tires MERCEDES-BENZ CLK CABRIOLET 2000 A208 User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2000, Model line: CLK CABRIOLET, Model: MERCEDES-BENZ CLK CABRIOLET 2000 A208Pages: 323, PDF Size: 9.32 MB

Page 210 of 323

Driving systems

Te ch n ica l

data Instruments

and controlsOperationDrivingInstrument

cluster displayPractical hints Car care Index

With the ESP system switched off, the engine torque

reduction feature is cancelled. Therefore, the enhanced

vehicle stability offered by ESP is unavailable.

Adapt your speed and driving to the prevailing road

conditions.

A portion of the ESP system remains active, even with

the switch in the OFF position.

If one drive wheel loses traction and begins to spin, the

brake is applied until the wheel regains sufficient

traction. The traction control engages at vehicle speeds

up to approximately 24 mph (40 km/h), and switches off

at 50 mph (80 km/h).

Note:

Avoid spinning of one drive wheel. This may cause

serious damage to the drive train which is not covered

by the Mercedes-Benz Limited Warranty.The ESP warning lamp, located in the speedometer dial,

starts to flash at any vehicle speed as soon as the tires

lose traction and the wheels begin to spin.

To return to the enhanced vehicle stability offered by

ESP: press lower half of the switch (the ESP warning

lamp in the speedometer dial goes out).

Important!

If the ESP warning lamp flashes:

•during take-off, apply as little throttle as possible,

•while driving, ease up on the accelerator.

210

Page 250 of 323

Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Wheels

Replace rims or tires with the same designation,

manufacturer and type as shown on the original part.

See your authorized Mercedes-Benz Center for further

information.

See your authorized Mercedes-Benz Center for

information on tested and recommended rims and tires

for summer and winter operation. They can also offer

advice concerning tire service and purchase.

Tire replacement

Front tires should be replaced in sets. Rims and tires

must be of the correct size and type. For dimensions,

see “Technical Data”

We recommend that you break in new tires for approx.

60 miles (100 km) at moderate speed.It is imperative that the wheel mounting bolts be

fastened to a tightening torque of 80 ft.lb. (110 Nm)

whenever wheels are mounted.

For rim and tire specifications, refer to “Technical Data”

Wa r n i n g !

Worn, old tires can cause accidents. If the tire tread

is badly worn, or if the tires have sustained

damage, replace them.When replacing rims, use only genuine

Mercedes-Benz wheel bolts specified for the

particular rim type. Failure to do so can result in

the bolts loosening and possibly an accident.

250

Page 251 of 323

Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Rotating wheels

CLK 430:

Wheel rotation applies only when winter tires are

mounted on all four wheels.

The wheels can be rotated according to the degree of

tire wear while retaining the same direction of travel.

Rotating, however, should be carried out as

recommended by the tire manufacturer, before the

characteristic tire wear pattern (shoulder wear on front

wheels and tread center wear on rear wheels) becomes

visible, as otherwise the driving properties deteriorate.

Important!

Unidirectional tires must always be mounted with arrow

on tire sidewall pointing in direction of vehicle forward

movement.Notes:

Thoroughly clean the inner side of the wheels any time

you rotate the wheels or wash the vehicle underside.

The use of retread tires is not recommended. Retread

tires may adversely affect the handling characteristics

and safety of the vehicle.

Dented or bent rims can cause tire pressure loss and

dam age to t he tire bead s. For this reason, ch eck rims for

damage at regular intervals. The rim flanges must be

checked for wear before a tire is mounted. Remove

burrs, if any.

Check and ensure proper tire inflation pressure after

rotating the wheels. For tire inflation pressure see

inside of fuel filler flap and also page259.

251

Page 252 of 323

Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Spare wheel

Spare wheel CLK 320

Important!

The spare wheel rim is mounted with a full size tire of

the same type as on the vehicle, and is fully functional.

