wheel bolts MERCEDES-BENZ C320 2001 W203 Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2001, Model line: C320, Model: MERCEDES-BENZ C320 2001 W203Pages: 381, PDF Size: 19.92 MB

Page 316 of 381

307 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index It is imperative that the wheel mounting bolts be

fastened to a tightening torque of 110 ft.lb. (150 Nm)

whenever wheels are mounted.

For rim and tire specifications, refer to “Technical Data”.Rotating wheels

The wheels can be rotated according to the degree of

tire wear while retaining the same direction of travel.

Rotating, however, should be carried out as

recommended by the tire manufacturer, before the

characteristic tire wear pattern (shoulder wear on front

wheels and tread center wear on rear wheels) becomes

visible, as otherwise the driving properties deteriorate.

Notes:

Thoroughly clean the inner side of the wheels any time

you rotate the wheels or wash the vehicle underside.

The use of retread tires is not recommended. Retread

tires may adversely affect the handling characteristics

and safety of the vehicle.

Dented or bent rims can cause tire pressure loss and

damage to the tire beads. For this reason, check rims for

damage at regular intervals. The rim flanges must be

checked for wear before a tire is mounted. Remove

burrs, if any.

Check and ensure proper tire inflation pressure after

rotating the wheels. For tire inflation pressure see

inside of fuel filler flap and also page 264.

Wa r n i n g !

Worn, old tires can cause accidents. If the tire tread

is badly worn, or if the tires have sustained

damage, replace them.When replacing rims, use only genuine

Mercedes-Benz wheel bolts specified for the

particular rim type. Failure to do so can result in

the bolts loosening and possibly an accident.

Page 320 of 381

311 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

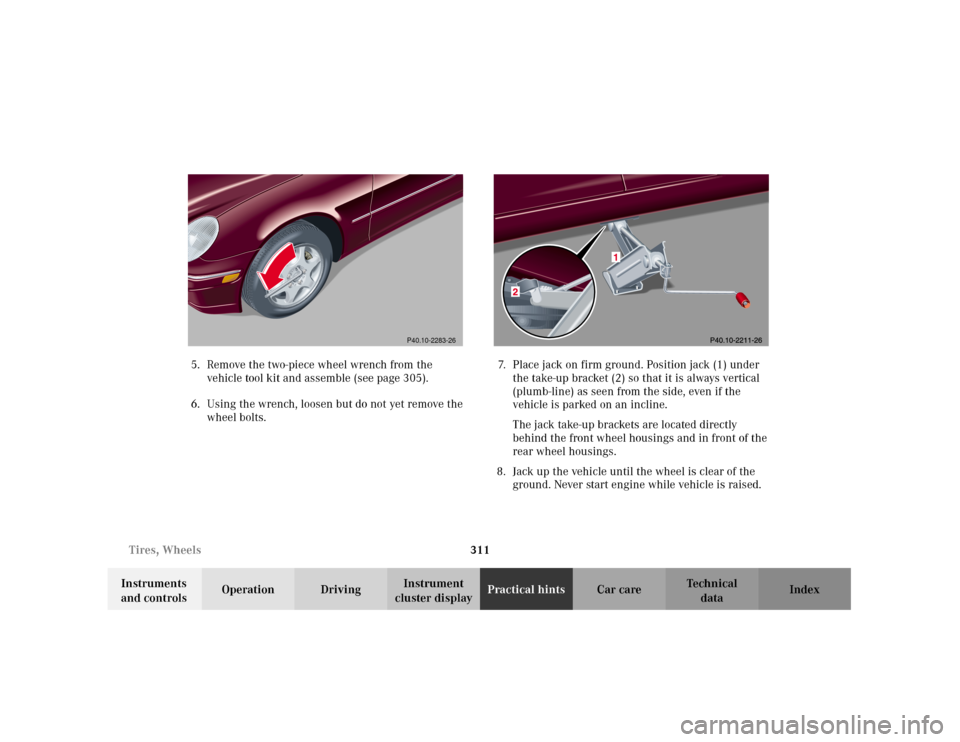

cluster displayPractical hintsCar care Index 5. Remove the two-piece wheel wrench from the

vehicle tool kit and assemble (see page 305).

