MERCEDES-BENZ AMG GT ROADSTER 2019 Owner's Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: AMG GT ROADSTER, Model: MERCEDES-BENZ AMG GT ROADSTER 2019Pages: 298, PDF Size: 7.9 MB

Page 251 of 298

Where will I find...?

Reflective safety jacket

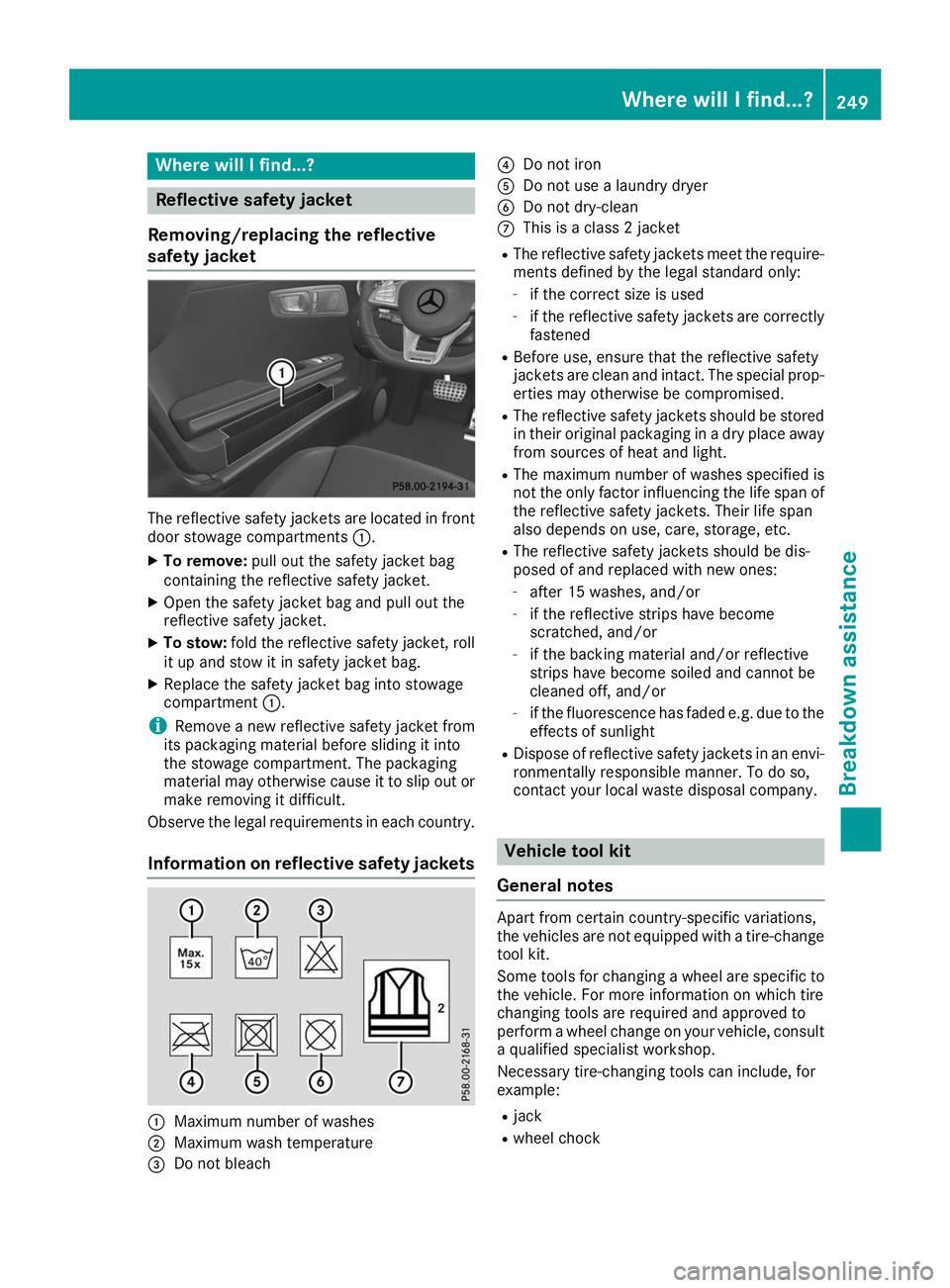

Removing/replacing the reflective

safety jacket The reflective safety jackets are located in front

door stowage compartments 0043.

X To remove: pull out the safety jacket bag

containing the reflective safety jacket.

X Open the safety jacket bag and pull out the

reflective safety jacket.

X To stow: fold the reflective safety jacket, roll

it up and stow it in safety jacket bag.

X Replace the safety jacket bag into stowage

compartment 0043.

i Remove a new reflective safety jacket from

its packaging material before sliding it into

the stowage compartment. The packaging

material may otherwise cause it to slip out or

make removing it difficult.

Observe the legal requirements in each country.

