light MERCEDES-BENZ C320 2001 W203 Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2001, Model line: C320, Model: MERCEDES-BENZ C320 2001 W203Pages: 381, PDF Size: 19.92 MB

Page 277 of 381

268 Malfunction and indicator lamps

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hints Car care Index

Malfunction and indicator lamps

in the instrument cluster

General information:

If a bulb in the instrument cluster fails to light up

during the bulb self-check when turning the electronic

key in steering lock to position 2, have it checked and

replaced if necessary.

Emission control

Certain systems of the engine serve to keep the toxic

components of the exhaust gases within permissible

limits required by law.

These systems, of course, will function properly only

when maintained strictly according to factory

specifications. Any adjustments on the engine should,

therefore, be carried out only by authorized

Mercedes-Benz Center qualified technicians. Engine

adjustments should not be altered in any way. Moreover,

the specified service jobs must be carried out regularly

according to Mercedes-Benz servicing requirements.

For details refer to the Service Booklet.On-board diagnostic system

Check engine malfunction indicator lamp

Engine malfunction indicator lamp. If the

“CHECK ENGINE” malfunction indicator

lamp comes on when the engine is running,

it indicates a malfunction of the fuel management

system, emission control system, systems which impact

emissions, or the fuel cap is not closed tight (check the

fuel cap). If the “CHECK ENGINE” lamp is illuminated

continuously and the vehicle is driving normally, you

Wa r n i n g !

Inhalation of exhaust gas is hazardous to your

health. All exhaust gas contains carbon monoxide,

and inhaling it can cause unconsciousness and

lead to death. Do not run the engine in confined areas (such as a

garage) which are not properly ventilated. If you

think that exhaust gas fumes are entering the

vehicle while driving, have the cause determined

and corrected immediately. If you must drive under

these conditions, drive only with at least one

window fully open.

Page 282 of 381

273 Malfunction and indicator lamps

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hints Car care Index Electronic stability program (ESP) — warning lamp

The yellow ESP warning lamp in the

speedometer dial comes on with the

electronic key in starter switch position 2.

It should go out with engine running.

If the ESP malfunction indicator lamp remains

illuminated with the engine running, a malfunction has

been detected in the system. Pressing the accelerator

pedal will require greater effort. Only partial engine

output will be available.

See elec tr on ic stability p rogram (ESP ) on p age 26 0 if t he

warning lamp lights up or flashes when the vehicle is

moving.

Seat belt nonusage warning lamp

With the electronic key in starter switch

position 2, the seat belt nonusage warning

lamp comes on, and a warning sounds for a

short time if the drivers seat belt is not fastened.

After starting the engine, the seat belt nonusage

warning lamp blinks for a brief period to remind the

driver and passengers to fasten seat belts.Malfunction and indicator lamp in the center

console

AIRBAG OFF indicator lamp

The ü indicator lamp will light up for approximately

6 seconds when you turn the electronic key in starter

switch to position 1 or 2.

It does not light up if there is a fault in the system.

The ü indicator lamp stays lit as long as a

Baby Smart

TM child seat is properly installed on the

front passenger seat. It indicates that the front

passenger airbag is switched off.

See page 62 for BabySmart

TM airbag and its deactivation

system.

Baby Smart

TM is a trademark of Siemens Automotive Corp.