6. Using the wrench, loosen but do not yet remove the

wheel bolts.7. Place jack on firm ground. Position jack (1) under

the take-up bracket (2) so that it is always vertical

(plumb-line) as seen from the side, even if the

vehicle is parked on an incline.

The jack take-up brackets are located directly

behind the front wheel housings and in front of the

rear wheel housings.

8. Jack up the vehicle until the wheel is clear of the

ground. Never start engine while vehicle is raised.

P40.10-2283-26

Page 321 of 381

312 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

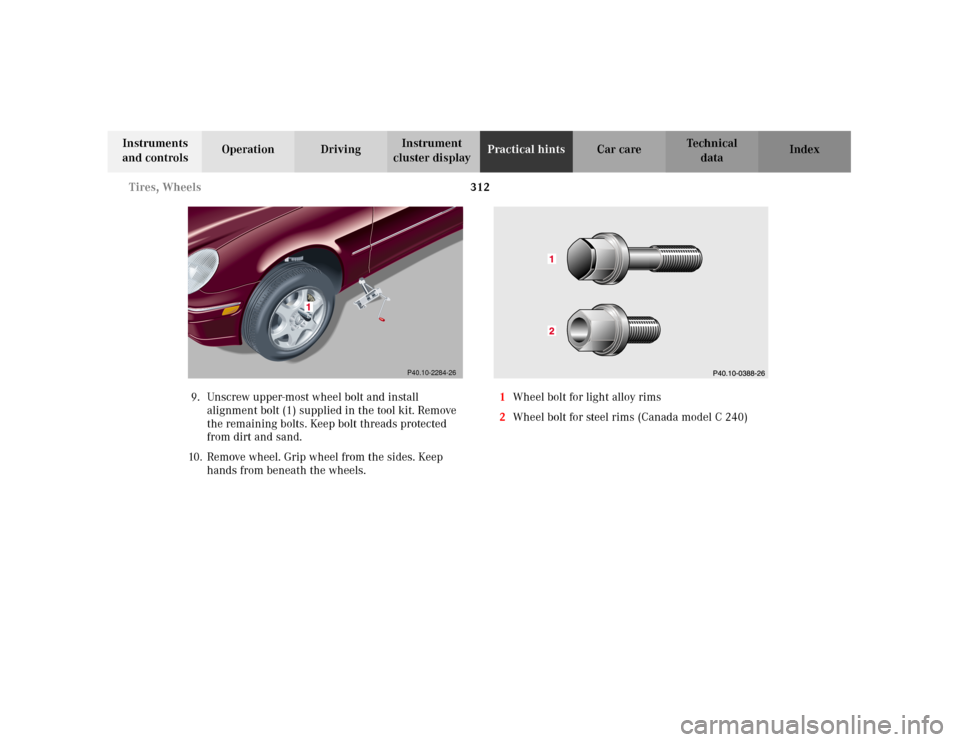

9. Unscrew upper-most wheel bolt and install

alignment bolt (1) supplied in the tool kit. Remove

the remaining bolts. Keep bolt threads protected

from dirt and sand.

10. Remove wheel. Grip wheel from the sides. Keep

hands from beneath the wheels.1Wheel bolt for light alloy rims

2Wheel bolt for steel rims (Canada model C 240)

