brake MERCEDES-BENZ CLA-Class 2014 C117 Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2014, Model line: CLA-Class, Model: MERCEDES-BENZ CLA-Class 2014 C117Pages: 358, PDF Size: 6.6 MB

Page 337 of 358

Tire pressure

This is pressure inside the tire applying an

outward force to each square inch of the tire's

surface. The tire pressure is specified in

pounds per square inch (psi), in kilopascal

(kPa) or in bar. The tire pressure should only

be corrected when the tires are cold. Tire pressure of cold tires

The tires are cold:

R if the vehicle has been parked without

direct sunlight on the tires for at least three

hours and

R if the vehicle has not been driven further

than 1 mile (1.6 km) Tread

The part of the tire that comes into contact

with the road. Bead

The tire bead ensures that the tire sits

securely on the wheel. There are several steel

wires in the bead to prevent the tire from

coming loose from the wheel rim. Sidewall

The part of the tire between the tread and the

bead. Weight of optional extras

The combined weight of those optional extras

that weigh more than the replaced standard

part and more than 2.3 kg (5 lbs). These

optional extras, such as high-performance

brakes, level control, a roof rack or a high-

performance battery, are not included in the

curb weight and the weight of the accesso-

ries. TIN (Tire Identification Number)

This is a unique identifier which can be used

by a tire manufacturer to identify tires, for

example for a product recall, and thus identify the purchasers. The TIN is made up of the

manufacturer's identity code, tire size, tire

type code and the manufacturing date. Load bearing index

The load bearing index (also load index) is a

code that contains the maximum load bearing

capacity of a tire. Traction

Traction is the result of friction between the

tires and the road surface. Treadwear indicators

Narrow bars (tread wear bars) that are dis-

tributed over the tire tread. If the tire tread is level with the bars, the wear limit of 00CDin

(1.6 mm) has been reached. Occupant distribution

The distribution of occupants in a vehicle at

their designated seating positions. Total load limit

Nominal load and luggage load plus

68 kilograms (150 lb) multiplied by the num-

ber of seats in the vehicle. Changing a wheel

Flat tire

You can find information on what to do in the

event of a flat tire in the "Flat tire" section

(Y page 296). Information on driving with

MOExtended tires in the event of a flat tire can Changing a

wheel

335Wheels an d tires Z

Page 338 of 358

be found under "MOExtended tires (tires with

run-flat characteristics" (Y page 297).Rotating the wheels

G

WARNING

Interchanging the front and rear wheels may

severely impair the driving characteristics if

the wheels or tires have different dimensions. The wheel brakes or suspension components

may also be damaged. There is a risk of acci-

dent.

Rotate front and rear wheels only if the wheels and tires are of the same dimensions.

! On vehicles equipped with a tire pressure

monitor, electronic components are loca-

ted in the wheel.

Tire-mounting tools should not be used

near the valve. This could damage the elec- tronic components.

Only have tires changed at a qualified spe-cialist workshop.

Always pay attention to the instructions and

safety notes when changing a wheel

(Y page 335).

The wear patterns on the front and rear tires

differ, depending on the operating conditions.

Rotate the wheels before a clear wear pattern has formed on the tires. Front tires typically

wear more on the shoulders and the rear tires in the center.

If your vehicle's tire configuration allows, you can rotate the wheels according to the inter-

vals in the tire manufacturer's warranty book

in your vehicle documents. If no warranty

book is available, the tires should be rotated

every 3,000 to 6,000 miles (5,000 to

10,000 km), or earlier if tire wear requires. Do not change the direction of wheel rotation.

Clean the contact surfaces of the wheel and

the brake disc thoroughly every time a wheel

is rotated. Check the tire pressure and reac-

tivate the tire pressure monitor if necessary. Direction of rotation

Tires with a specified direction of rotation

have additional benefits, e.g. if there is a risk of hydroplaning. You will only gain these ben-

efits if the correct direction of rotation is

maintained.

