warning MERCEDES-BENZ CLK CABRIOLET 2000 A208 Manual Online

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2000, Model line: CLK CABRIOLET, Model: MERCEDES-BENZ CLK CABRIOLET 2000 A208Pages: 323, PDF Size: 9.32 MB

Page 244 of 323

Engine compartment

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Hood

Warning!

To help prevent personal injury, stay clear of

moving parts when the hood is open and the engine

is running. Be sure the hood is properly closed

before driving. When closing hood, use extreme

caution not to catch hands or fingers.The engine is equipped with a transistorized

ignition system. Because of the high voltage it is

dangerous to touch any components (ignition coils,

spark plug sockets, diagnostic socket) of the

ignition system

• with the engine running,

• while starting the engine,

• if ignition is “on” and the engine is turned

manually.If you see flames, steam or smoke coming from the

engine compartment, or if the coolant temperature

gauge indicates that the engine is overheated, do

not open the hood. Move away from vehicle and do

not open the hood until the engine has cooled. If

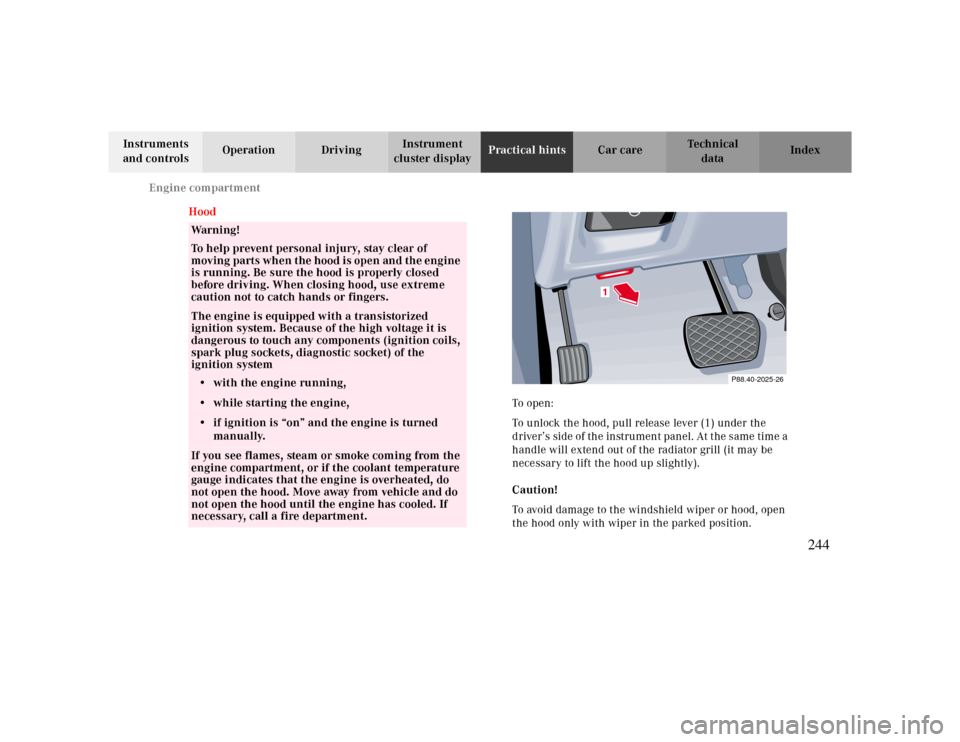

necessary, call a fire department.To o pen :

To unlock the hood, pull release lever (1) under the

driver’s side of the instrument panel. At the same time a

handle will extend out of the radiator grill (it may be

necessary to lift the hood up slightly).

Caution!

To avoid damage to the windshield wiper or hood, open

the hood only with wiper in the parked position.

