lock MERCEDES-BENZ CLA 2013 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2013, Model line: CLA, Model: MERCEDES-BENZ CLA 2013Pages: 352, PDF Size: 5.37 MB

Page 313 of 352

the combination switch, the hazard warn-

ing lamps start flashing again.

Vehicles with automatic transmission: the

automatic transmission automatically shifts

to position P when you open the driver's or

front-passenger door or when you remove the

key from the ignition lock. In order to ensure

that the automatic transmission stays in posi-

tion N when towing the vehicle, you must

observe the following points:XMake sure that the vehicle is stationary.XTurn the key to position 2 in the ignition

lock.XDepress and hold the brake pedal.XShift the automatic transmission to posi-

tion N.

Vehicles with manual transmission:

XTurn the key to position 2 in the ignition

lock.XDepress and hold the brake pedal.XDepress the clutch pedal fully and shift to

neutral.

Vehicles with manual or automatic trans-

mission:

XLeave the key in position 2 in the ignition

lock.XRelease the brake pedal.XRelease the electric parking brake.XSwitch on the hazard warning lamps

( Y page 110).

It is important that you observe the safety

instructions when towing away your vehicle

( Y page 308).

Transporting the vehicle

! You may only secure the vehicle by the

wheels, not by parts of the vehicle such as

axle or steering components. Otherwise,

the vehicle could be damaged.

XVehicles with manual transmission:

depress the clutch pedal fully and shift to

neutral.XVehicles with automatic transmission:

turn the key to position 2 in the ignition

lock.XMove the transmission to position N.

As soon as the vehicle is loaded:

XPrevent the vehicle from rolling away by

applying the electric parking brake.XVehicles with manual transmission:

depress the clutch pedal fully and engage

first or reverse gear.XVehicles with automatic transmission:

shift the transmission to position P.XTurn the key to position 0 in the ignition

lock and remove it.XSecure the vehicle.

The towing eyes or trailer tow hitch can be

used to pull the vehicle onto a trailer or trans-

porter if you wish to transport it.

Tow-starting (emergency engine

starting)

! Do not tow-start vehicles with automatic

transmission. You could otherwise damage

the automatic transmission.

Before tow-starting the following conditions

must be fulfilled:

R the battery is connected.

R the engine has cooled down.

R the exhaust system has cooled down.

XSwitch on the hazard warning lamps

( Y page 110).XFit the towing eye ( Y page 310).XSecure the rigid towing bar or the towing

rope.XDepress and hold the brake pedal.XTurn the key to position 2 in the ignition

lock.Towing and tow-starting311Breakdown assistanceZ

Page 314 of 352

XDepress the clutch pedal fully and shift to

neutral.XRelease the brake pedal.XTow-start the vehicle.XDepress the clutch pedal fully and engage

second gear.XRelease the clutch pedal slowly without

depressing the accelerator pedal.

The engine is started.XDepress the clutch pedal fully and shift to

neutral.XStop at a suitable place.XSecure the vehicle by applying the electric

parking brake.XRemove the rigid towing bar or towing rope.XRemove the towing eye ( Y page 310).XSwitch off the hazard warning lamps.

When tow-starting, it is important that you

observe the safety notes (Y page 308) and the

legal requirements in each respective coun-

try.

Electrical fuses

Important safety notes

GWARNING

If you manipulate, bridge or replace a faulty

fuse with a fuse of a higher amperage, the

electric cables could be overloaded. This may

result in a fire. There is a risk of an accident

and injury.

Always replace faulty fuses with specified new

fuses of the correct amperage.

! Only use fuses that have been approved

for Mercedes-Benz vehicles and which

have the correct fuse rating for the system

concerned. Only use fuses marked with an

"S". Components or systems could other-

wise be damaged.

The fuses in your vehicle serve to disconnect

faulty circuits. If a fuse blows, all the compo-

nents on the circuit and their functions will

fail.

Blown fuses must be replaced with fuses of

the same rating, which you can recognise by

the colour and fuse rating. The fuse ratings

are listed in the fuse allocation chart.

If the newly inserted fuse also blows, have the

cause traced and rectified at a qualified spe-

cialist workshop, e.g. a Mercedes-Benz

Service Centre.

Before replacing a fuse

XSecure the vehicle against rolling away

( Y page 162).XSwitch off all electrical consumers.XTurn the key to position 0 in the ignition

lock and remove it ( Y page 145). All indi-

cator lamps in the instrument cluster must

be off.

The fuses are located in various fuse boxes:

R fuse box in the engine compartment on the

left-hand side of the vehicle, when viewed

in the direction of travel

R fuse box in the front-passenger footwell

The fuse allocation chart is on the fuse box in

the front-passenger footwell ( Y page 313).

Fuse box in the engine compartment

GWARNING

When the bonnet is open, and the windscreen

wipers are set in motion, you can be injured

by the wiper linkage. There is a risk of injury.