Page 293 of 381

284 Malfunction and warning messages

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hints Car care Index

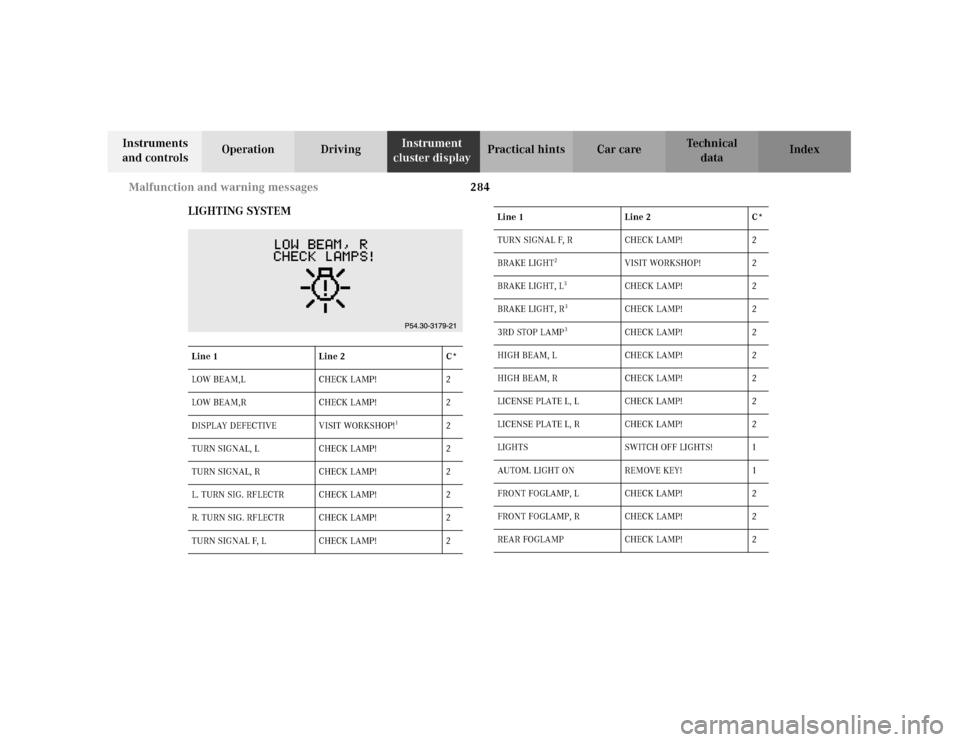

LIGHTING SYSTEM

Line 1 Line 2 C*

LOW BEAM,L CHECK LAMP! 2

LOW BEAM,R CHECK LAMP! 2

DISPLAY DEFECTIVE VISIT WORKSHOP!

