MERCEDES-BENZ CL55AMG 2001 C215 Owner's Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2001, Model line: CL55AMG, Model: MERCEDES-BENZ CL55AMG 2001 C215Pages: 424, PDF Size: 27.87 MB

Page 351 of 424

345 Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Tire inflation pressure

A table (see fuel filler f lap) lists the tire inflation

pressures specified for Mercedes-Benz recommended

tires as well as for the varying operating conditions.

Important!

Tire pressure changes by approx. 1.5 psi (0.1 bar) per

18°F (10°C) of air temperature change. Keep this in

mind when checking tire pressure inside a garage –

especially in the winter.

Example:

If garage temperature = approx. +68°F (+20°C) and

ambient temperature = approx. +32°F (0°C) then the

adjusted air pressure = specified air pressure +3 psi

(+0.2 bar).Tire pressures listed for light loads are minimum values

offering high driving comfort. Increased inflation

pressures for heavy loads produce favorable handling

characteristics with lighter loads and are perfectly

permissible. The ride of the vehicle, however, will

become somewhat harder.

Tire temperature and pressure increase with the vehicle

speed. Tire pressure should therefore only be checked

and corrected on cold tires. Correct tire pressure in

warm tires only if pressure has dropped below the

pressure listed in the table and the respective operating

conditions are taken into consideration.

An underinf lated tire due to a slow leak (e.g. due to a

nail in the tire) may cause damage such as tread

separation, bulging etc.. Regular tire pressure checks

(including the spare tire) at intervals of no more than

14 days are therefore essential.

If a tire constantly loses air, it should be inspected for

damage.

Page 352 of 424

346 Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

The spare tire should be checked periodically for

condition and inflation. Spare tire will age and become

worn over time even if never used, and thus should be

inspected and replaced when necessary.Battery

Wa r n i n g !

Do not overinflate tires. Overinflating tires can

result in sudden deflation (blowout) because they

are more likely to become punctured or damaged

by road debris, potholes etc.. Follow recommended

inflation pressures.Do not overload the tires by exceeding the specified

vehicle capacity weight (as indicated by the label

on the driver’s door latch post). Overloading the

tires can overheat them, possibly causing a

blowout.

Wa r n i n g !

Failure to follow these instructions can result in

severe injury or death.Never lean over batteries while connecting, you

might get injured.Battery fluid contains sulfuric acid. Do not allow

this fluid to come in contact with eyes, skin or

cloth ing. In c ase it does, im mediately f lush affected

area with water and seek medical help if necessary.A battery will also produce hydrogen gas, which is

flammable and explosive. Keep flames or sparks

away from battery, avoid improper connection of

jumper cables, smoking etc..