Always switch off the windscreen wipers and

the ignition before opening the bonnet.

! Make sure that no moisture can enter the

fuse box when the cover is open.

! When closing the cover, make sure that it

is lying correctly on the fuse box. Moisture

seeping in or dirt could otherwise impair

the operation of the fuses.

312Electrical fusesBreakdown assistance

Page 315 of 352

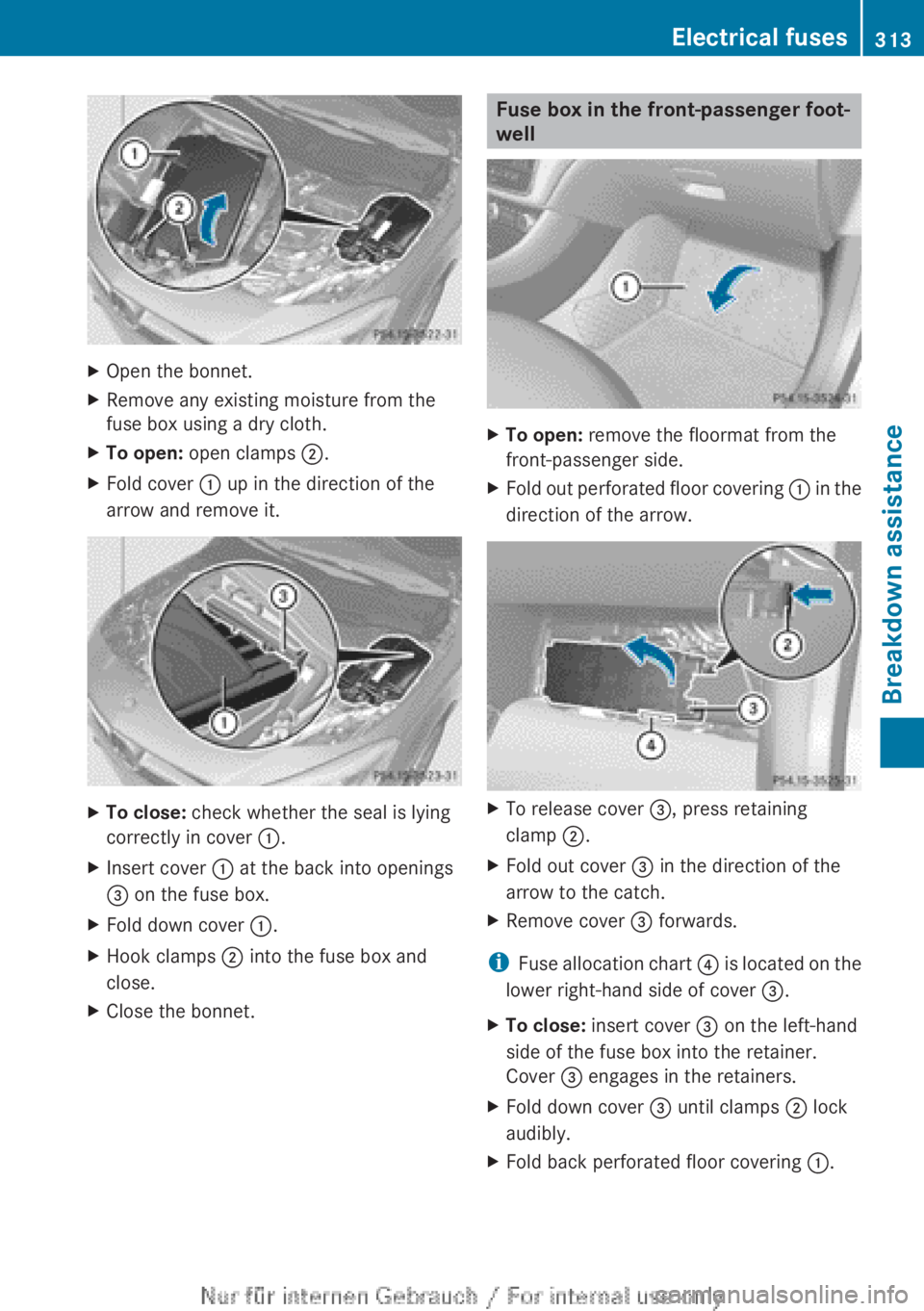

XOpen the bonnet.XRemove any existing moisture from the

fuse box using a dry cloth.XTo open: open clamps ;.XFold cover : up in the direction of the

arrow and remove it.XTo close: check whether the seal is lying

correctly in cover :.XInsert cover : at the back into openings

= on the fuse box.XFold down cover :.XHook clamps ; into the fuse box and

close.XClose the bonnet.Fuse box in the front-passenger foot-

wellXTo open: remove the floormat from the

front-passenger side.XFold out perforated floor covering : in the

direction of the arrow.XTo release cover =, press retaining

clamp ;.XFold out cover = in the direction of the

arrow to the catch.XRemove cover = forwards.

i

Fuse allocation chart ? is located on the

lower right-hand side of cover =.

