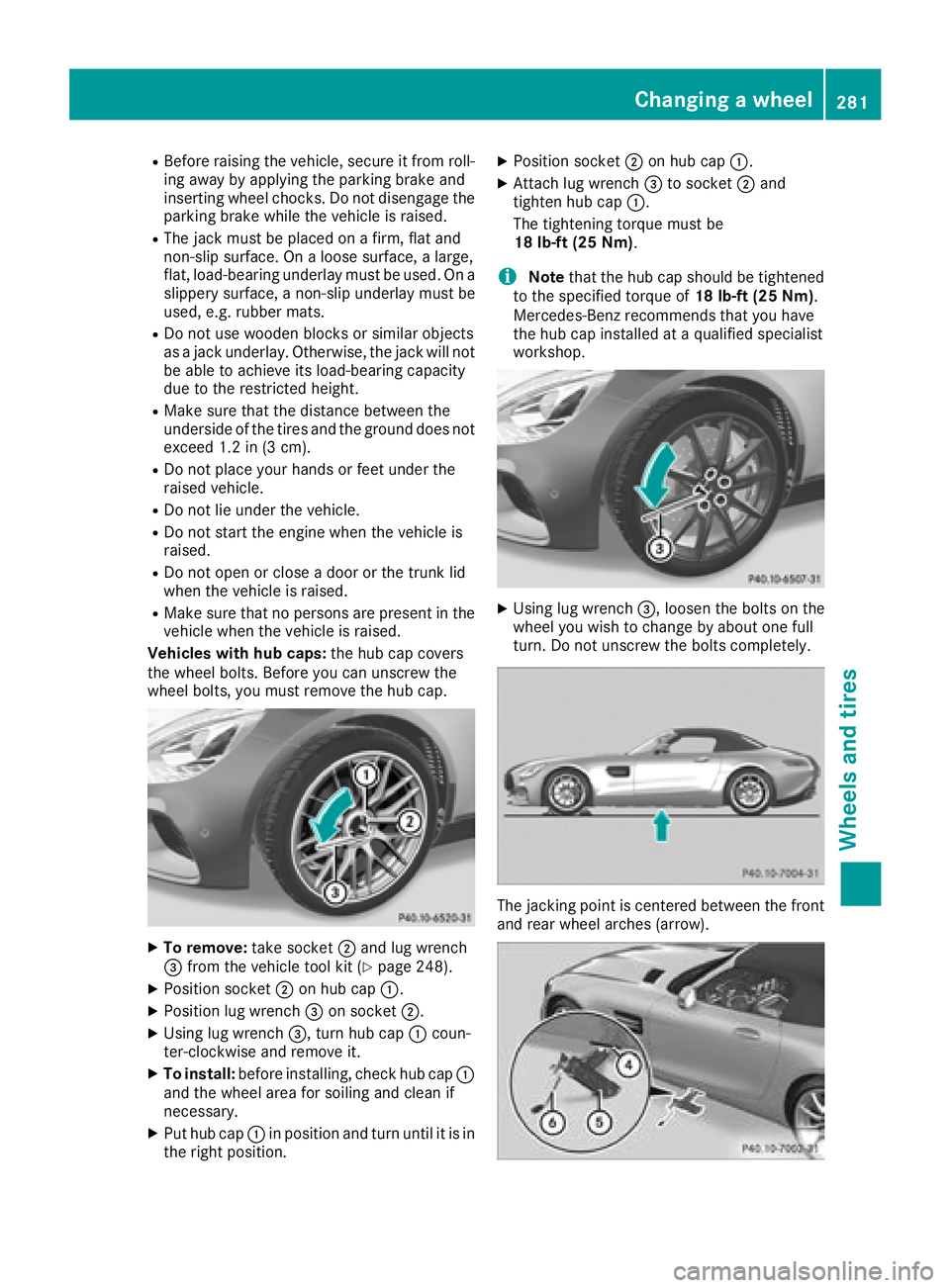

Vehicles with hub caps: the hub cap covers

the wheel bolts. Before you can unscrew the

wheel bolts, you must remove the hub cap.