P40.10-2284-26

Page 322 of 381

313 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

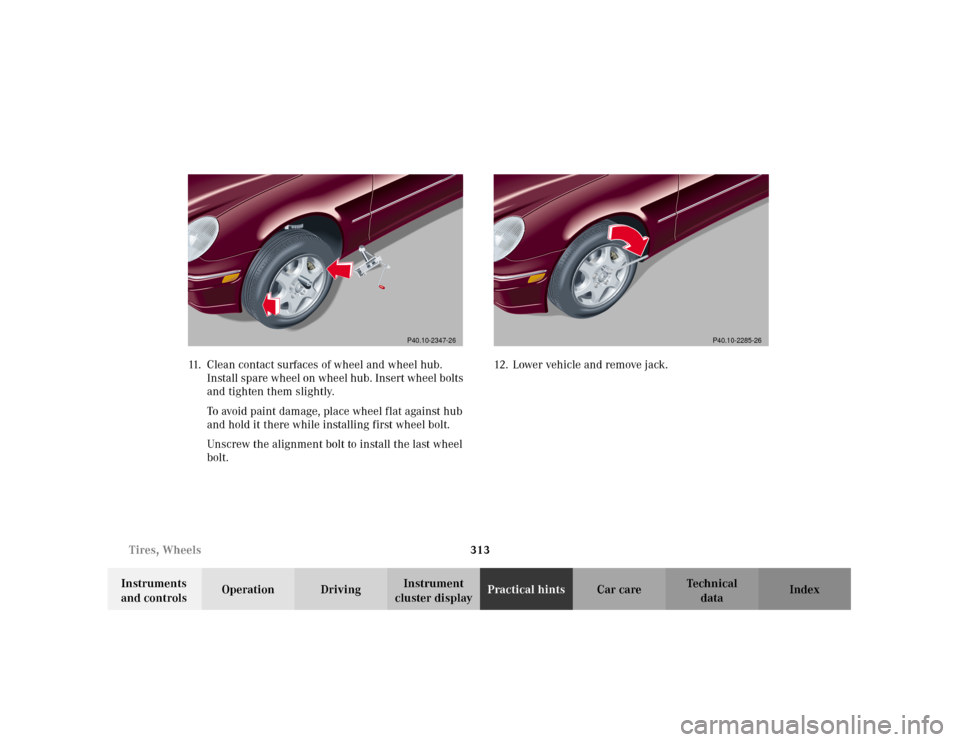

cluster displayPractical hintsCar care Index 11. Clean contact surfaces of wheel and wheel hub.

Install spare wheel on wheel hub. Insert wheel bolts

and tighten them slightly.

To avoid paint damage, place wheel flat against hub

and hold it there while installing first wheel bolt.

Unscrew the alignment bolt to install the last wheel

bolt.12. Lower vehicle and remove jack.

P40.10-2347-26

P40.10-2285-26

Page 323 of 381

314 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

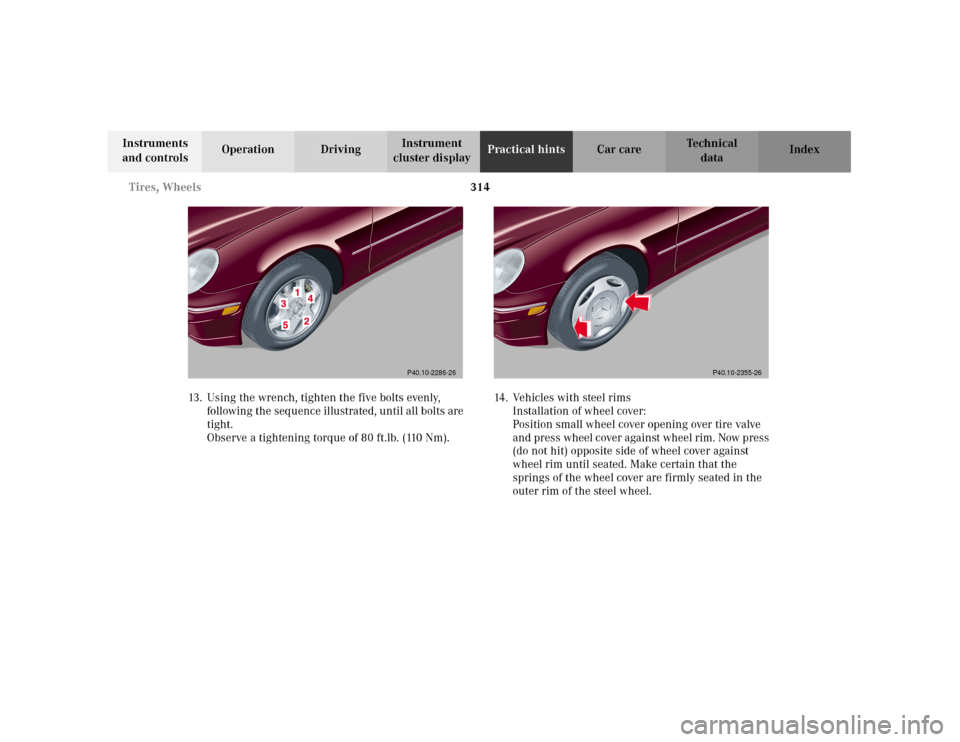

13. Using the wrench, tighten the five bolts evenly,

following the sequence illustrated, until all bolts are

tight.