P88.40-2025-26

1

244

Page 246 of 323

Engine compartment

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

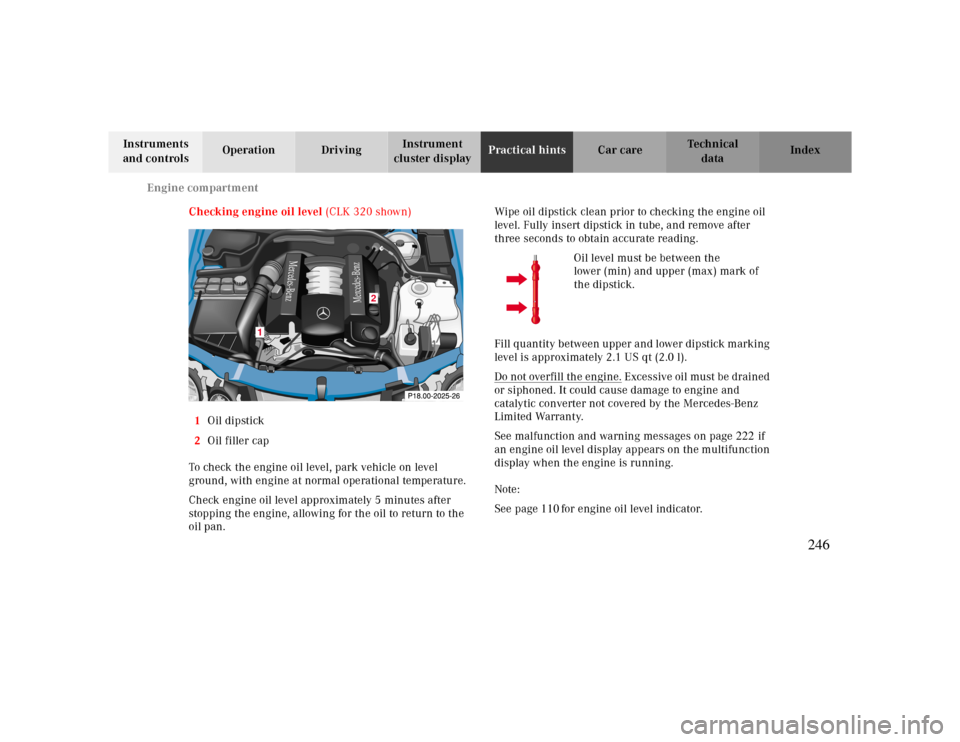

Checking engine oil level (CLK 320 shown)

1Oil dipstick

2Oil filler cap

To check the engine oil level, park vehicle on level

ground, with engine at normal operational temperature.

Check engine oil level approximately 5 minutes after

stopping the engine, allowing for the oil to return to the

oil pan.Wipe oil dipstick clean prior to checking the engine oil

level. Fully insert dipstick in tube, and remove after

three seconds to obtain accurate reading.

Oil level must be between the

lower (min) and upper (max) mark of

the dipstick.

Fill quantity between upper and lower dipstick marking

level is approximately 2.1 US qt (2.0 l).

Do not overfill the engine.

Excessive oil must be drained

or siphoned. It could cause damage to engine and

catalytic converter not covered by the Mercedes-Benz

Limited Warranty.

See malfunction and warning messages on page222 if

an engine oil level display appears on the multifunction

display when the engine is running.

Note:

See page110for engine oil level indicator.

Mercedes-Benz

Mercedes-Benz

2

1

246

Page 248 of 323

Engine compartment

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Adding coolant

If coolant has to be added, a 50 / 50 mixture of water and

MB anticorrosion / antifreeze should be added.

The drain plugs for the cooling system are located on

the right side of the engine block and at the bottom of

the radiator.

Anticorrosion / antifreeze mixture, see page311.

Warning!

In order to avoid possible serious burns or injury:

• Use extreme caution when opening the hood if

there are any signs of steam or coolant leaking

from the cooling system, or if the coolant

temperature gauge indicates that the coolant is

overheated.• Do not remove pressure cap on coolant

reservoir if engine temperature is above 194°F

(90°C). Allow engine to cool down before

removing cap. The coolant reservoir contains

hot fluid and is under pressure.

