clock MERCEDES-BENZ C CLASS 2018 User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2018, Model line: C CLASS, Model: MERCEDES-BENZ C CLASS 2018Pages: 370, PDF Size: 6.25 MB

Page 289 of 370

!If you exceed the maximum permitted load

of the EASY-PACK trunk box, objects may be

thrown out of the EASY-PACK trunk box and

strike vehicle occupants. There is a risk of

injury, particularly in the event of sudden

braking or a sudden change in direction.

Always observe the maximum permitted load

of the EASY-PACK trunk box. Always store

and secure heavy objects in the trunk outside

the EASY-PACK trunk box.

The maximum permitted load of the EASY-PACK

trunk box is 22 lbs (10 kg). With a load of above

approximately 11 lbs (5 kg), the bottom of the

box moves down until it rests on the mat of the

trunk floor. Thus, overloading of the box is avoi-

ded.

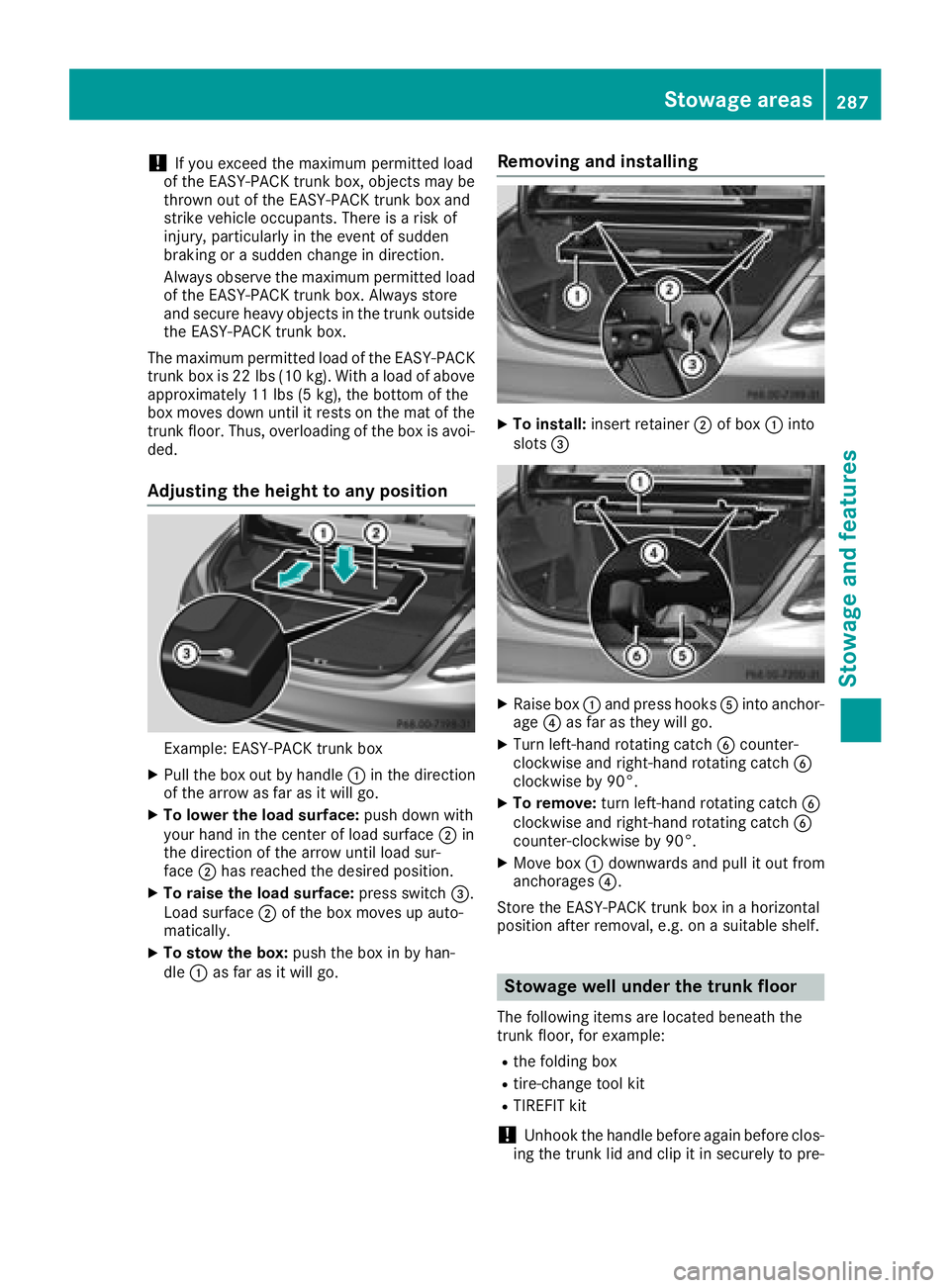

Adjusting the height to any position

Example: EASY-PACK trunk box

XPull the box out by handle :in the direction

of the arrow as far as it will go.

XTo lower the load surface: push down with

your hand in the center of load surface ;in

the direction of the arrow until load sur-

face ;has reached the desired position.

XTo raise the load surface: press switch=.

Load surface ;of the box moves up auto-

matically.

XTo stow the box: push the box in by han-

dle :as far as it will go.

Removing and installing

XTo install: insert retainer ;of box :into

slots =

XRaise box :and press hooks Ainto anchor-

age ?as far as they will go.

XTurn left-hand rotating catch Bcounter-

clockwise and right-hand rotating catch B

clockwise by 90°.

XTo remove: turn left-hand rotating catch B

clockwise and right-hand rotating catch B

counter-clockwise by 90°.

XMove box :downwards and pull it out from

anchorages ?.

Store the EASY-PACK trunk box in a horizontal

position after removal, e.g. on a suitable shelf.

Stowage well under the trunk floor

The following items are located beneath the

trunk floor, for example:

Rthe folding box

Rtire-change tool kit

RTIREFIT kit

!Unhook the handle before again before clos-

ing the trunk lid and clip it in securely to pre-

Stowage areas287

Stowage and features

Z

Page 307 of 370

Depending on the engine, the oil dipstick may be

in a different location.

When checking the oil level:

Rpark the vehicle on a level surface

Rthe engine should be switched off for approx-

imately five minutes if the engine is at normal

operating temperature

Rall vehicles (except Mercedes‑AMG C 63

and Mercedes ‑AMG C 63 S):if the engine is

not at normal operating temperature, e.g. if

the engine was started only briefly, wait

approximately 30 minutes before carrying out

the measurement

Mercedes ‑AMG C 63 and Mercedes ‑AMG C

63 S: the oil level must only be checked when

the engine is at normal operating temperature.