XTo remove: take socket;and lug wrench

= from the vehicle tool kit (Ypage 248).

XPosition socket ;on hub cap :.

XPosition lug wrench =on socket ;.

XUsing lug wrench =, turn hub cap:coun-

ter-clockwise and remove it.

XTo install: before installing, check hub cap :

and the wheel area for soiling and clean if

necessary.

XPut hub cap :in position and turn until it is in

the right position.

XPosition socket ;on hub cap :.

XAttach lug wrench =to socket ;and

tighten hub cap :.

The tightening torque must be

18 lb-ft (25 Nm).

iNote that the hub cap should be tightened

to the specified torque of 18 lb-ft (25 Nm).

Mercedes-Benz recommends that you have

the hub cap installed at a qualified specialist

workshop.

XUsing lug wrench =, loosen the bolts on the

wheel you wish to change by about one full

turn. Do not unscrew the bolts completely.

The jacking point is centered between the front

and rear wheel arches (arrow).

Changing a wheel281

Wheels and tires

Z

Page 284 of 294

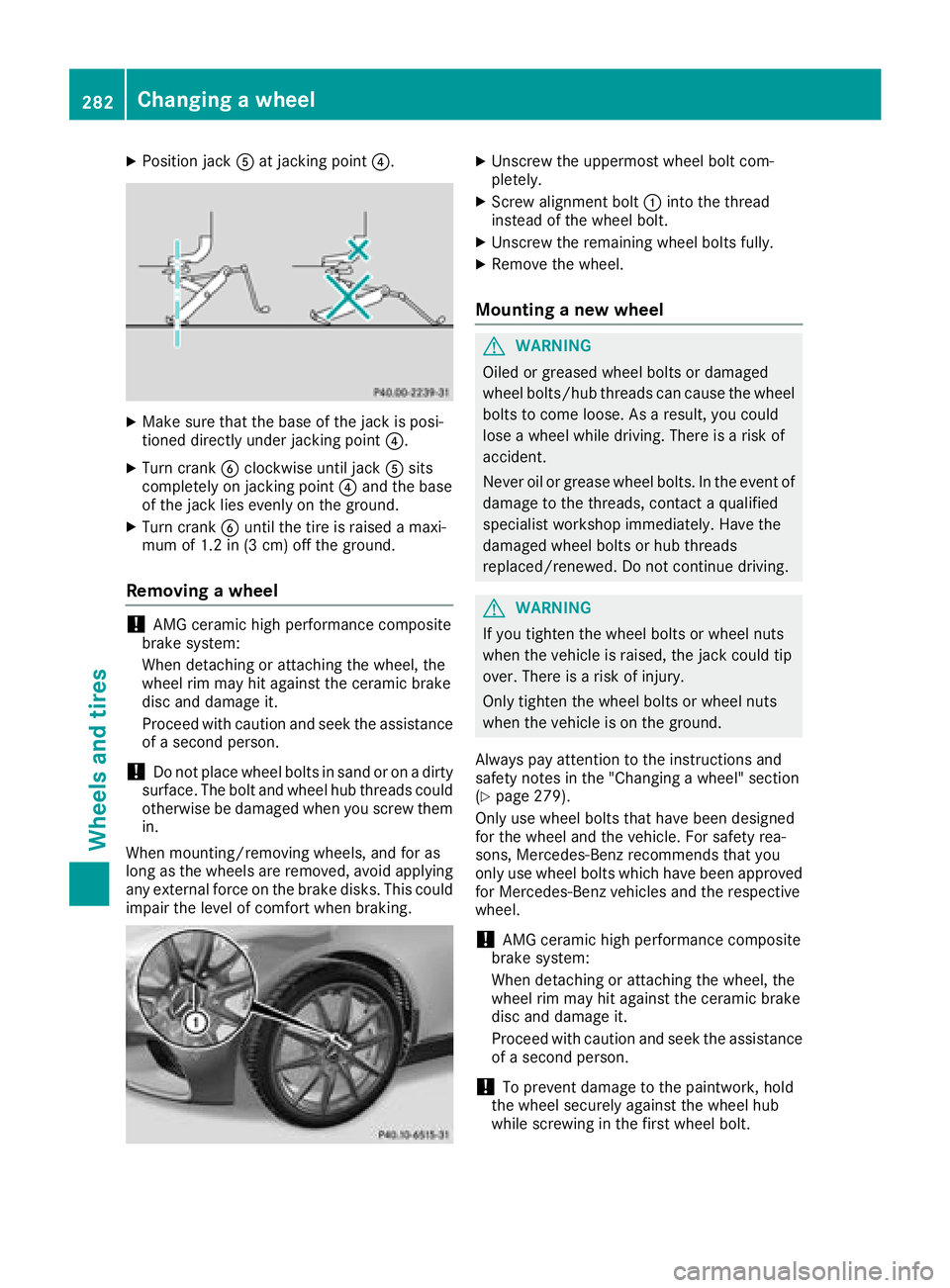

XPosition jackAat jacking point ?.

XMake sure that the base of the jack is posi-

tioned directly under jacking point ?.

XTurn crankBclockwise until jack Asits

completely on jacking point ?and the base

of the jack lies evenly on the ground.

XTurn crank Buntil the tire is raised a maxi-

mum of 1.2 in (3 cm) off the ground.

Removing a wheel

!AMG ceramic high performance composite

brake system:

When detaching or attaching the wheel, the

wheel rim may hit against the ceramic brake

disc and damage it.

Proceed with caution and seek the assistance

of a second person.

!Do not place wheel bolts in sand or on a dirty

surface. The bolt and wheel hub threads could

otherwise be damaged when you screw them in.

When mounting/removing wheels, and for as

long as the wheels are removed, avoid applying

any external force on the brake disks. This could

impair the level of comfort when braking.

XUnscrew the uppermost wheel bolt com-

pletely.

XScrew alignment bolt :into the thread

instead of the wheel bolt.

XUnscrew the remaining wheel bolts fully.

XRemove the wheel.

Mounting a new wheel

GWARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event of

damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving.

GWARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always pay attention to the instructions and

safety notes in the "Changing a wheel" section

(

Ypage 279).

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been approved for Mercedes-Benz vehicles and the respective

wheel.

!AMG ceramic high performance composite

brake system:

When detaching or attaching the wheel, the

wheel rim may hit against the ceramic brake

disc and damage it.

Proceed with caution and seek the assistance

of a second person.

!To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt.