• Using a rag, slowly open cap approximately

1/2 turn to relieve excess pressure. If opened

immediately, scalding hot fluid and steam will

be blown out under pressure.• Do not spill antifreeze on hot engine parts.

Antifreeze contains ethylene glycol which may

burn if it comes into contact with hot engine

parts.

248

Page 254 of 323

Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Changing wheelsMove vehicle to a level area which is a safe distance

from the roadway.

1. Set parking brake and turn on hazard warning

flasher.

2. Move selector lever to position “P” and turn off

engine.

3. Prevent vehicle from rolling away by blocking

wheels with wheel chocks (not supplied with

vehicle) or sizable wood block or stone. When

changing a wheel on a hill, place chocks on the

downhill side blocking both wheels of the other

axle. On a level road, place one chock in front of and

one behind the wheel that is diagonally opposite to

the wheel being changed.

Warning!

The jack is designed exclusively for jacking up the

vehicle at the jack tubes built into either side of the

vehicle. To help avoid personal injury, use the jack

only to lift the vehicle during a wheel change.

Never get beneath the vehicle while it is supported

by the jack. Keep hands and feet away from the area

under the lifted vehicle. Always firmly set parking

brake and block wheels before raising vehicle with

jack.Do not disengage parking brake while the vehicle is

raised. Be certain that the jack is always vertical

when in use, especially on hills. Always try to use

the jack on level surface. Be sure that the jack arm

is fully inserted in the jack tube. Always lower the

vehicle onto sufficient capacity jackstands before

working under the vehicle.

Wa r n i n g !

Before working on the vehicle, e.g. when changing

wheels, the roll bar should be raised with the

switch, and the electronic key be removed from the

steering lock, to prevent possible injury.

254

Page 258 of 323

Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

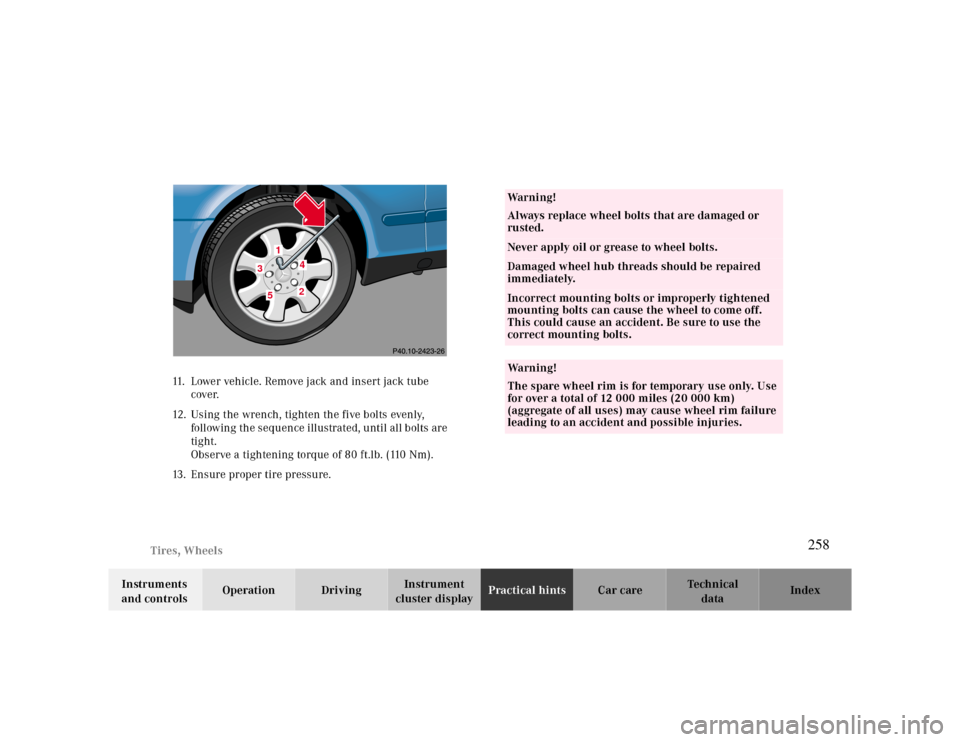

cluster displayPractical hintsCar care Index 11. Lower vehicle. Remove jack and insert jack tube

cover.