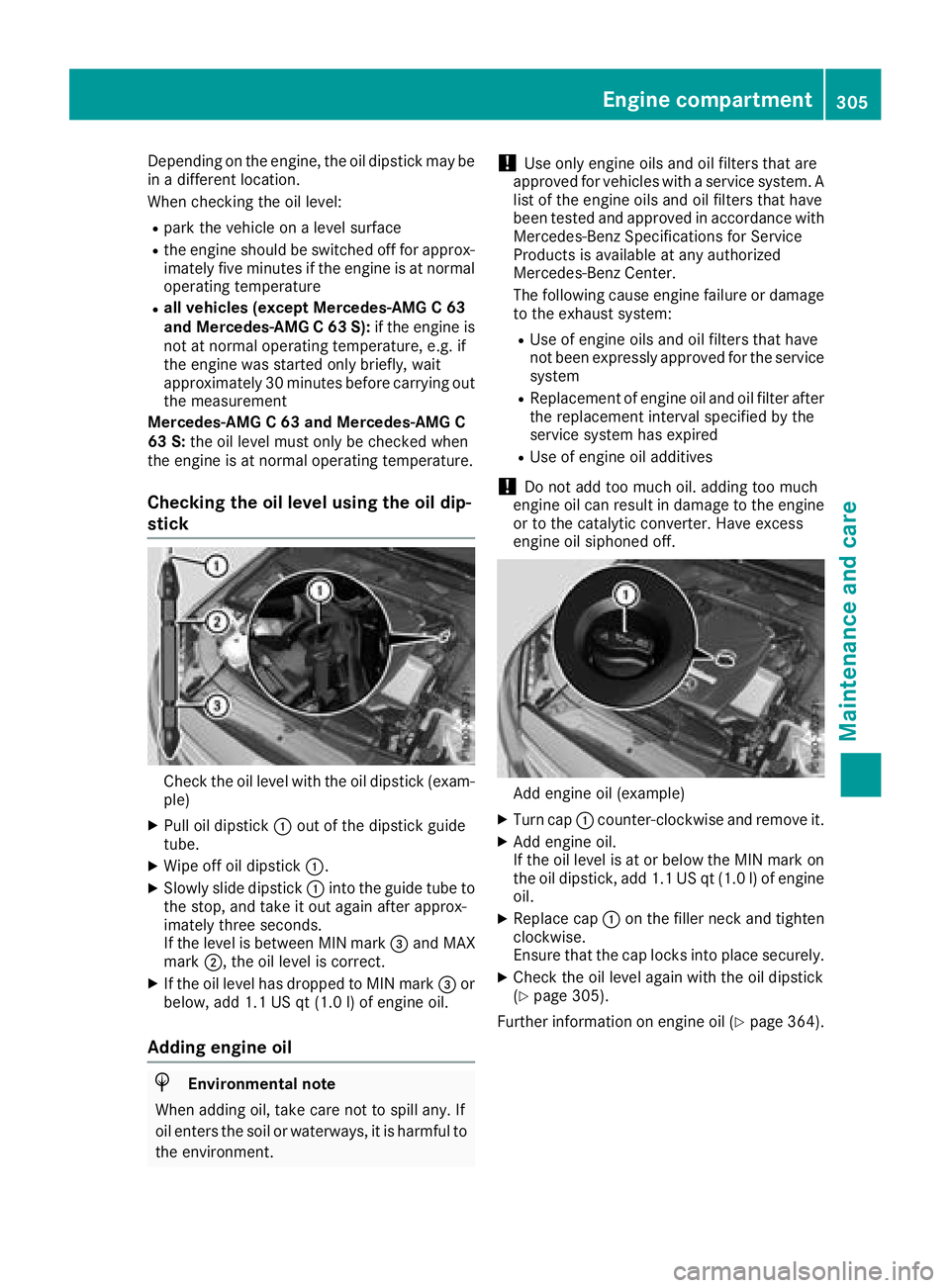

Checking the oil level using the oil dip-

stick

Check the oil level with the oil dipstick (exam-

ple)

XPull oil dipstick :out of the dipstick guide

tube.

XWipe off oil dipstick :.

XSlowly slide dipstick :into the guide tube to

the stop, and take it out again after approx-

imately three seconds.

If the level is between MIN mark =and MAX

mark ;, the oil level is correct.

XIf the oil level has dropped to MIN mark =or

below, add 1.1 US qt (1.0 l) of engine oil.

Adding engine oil

HEnvironmental note

When adding oil, take care not to spill any. If

oil enters the soil or waterways, it is harmful to

the environment.

!Use only engine oils and oil filters that are

approved for vehicles with a service system. A list of the engine oils and oil filters that have

been tested and approved in accordance with

Mercedes-Benz Specifications for Service

Products is available at any authorized

Mercedes-Benz Center.

The following cause engine failure or damage

to the exhaust system:

RUse of engine oils and oil filters that have

not been expressly approved for the service

system

RReplacement of engine oil and oil filter after

the replacement interval specified by the

service system has expired

RUse of engine oil additives

!Do not add too much oil. adding too much

engine oil can result in damage to the engine

or to the catalytic converter. Have excess

engine oil siphoned off.

Add engine oil (example)

XTurn cap :counter-clockwise and remove it.

XAdd engine oil.

If the oil level is at or below the MIN mark on

the oil dipstick, add 1.1 US qt (1.0 l)of engine

oil.

XReplace cap :on the filler neck and tighten

clockwise.

Ensure that the cap locks into place securely.

XCheck the oil level again with the oil dipstick

(Ypage 305).

Further information on engine oil (

Ypage 364).

Engine compartment305

Maintenance and care

Z

Page 308 of 370

Additional service products

Import ant safety notes

GWARNIN G

Certain component sin th eengin ecompart-

ment, suc has th eengine, radiato rand part s

of th eexhaust system, can become ver yhot .

Working in th eengin ecompartmen tposes a

ris kof injury.

Wher epossible, let th eengin ecool down and

touch only th ecomponent sdescribed in th e

following.

GWARNIN G

The engin ecompartmen tcontain smoving

components. Certain components, suc has

th eradiato rfan ,may continu eto run or start

again suddenly when th eignition is off .There

is aris kof injury.

If you need to do any wor kinside th eengin e

compartment:

Rswitch off th eignition

Rnever reac hint oth earea wher ethere is a

ris kof danger from moving components,

suc has th efan rotation area

Rremove jewelr yand watches

Rkeep items of clothing and hair ,for exam-

ple, away from moving part s

GWARNING

The coolin gsystem is pressurized, particularly

when th emotor is warm .If you open th ecap ,

you could be scalded if hot coolan tsprays out .

There is aris kof injury.

Let th eengin ecool down before you open th e

cap .Wear gloves and eye protection .Slowly

open th ecap to reliev epressure.

GWARNIN G

Opening th ehoo dwhen th eengin eis over-

heated or when there is afir ein th eengin e

compartmen tcould expos eyou to hot gase s

or other servic eproducts .There is aris kof

injury.

Let an overheate dengin ecool down before

opening th ehood. If there is afir ein th e

engin ecompartment, keep th ehoo dclosed

and contact th efir edepartment.