Page 353 of 424

347 Battery

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

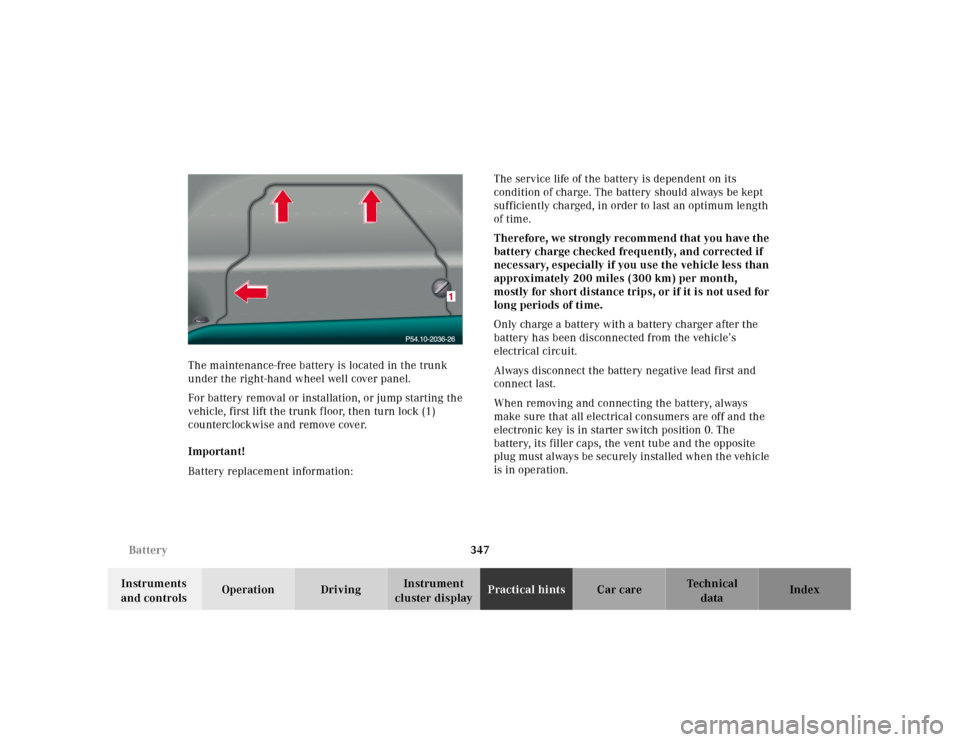

cluster displayPractical hintsCar care Index The maintenance-free battery is located in the trunk

under the right-hand wheel well cover panel.

For battery removal or installation, or jump starting the

vehicle, first lift the trunk f loor, then turn lock (1)

counterclockwise and remove cover.

Important!

Battery replacement information:The service life of the battery is dependent on its

condition of charge. The battery should always be kept

sufficiently charged, in order to last an optimum length

of time.

Therefore, we strongly recommend that you have the

battery charge checked frequently, and corrected if

necessary, especially if you use the vehicle less than

approximately 200 miles (300 km) per month,

mostly for sh ort di stance trips, or if it is not u sed for

long periods of time.

Only charge a battery with a battery charger after the

battery has been disconnected from the vehicle’s

electrical circuit.

Always disconnect the battery negative lead first and

connect last.

When removing and connecting the battery, always

make sure that all electrical consumers are off and the

electronic key is in starter switch position 0. The

battery, its filler caps, the vent tube and the opposite

plug must always be securely installed when the vehicle

is in operation.

Page 354 of 424

348 Battery

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

While the engine is running the battery terminal clamps

must not be loosened or detached, otherwise the

generator and other electronic components would be

damaged.

Note:

After reconnecting the battery also set the clock (see

COMAND operator’s manual) resynchronize the express

feature of the power windows (see page 180), the

sliding/pop-up roof (see page 183), and the electronic

stability program (see page 272).Battery recycling

Batteries contain materials that can harm the

environment with improper disposal.

Large 12 Volt storage batteries contain lead.

Recycling of batteries is the preferred method of

disposal.

Many states require sellers of batteries to accept old

batteries for recycling.

Page 355 of 424

349 Jump starting

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Jump startingImportant!

A discharged battery can freeze at approx. +14°F

(–10°C). In that case, it must be thawed out before

jumper cables are used. Attempting to jump start a

frozen battery can result in it exploding, causing

personal injury.

Jumper cable specifications:

•Minimum cable cross-section of 25 mm

2 or

approx. 2 AWG

•Maximum length of 11.5 ft. (3.5 m).

If th e battery is discha rged, th e eng ine shoul d be started

with jumper cables and the (12 V) battery of another

vehicle.

Only use 12 V battery to jump start your vehicle. Jump

starting with more powerful battery could damage the

vehicle’s electrical systems, which will not be covered

by the Mercedes-Benz Limited Warranty.

The battery is located in the trunk under the right-hand

wheel well cover panel.

Wa r n i n g !

Failure to follow these directions will cause

damage to the electronic components, and can lead

to a battery explosion and severe injury or death.Never lean over batteri es wh ile connec ting or jump

starting, you might get injured.Battery fluid contains sulfuric acid. Do not allow

this fluid to come in contact with eyes, skin or

cloth ing. In c ase it does, imm edi ately f lu sh af fec ted

area with water, and seek medical help if

necessary.A battery will also produce hydrogen gas, which is

flammable and very explosive. Keep flames or

sparks away from battery, avoid improper

connection of jumper cables, smoking etc..Read all instructions before proceeding.

Page 356 of 424

350 Jump starting

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Proceed as follows:

1. Position the vehicle with the charged battery so that

the jumper cables will reach, but never let the

vehicles touch. Make sure the jumper cables do not

have loose or missing insulation.