An arrow on the sidewall of the tire indicates

its correct direction of rotation. Storing wheels

Store wheels that are not being used in a cool, dry and preferably dark place. Protect the

tires from oil, grease, gasoline and diesel. Cleaning the wheels

G

WARNING

The water jet from a circular jet nozzle (dirt

blasters) can cause invisible exterior damage to the tires or chassis components. Compo-

nents damaged in this way may fail unexpect-edly. There is a risk of an accident.

Do not use power washers with circular jet

nozzles to clean the vehicle. Have damaged

tires or chassis components replaced imme-

diately. Mounting a wheel

Preparing the vehicle X

Stop the vehicle on solid, non-slippery and

level ground.

X Apply the electric parking brake manually

(Y page 158).

X Bring the front wheels into the straight-

ahead position.

X Move the DIRECT SELECT lever to position

P.

X Switch off the engine. 336

Changing a wheelWheels and tires

Page 340 of 358

R

before raising the vehicle, secure it from

rolling away by applying the parking brake

and inserting wheel chocks. Never disen-

gage the parking brake while the vehicle is raised.

R the jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a

large, flat, load-bearing underlay must be

used. On a slippery surface, a non-slip

underlay must be used, e.g. rubber mats.

R do not use wooden blocks or similar

objects as a jack underlay. Otherwise, the

jack will not be able to achieve its load-

bearing capacity due to the restricted

height.

R make sure that the distance between the

underside of the tires and the ground does

not exceed 1.2 in (3 cm).

R never place your hands and feet under the

raised vehicle.

R do not lie under the vehicle.

R do not start the engine when the vehicle is

raised.

R never open or close a door or the boot when

the vehicle is raised.

R make sure that no persons are present in

the vehicle when the vehicle is raised.

! The jack is designed exclusively for jack-

ing up the vehicle at the jacking points.

