tire pressure MERCEDES-BENZ AMG GT ROADSTER 2018 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2018, Model line: AMG GT ROADSTER, Model: MERCEDES-BENZ AMG GT ROADSTER 2018Pages: 409, PDF Size: 7.66 MB

Page 270 of 409

Ty

res without run-flat characteristics: #

Do not drive on with a flat tyre. #

Chan getheflat tyre immediately with

an emer gency spa rewheel or spare

wheel. Alternativel y,consult a qualified

specialist workshop.

Ty res with run-flat characteristics: #

Obse rveth e information and warning

no tes on MOExtended tyres (run-flat

tyres). In

theeve nt of a flat tyre, thefo llowing options

are available depending on your vehicle's equip‐

ment:

R Vehicles with MOExtended tyres: it is pos‐

sible tocontinue the journey for a short

period of time. Make sure you obse rvethe

no tes on MOExtended tyres (run-flat tyres)

(/ page 267).

R Vehicles with a TIREFIT kit: you can repair

th e tyre so that it is possible tocontinue the

jou rney for a short period of time. Todo this,

use the TIREFIT kit (/ page 268). R

Vehicles with Mercedes me connect: you

can make a call for breakdown assi stance via

th eove rhead control panel in the case of a

breakdown (/ page217).

R Allvehicles: change the wheel

(/ page 297). Note

s on MOExtended tyres (run-flat tyres) &

WARNING Risk of accident when driving

in eme rgency mode

When driving in emer gency mode, the han‐

dling characteristics are impaired. e.g. when

cornering, when accelerating stronglyand

when braking. #

Do not exceed the permissible maxi‐

mum speed. #

Avoid any abrupt steering and driving

maneuvers as well as driving over

obs tacles (curbs, pot holes, off-road).

This applies, in pa rticular, toa loaded

ve hicle. #

Stop driving in the emer gency mode if

yo u notice:

R banging noise

R vehicle vibration

R smoke which smells like rubber

R continuous ESP ®

inter vention

R crac ksin tire side walls #

After driving in emergency mode ha ve

th erims checkedby aqu alified special‐

ist workshop with rega rd totheir fur ther

use. #

The defective tire must be replaced in

eve rycase. Wi

th MOExtended tyres (run-flat tyres), you can

continue todrive your vehicle even if there is a

tot al loss of pressure in one or more tyres. How‐

eve r,th e tyre af fected must not show any clearly

visible damage.

Yo u can recognise MOExtended tyres bythe

MOExtended marking which appears onthe side

wa ll of the tyre. Breakdown assis

tance 267

Page 271 of 409

Ve

hicles with tyre pressure monitoring sys‐

te m: MOExtended tyres may only be used in

conjunction wi than activated tyre pressure mon‐

itoring sy stem.

If a pressure loss warning message appears in

th e multifunction displa y,proceed as follo ws:

R Check the tyre for dama ge.

R If driving on, obser vethefo llowing no tes.

Driving distance possible in emer gency

mode af ter the pressure loss warning: Load condition Driving distance pos‐

sible in emergency

mode

Pa rtially laden 80 km

Fu lly laden 30 kmThe driving dis

tance possible in emergency

mode may vary depending on the driving style.