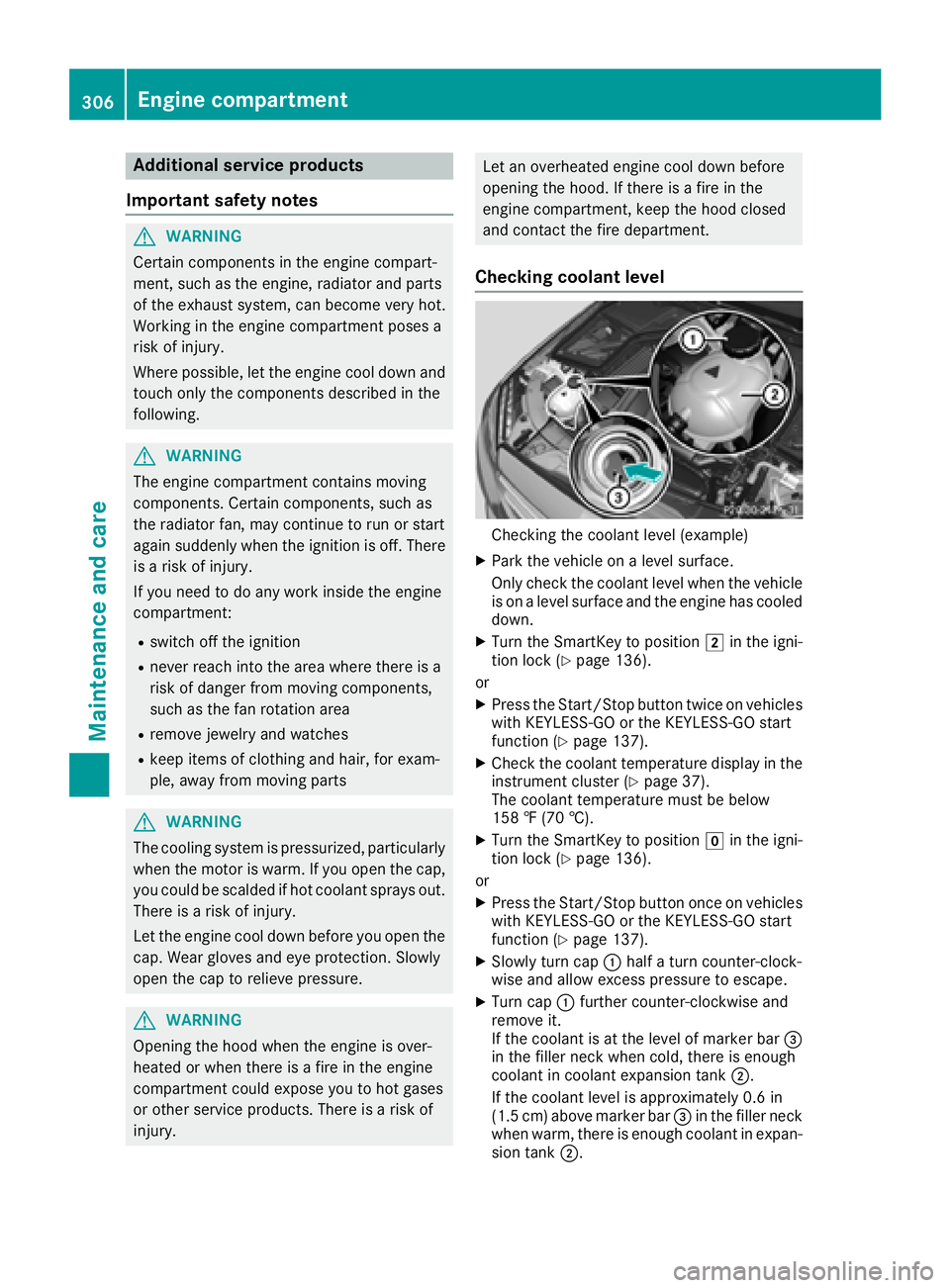

Checking coolant level

Checking th ecoolan tlevel (example)

XPark th evehicl eon alevel surface.

Only chec kth ecoolan tlevel when th evehicl e

is on alevel surfac eand th eengin ehas cooled

down .

XTurn th eSmartKey to position 2in th eigni-

tion loc k (Ypage 136).

or

XPress th eStart/Sto pbutto ntwice on vehicles

wit hKEYLESS-GO or th eKEYLESS-GO start

function (

Ypage 137).

XCheckth ecoolan ttemperature display in th e

instrumen tcluste r (Ypage 37).

The coolan ttemperature mus tbe belo w

15 8 ‡ (70 †).

XTurn th eSmartKey to position gin th eigni-

tion loc k (Ypage 136).

or

XPress th eStart/Sto pbutto nonce on vehicles

wit hKEYLESS-GO or th eKEYLESS-GO start

function (

Ypage 137).

XSlowly tur ncap :half atur ncounter-clock -

wise and allow excess pressur eto escape.

XTurn cap :further counter-clockwise and

remove it .

If th ecoolan tis at th elevel of marke rbar =

in th efiller neck when cold, there is enough

coolan tin coolan texpansion tan k;.

If th ecoolan tlevel is approximately 0. 6in

(1. 5cm) abov emarke rbar =in th efiller neck

when warm ,there is enough coolan tin expan -

sion tan k;.

306Engine compartment

Maintenance and care

Page 309 of 370

XIf necessary, add coolant that has been tested

and approved by Mercedes-Benz.

XReplace cap:and turn it clockwise as far as

it will go.

For further information on coolant, see

(

Ypage 365).

