trunk MERCEDES-BENZ C-CLASS 1999 Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1999, Model line: C-CLASS, Model: MERCEDES-BENZ C-CLASS 1999Pages: 122, PDF Size: 1.66 MB

Page 84 of 122

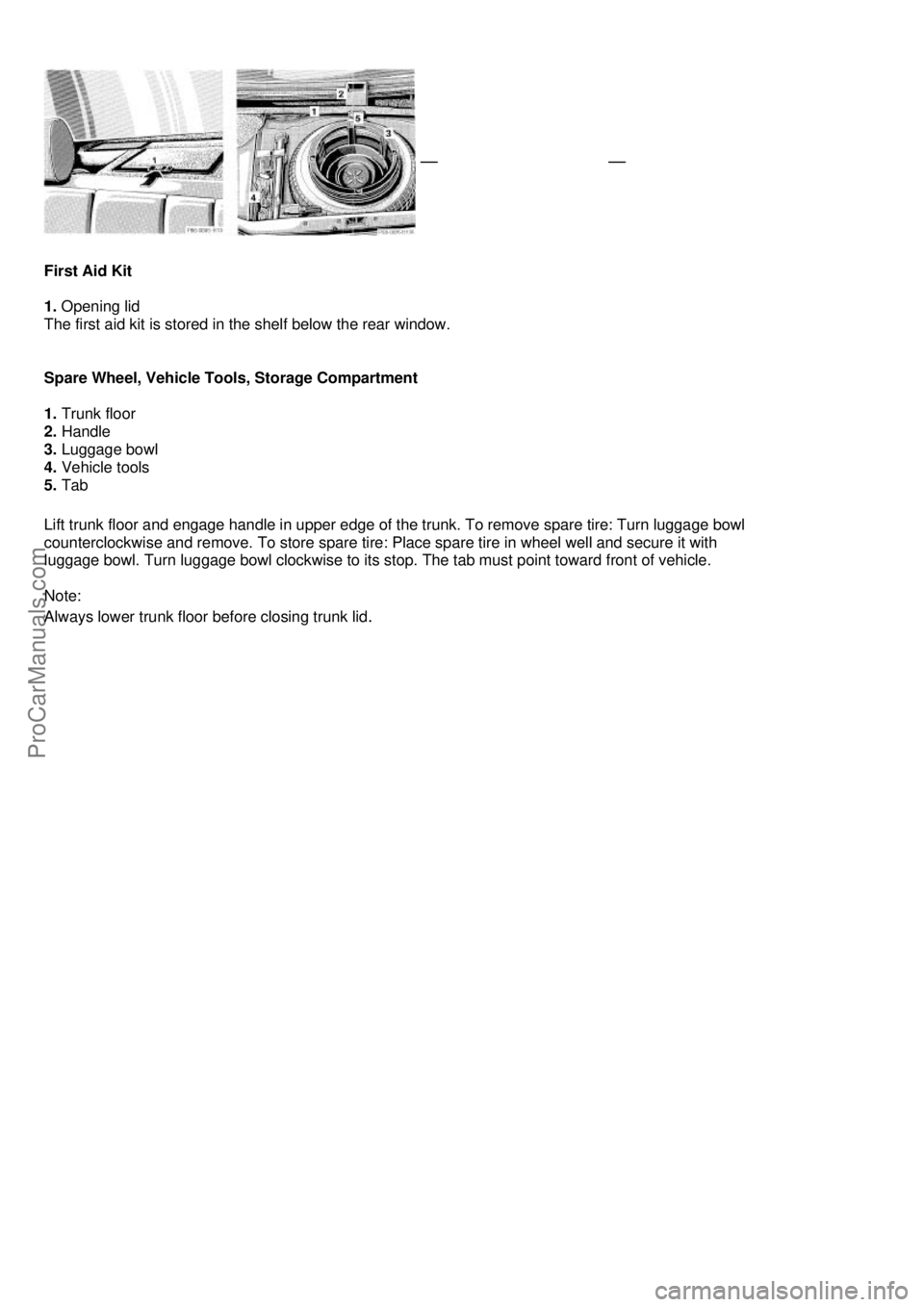

First Aid Kit

1. Opening lid

The first aid kit is stored in the shelf below the rear window.

Spare Wheel, Vehicle Tools, Storage Compartment

1. Trunk floor

2. Handle

3. Luggage bowl

4. Vehicle tools

5. Tab

Lift trunk floor and engage handle in upper edge of the trunk. To remove spare tire: Turn luggage bowl

counterclockwise and remove. To store spare tire: Place spare tire in wheel well and secure it with

luggage bowl. Turn luggage bowl clockwise to its stop . The tab must point toward front of vehicle.