1

2

TURN SIGNAL, L CHECK LAMP! 2

TURN SIGNAL, R CHECK LAMP! 2

L. TURN SIG. RFLECTR CHECK LAMP! 2

R. TURN SIG. RFLECTR CHECK LAMP! 2

TURN SIGNAL F, L CHECK LAMP! 2

TURN SIGNAL F, R CHECK LAMP! 2

BRAKE LIGHT

2

VISIT WORKSHOP! 2

BRAKE LIGHT, L

3

CHECK LAMP! 2

BRAKE LIGHT, R

3

CHECK LAMP! 2

3RD STOP LAMP

3

CHECK LAMP! 2

HIGH BEAM, L CHECK LAMP! 2

HIGH BEAM, R CHECK LAMP! 2

LICENSE PLATE L, L CHECK LAMP! 2

LICENSE PLATE L, R CHECK LAMP! 2

LIGHTS SWITCH OFF LIGHTS! 1

AUTOM. LIGHT ON REMOVE KEY! 1

FRONT FOGLAMP, L CHECK LAMP! 2

FRONT FOGLAMP, R CHECK LAMP! 2

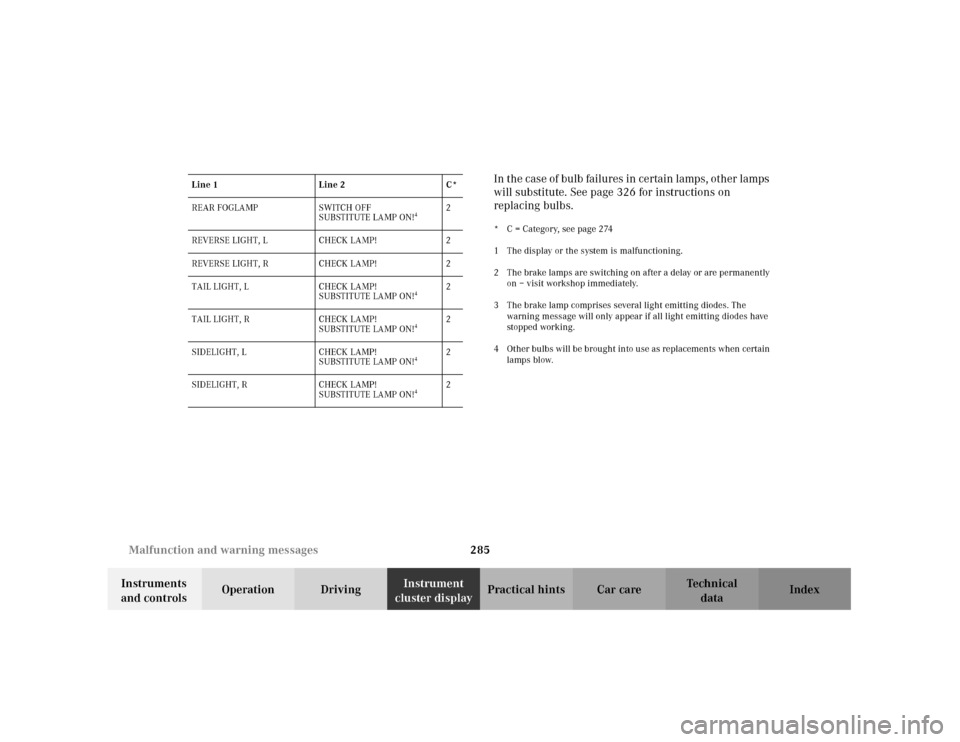

REAR FOGLAMP CHECK LAMP! 2 Line 1 Line 2 C*

Page 294 of 381

285 Malfunction and warning messages

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hints Car care IndexIn t he case of bulb failures in certain lamps, ot her lamps

will substitute. See page 326 for instructions on

replacing bulbs.

* C = Category, see page 274

1 The display or the system is malfunctioning.

2 The brake lamps are switching on after a delay or are permanently

on – visit workshop immediately.

3 The brake lamp comprises several light emitting diodes. The

warning message will only appear if all light emitting diodes have

stopped working.

4 Other bulbs will be brought into use as replacements when certain

lamps blow. REAR FOGLAMP SWITCH OFF

SUBSTITUTE LAMP ON!

4

2

REVERSE LIGHT, L CHECK LAMP! 2

REVERSE LIGHT, R CHECK LAMP! 2

TAIL LIGHT, L CHECK LAMP!

SUBSTITUTE LAMP ON!

4

2

TAIL LIGHT, R CHECK LAMP!

SUBSTITUTE LAMP ON!

4

2

SIDELIGHT, L CHECK LAMP!

SUBSTITUTE LAMP ON!

4

2

SIDELIGHT, R CHECK LAMP!

SUBSTITUTE LAMP ON!

4

2 Line 1 Line 2 C*

Page 295 of 381

286 Malfunction and warning messages

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hints Car care Index

LIGHT SENSOR

* C = Category, see page 274The headlamps will be switched on automatically if the

light sensor malfunctions.

The “LIGHTING” setting menu can be set to “MANUAL”

in the individual settings. See page 117. It will then be

possible to switch the headlamps on and off using the

exterior lamp switch. See page 130 for notes on the

exterior lamp switch. DOOR

* C = Category, see page 274. Line 1 Line 2 C*

LIGHT SENSOR VISIT WORKSHOP! 2Line 1 Line 2 C*

DOOR OPEN! 1

Page 299 of 381

290 Malfunction and warning messages

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hints Car care Index

RESTRAINT SYSTEM

* C = Category, see page 274.See page 55 for notes on the seat belts, and page 65 for

notes on the airbags.KEY

* C = Category, see page 274.