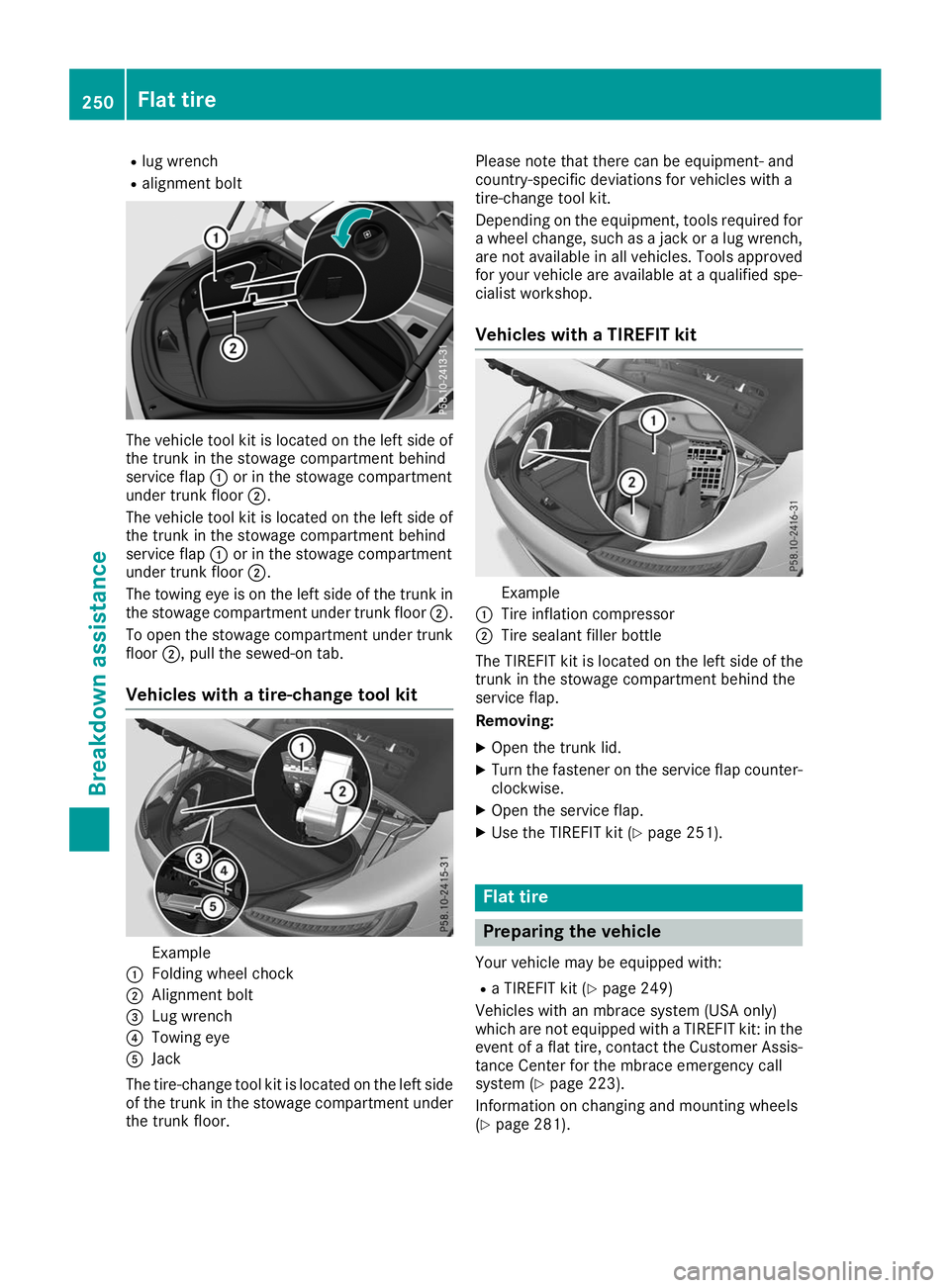

Information on reflective safety jackets 0043

Maximum number of washes

0044 Maximum wash temperature

0087 Do not bleach 0085

Do not iron

0083 Do not use a laundry dryer

0084 Do not dry-clean

006B This is a class 2 jacket

R The reflective safety jackets meet the require-

ments defined by the legal standard only:

- if the correct size is used

- if the reflective safety jackets are correctly

fastened

R Before use, ensure that the reflective safety

jackets are clean and intact. The special prop-

erties may otherwise be compromised.

R The reflective safety jackets should be stored

in their original packaging in a dry place away

from sources of heat and light.

R The maximum number of washes specified is

not the only factor influencing the life span of

the reflective safety jackets. Their life span

also depends on use, care, storage, etc.

R The reflective safety jackets should be dis-

posed of and replaced with new ones:

- after 15 washes, and/or

- if the reflective strips have become

scratched, and/or

- if the backing material and/or reflective

strips have become soiled and cannot be

cleaned off, and/or

- if the fluorescence has faded e.g. due to the

effects of sunlight

R Dispose of reflective safety jackets in an envi-

ronmentally responsible manner. To do so,

contact your local waste disposal company. Vehicle tool kit

General notes Apart from certain country-specific variations,

the vehicles are not equipped with a tire-change

tool kit.

Some tools for changing a wheel are specific to the vehicle. For more information on which tire

changing tools are required and approved to

perform a wheel change on your vehicle, consult

a qualified specialist workshop.

Necessary tire-changing tools can include, for

example:

R jack

R wheel chock Where will I find...?

249Breakdown assistance

Page 252 of 298

R

lug wrench

R alignment bolt The vehicle tool kit is located on the left side of

the trunk in the stowage compartment behind

service flap 0043or in the stowage compartment

under trunk floor 0044.

The vehicle tool kit is located on the left side of the trunk in the stowage compartment behind

service flap 0043or in the stowage compartment

under trunk floor 0044.

The towing eye is on the left side of the trunk in

the stowage compartment under trunk floor 0044.

To open the stowage compartment under trunk floor 0044, pull the sewed-on tab.