However, that spare wheel rim is weight optimized and

has a limited service life of 12 000 miles (20 000 km)

use before a standard wheel rim must replace it.

In the case of a flat tire, you may temporarily use the

spare wheel.

Do not operate vehicle with more than one spare wheel

mounted.Unid irectional tires must a lways be mou nted w it h a rrow

on tire sidewall pointing in direction of vehicle forward

movement.

If the arrow on tire side wall does not point in direction

of vehicle forward movement when using the spare

wheel, observe the following restriction:

•Drive to the nearest tire repair facility as soon as

possible.

For rim and tire specifications, refer to “Technical Data”

Wa r n i n g !

The spare wheel rim is for temporary use only. Use

for over a total of 12 000 miles (20 000 km)

(aggregate of all uses) may cause wheel rim failure

leading to an accident and possible injuries.

252

Page 253 of 323

Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Spare wheel CLK 430

Important!

The spare wheel rim size is 7

1/2J x 17 H 2.

The spare wheel rim is mounted with a full size tire of

the same type as on the vehicle’s front axle, and is fully

functional. However, that spare wheel rim is weight

optimized and has a limited service life of 12 000 miles

(20 000 km) use before a standard wheel rim must

replace it.

If the arrow on tire side wall does not point in direction

of vehicle forward movement when using the spare

wheel, observe the following restriction:

•Drive to the nearest tire repair facility as soon as

possible.

In the case of a rear axle f lat tire, you may temporarily

use the spare wheel, when observing the following

restrictions:

•Do not exceed vehicle speed of 50 mph (80 km/h)

•Drive to the nearest tire repair facility to have the

flat tire repaired or replaced as appropriate.Do not operate vehicle with more than one spare wheel

mounted.

Unid irectional tires must a lways be mou nted w it h a rrow

on tire sidewall pointing in direction of vehicle forward

movement.

For rim and tire specifications, refer to “Technical Data”

Wa r n i n g !

The spare wheel rim is for temporary use only. Use

for over a total of 12 000 miles (20 000 km)

(aggregate of all uses) may cause wheel rim failure

leading to an accident and possible injuries.The dimensions of the spare wheel are different

from those of the road wheels for the rear axle. As a

result, the vehicle handling characteristics change

when driving with a spare wheel mounted on the

rear axle.The spare wheel should only be used temporarily,

and replaced with a regular road wheel as quick as

possible.

253

Page 254 of 323

Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Changing wheelsMove vehicle to a level area which is a safe distance

from the roadway.

1. Set parking brake and turn on hazard warning

flasher.

2. Move selector lever to position “P” and turn off

engine.

3. Prevent vehicle from rolling away by blocking

wheels with wheel chocks (not supplied with

vehicle) or sizable wood block or stone. When

changing a wheel on a hill, place chocks on the

downhill side blocking both wheels of the other

axle. On a level road, place one chock in front of and

one behind the wheel that is diagonally opposite to

the wheel being changed.

Warning!

The jack is designed exclusively for jacking up the

vehicle at the jack tubes built into either side of the

vehicle. To help avoid personal injury, use the jack

only to lift the vehicle during a wheel change.

Never get beneath the vehicle while it is supported

by the jack. Keep hands and feet away from the area

under the lifted vehicle. Always firmly set parking

brake and block wheels before raising vehicle with

jack.Do not disengage parking brake while the vehicle is

raised. Be certain that the jack is always vertical

when in use, especially on hills. Always try to use

the jack on level surface. Be sure that the jack arm

is fully inserted in the jack tube. Always lower the

vehicle onto sufficient capacity jackstands before

working under the vehicle.

Wa r n i n g !

Before working on the vehicle, e.g. when changing

wheels, the roll bar should be raised with the

switch, and the electronic key be removed from the

steering lock, to prevent possible injury.