XTo close: insert cover = on the left-hand

side of the fuse box into the retainer.

Cover = engages in the retainers.XFold down cover = until clamps ; lock

audibly.XFold back perforated floor covering :.Electrical fuses313Breakdown assistanceZ

Page 319 of 352

wheels and tyres for damage. Hidden tyre

damage could also be causing the unusual

handling characteristics. If you find no

signs of damage, have the wheels and tyres

checked at a qualified specialist workshop.

R When parking your vehicle, make sure that

the tyres do not get deformed by the kerb

or other obstacles. If it is necessary to drive

over kerbs, speed humps or similar eleva-

tions, try to do so slowly and at an obtuse

angle. Otherwise, the tyres, particularly the

sidewalls, may be damaged.

Regular checking of wheels and tyres

GWARNING

Damaged tyres can cause tyre inflation pres-

sure loss. As a result, you could lose control

of your vehicle. There is a risk of accident.

Check the tyres regularly for signs of damage

and replace any damaged tyres immediately.

Regularly check the wheels and tyres of your

vehicle for damage at least once a month, as

well as after driving off-road or on rough

roads. Damaged wheels can cause a loss of

tyre pressure. Pay particular attention to

damage such as:

R cuts in the tyres

R punctures

R tears in the tyres

R bulges on tyres

R deformation or severe corrosion on wheels

Regularly check the tyre tread depth and the

condition of the tread across the whole width

of the tyre ( Y page 317). If necessary, turn

the front wheels to full lock in order to inspect

the inner side of the tyre surface.

All wheels must have a valve cap to protect

the valve against dirt and moisture. Do not fit

anything onto the valve other than the stand-

ard valve cap or other valve caps approved by

Mercedes-Benz for your vehicle. Do not fit any

other valve caps or systems, e.g. tyre pres-

sure monitoring systems.

Regularly check the pressure of all the tyres,

particularly prior to long trips. Adjust the tyre

pressure as necessary ( Y page 319).

Observe the notes on the emergency spare

wheel ( Y page 331).

The service life of tyres depends on various

factors, including the following:

R Driving style

R Tyre pressure

R Mileage

Important safety notes on the tyre

tread

GWARNING

Insufficient tyre tread will reduce tyre trac-

tion. The tyre is no longer able to dissipate

water. This means that on wet road surfaces,

the risk of aquaplaning increases, in particular

where speed is not adapted to suit the driving

conditions. There is a risk of accident.

If the tyre pressure is too high or too low, tyres

may exhibit different levels of wear at differ-

ent locations on the tyre tread. Thus, you

should regularly check the tread depth and

the condition of the tread across the entire

width of all tyres.

Minimum tyre tread depth for:

R summer tyres: 3 mm

R M+S tyres: 4 mm

For safety reasons, replace the tyres before

the legally prescribed limit for the minimum

tyre tread depth is reached..

Selecting, fitting and replacing tyres

R Only fit tyres and wheels of the same type

and make.

Exception: it is permissible to fit a different

type or make in the event of a flat tyre.

Observe the "MOExtended tyres (tyres with

Operation317Wheels and tyresZ

Page 323 of 352

iThe tyre pressure values given for low

loads are minimum values which offer you

good ride comfort characteristics.

However, you can also use the values given

for higher loads. These are permissible and

will not adversely affect the running of the

vehicle.

Tyre pressure loss warning system

General notes

While the vehicle is in motion, the tyre pres-

sure loss warning system monitors the set

tyre pressure using the rotational speed of

the wheels. This enables the system to detect

significant pressure loss in a tyre. If the speed

of rotation of a wheel changes as a result of

a loss of pressure, a corresponding warning

message will appear in the multifunction dis-

play.

You can recognise the tyre pressure loss

warning by the Run Flat Indicator

active Restart with OK message which

appears in the Service menu of the multi-

function display. Further information on the

message display can be found under "Restart-

ing the tyre pressure loss warning system"

( Y page 321).

Important safety notes

The tyre pressure warning system does not

warn you of an incorrectly set tyre pressure.

Observe the notes on the recommended tyre

pressure ( Y page 319).

The tyre pressure loss warning does not

replace the need to regularly check the tyre

pressures. An even loss of pressure on sev-

eral tyres at the same time cannot be detec-

ted by the tyre pressure loss warning system.

The tyre pressure monitor is not able to warn

you of a sudden loss of pressure, e.g. if the

tyre is penetrated by a foreign object. In the

event of a sudden loss of pressure, bring the

vehicle to a halt by braking carefully. Avoid

abrupt steering manoeuvres.

The function of the tyre pressure loss warning

system is limited or delayed if:

R snow chains are fitted to your vehicle's

tyres.

R road conditions are wintry.

R you are driving on sand or gravel.

R you adopt a very sporty driving style (cor-

nering at high speeds or driving with high

rates of acceleration).

R you are towing a very heavy or large trailer.