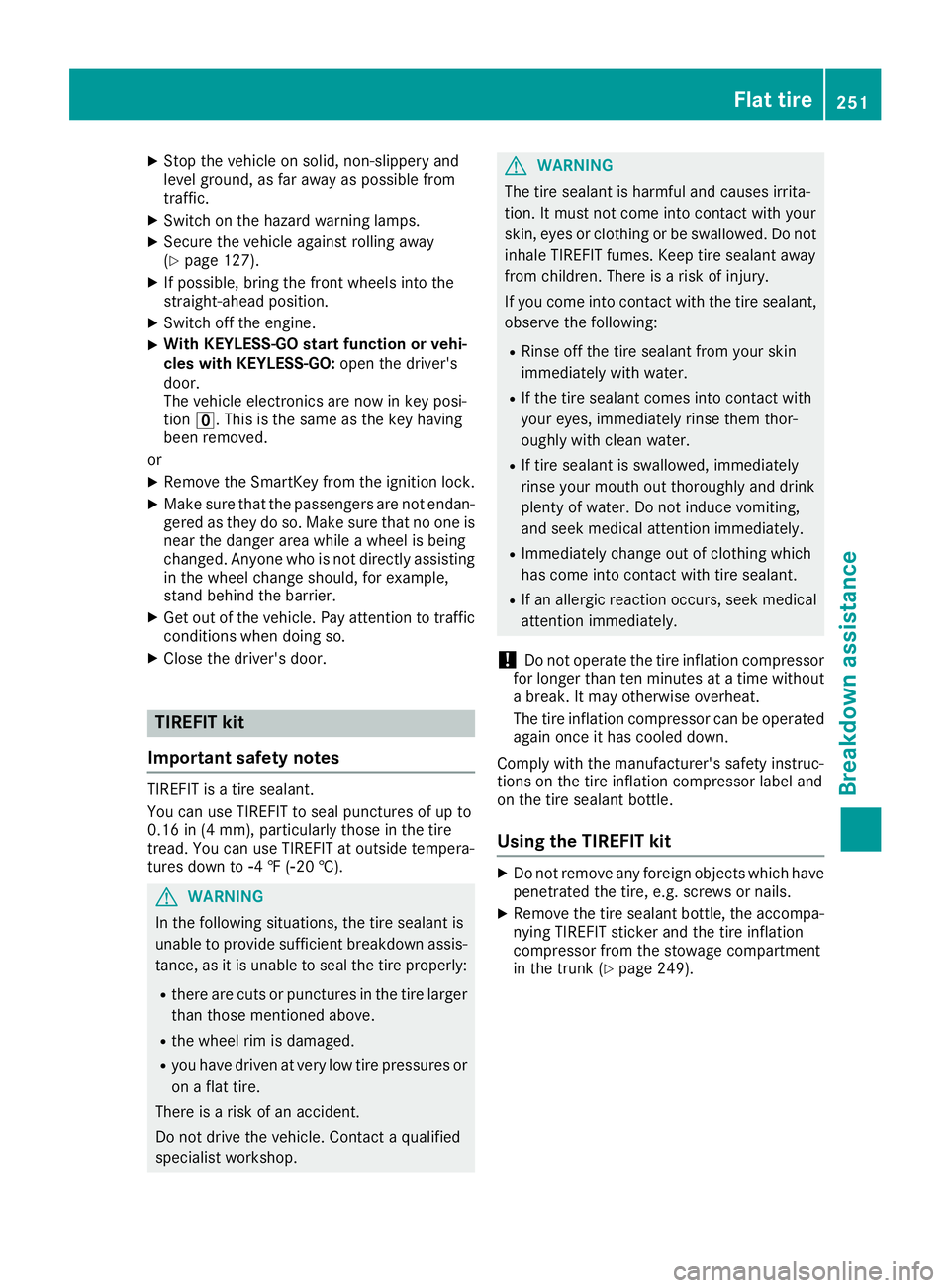

Vehicles with a tire-change tool kit Example

0043 Folding wheel chock

0044 Alignment bolt

0087 Lug wrench

0085 Towing eye

0083 Jack

The tire-change tool kit is located on the left side of the trunk in the stowage compartment under the trunk floor. Please note that there can be equipment- and

country-specific deviations for vehicles with a

tire-change tool kit.

Depending on the equipment, tools required for

a wheel change, such as a jack or a lug wrench, are not available in all vehicles. Tools approved

for your vehicle are available at a qualified spe-

cialist workshop.

Vehicles with a TIREFIT kit Example

0043 Tire inflation compressor

0044 Tire sealant filler bottle

The TIREFIT kit is located on the left side of the

trunk in the stowage compartment behind the

service flap.

Removing:

X Open the trunk lid.

X Turn the fastener on the service flap counter-

clockwise.

X Open the service flap.

X Use the TIREFIT kit (Y page 251). Flat tire

Preparing the vehicle

Your vehicle may be equipped with: R a TIREFIT kit (Y page 249)

Vehicles with an mbrace system (USA only)

which are not equipped with a TIREFIT kit: in the event of a flat tire, contact the Customer Assis-

tance Center for the mbrace emergency call

system (Y page 223).

Information on changing and mounting wheels

(Y page 281). 250

Flat tireBreakdown assistance

Page 253 of 298

X

Stop the vehicle on solid, non-slippery and

level ground, as far away as possible from

traffic.

X Switch on the hazard warning lamps.

X Secure the vehicle against rolling away

(Y page 127).

X If possible, bring the front wheels into the

straight-ahead position.

X Switch off the engine.

X With KEYLESS-GO start function or vehi-

cles with KEYLESS-GO: open the driver's

door.

The vehicle electronics are now in key posi-

tion 0092. This is the same as the key having

been removed.

or X Remove the SmartKey from the ignition lock.

X Make sure that the passengers are not endan-

gered as they do so. Make sure that no one is

near the danger area while a wheel is being

changed. Anyone who is not directly assisting in the wheel change should, for example,

stand behind the barrier.

X Get out of the vehicle. Pay attention to traffic

conditions when doing so.

X Close the driver's door. TIREFIT kit

Important safety notes TIREFIT is a tire sealant.

You can use TIREFIT to seal punctures of up to

0.16 in (4 mm), particularly those in the tire

tread. You can use TIREFIT at outside tempera-

tures down to 00F84 ‡ (00F820 †). G

WARNING

In the following situations, the tire sealant is

unable to provide sufficient breakdown assis- tance, as it is unable to seal the tire properly:

R there are cuts or punctures in the tire larger

than those mentioned above.

R the wheel rim is damaged.

R you have driven at very low tire pressures or

on a flat tire.

There is a risk of an accident.

Do not drive the vehicle. Contact a qualified

specialist workshop. G

WARNING

The tire sealant is harmful and causes irrita-

tion. It must not come into contact with your

skin, eyes or clothing or be swallowed. Do not inhale TIREFIT fumes. Keep tire sealant away

from children. There is a risk of injury.

If you come into contact with the tire sealant,

observe the following:

R Rinse off the tire sealant from your skin

immediately with water.

R If the tire sealant comes into contact with

your eyes, immediately rinse them thor-

oughly with clean water.

R If tire sealant is swallowed, immediately

rinse your mouth out thoroughly and drink

plenty of water. Do not induce vomiting,

and seek medical attention immediately.

R Immediately change out of clothing which

has come into contact with tire sealant.

R If an allergic reaction occurs, seek medical

attention immediately.

! Do not operate the tire inflation compressor

for longer than ten minutes at a time without a break. It may otherwise overheat.

The tire inflation compressor can be operatedagain once it has cooled down.

Comply with the manufacturer's safety instruc-

tions on the tire inflation compressor label and

on the tire sealant bottle.

Using the TIREFIT kit X

Do not remove any foreign objects which have

penetrated the tire, e.g. screws or nails.