Obser vethe maximum permissible speed of

80 km/h. If a tyre has gone

flat and cannot be replaced

with an MOEx tended tyre, you can use a stand‐

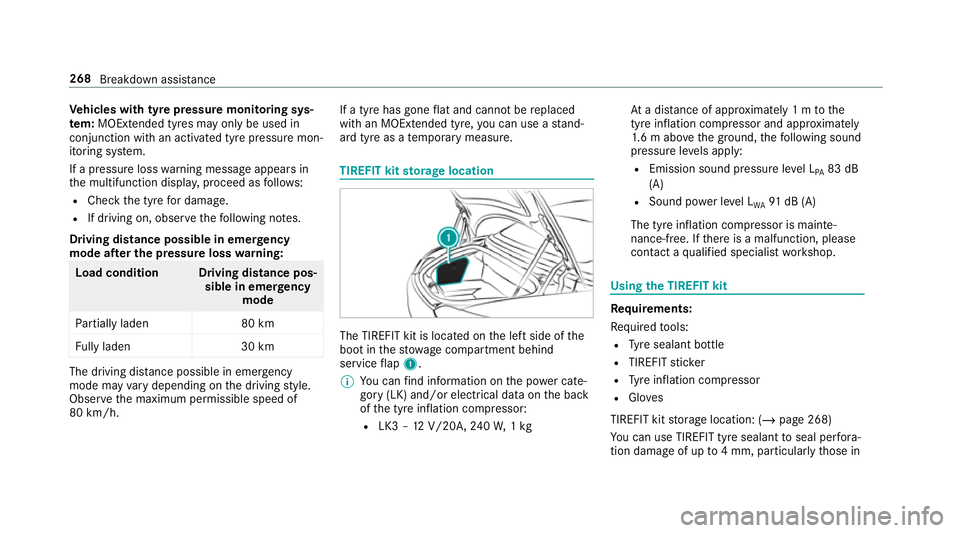

ard tyre as a temp orary measure. TIREFIT kit

storage location The TIREFIT kit is located on

the left side of the

boot in thestow age compartment behind

service flap 1.

% You can find information on the po wer cate‐

gory (LK) and/or electrical data on the back

of the tyre inflation compressor:

R LK3 – 12V/20A, 240W, 1kg At

a dis tance of appr oximately 1 m tothe

tyre inflation compressor and appr oximately

1. 6 m abo vethe ground, thefo llowing sound

pressure le vels apply:

R Emission sound pressure le vel L

PA 83 dB

(A)

R Sound po wer le vel L

WA 91

dB (A)

The tyre inflation compressor is mainte‐

nance-free. If there is a malfunction, please

conta ct aqualified specialist workshop. Using

the TIREFIT kit Re

quirements:

Re quired tools:

R Tyre sealant bottle

R TIREFIT sticker

R Tyre inflation compressor

R Gloves

TIREFIT kit storage location: (/ page 268)

Yo u can use TIREFIT tyre sealant toseal per fora‐

tion dama geof up to4 mm, particularly those in 268

Breakdown assis tance

Page 273 of 409

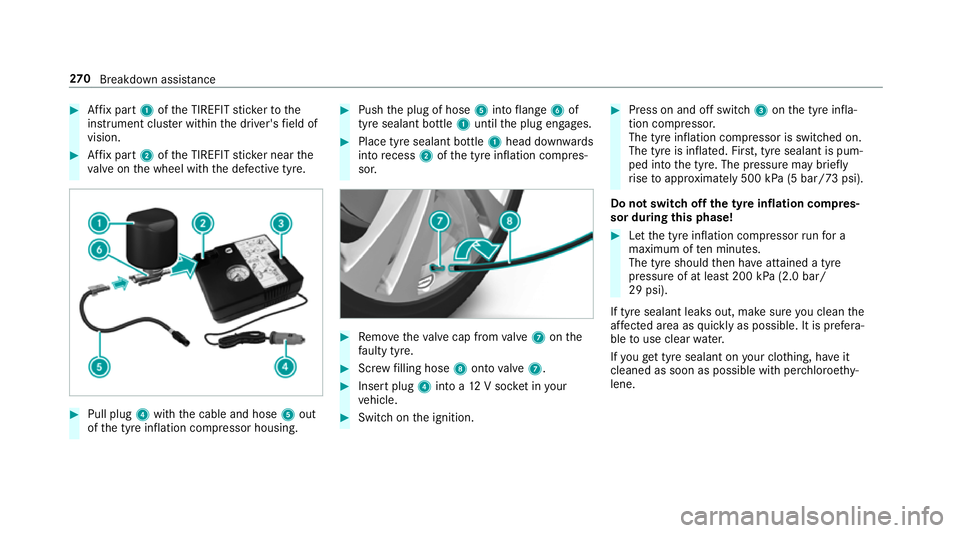

#

Affix pa rt1 ofthe TIREFIT sticke rto the

instrument clus ter within the driver's field of

vision. #

Affix pa rt2 ofthe TIREFIT sticke r near the

va lve on the wheel with the defective tyre. #

Pull plug 4with the cable and hose 5out

of the tyre inflation compressor housing. #

Push the plug of hose 5into flange 6of

tyre sealant bottle 1until the plug engages. #

Place tyre sealant bottle 1head down wards

into recess 2ofthe tyre inflation compres‐

sor. #

Remo vetheva lve cap from valve 7 onthe

fa ulty tyre. #

Screw filling hose 8onto valve 7. #

Insert plug 4into a 12V soc ket in your

ve hicle. #

Switch on the ignition. #

Press on and off switch 3onthe tyre infla‐

tion compressor.