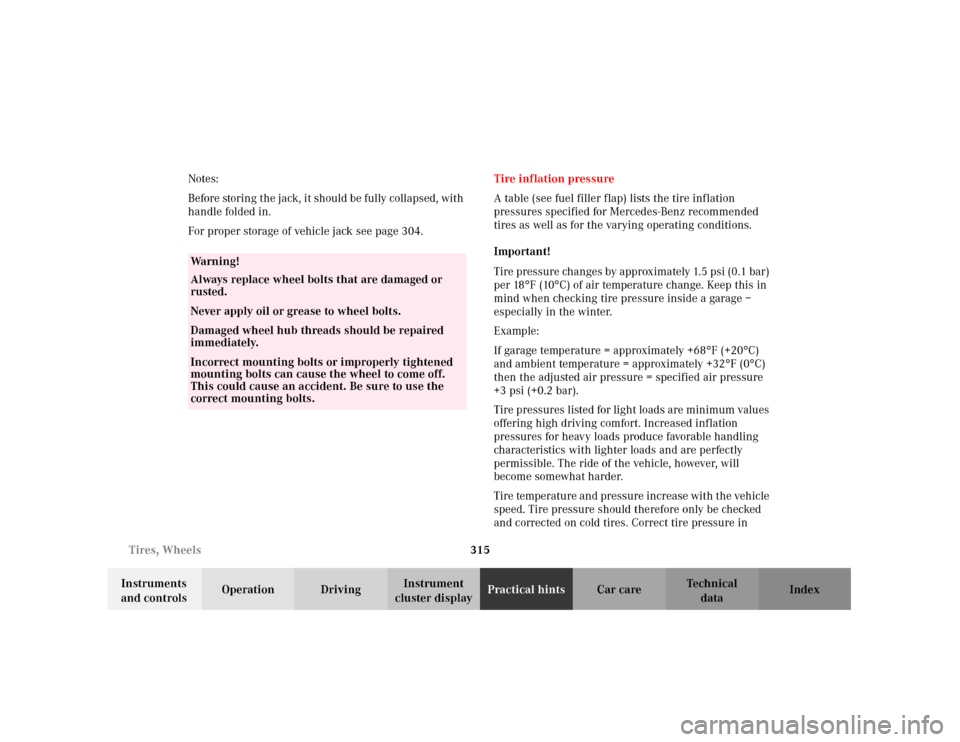

Observe a tightening torque of 80 ft.lb. (110 Nm).14. Vehicles with steel rims

Installation of wheel cover:

Position small wheel cover opening over tire valve

and press wheel cover against wheel rim. Now press

(do not hit) opposite side of wheel cover against

wheel rim until seated. Make certain that the

springs of the wheel cover are firmly seated in the

outer rim of the steel wheel.

P40.10-2286-26

P40.10-2355-26

Page 324 of 381

315 Tires, Wheels

Te ch n i c a l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Notes:

Before storing the jack, it should be fully collapsed, with

handle folded in.

For proper storage of vehicle jack see page 304.Tire inflation pressure

A table (see fuel filler flap) lists the tire inflation

pressures specified for Mercedes-Benz recommended

tires as well as for the varying operating conditions.

Important!

Tire pressure changes by approximately 1.5 psi (0.1 bar)

per 18

°F (10

°C) of air temperature change. Keep this in

mind when checking tire pressure inside a garage –

especially in the winter.

Example:

If garage temperature = approximately +68

°F (+20

°C)

and ambient temperature = approximately +32

°F (0

°C)

then the adjusted air pressure = specified air pressure

+3 psi (+0.2 bar).

Tire pressures listed for light loads are minimum values

offering high driving comfort. Increased inflation

pressures for heavy loads produce favorable handling

characteristics with lighter loads and are perfectly

permissible. The ride of the vehicle, however, will

become somewhat harder.

Tire temperature and pressure increase with the vehicle

speed. Tire pressure should therefore only be checked

and corrected on cold tires. Correct tire pressure in

Wa r n i n g !

Always replace wheel bolts that are damaged or

rusted.Never apply oil or grease to wheel bolts.Damaged wheel hub threads should be repaired

immediately.Incorrect mounting bolts or improperly tightened

mounting bolts can cause the wheel to come off.

This could cause an accident. Be sure to use the

correct mounting bolts.