1 Key needs possibly to be replaced. Line 1 Line 2 C*

RESTRAINT SYSTEM VISIT WORKSHOP! 1Line 1 Line 2 C*

REPLACE KEY

1

VISIT WORKSHOP! 2

AUTOM. LIGHT ON REMOVE KEY! 1

Page 304 of 381

295 Fuses

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Fuses

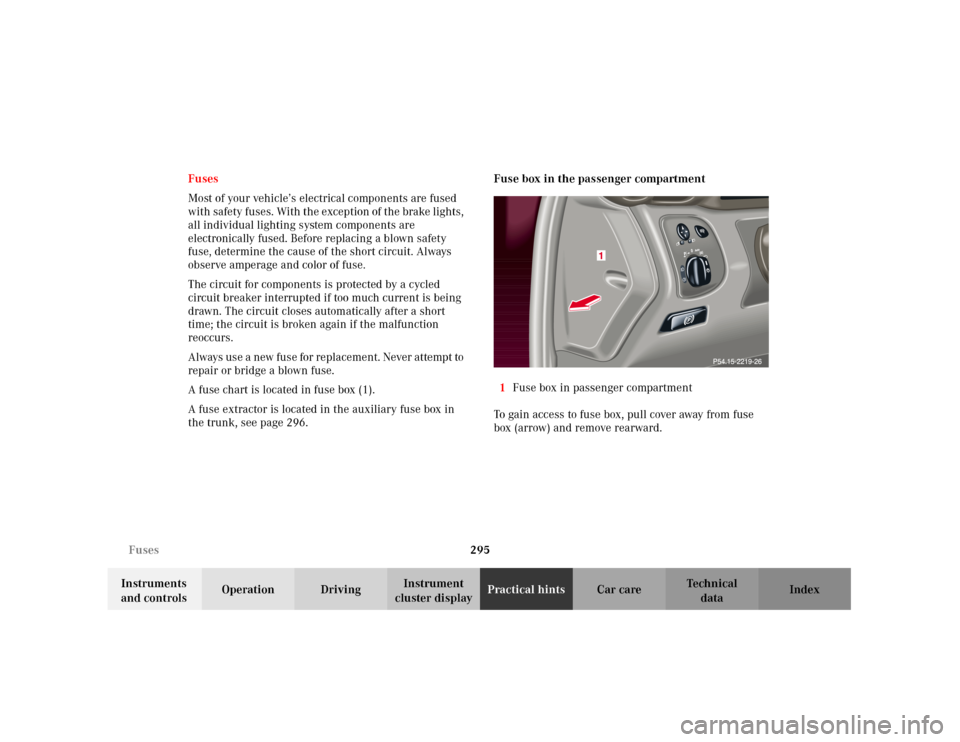

Most of your vehicle’s electrical components are fused

with safety fuses. With the exception of the brake lights,

all individual lighting system components are

electronically fused. Before replacing a blown safety

fuse, determine the cause of the short circuit. Always

observe amperage and color of fuse.

The circuit for components is protected by a cycled

circuit breaker interrupted if too much current is being

drawn. The circuit closes automatically after a short

time; the circuit is broken again if the malfunction

reoccurs.

A lways us e a new fus e for re placeme nt. Never atte mp t to

repair or bridge a blown fuse.

A fuse chart is located in fuse box (1).

A fuse extractor is located in the auxiliary fuse box in

the trunk, see page 296.Fuse box in the passenger compartment

1Fuse box in passenger compartment

To gain access to fuse box, pull cover away from fuse

box (arrow) and remove rearward.

Page 321 of 381

312 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

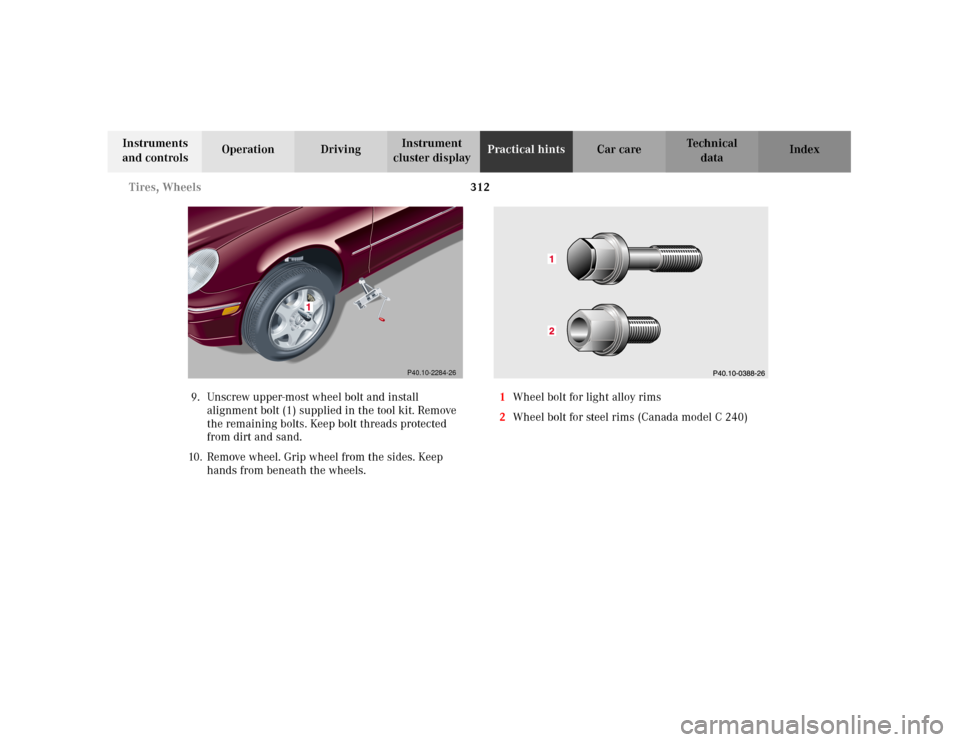

9. Unscrew upper-most wheel bolt and install

alignment bolt (1) supplied in the tool kit. Remove

the remaining bolts. Keep bolt threads protected

from dirt and sand.