The tyre inflation compressor is switched on.

The tyre is inflated. Fir st, tyre sealant is pum‐

ped into the tyre. The pressure may brief ly

ri se toappr oximately 500 kPa (5 bar/73 psi).

Do not switch off the ty reinflation compres‐

sor during this phase! #

Let the tyre inflation compressor runfo r a

maximum of ten minu tes.

The tyre should then ha veattained a tyre

pressure of at least 200 kPa (2.0 bar/

29 psi).

If tyre sealant leaks out, make sure you clean the

af fected area as quickly as possible. It is prefera‐

ble touse clear water.

If yo uge t tyre sealant on your clo thing, ha veit

cleaned as soon as possible with per chloroe thy‐

lene. 270

Breakdown assis tance

Page 274 of 409

If, af

terte n minutes, a tyre pressure of

200 kPa (2.0 bar/29 psi) has not been ach‐

ie ve d: #

Switch off the tyre inflation compressor. #

Unscr ew thefilling hose from theva lve of the

defective tyre.

Please no tethat tyre sealant may leak out when

unscr ewing thefilling hose. #

Drive forw ards or reve rseve ry slowly for

appr oximately 10m. #

Pump up the tyre again.

Af ter a maximum of ten minu testh e tyre

pressure must be at least 200 kPa (2.0 bar/

29 psi). &

WARNING Risk of accident due tothe

specified tyre pressure not being ach‐

ie ved

If th e specified tyre pressure is not achie ved

af te rth e specified time, the tyre is too badly

damaged. The tyre sealant cannot repair the

tyre in this ins tance. Dama

ged tyres and a tyre pressure that is

to o low can significantly impair braking and

handling characteristics. #

Do not drive on. #

Consult a qualified specialist workshop. If, af

terte n minutes, a tyre pressure of

200 kPa (2.0 bar/29 psi) has been achie ved: #

Switch off the tyre inflation compressor. #

Unscr ew thefilling hose from theva lve of the

defective tyre. &

WARNING Risk of accident from driving

wi th sealed tyres

A tyre temp orarily sealed with tyre sealant

impairs driving characteristics and is not

suitable for higher speeds. #

Adapt your driving style according lyand

drive carefull y. #

Do not exceed the maximum speed

limit with a tyre that has been repaired

using tyre sealant. #

Obser vethe maximum permissible speed for

a tyre sealed with tyre sealant 80 km/h. #

Affix th e upper section of the TIREFIT sticker

to the instrument clus ter in a location where

it will be easi lyseen bythe driver.

* NO

TEStaining from leaking tyre sealant Af

ter use, excess tyre sealant may leak out

from thefilling hose. #

Therefore, place thefilling hose in the

plastic bag that con tained the TIREFIT

kit. +

ENVIRONMEN

TALNO TEEnvironmental

pollution caused byenvironmen tally ir re‐

sponsible disposal Ty

re sealant contains polluta nts. #

Have the tyre sealant bottle disposed of

professionall y,e.g. at a Mercedes-Benz

Service Centre. #

Stow th e tyre sealant bottle, the tyre inflation

compressor and thewa rning triangle. Breakdown assis

tance 271

Page 288 of 409

Note

s on noise or unusual handling charac‐

te rist ics

While driving, pay attention tovibrations, noises

and unusual handling characteristics, e.g. pulling

to one side. This may indicate that the wheels or

tyres are damaged. If you suspect that a tyre is

defective, reduce your speed immediatel y.Stop

th eve hicle as soon as possible tocheck the

wheels and tyres for dama ge. Hidden tyre dam‐

age could also be causing the unusual handling

ch aracteristics. If youfind no signs of damage,

ha ve the tyres and wheels checked at a qualified

specialist workshop. Note

s onregular lyinspecting wheels and

tyres &

WARNING Risk of accident from dam‐

aged tyres

Dama ged tyres can cause tyre pressure loss.