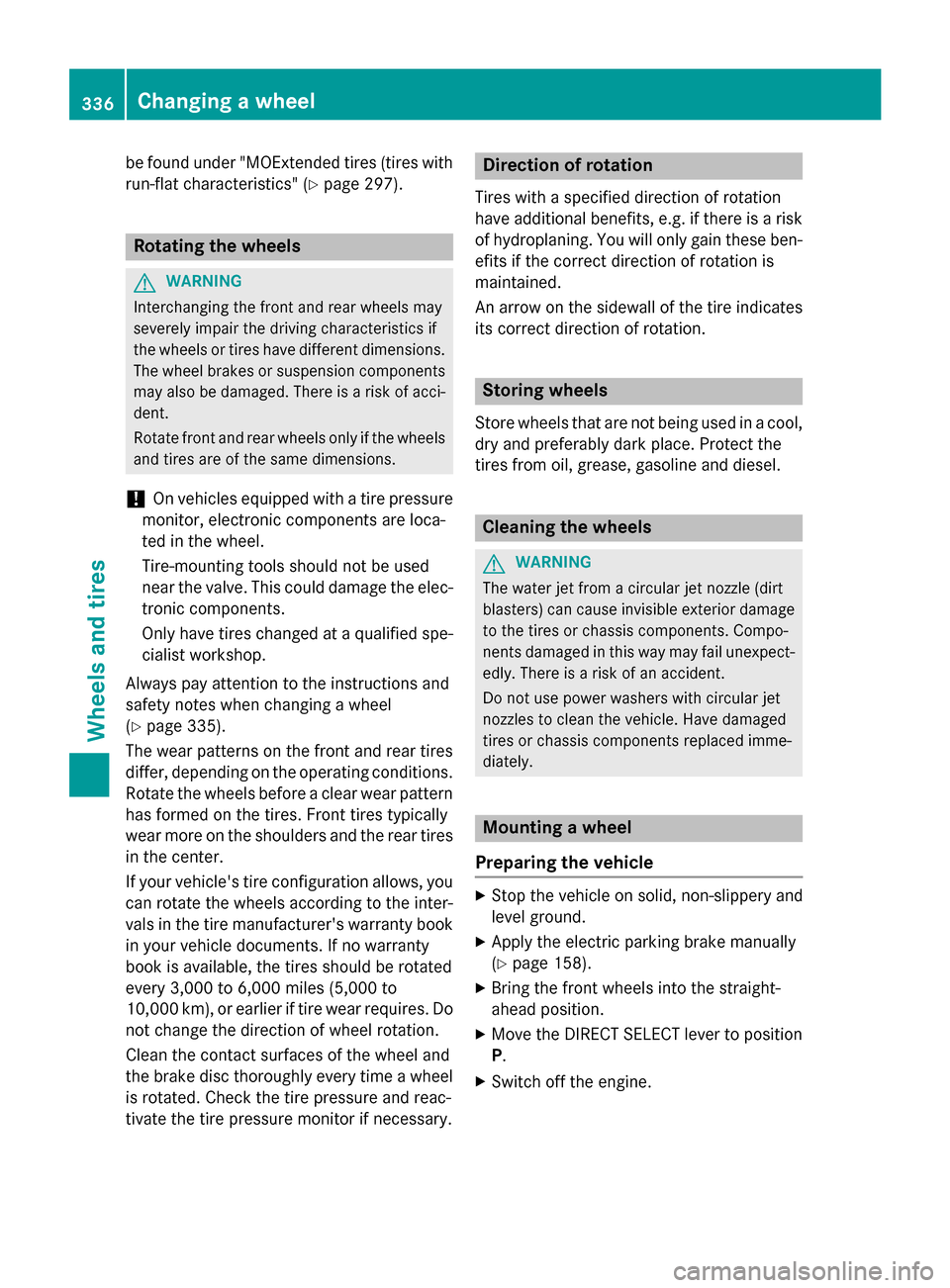

Otherwise, your vehicle could be damaged. Steel wheel with wheel trim

X

Vehicles with steel wheels: carefully

reach into two of the wheel trim openings

and remove the wheel trim. X

Using lug wrench 0043, loosen the bolts on

the wheel you wish to change by about one full turn. Do not unscrew the bolts com-

pletely. The jacking points are located just behind the

wheel housings of the front wheels and just in front of the wheel housings of the rear wheels(arrows).