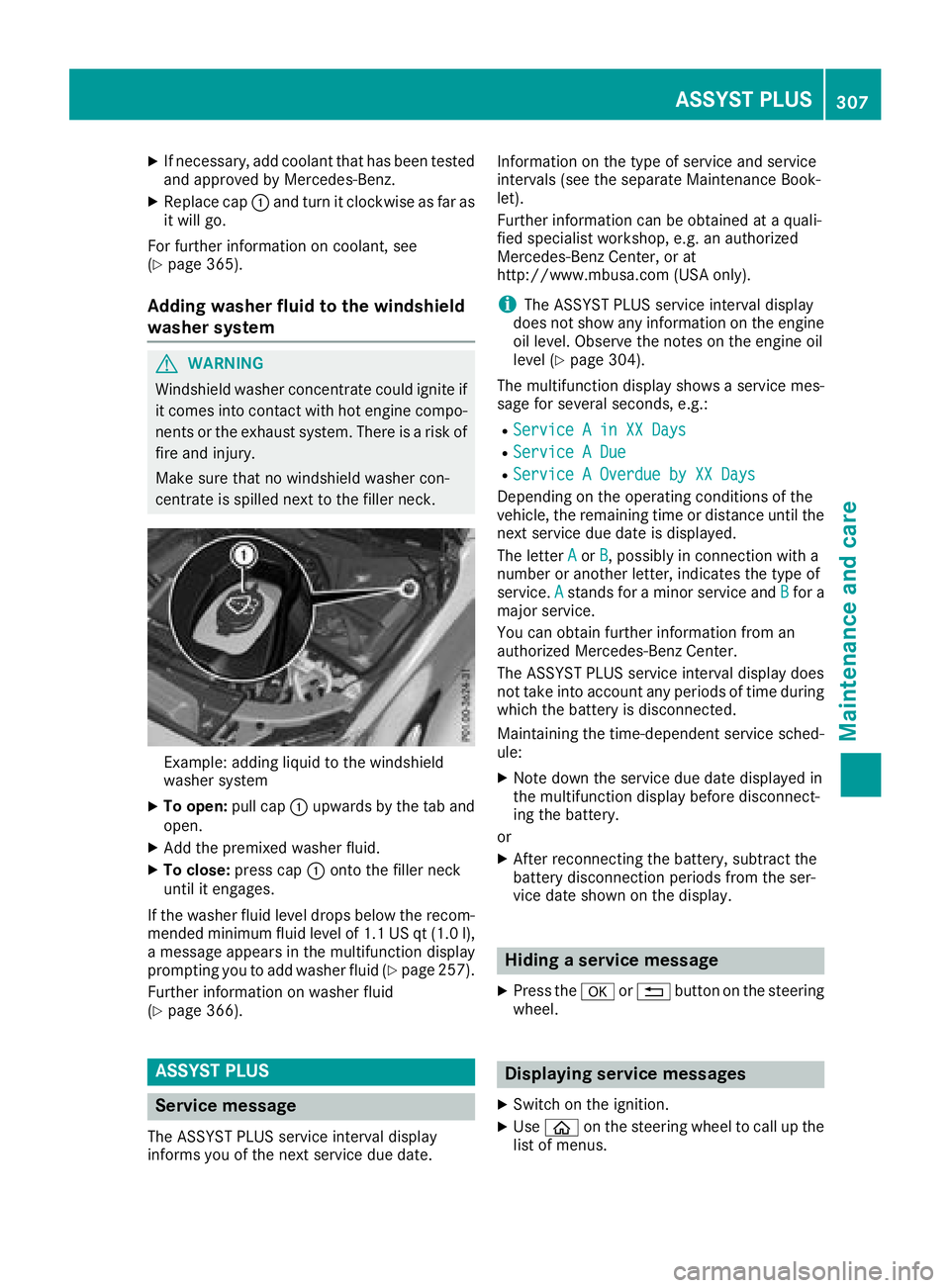

Adding washer fluid to the windshield

washer system

GWARNING

Windshield washer concentrate could ignite if it comes into contact with hot engine compo-

nents or the exhaust system. There is a risk of

fire and injury.

Make sure that no windshield washer con-

centrate is spilled next to the filler neck.

Example: adding liquid to the windshield

washer system

XTo open: pull cap:upwards by the tab and

open.

XAdd the premixed washer fluid.

XTo close: press cap :onto the filler neck

until it engages.

If the washer fluid level drops below the recom-

mended minimum fluid level of 1.1 US qt (1.0 l),

a message appears in the multifunction display

prompting you to add washer fluid (

Ypage 257).

Further information on washer fluid

(

Ypage 366).

ASSYST PLUS

Service message

The ASSYST PLUS service interval display

informs you of the next service due date. Information on the type of service and service

intervals (see the separate Maintenance Book-

let).

Further information can be obtained at a quali-

fied specialist workshop, e.g. an authorized

Mercedes-Benz Center, or at

http://www.mbusa.com (USA only).

iThe ASSYST PLUS service interval display

does not show any information on the engine

oil level. Observe the notes on the engine oil

level (

Ypage 304).

The multifunction display shows a service mes-

sage for several seconds, e.g.:

RService A in XX Days

RService A Due

RService A Overdue by XX Days

Depending on the operating conditions of the

vehicle, the remaining time or distance until the

next service due date is displayed.

The letter A

orB, possibly in connection with a

number or another letter, indicates the type of

service. A

stands for a minor service and Bfor a

major service.

You can obtain further information from an

authorized Mercedes-Benz Center.

The ASSYST PLUS service interval display does

not take into account any periods of time during

which the battery is disconnected.

Maintaining the time-dependent service sched-

ule:

XNote down the service due date displayed in

the multifunction display before disconnect-

ing the battery.

or

XAfter reconnecting the battery, subtract the

battery disconnection periods from the ser-

vice date shown on the display.

Hiding a service message

XPress the aor% button on the steering

wheel.

Displaying service messages

XSwitch on the ignition.

XUse ò on the steering wheel to call up the

list of menus.