As a result, you could lose cont rol of your

ve hicle. #

Check the tyres regularly for signs of

dama geand replace any damaged tyres

immediatel y. Car

ryout thefo llowing checks on all wheels reg‐

ularly, at least once a month or as requ ired, e.g.

prior toa long journey or driving off- road:

R Check the tyre pressure (/ page 286).

R Visually inspect tyres and wheels for dam‐

age.

R Check theva lve caps.

The valves must be pr otected against mois‐

ture and dirt bytheva lve caps appr oved

especially foryo ur vehicle byMercedes-Benz.

R Visual check of the tyre tread dep thand the

tyre contact su rface across the entire width.

The minimum tread dep thfor summer tyres

is 3 mm and for winter tyres 4 mm. Note

s on snow chains &

WARNING Risk of accident due toincor‐

re ct snow chain fitting

If yo u ha vefitted snow chains tothe front

wheels, the snow chains may drag against

th eve hicle body or chassis components.

This could cause damage totheve hicle or

th e tyres. #

Neverfit snow chains on the front

wheels. #

Only fit snow chains on there ar wheels

in pairs. *

NO

TEDama getothe wheel trim from fit‐

te d snow chains If sn

ow ch ains are fitted tosteel wheels, the

wheel trims can be damaged. #

Remo vethe wheel trims of steel wheels

before fitting snow chains. Wheels and tyres

285

Page 299 of 409

R

Vehicles with a tyre pressure monitoring

sy stem: allfitted wheels mu stbe equipped

with functioning sensors forth e tyre pres‐

sure monitoring sy stem.

R Attemp eratures below 7 °C, use winter tyres

or all-season tyres mar ked M+S for all

wheels.

Wi nter tyres bearing thei snowflake

symbol in addition tothe M+S marking pro‐

vide the best possible grip in wintry road

conditions.

R For M+S tyres, only use tyres with the same

tread.

R Obser vethe maximum permissible speed for

th e M+S tyres fitted.

If th is is below theve hicle's maximum speed,

th is must be indicated byan appropriate

label in the driver's field of vision.

R Run in new tyres at moderate speeds forthe

fi rs t10 0 km.

R Replace the tyres af ter six years at the latest,

re ga rdless of wear. R

When replacing with tyres that do not

fe ature run-flat characteristics: vehicles

with MOExtended tyres are not equipped

with a TIREFIT kit at thefa ctor y.Equip the

ve hicle with a TIREFIT kit af terre placing with

tyres that do not feature run-flat characteris‐

tics, e.g. winter tyres.

% You can permanently limit the maximum

ve hicle speed for driving with winter tyres

(/ page 146).

Fo r more information on wheels and tyres, con‐

ta ct a qualified specialist workshop.

Be sure toalso obse rveth efo llowing fur ther

re lated subjects:

R Notes on tyre pressure (/ page 286)

R Tyre pressure table (/ page 287) Note

s on inter changing wheels &

WARNING Risk of inju rythro ugh dif fer‐

ent wheel sizes

Inter changing the front and rear wheels if the

wheels or tyres ha vediffere nt dimensions

may se verely impair the driving characteris‐

tics.

The disk brakes or wheel suspension compo‐

nents may also be damaged. #

Rotate front and rear wheels on lyifthe

wheels and tyres are of the same

dimensions. Inter

changing the front and rear wheels if the

wheels or tyres ha vediffere nt dimensions can

re nder thege neral operating pe rmit in valid.