X Remove the tire sealant bottle, the accompa-

nying TIREFIT sticker and the tire inflation

compressor from the stowage compartment

in the trunk (Y page 249). Flat tire

251Breakdown assistance Z

Page 254 of 298

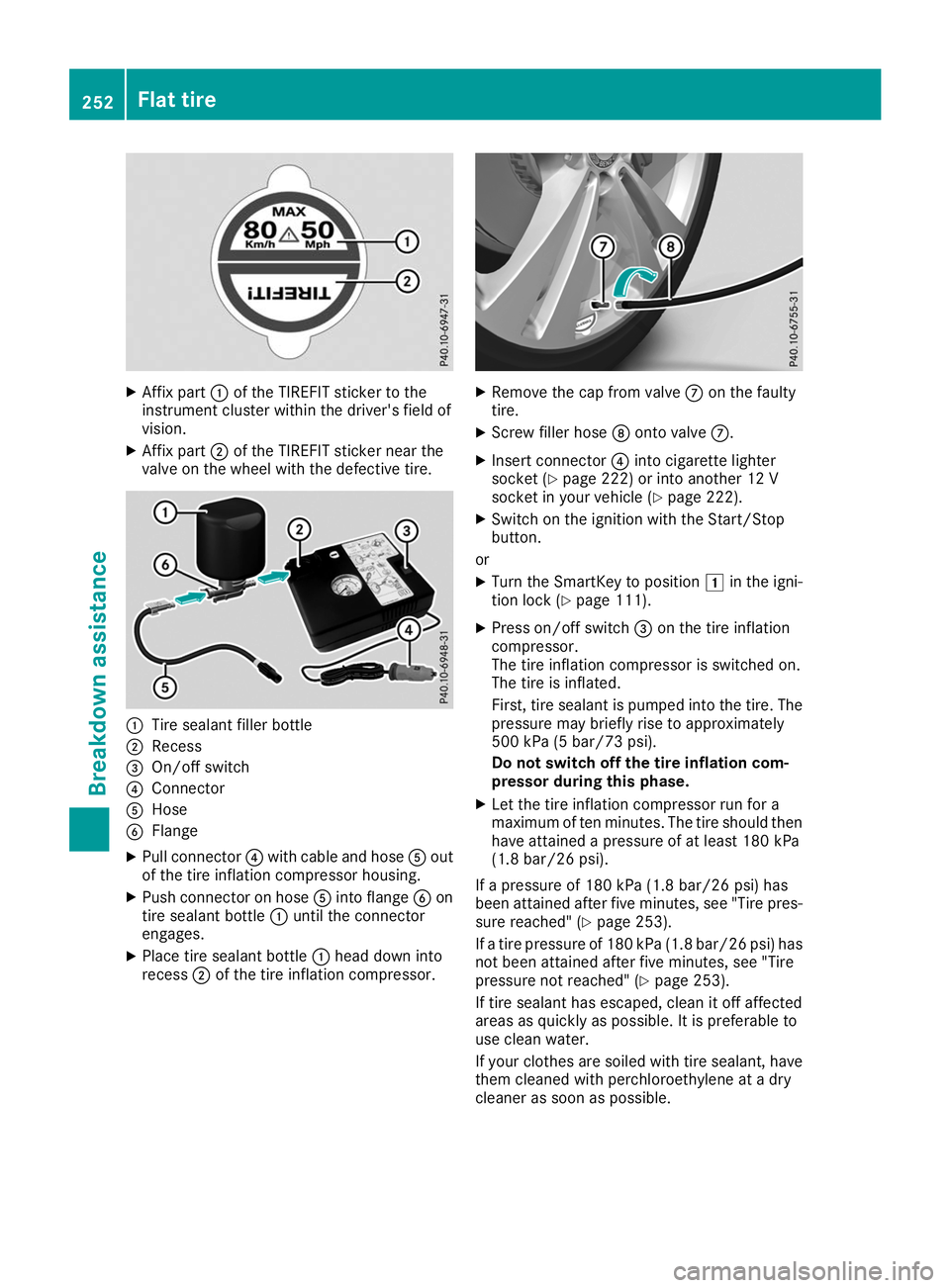

X

Affix part 0043of the TIREFIT sticker to the

instrument cluster within the driver's field of

vision.

X Affix part 0044of the TIREFIT sticker near the

valve on the wheel with the defective tire. 0043

Tire sealant filler bottle

0044 Recess

0087 On/off switch

0085 Connector

0083 Hose

0084 Flange

X Pull connector 0085with cable and hose 0083out

of the tire inflation compressor housing.

X Push connector on hose 0083into flange 0084on

tire sealant bottle 0043until the connector

engages.

X Place tire sealant bottle 0043head down into

recess 0044of the tire inflation compressor. X

Remove the cap from valve 006Bon the faulty

tire.

X Screw filler hose 006Conto valve 006B.

X Insert connector 0085into cigarette lighter

socket (Y page 222) or into another 12 V

socket in your vehicle (Y page 222).

X Switch on the ignition with the Start/Stop

button.

or X Turn the SmartKey to position 0047in the igni-

tion lock (Y page 111).

X Press on/off switch 0087on the tire inflation

compressor.

The tire inflation compressor is switched on.

The tire is inflated.

First, tire sealant is pumped into the tire. The

pressure may briefly rise to approximately

500 kPa (5 bar/73 psi).

Do not switch off the tire inflation com-

pressor during this phase.

X Let the tire inflation compressor run for a

maximum of ten minutes. The tire should then have attained a pressure of at least 180 kPa

(1.8 bar/26 psi).

If a pressure of 180 kPa (1.8 ba r/26 psi) has

been at tained after five minutes, see "Tire pres-

sure reached" (Y page 253).

If a tire pressure of 180 kPa (1.8 bar/26 psi) has not been attained after five minutes, see "Tire

pressure not reached" (Y page 253).

If tire sealant has escaped, clean it off affected

areas as quickly as possible. It is preferable to

use clean water.

If your clothes are soiled with tire sealant, have them cleaned with perchloroethylene at a dry