R you are driving with a heavy load (in the

vehicle or on the roof).

Restarting the tyre pressure loss warn-

ing system

Restart the tyre pressure loss warning system

if you have:

R changed the tyre pressure

R changed the wheels or tyres

R fitted new wheels or tyres

XBefore restarting, make sure that the tyre

pressures are set properly on all four tyres

for the respective operating conditions.

The recommended tyre pressures can be

found in the table on the fuel filler flap.

The tyre pressure loss warning system can

only give reliable warnings if you have set

the correct tyre pressure. If an incorrect

tyre pressure is set, these incorrect values

will be monitored.XObserve the notes in the section on tyre

pressures ( Y page 319).XMake sure that the key is in position 2 in

the ignition lock ( Y page 145).XPress = or ; on the steering wheel

to select the Service menu.XPress the 9 or : button to select

Tyre press. .XPress the a button.

The Run Flat Indicator active

Restart with OK message appears in the

multifunction display.Tyre pressure321Wheels and tyresZ

Page 325 of 352

pressure warning lamp to inform you of the

malfunction by flashing for approximately one

minute and then remaining lit. When the fault

has been rectified, the tyre pressure warning

lamp goes out after you have driven for a few

minutes.

The tyre pressure values indicated by the on-

board computer may differ from those meas-

ured at a filling station using a pressure

gauge. The tyre pressures shown by the on-

board computer refer to those measured at

sea level. At high altitudes, the tyre pressure

values indicated by a pressure gauge are

higher than those shown by the on-board

computer. In this case, do not reduce the tyre

pressures.

The operation of the tyre pressure monitor

can be affected by interference from radio

transmitting equipment (e.g. radio head-

phones, two-way radios) that may be being

operated in or near the vehicle.

Checking the tyre pressure electroni-

callyXMake sure that the key is in position 2 in

the ignition lock ( Y page 145).XPress the = or ; button on the steer-

ing wheel to select the Service menu.XPress the 9 or : button to select

Tyre pressure .XPress the a button.

The current tyre pressure for each wheel

will be displayed in the multifunction dis-

play.

If the vehicle has been parked for over

20 minutes, the Tyre pressures will be

displayed after a few minutes of

driving message appears.

After a teach-in period, the tyre pressure

monitor automatically recognises new

wheels or new sensors. As long as a clear

allocation of the tyre pressure values to the

individual wheels is not possible, the Tyre

pressure monitor active display mes-

sage is shown instead of the tyre pressure

display. The tyre pressures are already being

monitored.

i If an emergency spare wheel is fitted, the

system may continue to show the tyre pres-

sure of the wheel that has been removed

for a few minutes. If this occurs, note that

the value displayed for the position where

the spare wheel is fitted is not the same as

the current tyre pressure of the emergency

spare wheel.

Warning messages of the tyre pressure

monitor

If the tyre pressure monitor detects a pres-

sure loss in one or more tyres, a warning mes-

sage is shown in the multifunction display and

the yellow tyre pressure monitor warning light

comes on.

R If the Please correct tyre pressure

message appears in the multifunction dis-

play, the tyre pressure in at least one tyre

is too low and must be corrected at the next

opportunity.

R If the Tyre pressure Check tyre(s)

message appears in the multifunction dis-

play, the tyre pressure in one or more tyres

has dropped significantly and the tyres

must be checked.

R If the Tyre pressure Caution, tyre

defect message appears in the multifunc-

tion display, the tyre pressure in one or

more tyres has dropped suddenly and the

tyres must be checked.

Observe the instructions and safety notes in

the display messages in the "Tyres" section

( Y page 248).

i If the wheel positions on the vehicle are

interchanged, the tyre pressures may be

displayed for the wrong positions for a

short time. This is rectified after a few

minutes of driving and the tyre pressures

are displayed for the correct positions.

Tyre pressure323Wheels and tyresZ

Page 326 of 352

Restarting the tyre pressure monitor

When you restart the tyre pressure monitor,

all existing warning messages are deleted and

the warning lamps go out. The monitor uses

the currently set tyre pressures as the refer-

ence values for monitoring. In most cases, the

tyre pressure monitor will automatically

detect the new reference values after you

have changed the tyre pressure. However,

you can also define reference values man-

ually as described here. The tyre pressure

monitor then monitors the new tyre pressure

values.

XUse the table on the inside of the fuel filler

flap to ensure that the tyre pressure is set

correctly in all four tyres for the current

operating conditions.

Also observe the notes in the section on

tyre pressures ( Y page 319).XMake sure that the key is in position 2 in

the ignition lock.XPress the = or ; button on the steer-

ing wheel to select the Service menu.XPress the 9 or : button to select

Tyre pressure .XPress the a button.

The multifunction display shows the cur-

rent tyre pressure for the individual tyres or

the Tyre pressures will be dis‐

played after a few minutes of driv‐

ing message.XPress the : button.

The Use current pressures as new

reference values message appears in

the multifunction display.