254

Page 255 of 323

Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

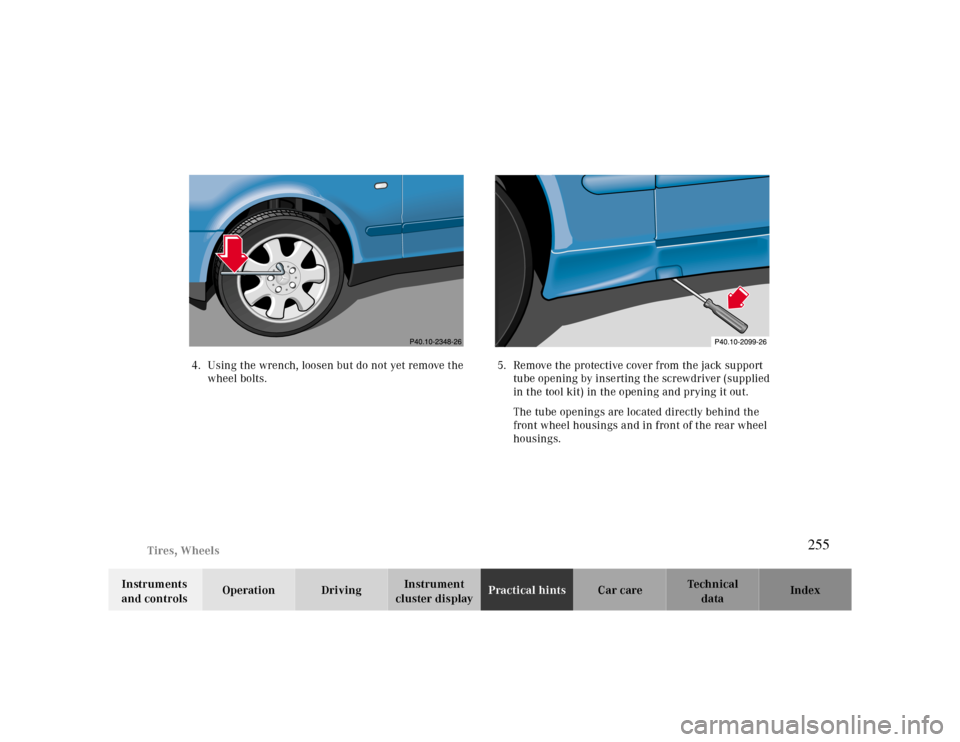

cluster displayPractical hintsCar care Index 4. Using the wrench, loosen but do not yet remove the

wheel bolts.5. Remove the protective cover from the jack support

tube opening by inserting the screwdriver (supplied

in the tool kit) in the opening and prying it out.

The tube openings are located directly behind the

front wheel housings and in front of the rear wheel

housings.