ASSYST PLUS307

Maintenance and care

Z

Page 331 of 370

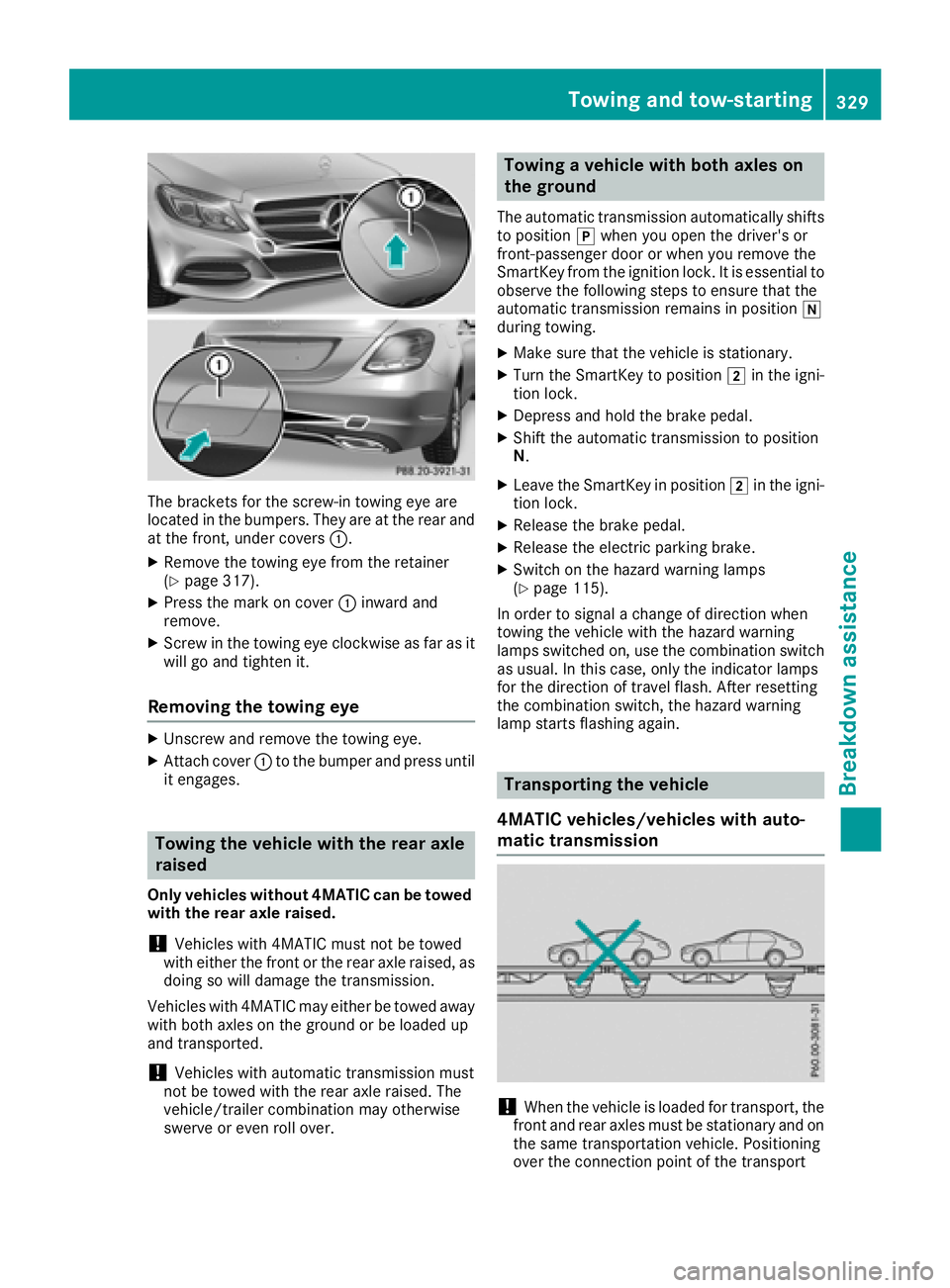

The brackets for the screw-in towing eye are

located in the bumpers. They are at the rear and

at the front, under covers:.

XRemove the towing eye from the retainer

(Ypage 317).

XPress the mark on cover:inward and

remove.

XScrew in the towing eye clockwise as far as it

will go and tighten it.

Removing the towing eye

XUnscrew and remove the towing eye.

XAttach cover :to the bumper and press until

it engages.

Towing the vehicle with the rear axle

raised

Only vehicles without 4MATIC can be towed

with the rear axle raised.

!Vehicles with 4MATIC must not be towed

with either the front or the rear axle raised, as doing so will damage the transmission.

Vehicles with 4MATIC may either be towed away

with both axles on the ground or be loaded up

and transported.

!Vehicles with automatic transmission must

not be towed with the rear axle raised. The

vehicle/trailer combination may otherwise

swerve or even roll over.

Towing a vehicle with both axles on

the ground

The automatic transmission automatically shifts

to position jwhen you open the driver's or

front-passenger door or when you remove the

SmartKey from the ignition lock. It is essential to observe the following steps to ensure that the

automatic transmission remains in position i

during towing.

XMake sure that the vehicle is stationary.

XTurn the SmartKey to position 2in the igni-

tion lock.

XDepress and hold the brake pedal.

XShift the automatic transmission to position

N .

XLeave the SmartKey in position 2in the igni-

tion lock.

XRelease the brake pedal.

XRelease the electric parking brake.

XSwitch on the hazard warning lamps

(Ypage 115).

In order to signal a change of direction when

towing the vehicle with the hazard warning

lamps switched on, use the combination switch

as usual. In this case, only the indicator lamps

for the direction of travel flash. After resetting

the combination switch, the hazard warning

lamp starts flashing again.