cleaner as soon as possible. 252

Flat tireBreakdown assistance

Page 255 of 298

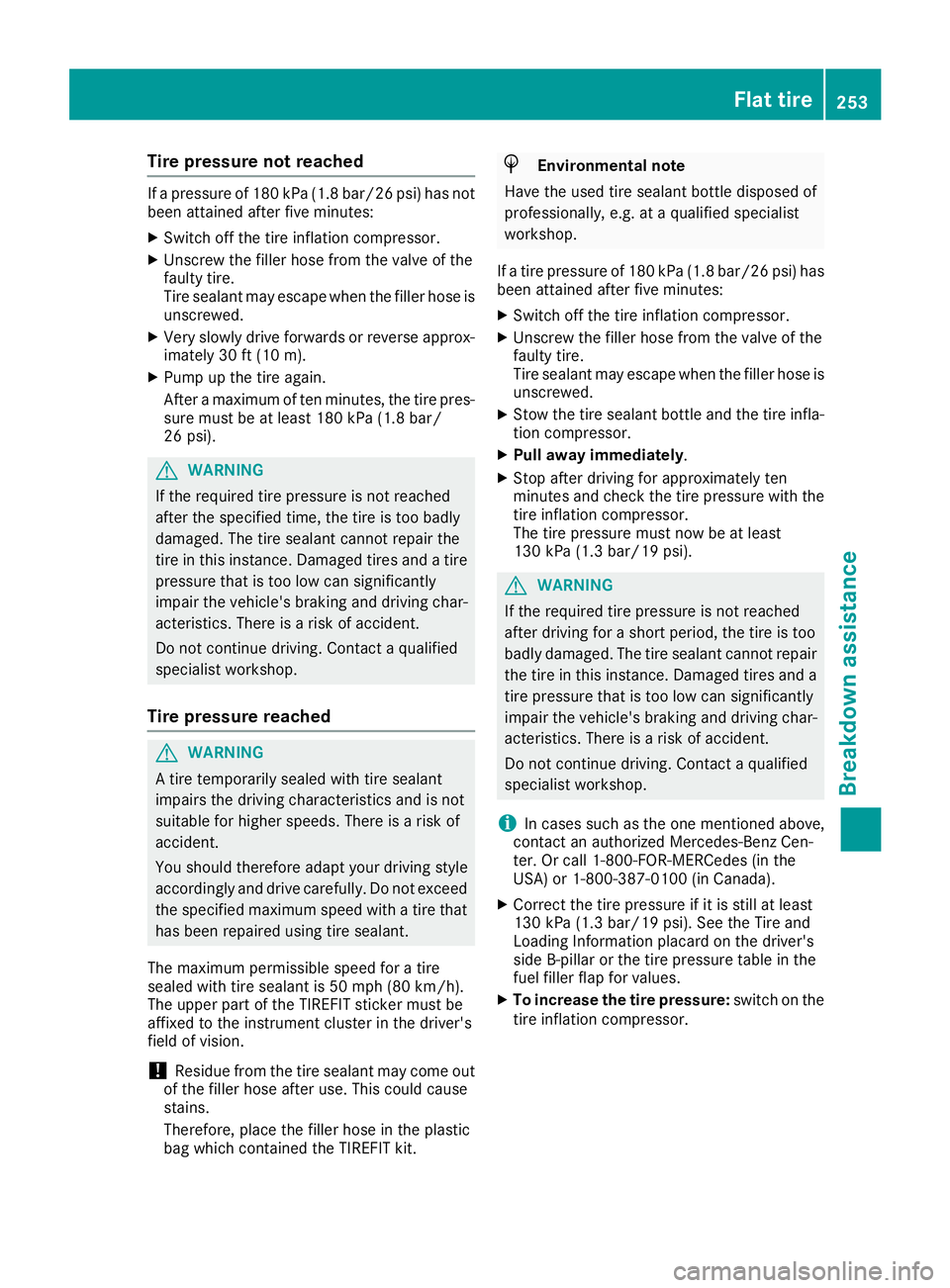

Tire pressure not reached

If a pressure of 180 kPa (1.8 bar/26 psi) has not

been attained after five minutes:

X Switch off the tire inflation compressor.

X Unscrew the filler hose from the valve of the

faulty tire.

Tire sealant may escape when the filler hose is

unscrewed.

X Very slowly drive forwards or reverse approx-

imately 30 ft (10 m).

X Pump up the tire again.

After a maximum of ten minutes, the tire pres- sure must be at least 180 kPa (1.8 ba r/

26 psi). G

WA

RNING

If the required tire pressure is not reached

after the specified time, the tire is too badly

damaged. The tire sealant cannot repair the

tire in this instance. Damaged tires and a tire pressure that is too low can significantly

impair the vehicle's braking and driving char-

acteristics. There is a risk of accident.

Do not continue driving. Contact a qualified

specialist workshop.

Tire pressure reached G

WARNING

A tire temporarily sealed with tire sealant

impairs the driving characteristics and is not

suitable for higher speeds. There is a risk of

accident.

You should therefore adapt your driving style

accordingly and drive carefully. Do not exceed the specified maximum speed with a tire that

has been repaired using tire sealant.

The maximum permissible speed for a tire

sealed with tire sealant is 50 mph (80 km/h).

The upper part of the TIREFIT sticker must be

affixed to the instrument cluster in the driver's

field of vision.

! Residue from the tire sealant may come out

of the filler hose after use. This could cause

stains.

Therefore, place the filler hose in the plastic

bag which contained the TIREFIT kit. H

Environmental note

Have the used tire sealant bottle disposed of

professionally, e.g. at a qualified specialist

workshop.

If a tire pressure of 180 kPa (1.8 ba r/26 psi) has

been attained after five minutes:

X Switch off the tire inflation compressor.

X Unscrew the filler hose from the valve of the

faulty tire.

Tire sealant may escape when the filler hose is unscrewed.

X Stow the tire sealant bottle and the tire infla-

tion compressor.

X Pull away immediately.

X Stop after driving for approximately ten

minutes and check the tire pressure with the

tire inflation compressor.

The tire pressure must now be at least

130 kPa (1.3 bar/19 psi). G

WARNING

If the required tire pressure is not reached

after driving for a short period, the tire is too

badly damaged. The tire sealant cannot repair the tire in this instance. Damaged tires and a

tire pressure that is too low can significantly

impair the vehicle's braking and driving char-

acteristics. There is a risk of accident.

Do not continue driving. Contact a qualified

specialist workshop.

i In cases such as the one mentioned above,

contact an authorized Mercedes-Benz Cen-

ter. Or call 1-800-FOR-MERCedes (in the

USA) or 1-800-387-0100 (in Canada).

X Correct the tire pressure if it is still at least

130 kPa (1.3 bar/19 psi). See the Tire and

Loading Information placard on the driver's

side B-pillar or the tire pressure table in the

fuel filler flap for values.