If you wish to confirm the restart:

XPress the a button.

The Tyre press. monitor restarted

message appears in the multifunction dis-

play.

After you have driven for a few minutes, the

system checks whether the current tyre

pressures are within the specified range.The new tyre pressures are then accepted

as reference values and monitored.

If you wish to cancel the restart:

XPress the % button.

The tyre pressure values stored at the last

restart will continue to be monitored.

Changing a wheel

Flat tyre

You can find information on what to do in the

event of flat tyre in the "Flat tyre" section

( Y page 298). Information on driving with

MOExtended tyres in the event of a flat tyre

can be found under "Breakdown assistance"

( Y page 298).

Vehicles with an emergency spare

wheel: in the event of a flat tyre, the emer-

gency spare wheel is fitted according to the

description under "Fitting a wheel"

( Y page 325).

Interchanging the wheels

GWARNING

Interchanging the front and rear wheels may

severely impair the driving characteristics if

the wheels or tyres have different dimensions.

The wheel brakes or suspension components

may also be damaged. There is a risk of acci-

dent.

Interchange front and rear wheels only if the

wheels and tyres are of the same dimensions.

! On vehicles fitted with a tyre pressure

monitor, electronic components are loca-

ted in the wheel.

Tyre-fitting tools should not be applied in

the area of the valve, as this could damage

the electronic components.

Only have tyres changed at a qualified spe-

cialist workshop.

324Changing a wheelWheels and tyres

Page 327 of 352

Interchanging the front and rear wheels of

differing dimensions can render the general

operating permit invalid.

Always pay attention to the instructions and

safety notes when changing a wheel

( Y page 324).

The wear patterns on the front and rear tyres

differ, depending on the operating conditions.

Interchange the wheels before a clear wear

pattern has formed on the tyres. Front tyres

typically wear more on the shoulders and the

rear tyres in the centre.

On vehicles that have the same size front and

rear wheels, you can interchange the wheels

every 5,000 to 10,000 km depending on the

degree of tyre wear. Ensure the direction of

rotation is maintained.

Clean the contact surfaces of the wheel and

the brake disc thoroughly every time a wheel

is interchanged. Check the tyre pressure and,

if necessary, restart the tyre pressure loss

warning system or the tyre pressure monitor.

Direction of rotation

Tyres with a specified direction of rotation

have additional benefits, e.g. if there is a risk

of aquaplaning. You will only gain these ben-

efits if the correct direction of rotation is

observed.

An arrow on the sidewall of the tyre indicates

its correct direction of rotation.

Storing wheels

Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the

tyres against oil, grease, petrol and diesel.

Cleaning the wheels

GWARNING

The water jet of circular-jet nozzles (dirt grind-

ers) can cause damage not visible from the

outside to tyres or chassis components. Com-

ponents damaged in this way can unexpect-

edly fail. There is a risk of an accident.

Do not use high-pressure cleaners with circu-

lar-jet nozzles to clean the vehicle. Have dam-

aged tyres or chassis components replaced

immediately.

Fitting a wheel

Preparing the vehicle

XStop the vehicle on solid, non-slippery and

level ground.XApply the electric parking brake manually

( Y page 163).XBring the front wheels into the straight-

ahead position.XVehicles with manual transmission:

fully depress the clutch pedal and engage

first or reverse gear.XVehicles with automatic transmission:

move the DIRECT SELECT lever to P.XSwitch off the engine.XRemove the key from the ignition lock.XIf a trailer is coupled to the vehicle, uncou-

ple it.XIf included in the vehicle equipment,

remove the tyre-change tool kit from the

vehicle.XSecure the vehicle to prevent it from rolling

away.

i Apart from certain country-specific varia-

tions, vehicles are not equipped with a tyre-

change tool kit. For information on which

tools are required to perform a wheel

change on your vehicle, consult a

Mercedes-Benz Service Centre.

Necessary wheel-changing tools can

include, for example:

R Jack

R Wheel chock

R Wheel wrench

Changing a wheel325Wheels and tyresZ

Page 329 of 352

Rthe jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a

large, load-bearing underlay must be used.

On a slippery surface, a non-slip underlay

must be used, e.g. rubber mats.

R do not use wooden blocks or similar

objects as a jack underlay. Otherwise, the

jack will not be able to achieve its load-

bearing capacity due to the restricted

height.

R make sure that the distance between the

underside of the tyres and the ground does

not exceed 3 cm.

R never place your hands or feet under the

raised vehicle.

R never lie under the raised vehicle.

R never start the engine when the vehicle is

raised.

R never open or close a door or the boot lid

when the vehicle is raised.

R make sure that no persons are present in

the vehicle when the vehicle is raised.