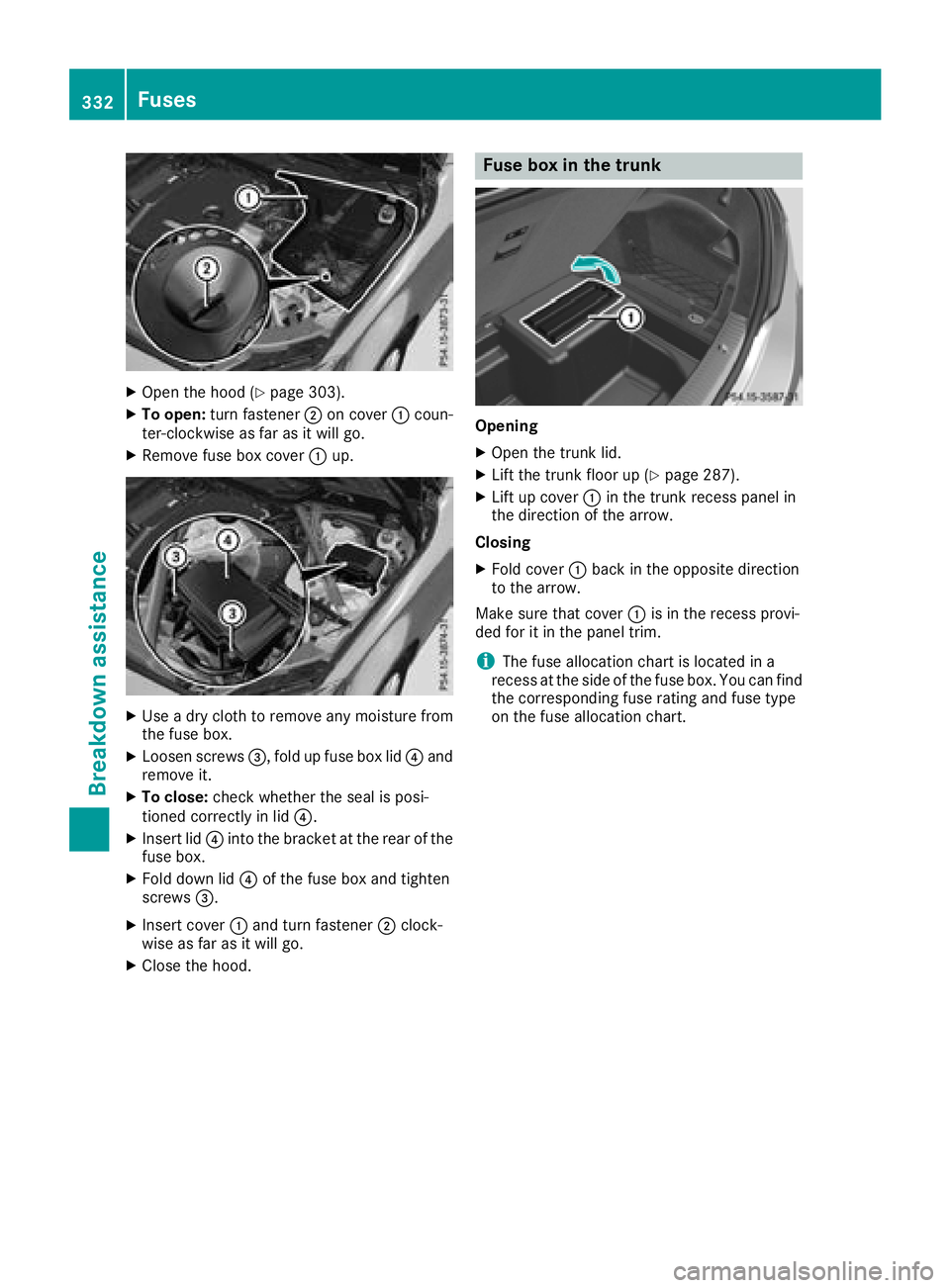

Transporting the vehicle

4MATIC vehicles/vehicles with auto-

matic transmission

!When the vehicle is loaded for transport, the

front and rear axles must be stationary and on

the same transportation vehicle. Positioning

over the connection point of the transport

Towing and tow-starting329

Breakdown assistance

Z

Page 334 of 370

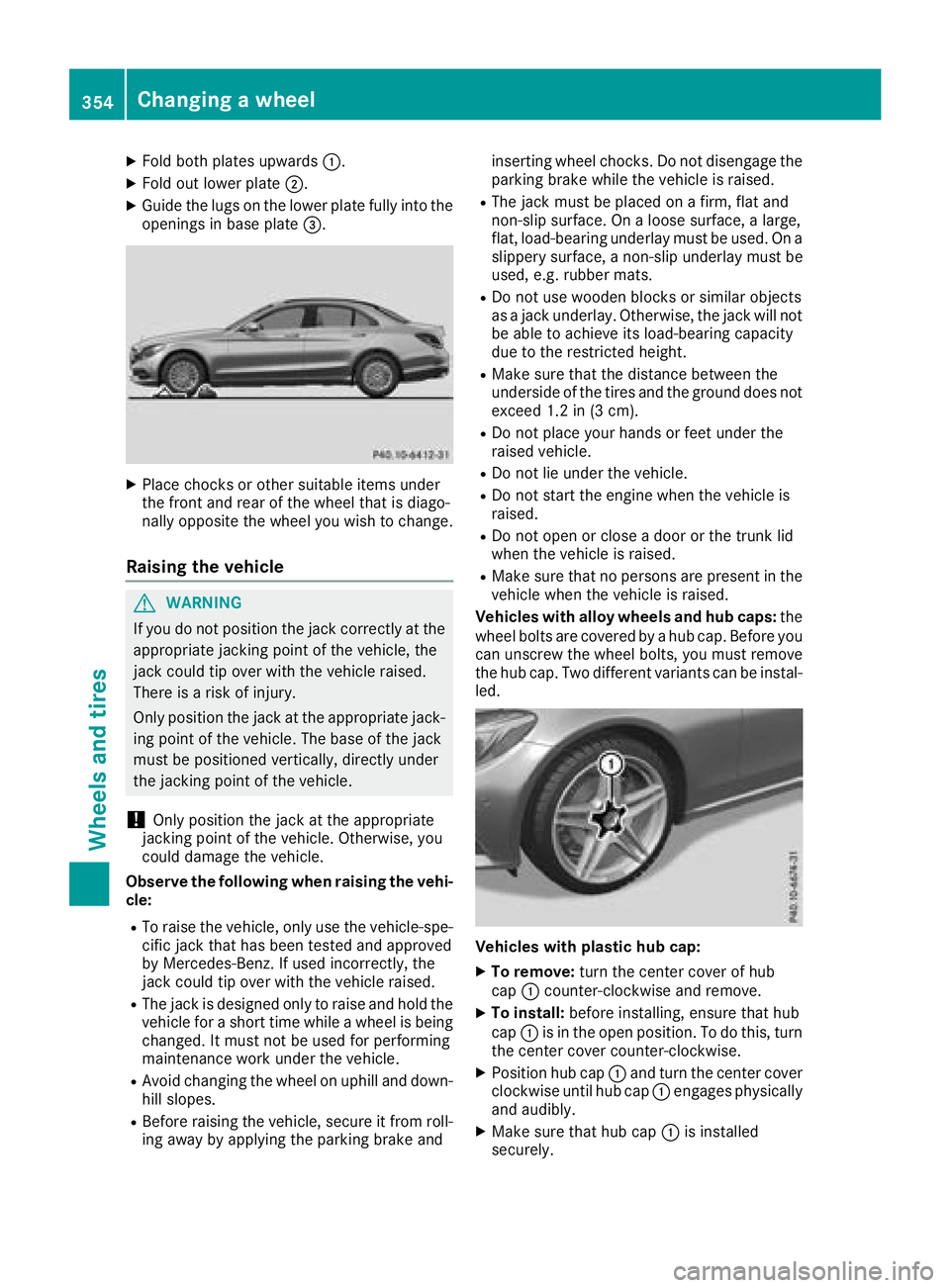

XOpen the hood (Ypage 303).

XTo open:turn fastener ;on cover :coun-

ter-clockwise as far as it will go.

XRemove fuse box cover :up.

XUse a dry cloth to remove any moisture from

the fuse box.

XLoosen screws =, fold up fuse box lid ?and

remove it.

XTo close: check whether the seal is posi-

tioned correctly in lid ?.

XInsert lid?into the bracket at the rear of the

fuse box.

XFold down lid ?of the fuse box and tighten

screws =.

XInsert cover :and turn fastener ;clock-

wise as far as it will go.

XClose the hood.

Fuse box in the trunk

Opening

XOpen the trunk lid.

XLift the trunk floor up (Ypage 287).

XLift up cover :in the trunk recess panel in

the direction of the arrow.

Closing

XFold cover :back in the opposite direction

to the arrow.

Make sure that cover :is in the recess provi-

ded for it in the panel trim.

iThe fuse allocation chart is located in a

recess at the side of the fuse box. You can find

the corresponding fuse rating and fuse type

on the fuse allocation chart.