12. Using the wrench, tighten the five bolts evenly,

following the sequence illustrated, until all bolts are

tight.

Observe a tightening torque of 80 ft.lb. (110 Nm).

13. Ensure proper tire pressure.

34

2

5

Warning!

Always replace wheel bolts that are damaged or

rusted.Never apply oil or grease to wheel bolts.Damaged wheel hub threads should be repaired

immediately.Incorrect mounting bolts or improperly tightened

mounting bolts can cause the wheel to come off.

This could cause an accident. Be sure to use the

correct mounting bolts.Wa r n i n g !

The spare wheel rim is for temporary use only. Use

for over a total of 12 000 miles (20 000 km)

(aggregate of all uses) may cause wheel rim failure

leading to an accident and possible injuries.

258

Page 260 of 323

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

If a tire constantly loses air, it should be inspected for

damage.

The spare tire should be checked periodically for

condition and inflation. Spare tire will age and become

worn over time even if never used, and thus should be

inspected and replaced when necessary.

Warning!

Do not overinflate tires. Overinflating tires can

result in sudden deflation (blowout) because they

are more likely to become punctured or damaged

by road debris, potholes etc.. Follow recommended

inflation pressures.Do not overload the tires by exceeding the specified

vehicle capacity weight (as indicated by the label

on the driver’s door latch post). Overloading the

tires can overheat them, possibly causing a

blowout. Tires, Wheels

260

Page 263 of 323

Jump starting

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Jump starting

If the battery is discharged, the engine should be started

with jumper cables and the (12 V) battery of another

vehicle.

Only use 12 V battery to jump start your vehicle. Jump

starting with more powerful battery could damage the

vehicle’s electrical systems, which will not be covered

by the Mercedes-Benz Limited Warranty.

The battery is located in the trunk under the trunk floor.

Warning!

Failure to follow these directions will cause

damage to the electronic components, and can lead

to a battery explosion and severe injury or death.Never lean over batteries while connecting or jump

starting, you might get injured.Battery fluid contains sulfuric acid. Do not allow

this fluid to come in contact with eyes, skin or

clothing. In case it does, immediately flush affected

area with water, and seek medical help if

necessary.A battery will also produce hydrogen gas, which is

flammable and very explosive. Keep flames or

sparks away from battery, avoid improper

connection of jumper cables, smoking etc..Read all instructions before proceeding.Proceed as follows:

1. Position the vehicle with the charged battery so that

the jumper cables will reach, but never let the

vehicles touch. Make sure the jumper cables do not

have loose or missing insulation.

2. On both vehicles:

•Turn off engine and all lights and accessories,

except hazard warning flashers or work lights.

•Apply parking brake and shift selector lever to

position “P”.