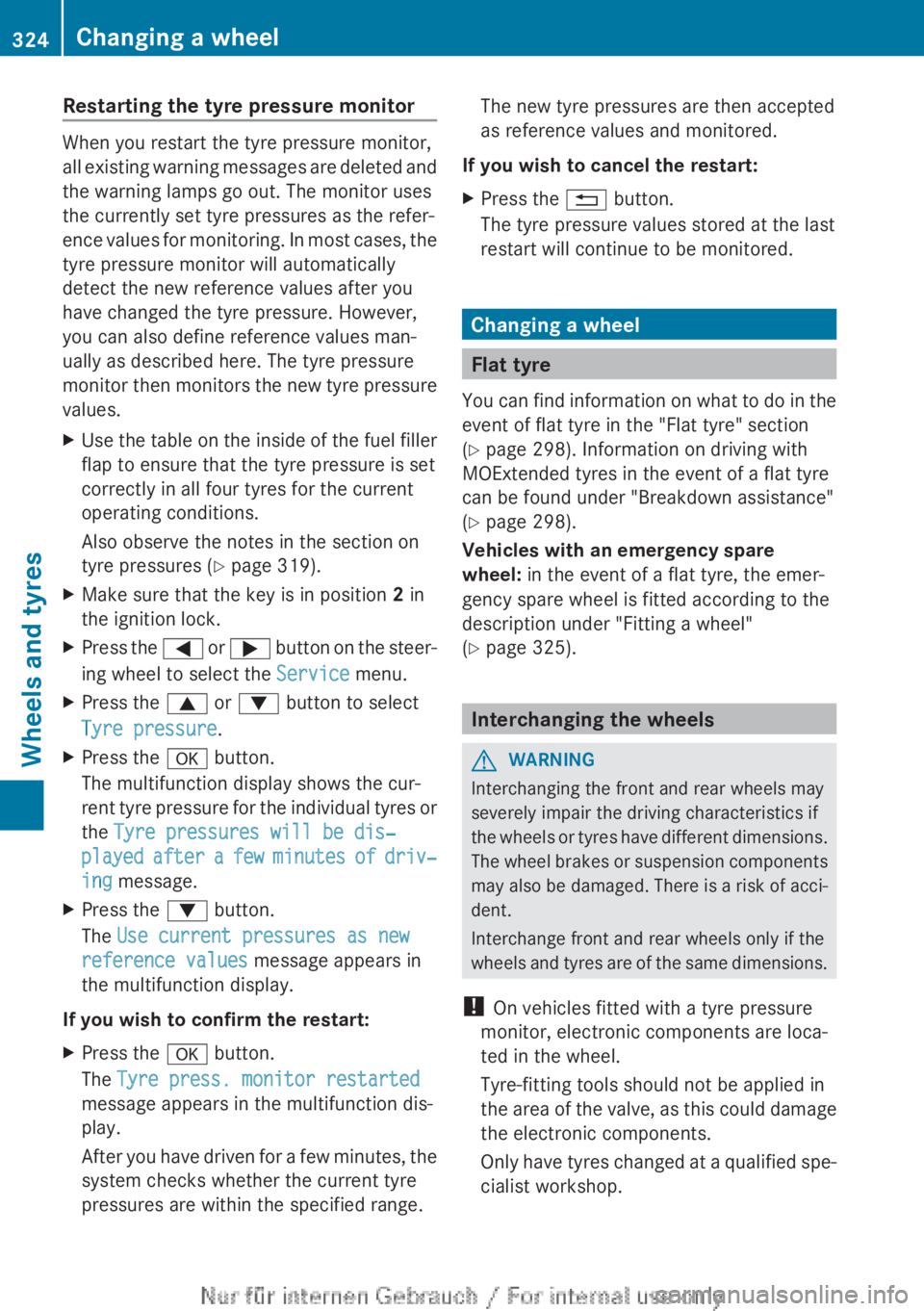

Steel wheel with wheel trim

XVehicles with steel wheels: carefully

reach into two of the wheel trim openings

and remove the wheel trim.XUsing wheel wrench :, loosen the bolts on

the wheel you wish to change by about one

full turn. Do not unscrew the bolts com-

pletely.