332Fuses

Breakdown assistance

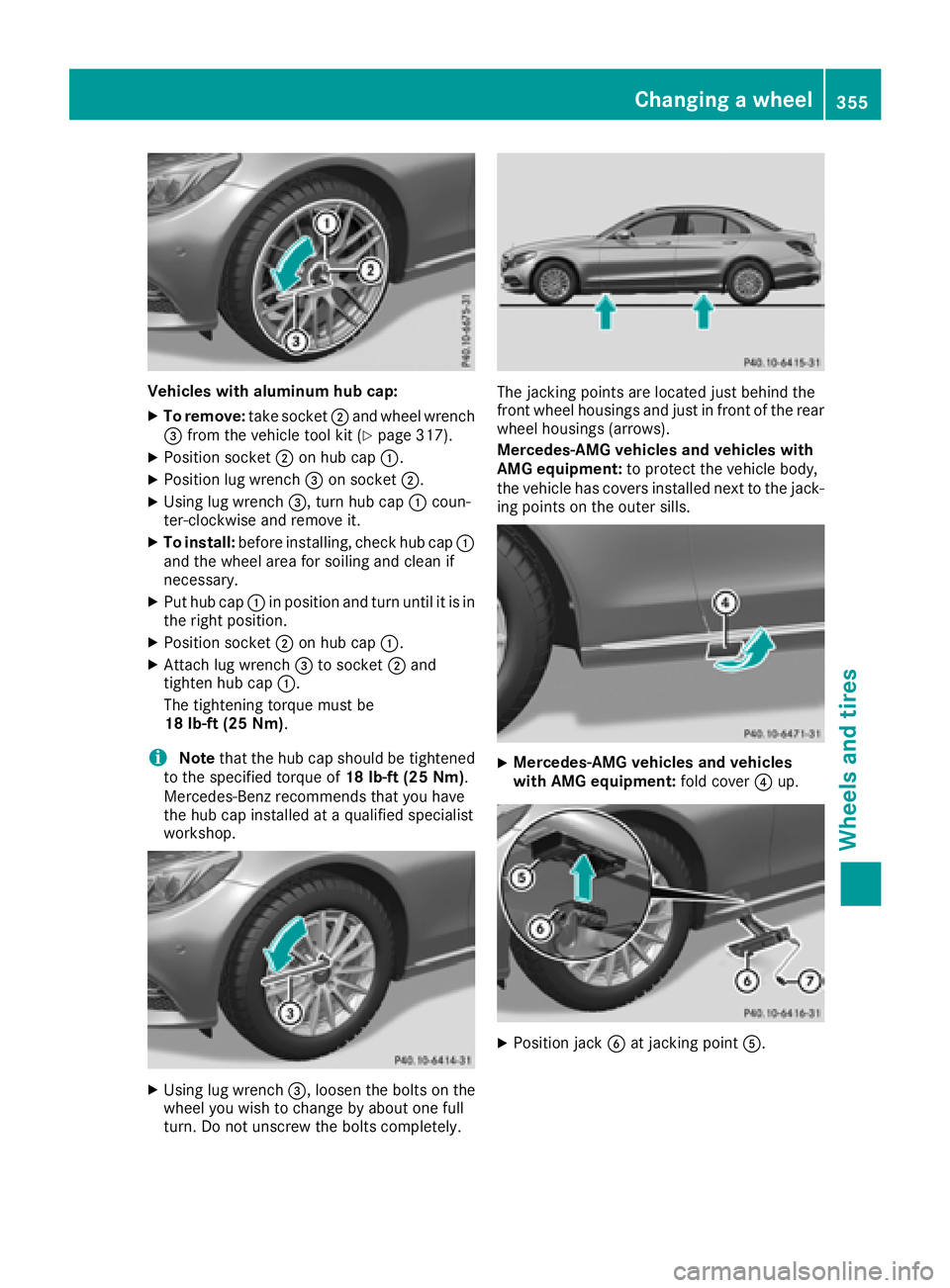

Page 356 of 370

XFold both plates upwards:.

XFold out lower plate;.

XGuide the lugs on the lower plate fully into the

openings in base plate =.

XPlace chocks or other suitable items under

the front and rear of the wheel that is diago-

nally opposite the wheel you wish to change.

Raising the vehicle

GWARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

!Only position the jack at the appropriate

jacking point of the vehicle. Otherwise, you

could damage the vehicle.

Observe the following when raising the vehi-

cle:

RTo raise the vehicle, only use the vehicle-spe-

cific jack that has been tested and approved

by Mercedes-Benz. If used incorrectly, the

jack could tip over with the vehicle raised.

RThe jack is designed only to raise and hold the

vehicle for a short time while a wheel is being

changed. It must not be used for performing

maintenance work under the vehicle.

RAvoid changing the wheel on uphill and down- hill slopes.

RBefore raising the vehicle, secure it from roll-

ing away by applying the parking brake and inserting wheel chocks. Do not disengage the

parking brake while the vehicle is raised.

RThe jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

flat, load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats.

RDo not use wooden blocks or similar objects

as a

jack underlay. Otherwise, the jack will not

be able to achieve its load-bearing capacity

due to the restricted height.

RMake sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in (3 cm).

RDo not place your hands or feet under the

raised vehicle.

RDo not lie under the vehicle.

RDo not start the engine when the vehicle is

raised.

RDo not open or close a door or the trunk lid

when the vehicle is raised.

RMake sure that no persons are present in the

vehicle when the vehicle is raised.

Vehicles with alloy wheels and hub caps: the

wheel bolts are covered by a hub cap. Before you

can unscrew the wheel bolts, you must remove

the hub cap. Two different variants can be instal- led.

Vehicles with plastic hub cap:

XTo remove: turn the center cover of hub

cap :counter-clockwise and remove.

XTo install: before installing, ensure that hub

cap :is in the open position. To do this, turn

the center cover counter-clockwise.

XPosition hub cap :and turn the center cover

clockwise until hub cap :engages physically

and audibly.

XMake sure that hub cap :is installed

securely.

354Changing a wheel

Wheels and tires

Page 357 of 370

Vehicles with aluminum hub cap:

XTo remove:take socket;and wheel wrench

= from the vehicle tool kit (Ypage 317).

XPosition socket ;on hub cap :.

XPosition lug wrench =on socket ;.

XUsing lug wrench =, turn hub cap:coun-

ter-clockwise and remove it.

XTo install: before installing, check hub cap :

and the wheel area for soiling and clean if

necessary.

XPut hub cap :in position and turn until it is in

the right position.

XPosition socket ;on hub cap :.

XAttach lug wrench =to socket ;and

tighten hub cap :.

The tightening torque must be

18 lb-ft (25 Nm) .

iNotethat the hub cap should be tightened

to the specified torque of 18 lb-ft (25 Nm).

Mercedes-Benz recommends that you have

the hub cap installed at a qualified specialist

workshop.

XUsing lug wrench =, loosen the bolts on the

wheel you wish to change by about one full

turn. Do not unscrew the bolts completely.

The jacking points are located just behind the

front wheel housings and just in front of the rear

wheel housings (arrows).

Mercedes-AMG vehicles and vehicles with

AMG equipment: to protect the vehicle body,

the vehicle has covers installed next to the jack-

ing points on the outer sills.

XMercedes-AMG vehicles and vehicles

with AMG equipment: fold cover?up.

XPosition jack Bat jacking point A.