X To increase the tire pressure: switch on the

tire inflation compressor. Flat tire

253Breakdown assistance Z

Page 256 of 298

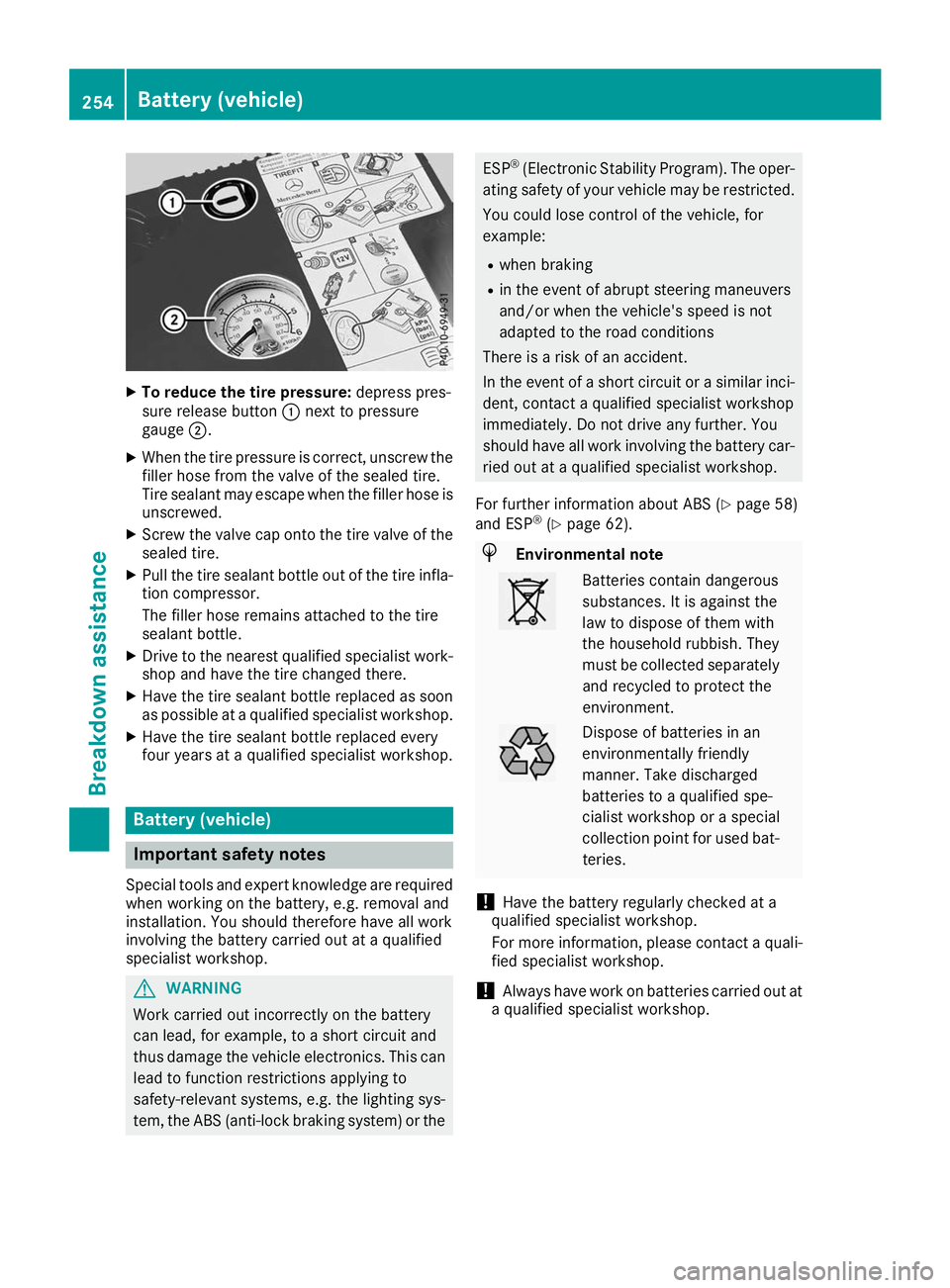

X

To reduce the tire pressure: depress pres-

sure release button 0043next to pressure

gauge 0044.

X When the tire pressure is correct, unscrew the

filler hose from the valve of the sealed tire.

Tire sealant may escape when the filler hose is unscrewed.

X Screw the valve cap onto the tire valve of the

sealed tire.

X Pull the tire sealant bottle out of the tire infla-

tion compressor.

The filler hose remains attached to the tire

sealant bottle.

X Drive to the nearest qualified specialist work-

shop and have the tire changed there.

X Have the tire sealant bottle replaced as soon

as possible at a qualified specialist workshop.

X Have the tire sealant bottle replaced every

four years at a qualified specialist workshop. Battery (vehicle)

Important safety notes

Special tools and expert knowledge are required

when working on the battery, e.g. removal and

installation. You should therefore have all work

involving the battery carried out at a qualified

specialist workshop. G

WARNING

Work carried out incorrectly on the battery

can lead, for example, to a short circuit and

thus damage the vehicle electronics. This can lead to function restrictions applying to

safety-relevant systems, e.g. the lighting sys- tem, the ABS (anti-lock braking system) or the ESP

®

(Electronic Stability Program). The oper-

ating safety of your vehicle may be restricted.

You could lose control of the vehicle, for

example:

R when braking

R in the event of abrupt steering maneuvers

and/or when the vehicle's speed is not

adapted to the road conditions

There is a risk of an accident.

In the event of a short circuit or a similar inci-

dent, contact a qualified specialist workshop

immediately. Do not drive any further. You

should have all work involving the battery car- ried out at a qualified specialist workshop.

For further information about ABS (Y page 58)

and ESP ®

(Y page 62). H

Environmental note Batteries contain dangerous

substances. It is against the

law to dispose of them with

the household rubbish. They

must be collected separately

and recycled to protect the

environment. Dispose of batteries in an

environmentally friendly

manner. Take discharged

batteries to a qualified spe-

cialist workshop or a special

collection point for used bat-

teries.

! Have the battery regularly checked at a

qualified specialist workshop.

For more information, please contact a quali- fied specialist workshop.

! Always have work on batteries carried out at

a qualified specialist workshop. 254

Battery (vehicle)Breakdo

wn assis tance

Page 257 of 298

Should it, in exceptional circumstances, be

absolutely necessary to disconnect the 12-

volt battery yourself, please observe the fol-

lowing:

R Secure the vehicle to prevent it from rolling

away.

R Switch off the ignition.

R Disconnect the negative terminal first and

then the positive terminal.

The transmission is locked in position 005D

after disconnecting the battery.

After the work has been done, install the bat-

tery and replace the cover of the positive ter- minal clamp firmly.

Comply with safety precautions and take pro-

tective measures when handling batteries. Risk of explosion.

Fire, open flames and smoking are

prohibited when handling the bat-

tery. Avoid creating sparks.

The electrolyte of the battery is cor-

rosive. Avoid contact with skin, eyes

or clothing.

Wear suitable protective clothing,

especially gloves, apron and face-

guard.

Immediately rinse electrolyte

splashes off with clean water. Con-

tact a physician if necessary. Wear eye protection.

Keep children away.

Observe this Operator's Manual.

For safety reasons, Mercedes-Benz recom-

mends that you only use batteries which have

been tested and approved for your vehicle by

Mercedes-Benz. These batteries provide

increased impact protection to prevent vehicle

occupants from suffering acid burns should the battery be damaged in the event of an accident. In order for the battery to achieve the maximum

possible service life, it must always be suffi-

ciently charged.

Like other batteries, the vehicle battery may

discharge over time if you do not use the vehicle.In this case, have the battery disconnected at a

qualified specialist workshop. You can also

charge the battery with a special charger rec-

ommended by Mercedes-Benz. Contact a quali- fied specialist workshop for further information.

Have the battery condition of charge checked

more frequently if you use the vehicle mainly for

short trips or if you leave it standing idle for a

lengthy period. Consult a qualified specialist

workshop if you wish to leave your vehicle

parked for a long period of time.

When you use the SmartKey in the ignition and

you park the car, remove the SmartKey if you do not require any electrical consumers. The vehi-

cle will then use very little energy, thus conserv-

ing battery power.

If the power supply has been interrupted, e.g. if

you reconnect the battery, you will have to:

R reset the function for automatically folding

the exterior mirrors in/out by folding the mir-

rors out once (Y page 92)

R reset the side windows, see (Y page 78) Charging the battery

! Only use battery chargers with a maximum

charging voltage of 14.4 V.

! Only

charge the battery using the jump-

starting connection point.

The jump-starting connection point is in the

engine compartment (Y page 256).

X Open the hood.

X Connect the battery charger to the positive

terminal and ground point in the same order

as when connecting the donor battery in the

jump-starting procedure (Y page 256).

Keep away from fire and open flames. Do not

lean over a battery. Never charge the battery if it is still installed in the vehicle, unless you use a

battery charger which has been tested and

approved by Mercedes-Benz. A battery charger

unit specially adapted for Mercedes-Benz vehi-

cles and tested and approved by Mercedes-

Benz is available as an accessory. It permits the

charging of the battery in its installed position.

Contact an authorized Mercedes-Benz Center Battery (vehicle)

255Breakdown assistance Z

Page 258 of 298

for further information and availability. Read the

battery charger's operating instructions before

charging the battery.

Do not charge a battery which has been

removed at low temperatures with a battery

charger. Allow the battery to warm up gently

first, if necessary. Otherwise, the service life can be shortened and the starting characteristics

impaired, especially at low temperatures. Replacing the 12 V battery

Observe the notes on the 12 V battery

(Y page 254).