255

Page 256 of 323

Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

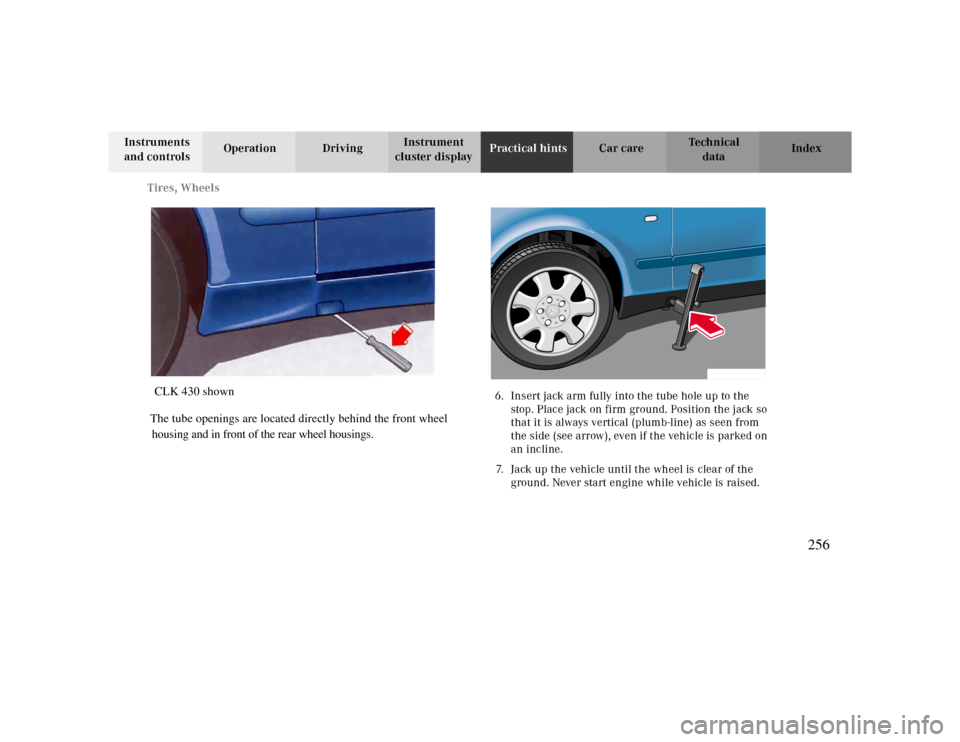

6. Insert jack arm fully into the tube hole up to the

stop. Place jack on firm ground. Position the jack so

that it is always vertical (plumb-line) as seen from

the side (see arrow), even if the vehicle is parked on

an incline. housing and in front of the rear wheel housings.

7. Jack up the vehicle until the wheel is clear of the

ground. Never start engine while vehicle is raised. The tube openings are located directly behind the front wheel CLK 430 shown

256

Page 257 of 323

Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

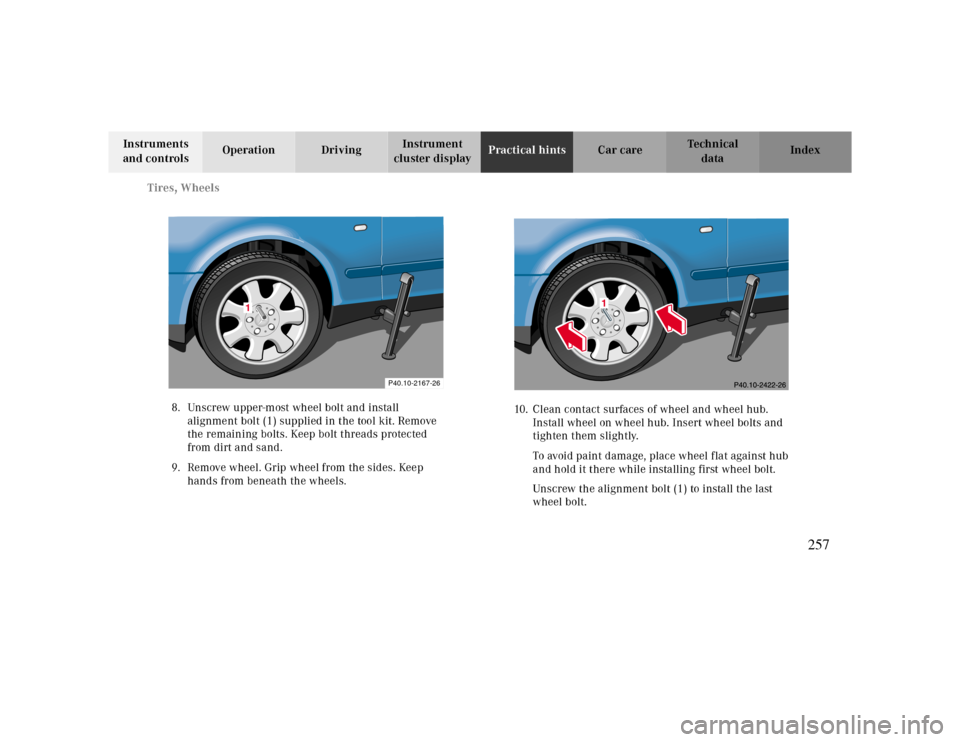

8. Unscrew upper-most wheel bolt and install

alignment bolt (1) supplied in the tool kit. Remove

the remaining bolts. Keep bolt threads protected

from dirt and sand.