AMG vehicles and vehicles with AMG

equipment: to protect the vehicle body, the

vehicle has covers installed next to the jack-

ing points on the outer sills. Covers, front (example: vehicles with AMG equip-

ment) 338

Changing a wheelWheels and tires

Page 349 of 358

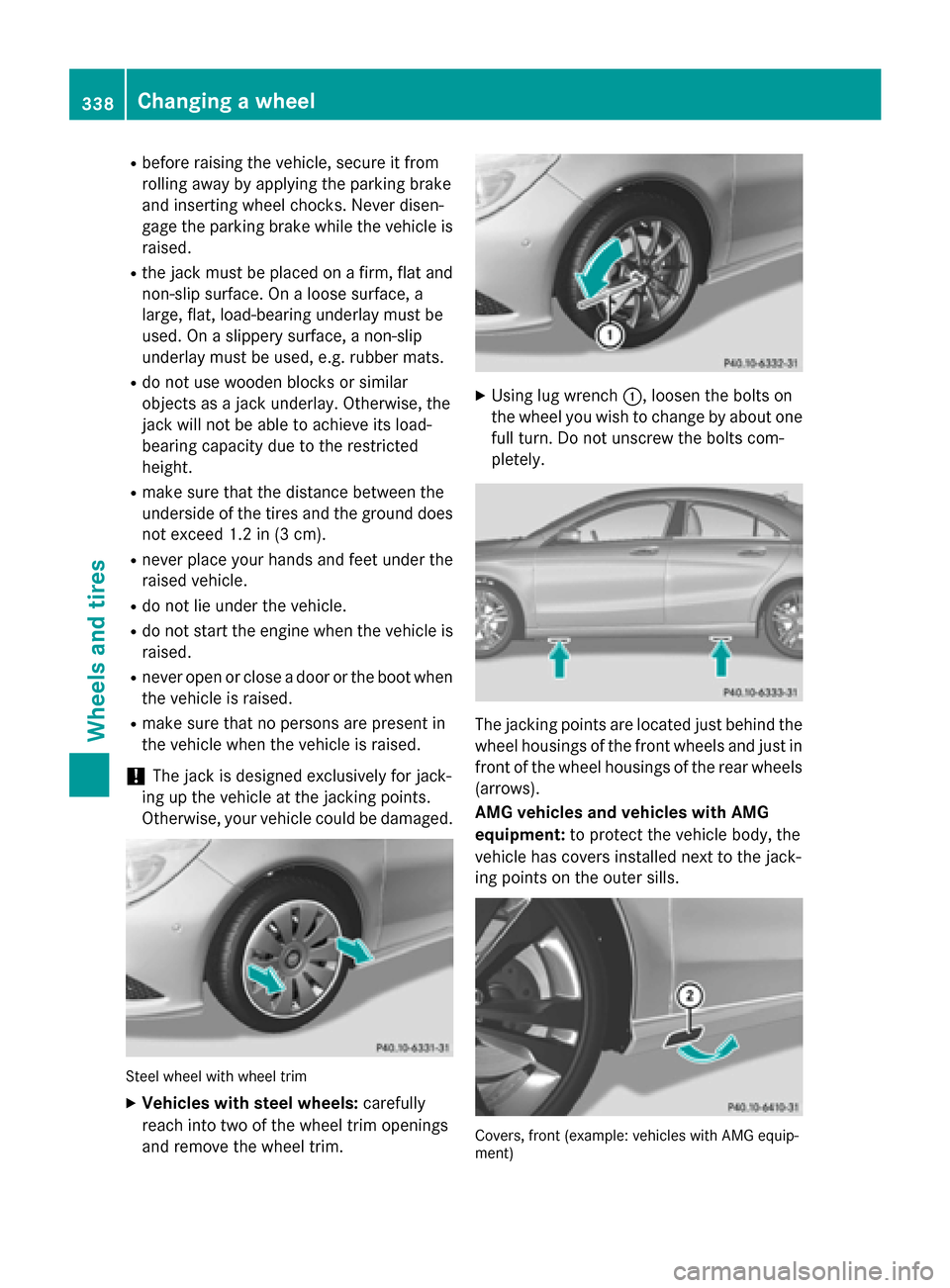

VIN

X

Slide the right-hand front seat to its rear-

most position.

X Fold up floor covering 0043in front of the

right-hand front seat.

You will see VIN 0044.

The VIN can also be found in the following

locations:

R on the lower edge of the windshield

(Y page 347)

R on the vehicle identification plate

(Y page 346) Engine number

0043

Emission control information plate,

including the certification of both federal

and Californian emissions standards

0044 VIN (on the lower edge of the windshield)

0087 Engine number (stamped into the crank-

case) Service products and filling capaci-

ties

Important safety notes

G

WARNING

Service products may be poisonous and haz-

ardous to health. There is a risk of injury.

Comply with instructions on the use, storage

and disposal of service products on the labels of the respective original containers. Always

store service products sealed in their original containers. Always keep service products out

of the reach of children. H

Environmental note

Dispose of service products in an environ-

mentally responsible manner.

Service products include the following:

R Fuels

R Lubricants (e.g. engine oil, transmission oil)

R Coolant

R Brake fluid

R Windshield washer fluid

R Climate control system refrigerant

Components and service products must be

matched. You should therefore only use prod- ucts that have been tested and approved by

Mercedes-Benz.

Information about tested and approved prod- ucts can be obtained from an authorized

Mercedes-Benz Center or on the Internet at

http://bevo.mercedes-benz.com.

You can recognize service products approved

by Mercedes-Benz by the following inscrip-

tion on the containers:

R MB-Freigabe (e.g. MB-Freigabe 229.51)

R MB Approval (e.g. MB Approval 229.51)

Other designations or recommendations indi- cate a level of quality or a specification in

accordance with an MB Sheet number (e.g.

MB 229.5). They have not necessarily been

approved by Mercedes-Benz. Service products and filling capacities

347Technical data Z

Page 352 of 358

engine oils and oil filters that are approved for

vehicles with maintenance systems.

For a list of approved engine oils and oil filters,

consult an authorized Mercedes-Benz Cen-

ter. Or visit the website

http://bevo.mercedes-benz.com.