10. Remove wheel. Grip wheel from the sides. Keep

hands from beneath the wheels.1Wheel bolt for light alloy rims

2Wheel bolt for steel rims (Canada model C 240)

P40.10-2284-26

Page 322 of 381

313 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

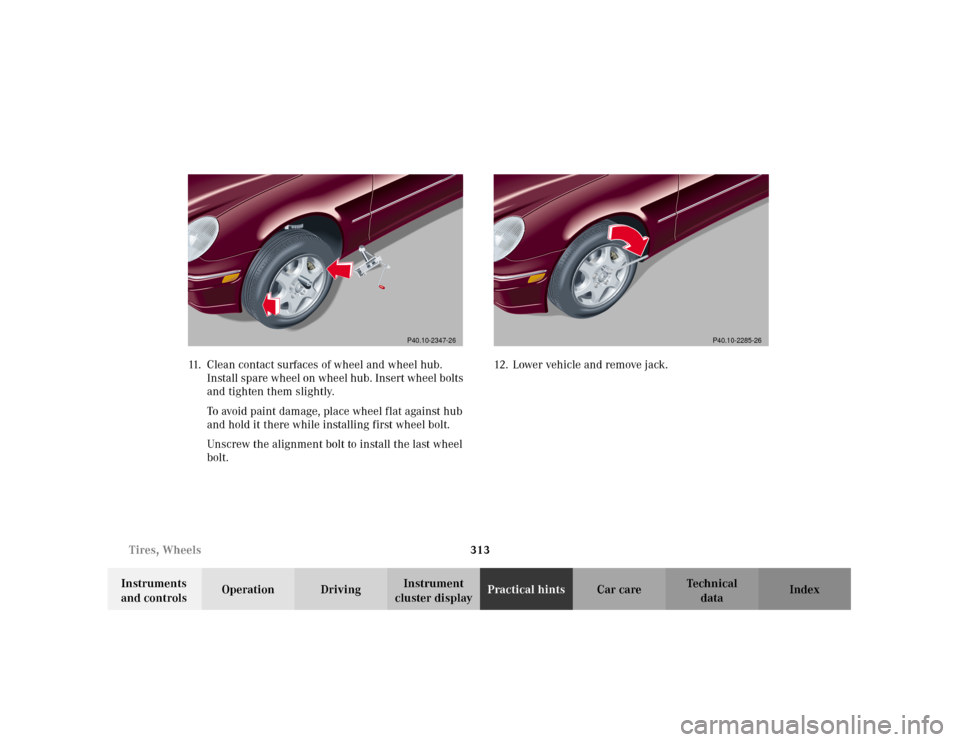

cluster displayPractical hintsCar care Index 11. Clean contact surfaces of wheel and wheel hub.

Install spare wheel on wheel hub. Insert wheel bolts

and tighten them slightly.

To avoid paint damage, place wheel flat against hub

and hold it there while installing first wheel bolt.

Unscrew the alignment bolt to install the last wheel

bolt.12. Lower vehicle and remove jack.

P40.10-2347-26

P40.10-2285-26

Page 324 of 381

315 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Notes:

Before storing the jack, it should be fully collapsed, with

handle folded in.

For proper storage of vehicle jack see page 304.Tire inflation pressure

A table (see fuel filler flap) lists the tire inflation

pressures specified for Mercedes-Benz recommended

tires as well as for the varying operating conditions.

Important!

Tire pressure changes by approximately 1.5 psi (0.1 bar)

per 18

°F (10

°C) of air temperature change. Keep this in

mind when checking tire pressure inside a garage –

especially in the winter.

Example:

If garage temperature = approximately +68

°F (+20

°C)

and ambient temperature = approximately +32

°F (0

°C)

then the adjusted air pressure = specified air pressure

+3 psi (+0.2 bar).

Tire pressures listed for light loads are minimum values

offering high driving comfort. Increased inflation

pressures for heavy loads produce favorable handling

characteristics with lighter loads and are perfectly

permissible. The ride of the vehicle, however, will

become somewhat harder.

Tire temperature and pressure increase with the vehicle

speed. Tire pressure should therefore only be checked

and corrected on cold tires. Correct tire pressure in

Wa r n i n g !

Always replace wheel bolts that are damaged or

rusted.Never apply oil or grease to wheel bolts.Damaged wheel hub threads should be repaired

immediately.Incorrect mounting bolts or improperly tightened

mounting bolts can cause the wheel to come off.

This could cause an accident. Be sure to use the

correct mounting bolts.