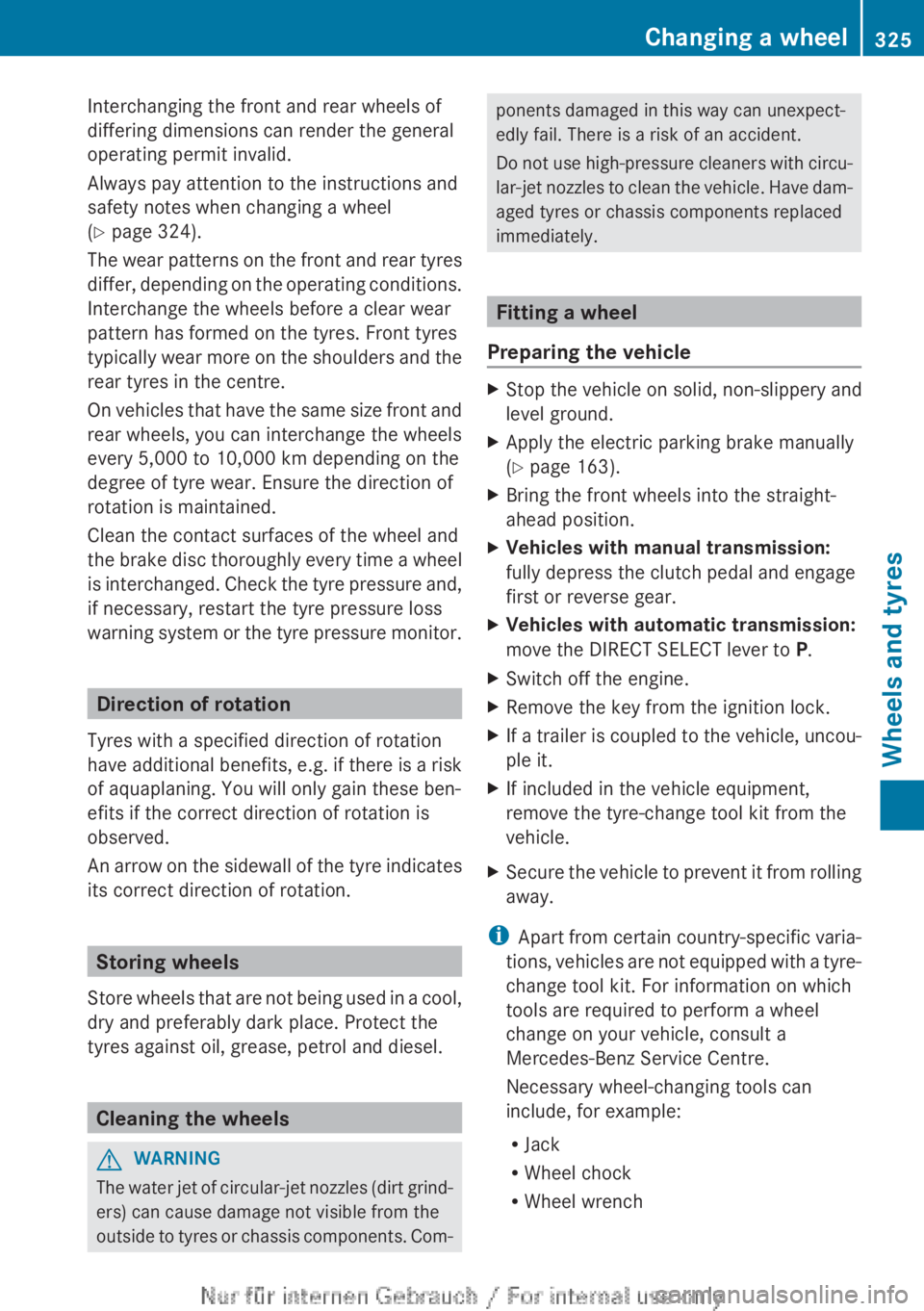

The jacking points are located just behind the

front wheel arches and just in front of the rear

wheel arches (arrows).