2. On both vehicles:

•Turn off engine and all lights and accessories,

except hazard warning flashers or work lights.

•Apply parking brake and shift selector lever to

position “P”.

Important!

3. Clamp one end of the first jumper cable to the

positive (+) terminal of the discharged battery and

the other end to the positive (+) terminal of the

charged battery. Make sure the cable clamps do not

touch any other metal parts.

4. Clamp one end of the second jumper cable to the

grounded negative (–) terminal of the charged

battery and the final connection to the negative (–)

under hood terminal of the disabled vehicle.Important!

5. Start engine of the vehicle with the charged battery

and run at high idle. Make sure the cables are not

on or near pulleys, fans, or other parts that move

when the engine is started. Allow the discharged

battery to charge for a few minutes. Start engine of

the disabled vehicle in the usual manner.

6. After the engine has started, remove jumper cables

by exactly reversing the above installation

sequence, starting with the last connection made

first. When removing each clamp, make sure that it

does not touch any other metal while the other end

is still attached.

Notes:

If engine does not run after several unsuccessful

starting attempts, have it checked at the nearest

authorized Mercedes-Benz Center.

Excessive unburned fuel may damage the catalytic

converter.

Page 357 of 424

351 Towing the vehicle

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Towing the vehicleImportant!

When towing the vehicle, please, note the following:

With the automatic central locking activated and the

electronic key in starter switch position 2 (vehicles with

KEYLESS-GO: in “On” position, see page 224), the

vehicle doors lock if the left front wheel as well as the

rig ht rear wh eel a re turning a t vehicle speeds of approx.

9 mph (15 km/h) or more.

To prevent the vehicle door locks from locking,

deactivate the automatic central locking. See

“VEHICLE” under “Individual settings” on page 144.

Towing of the vehicle should only be done using the

properly installed towing eye bolt. Never attach tow

cable, tow rope or tow rod to vehicle chassis, frame

or suspension parts.

Note:

The selec tor lever will rem ain l ocked in position “P” and

the electronic key could not be turned in the starter

switch if the battery is disconnected or discharged. See

battery on page 346 or jump starting on page 349.

Wa r n i n g !

Prior to towing the vehicle with all wheels on the

ground, make certain that the electronic key is in

starter switch position 2.If the electronic key is left in the starter switch

position 0 for an extended period of time, it can no

longer be turned in the switch. In this case, the

steering i s locked. To unlock, rem ove elec tronic key

from starter switch and reinsert.