Note:

Always lower trunk floor before closing trunk lid

.

ProCarManuals.com

Page 92 of 122

Adjusting Headlamp Aim

(Halogen)

Correct headlamp adjustment is extremely important. To check and readjust a headlamp do the following:

• Horizontal aim will change and must be corrected as descri bed below, whenever a vertical adjustment is made.

• Low beam adjustments simultaneously aim the high beam and fog lamp.

• Vehicle should have a normal trunk load.

1 . Park vehicle on level surface approximately 6 inches (152 mm ) from a vertical test screen or wall. The centerline

of

the vehicle must be at a 90° angle to the test screen.

2 . Using a "T" square and a carpenter's level, align and ma rk avertical centerline (8) on the test screen using the

outer

reference point (low centerlines should be 47 1/4 inches (1198 mm).

3 . Move vehicle on the level surface 25 feet (7.6 m) straight back from the wall.

4 . Open hood, depress latch (1), and remove access cover (2) from the headlamp.

5 . Vertical headlamp aim (low beams on): Turn adjusting screw (3) (counterclockwise to adjust headlamp downward,

clockwise upward) until bubble in the level (4) is centered on the "0" mark. Graduations: 0.18° pitch.

6 . Horizontal headlamp aim (low beams on):

Turn adjusting screw (5) (Right fr ont headlamp: counterclockwise to adjust to the left, clockwise to the right; left

front headlamp: counterclockwise to adjust to the right, clockwise to the left.) until the headlamps (low beam)

illuminate the test screen as shown. The vertex of the angle formed in each beam image should align with the

vertical centerline (8) of each lamp. The left and right headlamps must be adjusted individually.

7 . The indicator (6) in the sight glass should align with the "0" mark after any horizontal adjustment. If it does not,

slide the "0" mark on the scale (7) until it a ligns with the indicator (6). Graduations: 0.38° pitch.

8 . Reinstall access cover(2).

ProCarManuals.com

Page 93 of 122

Adjusting Headlamp Aim

(Xenon)

Correct headlamp adjustment is extremely important. To ch eck and readjust a headlamp, follow steps 1 through 5.

Please note:

• Low beam adjustments simultaneously aim the high beam.

• Vehicle should have a normal trunk load.

• Vertical aim adjustments change horizontal aim.

1 . Park vehicle on level surface approximately 25 feet (7.6 m) from a vertical test screen or wall. The centerline of the

vehicle must be at a 90° angle to the test screen.

2 . (low beams on) Using a "T" square and a carpenter's leve l, align and mark a vertical centerline (8) on the test

screen using the vertex of the angle formed in each beam image. As a check, the distance between centerlines

should be 47

1/4inches(1198mm).

3 . Mark a horizontal centerline (9) at a height of 221/2 inches (570 mm) on the test screen. It must be at a 90° angle

to the vertical centerline.

4 . Open hood.

5 . Vertical headlamp aim (low beams on):

Turn adjusting screws (1 and 2) equally in direct ion and turns (counterclockwise to adjust headlamp downward,

clockwise upward) until the headlamps (low beam) illuminate the test screen as shown. The left and right

headlamps

must be adjusted individually.

Note:

If it is not possible to obtain a proper headlamp ad justment, have the system checked at your authorized

Mercedes-Benz dealer.

ProCarManuals.com

Page 94 of 122

Taillamp Assemblies

1. Stop lamp (21 W/32 cp bulb)

2. Turn signal lamp (21 W/32 cp bulb)

3. Backup lamp (21 W/32 cp bulb)

4. Tail, parking, side marker and standing lamp (5 W/4 cp bulb)

5. Passenger side: Tail and parking lamp (21/4W bulb) Driver 's side: Tail, parking and rear fog lamp (21/4 bulb)

To replace bulbs:

From inside trunk, open locks and swing open lamp cover. Turn locking lever on lamp to horizontal

position and remove bulb carrier. Push down on bulb to be changed, twist counterclockwise and remove.

ProCarManuals.com

Page 95 of 122

Battery

Warning !

Failure to follow these instructions can result in severe injury or death. Never lean over batteries while

connecting, you might get injured. Battery fluid contains sulfuric acid. Do not allow this fluid to come in

contact with eyes, skin or clothing. In case it does, immediately flush affected area with water and seek

medical help if necessary. A battery will also produ ce hydrogen gas, which is flammable and explosive.

Keep flames or sparks away from battery, avoid im proper connection of jumper cables, smoking etc..

Important !