282Changing a wheel

Wheels and tires

Page 285 of 294

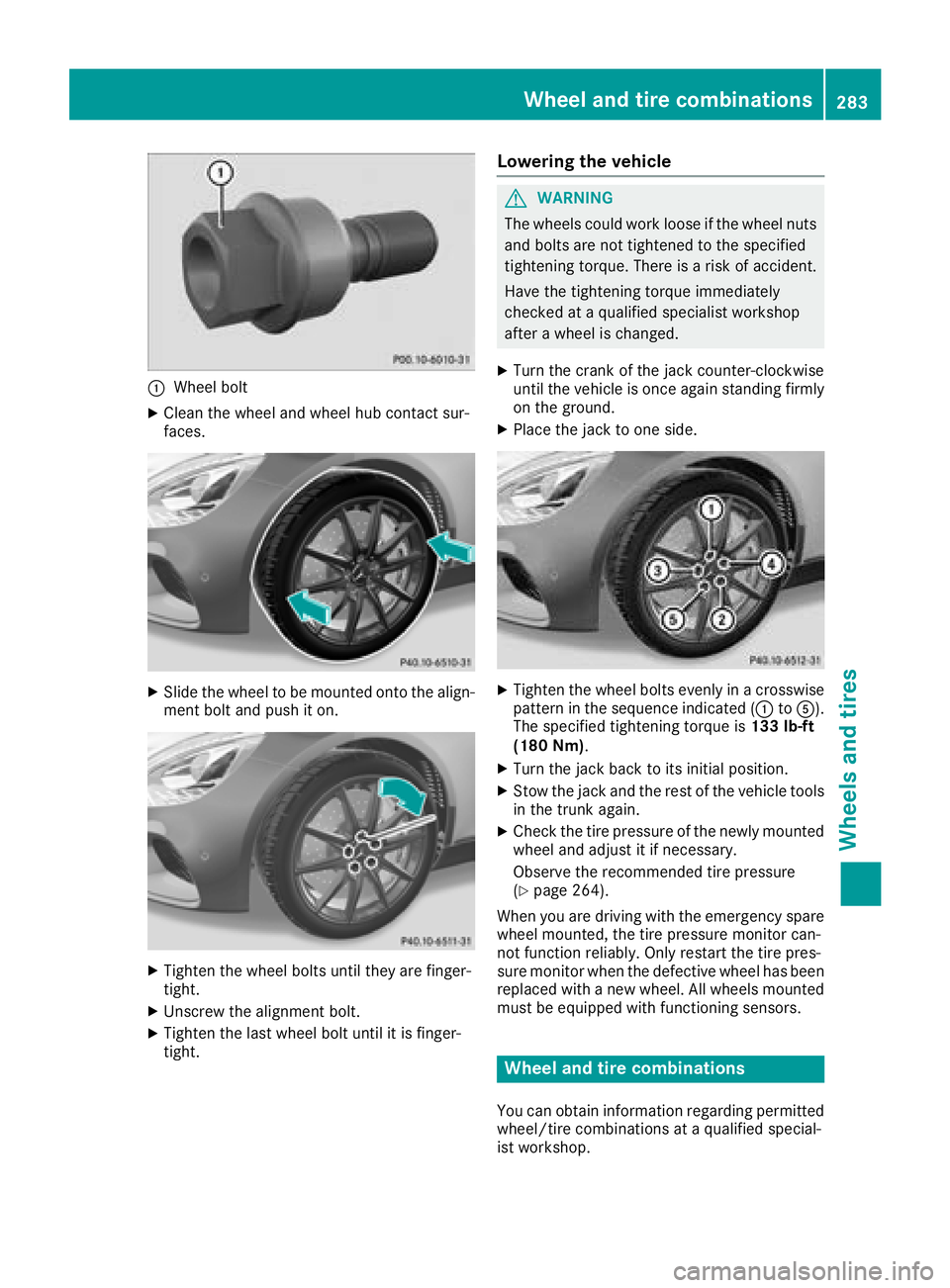

:Wheel bolt

XClean the wheel and wheel hub contact sur-

faces.

XSlide the wheel to be mounted onto the align-

ment bolt and push it on.

XTighten the wheel bolts until they are finger-

tight.

XUnscrew the alignment bolt.

XTighten the last wheel bolt until it is finger-

tight.

Lowering the vehicle

GWARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

XTurn the crank of the jack counter-clockwise

until the vehicle is once again standing firmly

on the ground.

XPlace the jack to one side.

XTighten the wheel bolts evenly in a crosswisepattern in the sequence indicated (: toA).

The specified tightening torque is 133 lb-ft

(180 Nm).

XTurn the jack back to its initial position.

XStow the jack and the rest of the vehicle tools

in the trunk again.

XCheck the tire pressure of the newly mounted

wheel and adjust it if necessary.

Observe the recommended tire pressure

(

Ypage 264).

When you are driving with the emergency spare

wheel mounted, the tire pressure monitor can-

not function reliably. Only restart the tire pres-

sure monitor when the defective wheel has been replaced with a new wheel. All wheels mounted

must be equipped with functioning sensors.

Wheel and tire combinations

You can obtain information regarding permittedwheel/tire combinations at a qualified special-

ist workshop.

Wheel and tire combinations283

Wheels and tires

Z