9. Remove wheel. Grip wheel from the sides. Keep

hands from beneath the wheels.

P40.10-2167-26

1

10. Clean contact surfaces of wheel and wheel hub.

Install wheel on wheel hub. Insert wheel bolts and

tighten them slightly.

To avoid paint damage, place wheel flat against hub

and hold it there while installing first wheel bolt.

Unscrew the alignment bolt (1) to install the last

wheel bolt.

257

Page 258 of 323

Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

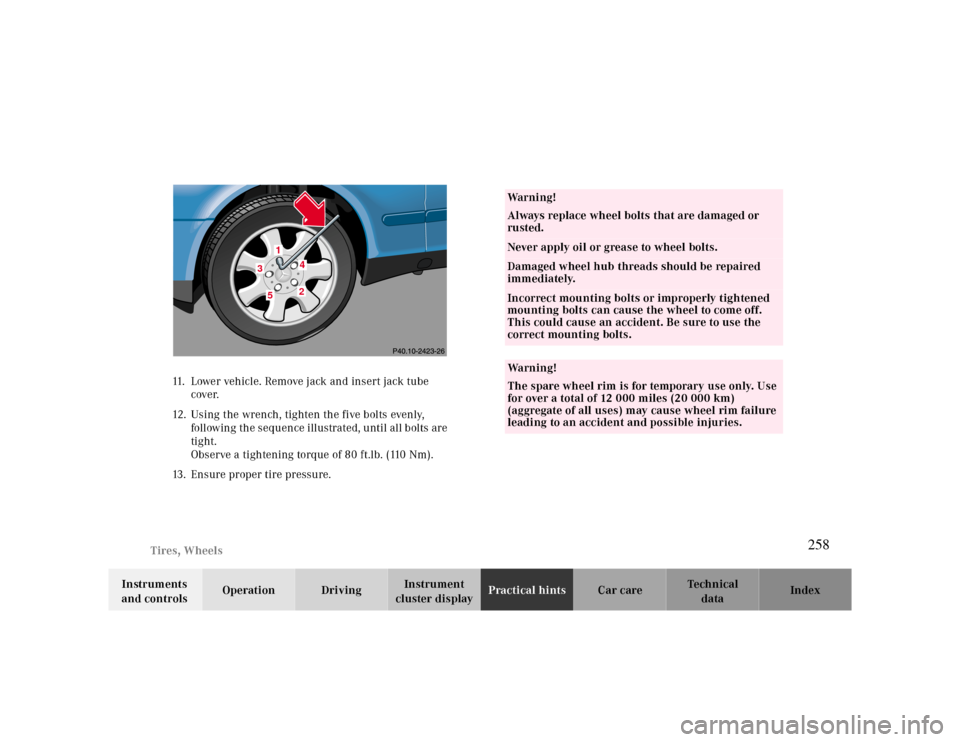

cluster displayPractical hintsCar care Index 11. Lower vehicle. Remove jack and insert jack tube

cover.

12. Using the wrench, tighten the five bolts evenly,

following the sequence illustrated, until all bolts are

tight.

Observe a tightening torque of 80 ft.lb. (110 Nm).

13. Ensure proper tire pressure.

34

2

5

Warning!

Always replace wheel bolts that are damaged or

rusted.Never apply oil or grease to wheel bolts.Damaged wheel hub threads should be repaired

immediately.Incorrect mounting bolts or improperly tightened

mounting bolts can cause the wheel to come off.

This could cause an accident. Be sure to use the

correct mounting bolts.Wa r n i n g !

The spare wheel rim is for temporary use only. Use

for over a total of 12 000 miles (20 000 km)

(aggregate of all uses) may cause wheel rim failure

leading to an accident and possible injuries.

258