Battery maintenance information:

The battery is located in the trunk under the trunk floor. The fluid level must be checked at every A and B service.

Always insure that the fluid level is at the specified maximum level and that only distilled water is used. Failure to

maintain proper fluid level may result in cell deterioration and possible battery rupture. The service life of the battery is

dependent on its condition of charge. The battery should alwa ys be kept sufficiently charged, in order to last an

optimum length of time.

Therefore, we strongly recommend that you have the battery charge checked frequently, and corrected if

necessary, especially if you use the vehicle less than approximately 200 miles (300 km) per month, mostly for

short distance trips, or if it is not used for long periods of time.

Only charge a battery with a battery charger after the battery has been disconnected from the vehicle electrical circuit.

Always disconnect the battery negative lead first and connect last. When removing and connecting the battery,

always make sure that all electrical consumers are off and the electronic key is in steering lock position 0. The battery

and its vent tube must always be securely installed when the car is in operation. While the engine is running the

battery terminal clamps must not be loosened or detached, otherwise the generator and other electronic components

would be damaged.

Note:

After reconnecting the battery al so resynchronize the Express feature of the power windows

(see Power Windows in Index).

Battery Recycling

Batteries contain materials that can harm the environment with improper disposal. Large 12 Volt storage batteries

contain lead. Recycling of batteries is the preferred method of disposal. Many states require sellers of batteries to

accept old batteries for recycling.

ProCarManuals.com

Page 96 of 122

Fuses

1. Main fuse box in engine compartment

2. Auxiliary fuse box in trunk

3. Auxiliary fuse in trunk

4. Auxiliary fuse in engine compartment

Before replacing a blown fuse, determine the cause of the short circuit. Spare fuses are supplied inside the

main fuse box. Observe amperage and color of fuse. To gai n access to the main fuse box, release clamp (1),

lift the fuse box cover up and remove it. A special fuse puller comes with the vehicle tools. Always use a

new fuse for replacement. Never attempt to repair or bridge a blown fuse. After replacing a blown fuse, close

fuse box cover. To close the main fuse box, engag e cover at the rear and secure with clamp.

ProCarManuals.com

Page 97 of 122

Jump Starting

Warning !

Failure to follow these directions will cause damage to the electronic components, and can lead to a battery

explosion and severe injury or death. Never lean over batteries while connecting or jump starting, you might

get injured. Battery fluid contains sulfuric acid. Do not allow this fluid to come in contact with eyes, skin or

clothing. In case it does, immediately flush affected ar ea with water, and seek medical help if necessary.

A battery will also produce hydrogen gas, which is flammable and very explosive. Keep flames or sparks

away from battery, avoid improper connection of jumper cables, smoking etc.. Read all instructions before

proceeding.

If the battery is discharged, the engine should be started with jumper cables and the (12 V) battery of another vehicle.

The battery is located in the trunk under the trunk floor.

Proceed as follows:

1 . Position the vehicle with the charged battery so that the jumper cables will reach, but never

let the vehicles touch. Make sure the jump er cables do not have loose or missing insulation.

2. On both vehicles:

• Turn off engine and all lights and acce ssories, except hazard warning flashers or

work lights.

• Apply parking brake and shift selector lever to position "P".

Important !

3. Clamp one end of the first jumper cable to the positive (+) terminal of the discharged

battery and the other end to the positive (+ ) terminal of the charged battery. Make sure

the cable clamps do not touch any other metal parts.

4. Clamp one end of the second jumper cable to the grounded negative (-) terminal of the

charged battery and the final connection to the negative (-) terminal of the discharged battery.

Important !

5. Start engine of the vehicle with the charged battery and run at high idle. Make sure the

cables are not on or near pulleys, fans, or other parts that will move when the engine is

started. Allow the discharged battery to charge for a few minutes. Start engine of the

disabled vehicle in the usual manner.

6. After the engine has started, remove jumper cables exactly reversing the above

installation sequence, starting with the last connection made first. When removing each

clamp, make sure that it does not touch any other metal while the other end is still attached.

Important !

A discharged battery can freeze at approx. +14°F (-10°C ). In that case, it must be thawed out before

jumper cables are used. A frozen battery can explode and cause personal injury.

Jumper cable specifications:

• Minimum cable cross-section of 25 mm

2 or approx. 2 AWG

• Maximum length of 11.5 ft. (3.5 m).

ProCarManuals.com

Page 106 of 122

Manual Release of Fuel Filler Flap

The manual release knob is located behind the right side trunk panel and felt pad.

In case the central locking system does not release the fuel filler flap, pull the manual

release knob while simultaneously opening the fuel filler flap.