263

Page 266 of 323

Towing

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

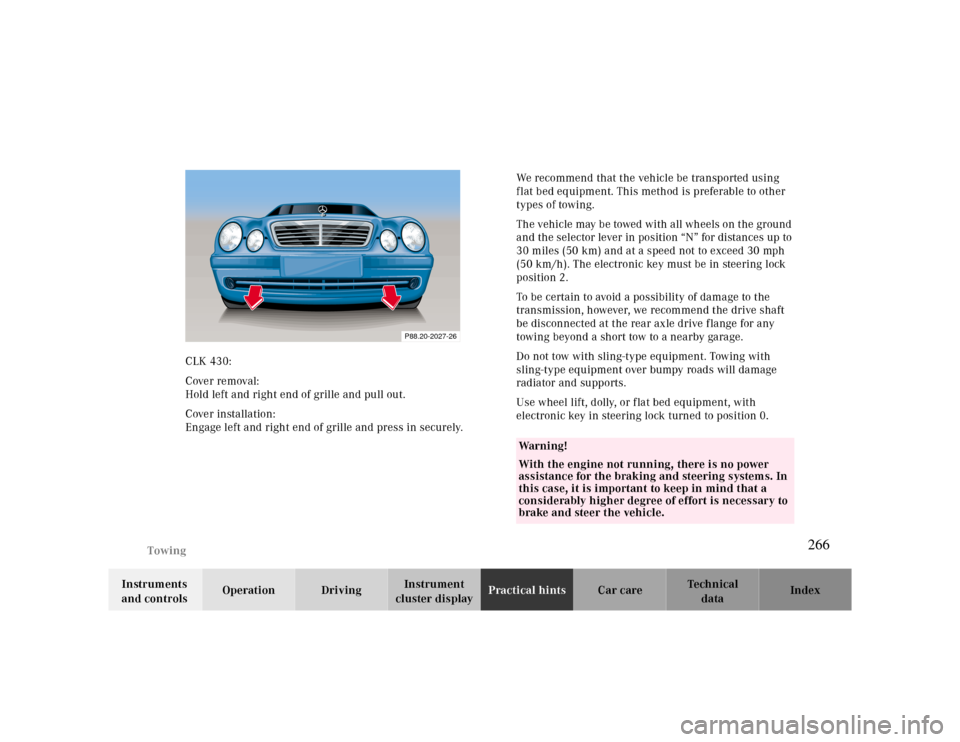

cluster displayPractical hintsCar care Index CLK 430:

Cover removal:

Hold left and right end of grille and pull out.

Cover installation:

Engage left and right end of grille and press in securely.

P88.20-2027-26

We recommend that the vehicle be transported using

flat bed equipment. This method is preferable to other

types of towing.

The vehicle may be towed with all wheels on the ground

and the selector lever in position “N” for distances up to

30 miles (50 km) and at a speed not to exceed 30 mph

(50 km/h). The electronic key must be in steering lock

position 2.

To be certain to avoid a possibility of damage to the

transmission, however, we recommend the drive shaft

be disconnected at the rear axle drive f lange for any

towing beyond a short tow to a nearby garage.

Do not tow with sling-type equipment. Towing with

sling-type equipment over bumpy roads will damage

radiator and supports.

Use wheel lift, dolly, or flat bed equipment, with

electronic key in steering lock turned to position 0.Warning!

With the engine not running, there is no power

assistance for the braking and steering systems. In

this case, it is important to keep in mind that a

considerably higher degree of effort is necessary to

brake and steer the vehicle.

266

Page 267 of 323

Towing

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Note:

To signal turns while being towed with hazard warning

flasher in use, turn electronic key in steering lock to

position 2 and activate combination switch for left or

right turn signal in usual manner – only the selected

turn signal will operate.

Upon canceling the turn signal, the hazard warning

flasher will operate again.Caution!

If the vehicle is towed with the front axle raised, the

engine must be shut off (electronic key in steering lock

position 0 or 1). Otherwise, the ESP will immediately be

engaged and will apply the rear wheel brakes. Switch off

the tow-away alarm as well as the ESP

.

267

Page 269 of 323

Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Bulbs

Headlamp adjustment

Correct headlamp adjustment is extremely important.

Check and readjust headlamps at regular intervals and

when a bulb has been replaced.

For adjusting headlamp aim see page274.

Replacing bulbsNotes:

To prevent a possible electrical short circuit, switch off

lamp prior to replacing a bulb.

When replacing bulbs, install only 12 volt bulbs with

the specified watt rating.

When replacing halogen bulbs do not touch glass

portion of bulb with bare hands. Use plain paper or a

clean cloth.

Warning!

Bulbs and bulb holders can be very hot. Allow the

lamp to cool down before changing a bulb.

Halogen lamps contain pressurized gas. A bulb can

explode if you:

• touch or move it when hot,

• drop the bulb,

• scratch the bulb.Wear eye and hand protection.

Wa r n i n g !

Because of high voltage in Xenon lamps, it is

dangerous to replace the bulb or repair the lamp

and its components. We recommend that you have

such work done by a qualified technician.

269