Page 358 of 424

352 Towing the vehicle

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

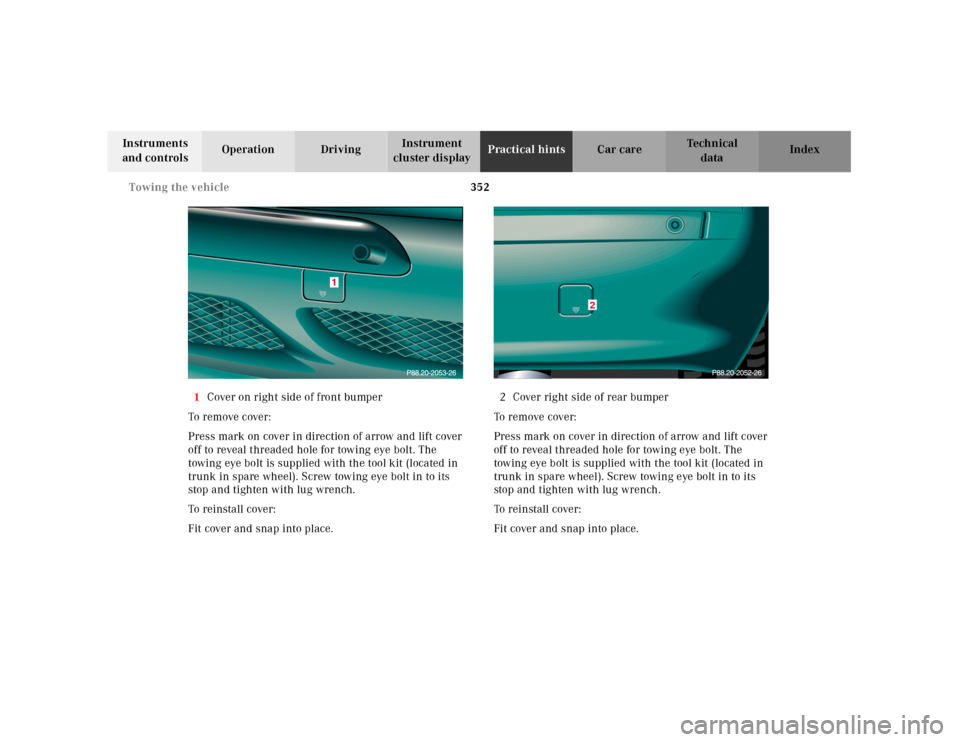

1Cover on right side of front bumper

To remove cover:

Press mark on cover in direction of arrow and lift cover

off to reveal threaded hole for towing eye bolt. The

towing eye bolt is supplied with the tool kit (located in

trunk in spare wheel). Screw towing eye bolt in to its

stop and tighten with lug wrench.

To reinstall cover:

Fit cover and snap into place.2 Cover right side of rear bumper

To remove cover:

Press mark on cover in direction of arrow and lift cover

off to reveal threaded hole for towing eye bolt. The

towing eye bolt is supplied with the tool kit (located in

trunk in spare wheel). Screw towing eye bolt in to its

stop and tighten with lug wrench.

To reinstall cover:

Fit cover and snap into place.

2

Page 359 of 424

353 Towing the vehicle

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index We recommend that the vehicle be transported using

flat bed equipment. This method is preferable to other

types of towing.

Important!

To prevent damage du ri ng transport, do not ti e down

vehicle by its chassis or suspension parts.

The vehicle may be towed with all wheels on the ground

and the selector lever in position “N” for distances up to

30 miles (50 km) and at a speed not to exceed 30 mph

(50 km/h). The electronic key must be in starter switch

position 2.

To be certain to avoid a possibility of damage to the

transmission, however, we recommend the drive shaft

be disconnected at the rear axle drive f lange for any

towing beyond a short tow to a nearby garage.

Do not tow with sling-type equipment. Towing with

sling-type equipment over bumpy roads will damage

radiator and supports.

Use wheel lift, dolly, or flat bed equipment, with

electronic key in starter switch turned to position 0.Note:

To signal turns while being towed with hazard warning

flasher in use, turn electronic key in starter switch to

position 2 and activate combination switch for left or

right turn signal in usual manner – only the selected

turn signal will operate.

Upon canceling the turn signal, the hazard warning

f lasher will operate again.

Caution!

If the vehicle is towed with the front axle raised, the

engine must be shut off (electronic key in starter switch

position 0 or 1). Otherwise, the ESP will immediately be

engaged and will apply the rear wheel brakes.

Switch off the tow-away alarm (see “VEHICLE” under

“Individual settings” on page 144) as well as the ESP

(see page 273).

Wa r n i n g !

With the engine not running, there is no power

assistance for the braking and steering systems. In

this case, it is important to keep in mind that a

considerably higher degree of effort is necessary to

brake and steer the vehicle.

Page 360 of 424

354 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Exterior lamps

Headlamp adjustment

Correct headlamp adjustment is extremely important.

Check and readjust headlamps at regular intervals and

when a bulb has been replaced.Replacing bulbs

Notes:

To prevent a possible electrical short circuit, switch off

lamp prior to replacing a bulb.

When replacing bulbs, install only 12 volt bulbs with

the specified watt rating.

When replacing halogen bulbs do not touch glass

portion of bulb with bare hands. Use plain paper or a

clean cloth.

If the newly installed bulb does not light up, switch the

lamp off and on again. If the bulb still does not light up,

have the system checked at an authorized

Mercedes-Benz Center.

Wa r n i n g !

Bulbs and bulb holders can be very hot. Allow the

lamp to cool down before changing a bulb.

Halogen lamps contain pressurized gas. A bulb can

explode if you:

• touch or move it when hot,

•drop the bulb,

• scratch the bulb.Wear eye and hand protection.

Wa r n i n g !

Because of high voltage in Xenon lamps, it is

dangerous to replace the bulb or repair the lamp

and its components. We recommend that you have

such work done by a qualified technician.