Roof Rack

Use only those roof racks appr oved by Mercedes-Benz to avoid damage to the vehicle.

Follow manufacturer's installation instructions.

Mount supports only between markings on border of roof which

are visible when doors are opened.

ProCarManuals.com

Page 110 of 122

Technical Data C 230

Model C 230 (202 023)1 Rims - Tires

Engine 111 Rims (light alloy rims) 7J x 15 H 2

Mode of operation 4-stroke engine,

gasoline injection

Wheel offset 1.46 in (37 mm)

No. of cylinders

4 All season;Radial-ply tires 205/60 R 15 91 H

Bore 3.58 in (90.90 mm) Winter tires;Radial-ply tires 205/60 R 15 91 T M+S

Stroke 3.48 in (88.40 mm) Model C 230- Canada only

Total piston displacement 140.1 cu.in. (2295 cm3) Rims (steel rims) 61/2J x 15 H 2

Compression ratio 10,4:1 Wheel offset 1.46 in (37 mm)

Output acc. to SAE J 1349 148 hp/5500 rpm

(110 kW/5500 rpm)

All season;Radial-ply tires 195/65 R 15 91 H

Maximum torque acc. to SAE

J 1349

162 ft.lb./4000 rpm

(220 Nm/40OOrpm)

Winter tires;Radial-ply tires

195/65 R 15 91 T M+S

Maximum engine speed 6000 rpm Electrical System

Firing order 1-3-4-2 Generator (alternator) 14 V/90 A

Poly-V-belt 2155 mm Starter motor 12 V/1.4KW

Main Dimensions Battery 12 V/100 Ah

Overall vehicle length 177.4 in (4507 mm) Spark plugs Bosch F 9 DCO

Overall vehicle width 67.7 in (1720mm) Beru 14 F-9 DUO

Overall height 56.1 in (1424 mm)

Champion C 12 YCC

Wheel base 105.9 in (2690 mm) Electrode gap 0.032 in (0,8 mm)

Track, front 59.0 in (1499 mm) Tightening torque 15-22ft.lb. (20-30 Mm)

Track, rear 57.6 in (1464mm)

Weights See certification tag

Roof load max. 220 lb(100 kg)

Trunk load max 220 lb(100 kg)

1 The quoted data apply only to the standard vehicle. See an authorized Mercedes-Benz

dealer for the correspon-ding data of ali special bodies and special equipment,

ProCarManuals.com

Page 111 of 122

Technical Data C 280

Model C 280 (202 029)1 Rims - Tires

Engine 112 Rims (light

alloy rims)

7J x 15 H 2

Mode of operation 4-stroke engine,

gasoline injection

Wheel

offset

1.46 in (37 mm)

No. of cylinders 6

Summer

tires;

Radial-ply

tires

205/60R 15 91 H

Bore 3.54 in (89.90 mm)

Winter

tires;

Radial-ply

tires

205/60 R 15 91 T M+S

Stroke 2.89 in (73.50 mm)

Rims and All season Tires ( Sport Package)

Rims (light alloy rims) 7J x 16 H 2

Wheel offset 1.46 in (37 mm)

Summer tires;

Radial-ply tires

205/55 R 16 91 H

Electrical System

Total piston displacement 170.8 cu.in. (2799 cm3) Generator

(alternator) 14 V/90 A

Compression ratio 10:1

Starter

motor

12 V/1.7KW

Output acc. to SAE J

1349

195 hp/5800 rpm

(145 kW/5800 rpm)

Battery 12 V/100 Ah

Maximum torque acc.

to SAE J 1349

195 ft.lb./3000 rpm

(265 Nm/3000rpm)

Spark

plugs

Electrode

gap

Tightening

torque

Bosch F 9 DPER

0.032 in (0,8 mm)

15-22ft.lb. (20-30 Mm)

Maximum engine speed 6000 rpm Main Dimensions

Firing order 1-4-3-6-2-5 Overall

vehicle

length

177.4 in (4507 mm)

Poly-V-belt 2390 mm

Overall

vehicle

width

67.7 in (1720mm)

Weights: See certification tag

Overall

height

56.1 in (1424 mm)

Roof load max. 220 lb(100 kg) Wheel

base

105.9 in (2690 mm)

Trunk load max. 220 lb(100 kg) Track,

front

59.0 in (1499 mm)

Track, rear57.6 in (1464mm)

1 The quoted data apply only to the standard vehicle. See an authorized Mercedes-Benz dealer

for the correspon-ding data of ali special bodies and special equipment,

ProCarManuals.com