The table shows which engine oils have been

approved for your vehicle. Model Engine

model MB

Approval CLA 250

CLA 250 4MATIC

270 229.5

AMG vehicles

133 229.5

Use only SAE 0W-40o

r SAE 5W-40 engine oils

for AMG vehicles.

i MB approval is indicated on the oil con-

tainers.

Filling capacities The following values refer to an oil change

including the oil filter. Model Capacity

CLA 250

CLA 250 4MATIC

5.9 US qt (5.6

l) AMG vehicles

5.8 US qt (5.5

l) Additives

!

Do not use any additives in the engine oil.

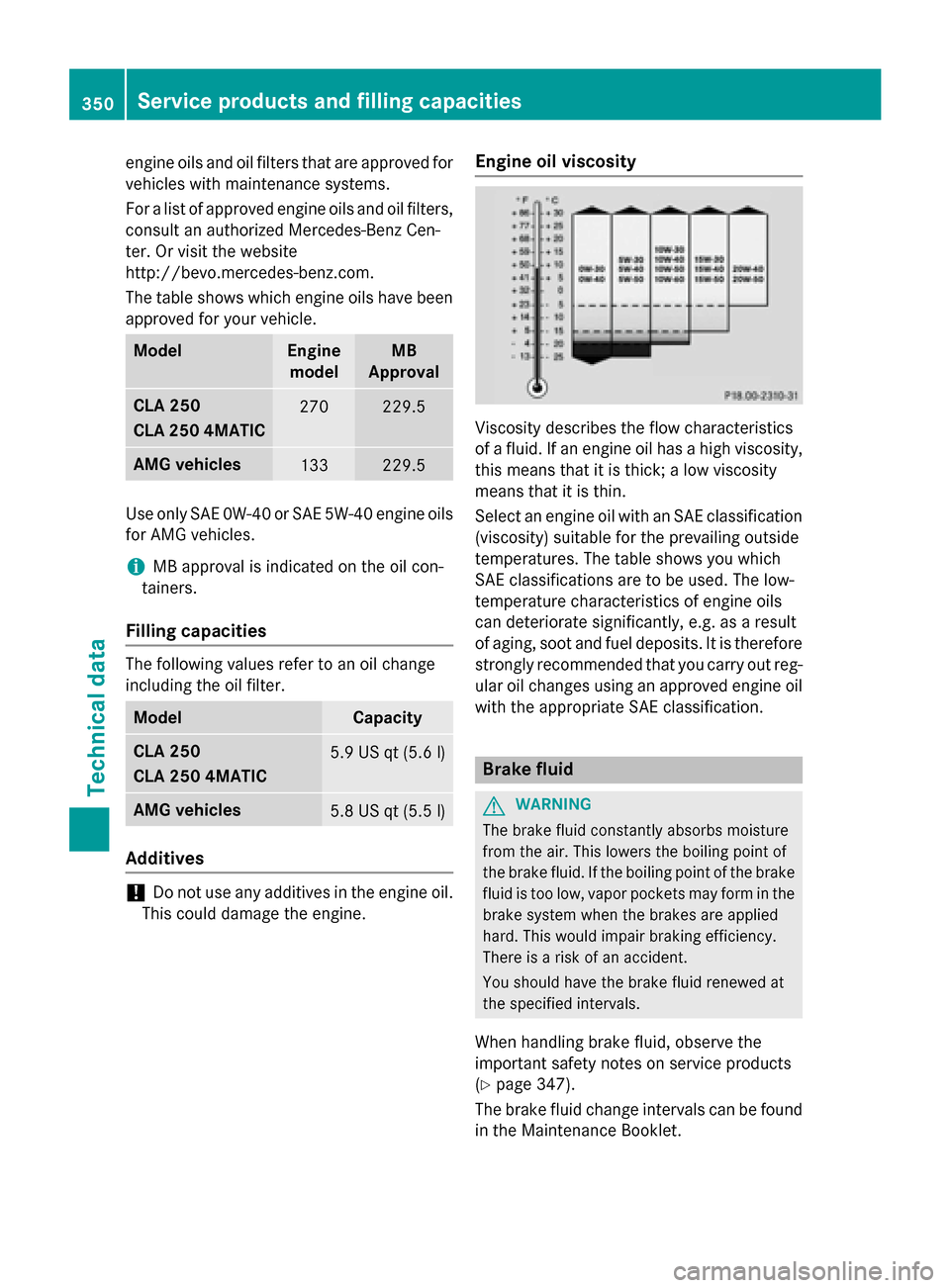

This could damage the engine. Engine oil viscosity Viscosity describes the flow characteristics

of a fluid. If an engine oil has a high viscosity, this means that it is thick; a low viscosity

means that it is thin.