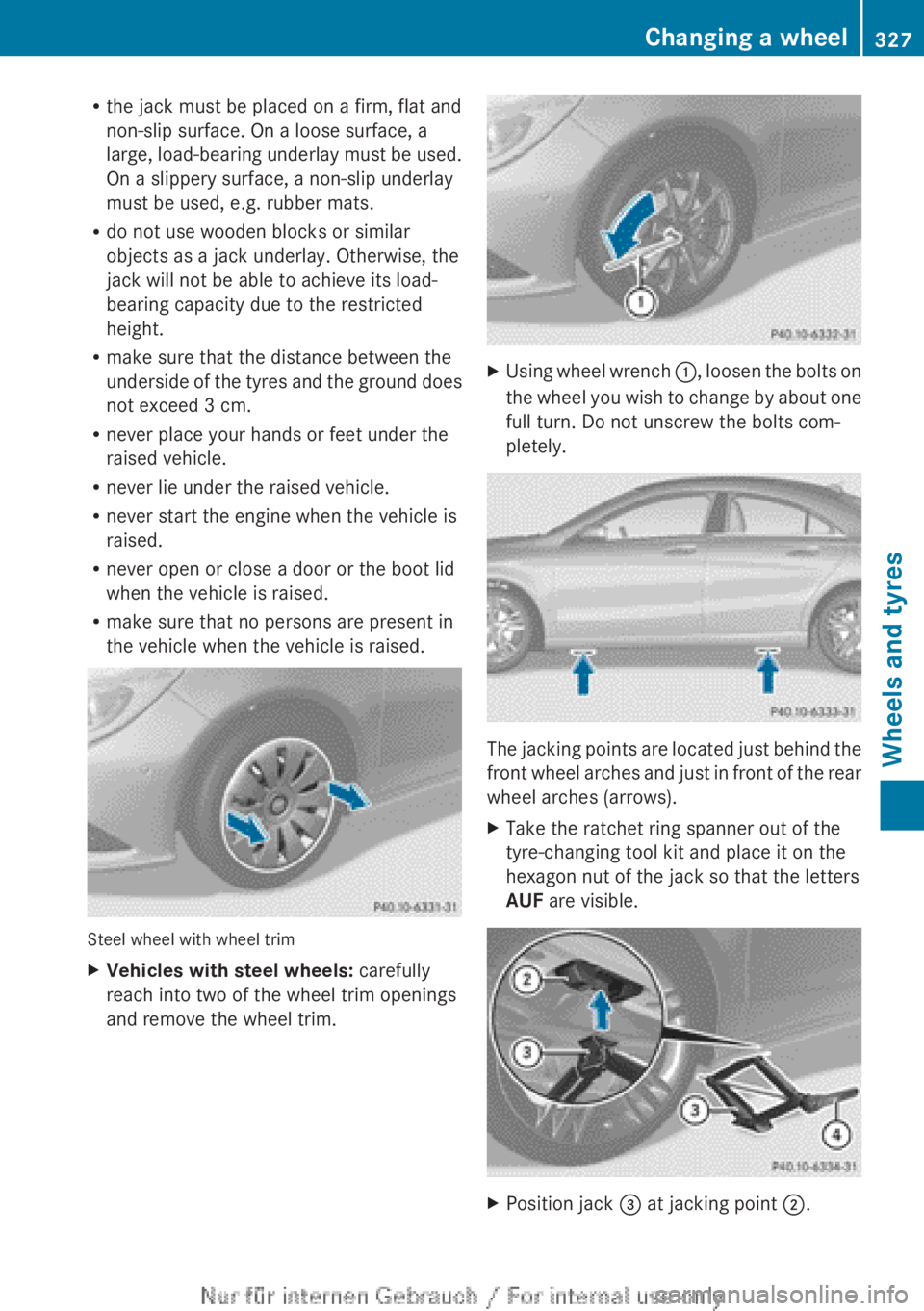

XTake the ratchet ring spanner out of the

tyre-changing tool kit and place it on the

hexagon nut of the jack so that the letters

AUF are visible.XPosition jack = at jacking point ;.Changing a wheel327Wheels and tyresZ

Page 344 of 352

for Service Products, MB Specifications for

Service Products 310.1, e.g. on the Inter-

net at http://bevo.mercedes-benz.com.

Or contact a qualified specialist workshop.

! Always use a suitable coolant mixture,

even in countries where high temperatures

prevail.

Otherwise, the engine cooling system is not

sufficiently protected from corrosion and

overheating.

! The engine cooling system is filled with

coolant, which must be renewed after

15 years or after 250,000 kilometres at the

latest.

When handling coolant, observe the impor-

tant safety notes on service products

( Y page 336).

The coolant is a mixture of water and anti-

freeze/corrosion inhibitor. It performs the

following tasks:

R anti-corrosion protection

R antifreeze protection

R raising the boiling point

If antifreeze/corrosion inhibitor is present in

the correct concentration, the boiling point of

the coolant during operation will be approx-

imately 130 †.

The antifreeze/corrosion inhibitor concentra-

tion in the engine cooling system should:

R be at least 50%. This will protect the engine

cooling system against freezing down to

approximately -37 †.

R not exceed 55% (antifreeze protection

down to -45 †). Heat will otherwise not be

dissipated as effectively.

If the vehicle has lost coolant, top it up with

equal amounts of water and antifreeze/cor-

rosion inhibitor.

Mercedes-Benz recommends an antifreeze/

corrosion inhibitor concentrate in accord-

ance with MB Specifications for Service Prod-

ucts 310.1.

The coolant is checked at every maintenance

interval at a qualified specialist workshop.i When the vehicle is first delivered, it is fil-

led with a coolant mixture that ensures

adequate antifreeze and corrosion protec-

tion.

Windscreen washer system and head-

lamp cleaning system

Important safety notes

GWARNING

Windscreen washer concentrate is highly

flammable. If it comes into contact with hot

engine components or the exhaust system it

could ignite. There is a risk of fire and injury.

Make sure that no windscreen washer con-

centrate is spilled next to the filler neck.

! Only use washer fluid that is suitable for

plastic lamp lenses, e.g. MB SummerFit or

MB WinterFit. Unsuitable washer fluid

could damage the plastic lenses of the

headlamps.

! Do not use distilled or de-ionised water in

the washer fluid reservoir. Otherwise, the

level sensor may be damaged.

! Only the washer fluids SummerFit and

WinterFit can be mixed. Otherwise, the

spraying nozzles could become blocked.

When handling washer fluid, observe the

important safety notes on service products

( Y page 336).

At temperatures above freezing:

XFill the washer fluid reservoir with a mixture

of water and washer fluid, e.g. MB Sum-

merFit.

Mix 1 part MB SummerFit to 100 parts water.

342Service products and capacitiesTechnical data