Mercedes-Benz recommends that you have the

12 V battery replaced at a qualified specialist

workshop, e.g. at an authorized Mercedes-Benz

Center.

If you want to replace the battery yourself,

observe the following notes:

R Always replace a defective battery with a bat-

tery which meets the specific requirements of

the vehicle. The vehicle is equipped with an AGM (Absorb-

ent Glass Mat) technology battery or a lith-

ium-ion battery. Full vehicle functionality is

only guaranteed with an AGM or lithium-ion

battery. For safety reasons, Mercedes-Benz

recommends that you only use batteries

which have been tested and approved for yourvehicle by Mercedes-Benz.

R Use detachable parts such as breather hoses,

angled connecting pieces or terminal covers

from the battery which is to be replaced.

R Make sure that the vent hose is always con-

nected to the original opening on the battery

side.

Install any existing or supplied stop plugs.

Otherwise, gases or battery acid could

escape.

R Make sure that the detachable parts are con-

nected again in the same way. Jump-starting

X For the jump-starting procedure, use only the jump-starting connection point in the engine com-

partment, consisting of a positive terminal and a ground point.

! Avoid repeated and lengthy starting attempts. Otherwise, the catalytic converter could be

damaged by the non-combusted fuel.

X Do not start the vehicle using a rapid charging device.

If your vehicle's battery is discharged, the engine can be jump-started from another vehicle or

from a donor battery using jumper cables.

The battery is not accessible in all vehicles. If the other vehicle's battery is not accessible, jump-start the vehicle using a donor battery or a jump-starting device.

Observe the following during the jump-starting procedure:

R the jumper cables must not come into contact with parts that can move when the engine is

running, such as the V-belt pulley or the fan.

R non-insulated parts of the terminal clamps must not come into contact with other metal parts

while the jumper cables are connected to the battery and the jump-starting connection point.

R only use jumper cables that are not damaged and have a sufficient cross-section and insulated

terminal clamps.

R jump-starting may be performed only using batteries with a nominal voltage of 12 V.

R you may only jump-start the vehicle when the engine and exhaust system are cold.

R the vehicles must not touch each other.

R If the battery is fully discharged, leave the battery that is being used to jump-start connected for

a few minutes before attempting to start. This charges the battery slightly. 256

Jump-startingBreakdown assistance

Page 259 of 298

X

Secure the vehicle by applying the electric parking brake.

X Shift the transmission to position 005D.

X Make sure the ignition and all electrical consumers are switched off.

All indicator lamps in the instrument cluster must be off. When using the SmartKey, turn the

SmartKey to position 0092in the ignition lock and remove it (Y page 111).

X Open the hood.

i Right-hand-drive vehicle:

the jump-starting connection points may be located on the other

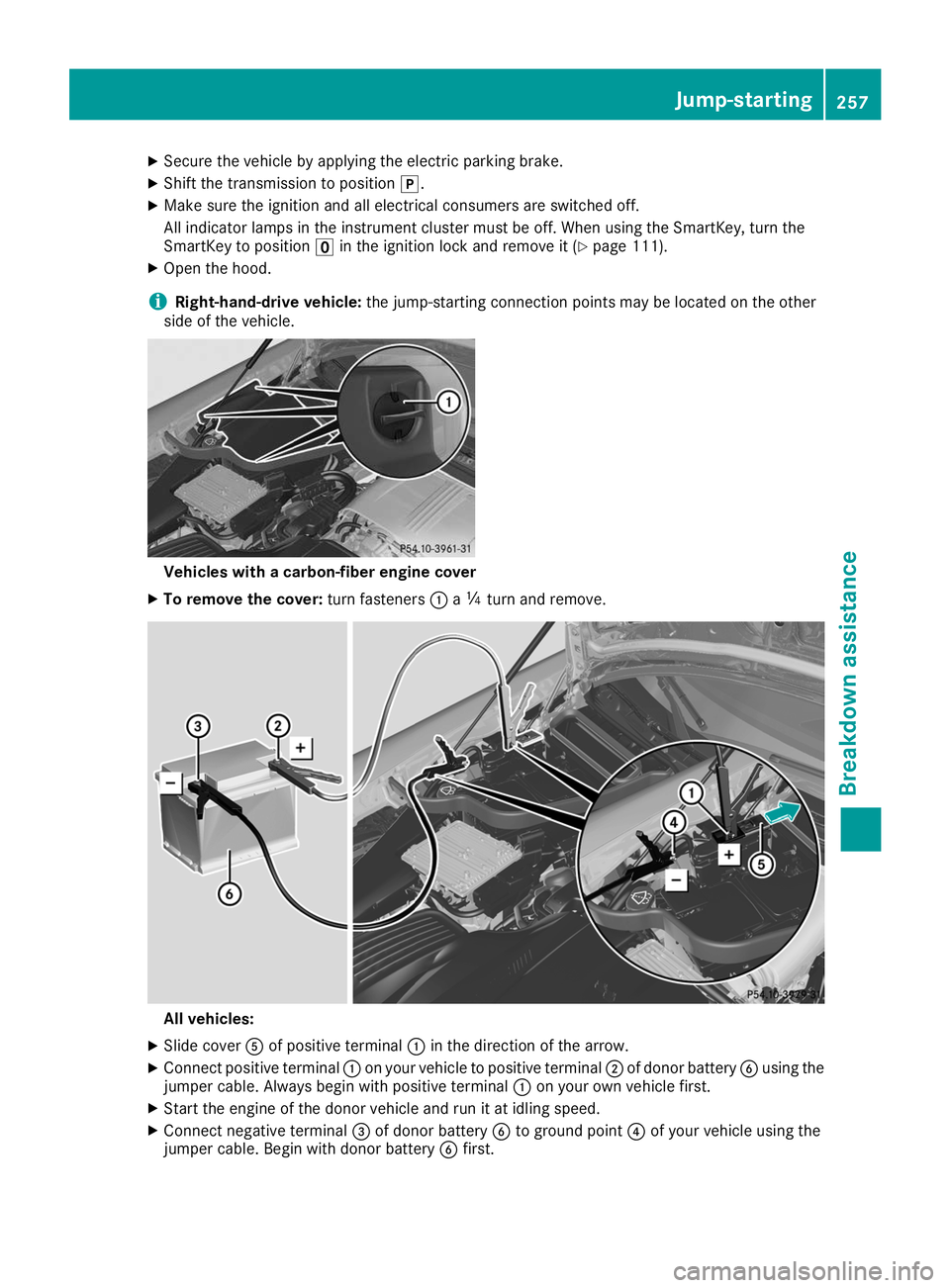

side of the vehicle. Vehicles with a carbon-fiber engine cover

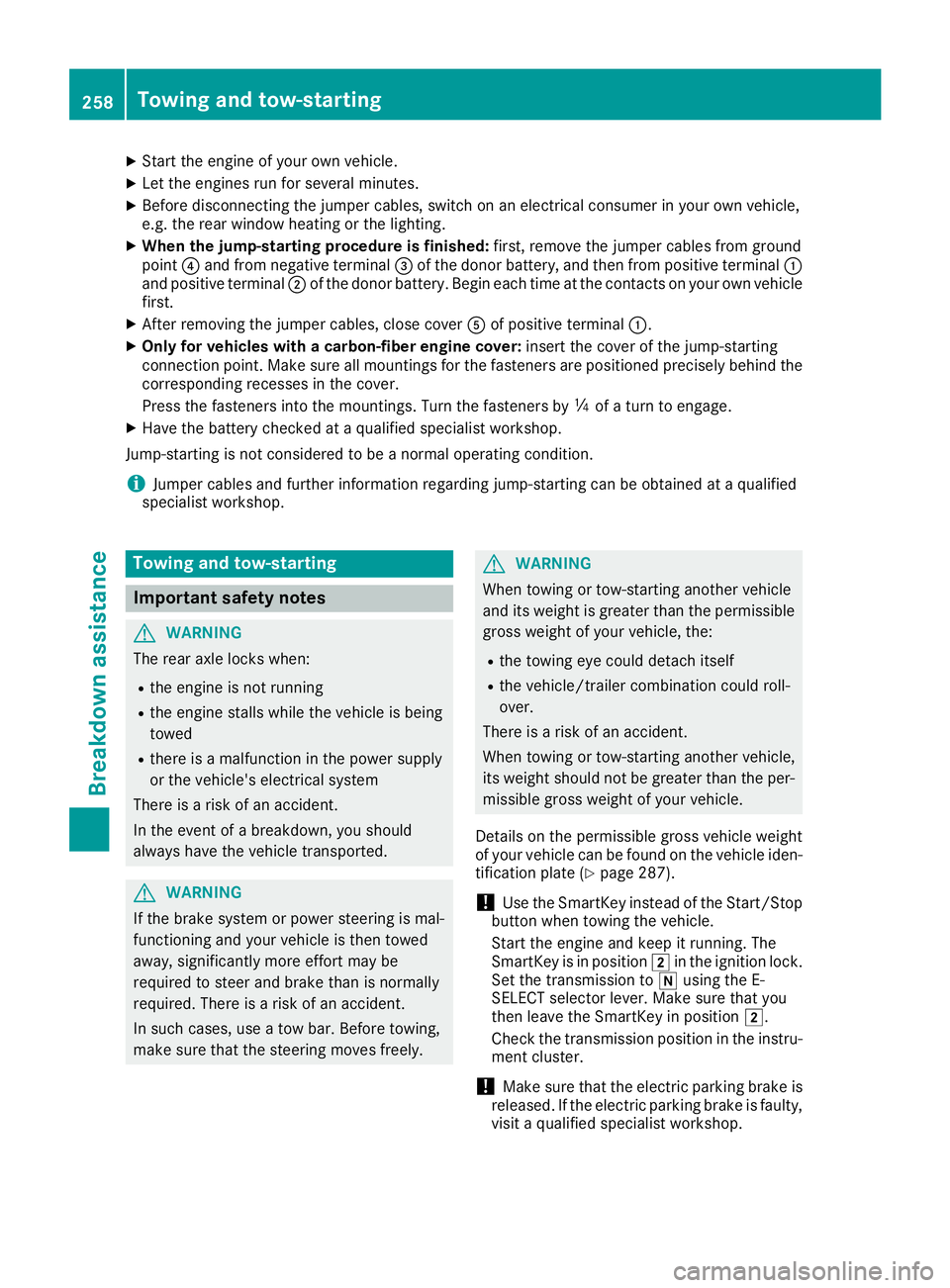

X To remove the cover: turn fasteners0043a00C4 turn and remove. All vehicles:

X Slide cover 0083of positive terminal 0043in the direction of the arrow.

X Connect positive terminal 0043on your vehicle to positive terminal 0044of donor battery 0084using the

jumper cable. Always begin with positive terminal 0043on your own vehicle first.

X Start the engine of the donor vehicle and run it at idling speed.

X Connect negative terminal 0087of donor battery 0084to ground point 0085of your vehicle using the

jumper cable. Begin with donor battery 0084first. Jump-starting

257Breakdown assistance Z

Page 260 of 298

X

Start the engine of your own vehicle.

X Let the engines run for several minutes.

X Before disconnecting the jumper cables, switch on an electrical consumer in your own vehicle,

e.g. the rear window heating or the lighting.

X When the jump-starting procedure is finished: first, remove the jumper cables from ground

point 0085and from negative terminal 0087of the donor battery, and then from positive terminal 0043

and positive terminal 0044of the donor battery. Begin each time at the contacts on your own vehicle

first.

X After removing the jumper cables, close cover 0083of positive terminal 0043.

X Only for vehicles with a carbon-fiber engine cover: insert the cover of the jump-starting

connection point. Make sure all mountings for the fasteners are positioned precisely behind the corresponding recesses in the cover.

Press the fasteners into the mountings. Turn the fasteners by 00C4of a turn to engage.

X Have the battery checked at a qualified specialist workshop.

Jump-starting is not considered to be a normal operating condition.

i Jumper cables and further information regarding jump-starting can be obtained at a qualified

specialist workshop. Towing and tow-starting

Important safety notes

G

WARNING

The rear axle locks when:

R the engine is not running

R the engine stalls while the vehicle is being

towed

R there is a malfunction in the power supply

or the vehicle's electrical system

There is a risk of an accident.

In the event of a breakdown, you should

always have the vehicle transported. G

WARNING

If the brake system or power steering is mal-

functioning and your vehicle is then towed

away, significantly more effort may be

required to steer and brake than is normally

required. There is a risk of an accident.

In such cases, use a tow bar. Before towing,

make sure that the steering moves freely. G

WARNING

When towing or tow-starting another vehicle

and its weight is greater than the permissible gross weight of your vehicle, the:

R the towing eye could detach itself

R the vehicle/trailer combination could roll-

over.

There is a risk of an accident.

When towing or tow-starting another vehicle,

its weight should not be greater than the per- missible gross weight of your vehicle.

Details on the permissible gross vehicle weight

of your vehicle can be found on the vehicle iden-

tification plate (Y page 287).

! Use the SmartKey instead of the Start/Stop

button when towing the vehicle.

Start the engine and keep it running. The

SmartKey is in position 0048in the ignition lock.

Set the transmission to 005Cusing the E-

SELECT selector lever. Make sure that you

then leave the SmartKey in position 0048.

Check the transmission position in the instru-

ment cluster.

! Make sure that the electric parking brake is

released. If the electric parking brake is faulty,

visit a qualified specialist workshop. 258

Towing and tow-startingBreakdown assistance