Select an engine oil with an SAE classification

(viscosity) suitable for the prevailing outside

temperatures. The table shows you which

SAE classifications are to be used. The low-

temperature characteristics of engine oils

can deteriorate significantly, e.g. as a result

of aging, soot and fuel deposits. It is therefore strongly recommended that you carry out reg-

ular oil changes using an approved engine oil with the appropriate SAE classification. Brake fluid

G

WARNING

The brake fluid constantly absorbs moisture

from the air. This lowers the boiling point of

the brake fluid. If the boiling point of the brake fluid is too low, vapor pockets may form in the brake system when the brakes are applied

hard. This would impair braking efficiency.

There is a risk of an accident.

You should have the brake fluid renewed at

the specified intervals.

When handling brake fluid, observe the

important safety notes on service products

(Y page 347).

The brake fluid change intervals can be found

in the Maintenance Booklet. 350

Service products and filling capacitiesTechnical data

Page 353 of 358

Only use brake fluid approved by Mercedes-

Benz according to MB Approval 331.0.

Information about approved brake fluid can

be obtained at any qualified specialist work-

shop or on the Internet at

http://bevo.mercedes-benz.com.

i Have the brake fluid renewed regularly at

a qualified specialist workshop. Coolant

Important safety notes G

WARNING

If antifreeze comes into contact with hot com- ponents in the engine compartment, it may

ignite. There is a risk of fire and injury.

Let the engine cool down before you add anti-

freeze. Make sure that antifreeze is not spilled

next to the filler neck. Thoroughly clean the

antifreeze from components before starting

the engine.

! Only add coolant that has been premixed

with the desired antifreeze protection. You

could otherwise damage the engine.

Further information on coolants can be

found in the Mercedes-Benz Specifications for Service Products, MB Specifications for

Service Products 310.1, e.g. on the Inter-

net at http://bevo.mercedes-benz.com.

Or contact a qualified specialist workshop.

! Always use a suitable coolant mixture,

even in countries where high temperatures prevail.

Otherwise, the engine cooling system is not

sufficiently protected from corrosion and

overheating.

i Have the coolant regularly replaced at a

qualified specialist workshop and the

replacement confirmed in the Maintenance Booklet.

Comply with the important safety precautions

for service products when handling coolant

(Y page 347). The coolant is a mixture of water and anti-

freeze/corrosion inhibitor. It performs the

following tasks:

R corrosion protection

R antifreeze protection

R raising the boiling point

If the coolant has antifreeze protection down to -35 ‡(-37 †), the boiling point of the cool-

ant during operation is approximately 266 ‡

(130 †).

The antifreeze/corrosion inhibitor concentra- tion in the engine cooling system should:

R be at least 50%. This will protect the engine

cooling system against freezing down to

approximately -35 ‡ (-37 †).

R not exceed 55% (antifreeze protection

down to -49 ‡[-45 †]). Other wise, heat

will not be dissipated as effectively.

Mercedes-Benz recommends an antifreeze/

corrosion inhibitor concentrate in accord-

ance with MB Specifications for Service Prod-

ucts 310.1.

i When the vehicle is first delivered, it is fil-

led with a coolant mixture that ensures

adequate antifreeze and corrosion protec-

tion.

i The coolant is checked with every main-

tenance interval at a qualified specialist

workshop.

Filling capacities Model Capacity

AMG vehicles

Approx. 9.1 US qt

(8.6l) All ot

her models Approx. 8.2 US qt

(7.8l) i

Use antifreeze/corrosion inhibitor

according to MB approval 325.0 or 326.0. Service products and filling capacities

351Technical data Z