The wear pat tern s on the front and rear wheels

dif fer:

R Front wheels wear more on the shoulder of

th e tyre

R Rear wheels wear more in the cent reofthe

tyre 296

Wheels and tyres

Page 402 of 409

Tr

ip

Menu (on-board computer) .................. 174

Tr ip computer

Displaying ............................................ 174

Re setting ............................................. 175

Tr ip distance ............................................ .174

Displ aying ............................................ 174

Re setting ............................................. 175

Tr ip me ter

see Trip dis tance

Tu rn signal indicator

see Turn signal lights

Tu rn signal lights ....................................... 99

Switching on/off ................................... 99

Tw o phone mode

see Second telephone

Ty re inflation compressor

see TIREFIT kit

Ty re pressure ........................................... 287

Checking (ty repressure monitoring

sy stem) ............................................... 288

No tes .................................................. 286 Re

starting the tyre pressure monitor‐

ing sy stem ...........................................2 89

TIREFIT kit .......................................... .268

Ty re pressure monitoring sy stem

(function) ............................................. 287

Ty re pressure table .............................. 287

Ty re pressure moni toring sy stem

Checking the tyre pressure ................. 288

Fu nction .............................................. 287

Re starting ............................................ 289

Te ch nical da ta..................................... 289

Ty re pressure table ................................. 287

Ty re temp erature

Ty re pressure monitoring sy stem

(function) ............................................. 287

Ty re tread ................................................. 285

Ty re-change tool kit

Overview ............................................ .297

Ty res

Checking ............................................ .285

Che cking the tyre pressure (tyre

pressure monitoring sy stem) ............... 288

Fitting .................................................. 301

Flat tyre ............................................... 266 Inter

changing ...................................... 296

MOExtended tyres .............................. .267

No ise .................................................. .285

No tes on fitting ................................... 293

Re moving ............................................ 300

Re placing .................................... 293, 297

Re starting the tyre pressure monitor‐

ing sy stem ...........................................2 89

Selection ............................................. 293

Snow chains ........................................ 285

St oring .................................................2 97

TIREFIT kit ...........................................2 68

Ty re pressure (N otes) .......................... 286

Ty re pressure monitoring sy stem

(function) ............................................. 287

Ty re pressure table .............................. 287

Un usual handling characteristics ........ 285 U

Un its of measurement

Setting ................................................ .191

Un locking setting ...................................... 57

USB devices Connecting .......................................... 235 Index

399

Page 405 of 409

We

bsite

Calling up ............................................ 228

Showing/hiding thewe b br ows er

menu ................................................... 228

Wheel change

Fitting a new wheel .............................. 301

Fitting/removing pla stic hub caps ...... 298

Lo we ring theve hicle ........................... 302

Preparation .......................................... 297

Ra ising theve hicle .............................. 298

Re moving a wheel .............................. .300

Wheel rotation ........................................ .296

Wheels Care .................................................... 260

Checking ............................................. 285

Checking the tyre pressure (tyre

pressure monitoring sy stem) ............... 288

Fitting .................................................. 301

Flat tyre ............................................... 266

Inter changing ...................................... 296

MOExtended tyres .............................. .267

No ise .................................................. .285

No tes on fitting ................................... 293

Re moving ............................................ 300

Re placing .................................... 293, 297 Re

starting the tyre pressure monitor‐

ing sy stem ...........................................2 89

Selection ............................................. 293

Snow chains ........................................ 285

St oring .................................................2 97

TIREFIT kit ...........................................2 68

Ty re pressure (N otes) .......................... 286

Ty re pressure monitoring sy stem

(function) ............................................. 287

Ty re pressure table .............................. 287

Un usual handling characteristics ........ 285

Wi -Fi .......................................................... 189

Overview ............................................. 189

Setting ................................................. 189

Setting up a hotspot ............................ 19 0

Setting up an Internet connection ....... 224

Wi ndo ws

see Side windo ws

Wi ndo ws(Care) ...................................... .260

Wi ndscreen

see Windshield

Wi ndscreen washer fluid ........................ 313

No tes ................................................... 313Wi

ndscreen washer sy stem

To pping up ...........................................2 53

Wi ndscreen wipers

Changing the wiper blades .................. 103

Switching on/off ................................. 103

Wi ndshield ............................................... 103

Changing the wiper blades .................. 103

Wi nter operation

Snow chains ........................................ 285

Wi nter tyres

Setting the permanent speed limita‐

tion ...................................................... 14 6

Wi per blades

Ca re .................................................... 260

Re placing .............................................1 03

Wire lessvehicle comp onents

Declaration of con form ity ...................... 22

Wo rkshop

see Qualified specialist workshop 402

Index