Changing a wheel355

Wheels and tires

Z

Page 358 of 370

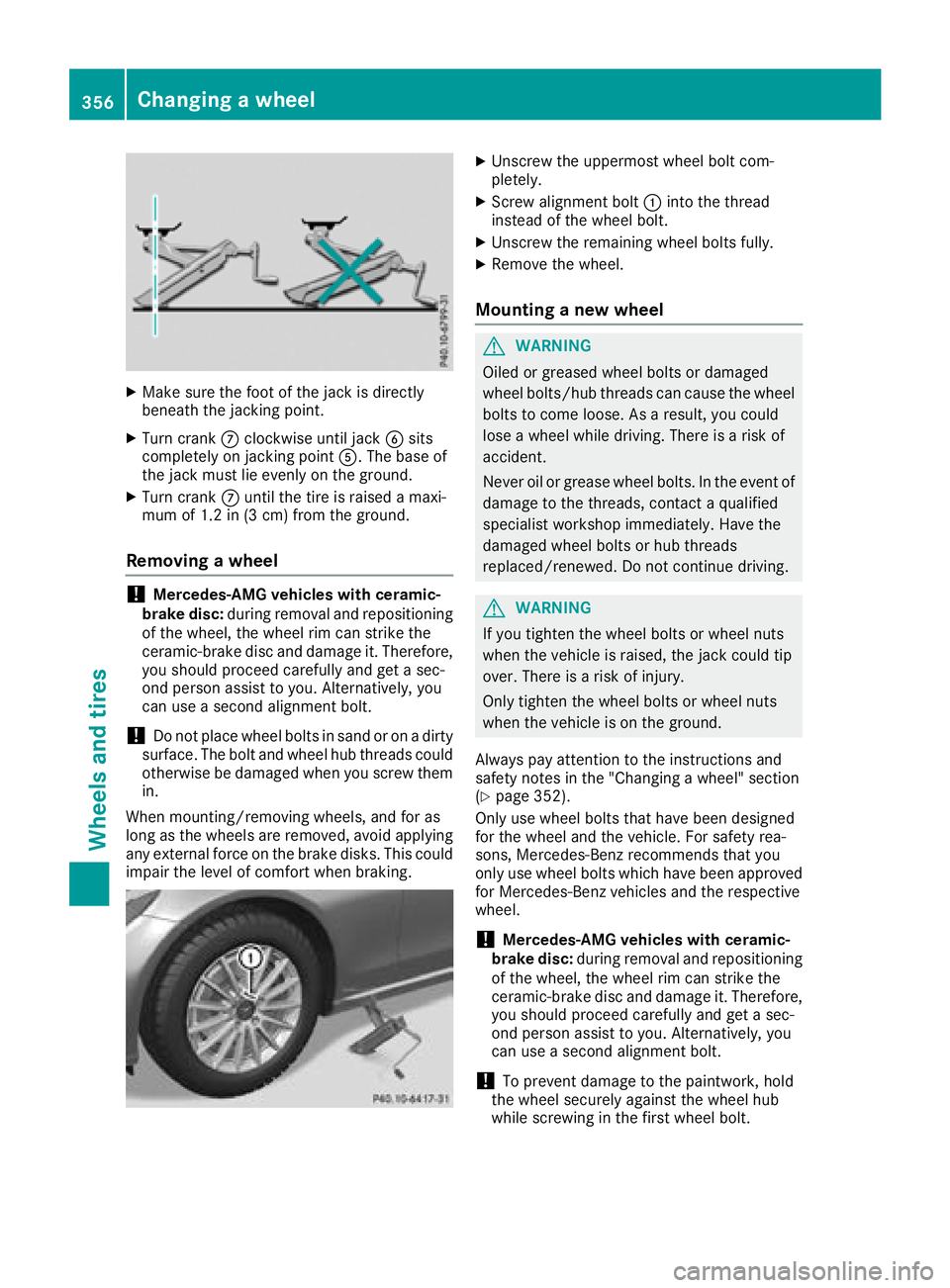

XMake sure the foot of the jack is directly

beneath the jacking point.

XTurn crankCclockwise until jack Bsits

completely on jacking point A. The base of

the jack must lie evenly on the ground.

XTurn crank Cuntil the tire is raised a maxi-

mum of 1.2 in (3 cm) from the ground.

Removing a wheel

!Mercedes-AMG vehicles with ceramic-

brake disc: during removal and repositioning

of the wheel, the wheel rim can strike the

ceramic-brake disc and damage it. Therefore,

you should proceed carefully and get a sec-

ond person assist to you. Alternatively, you

can use a second alignment bolt.

!Do not place wheel bolts in sand or on a dirty

surface. The bolt and wheel hub threads could

otherwise be damaged when you screw them

in.

When mounting/removing wheels, and for as

long as the wheels are removed, avoid applying

any external force on the brake disks. This could

impair the level of comfort when braking.

XUnscrew the uppermost wheel bolt com-

pletely.

XScrew alignment bolt :into the thread

instead of the wheel bolt.

XUnscrew the remaining wheel bolts fully.

XRemove the wheel.

Mounting a new wheel

GWARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event of

damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving.

GWARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always pay attention to the instructions and

safety notes in the "Changing a wheel" section

(

Ypage 352).

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been approved for Mercedes-Benz vehicles and the respective

wheel.

!Mercedes-AMG vehicles with ceramic-

brake disc: during removal and repositioning

of the wheel, the wheel rim can strike the

ceramic-brake disc and damage it. Therefore,

you should proceed carefully and get a sec-

ond person assist to you. Alternatively, you

can use a second alignment bolt.

!To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt.

356Changing a wheel

Wheels and tires

Page 359 of 370

XClean the wheel and wheel hub contact sur-

faces.

XSlide the wheel to bemounted onto the align-

ment boltand push iton.

XTighten the wheel bolts unt ilthey are finger-

tight.

XUnscrew the alignment bolt.

XTighten the last wheel boltuntil it is finger-

tight.

Lowering the vehicle

GWAR NING

The wheels could work loose ifthe wheel nuts

and bolts are not tightened to the specifie d

tightening torque. There isa risk of acc ident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel ischanged.

XTurn the crank of the jack counter-clock wise

unt ilthe veh icle isonce again standing firmly

on the ground.

XPlace the jack to one side.

XTighten the wheel bolts evenly ina crosswise

pattern inthe sequence indicated (: toA). The tightening torque must be

111lb-ft

(1 50 Nm) .

XTurn the jack back to its initial position.

XStow the jack and the rest of the vehicle tools

in the trunk again.

XMercedes-AMG vehicles and vehicles

with AMG equipment: insert the cover into

the outer sill.

XCheck the tire pressure of the ne wlymounted

wheel and adjust it if necessary.

Observe the recommended tire pressure

(

Ypage 336).

When you are driving with the collapsible spare

wheel mounte d,the tire pressure loss warning

system or the tire pressure monitor cannot func-

tion reliably. Only restart the tire pressure loss

warning system or tire pressure monitor when

the defective wheel has been replaced with a

new wheel.

Vehicles with a tire pressure controlsys-

tem: all installed wheels must be equipped with

functioning sensors.

Wheel/tire combination

You can ask for information regarding permitted wheel/t ire combinations at an authorized

Mercedes-Benz Center.

!For safety reasons, Mercedes-Benz recom-

men dsthat you only use tires and wheels

whic h have been approved byMercedes-Benz

specifically for your vehicle.

These tires have been specially adapted for

use with the control systems, such as ABS or

ESP

®, and are marked as follows:

RMO = Mercedes-Benz Original

RMOE = Mercedes-Benz Original Extended

(tires featuring run-flat characteristics)

RMO1 = Mercedes-Benz Original (only cer-

tain AMG tires)

Mercedes-Benz Original Extended tires may

only beused on wheels that have been spe-

cifically approved by Mercedes-Benz.

Only use tires, wheels or accessories tested

and approved by Mercedes-Benz. Certain

characteristics, e.g. handling, vehicle noise

emissions or fuel consumption, may other-

wise be adverselyaffected. In addition, when

driving with a load, tire dimension variations

could cause the tires to come into contact

Wheel/tire combination357

Wheels and tires

Z