ESP MERCEDES-BENZ CLK320 CABRIOLET 2002 A208 Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2002, Model line: CLK320 CABRIOLET, Model: MERCEDES-BENZ CLK320 CABRIOLET 2002 A208Pages: 346

Page 248 of 346

245 Malfunction and warning messages

Technical

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hints Car care Index ELEC. STABIL. PROG.

(Electronic stability program)

1 A malfunction has been detected in the system. Pressing the

accelerator pedal will require greater effort. Only partial engine

output will be available.

2 This message may be displayed if the power supply was

interrupted (battery disconnected or empty).

3 Synchronize ESP. See page 221

REMOVE KEY

This message plus an audible alarm indicate that the

electronic key is in steering lock position 0 or 1, and the

driver’s door is open.

Line 1 Line 2

DISPLAY DEFECTIVE VISIT WORKSHOP!

ELEC. STABIL. PROG. VISIT WORKSHOP!

1, 2, 3

Line 1 Line 2

REMOVE KEY!

P54.30-3573-21

J_A208.book Seite 245 Donnerstag, 31. Mai 2001 9:35 09

Page 255 of 346

252 Fuses

Technical

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

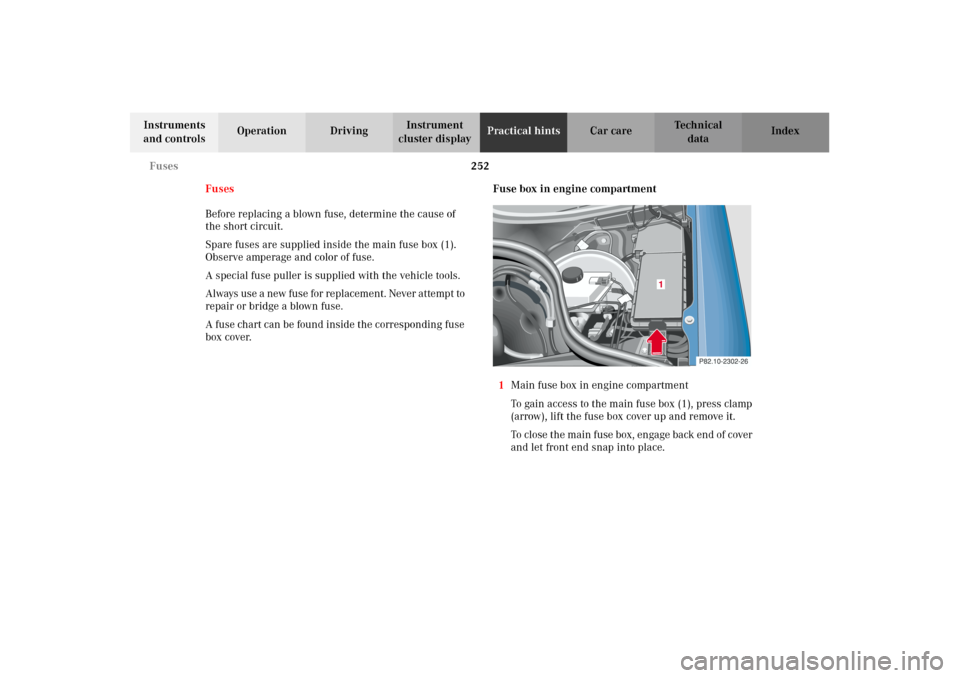

Fuses

Before replacing a blown fuse, determine the cause of

the short circuit.

Spare fuses are supplied inside the main fuse box (1).

Observe amperage and color of fuse.

A special fuse puller is supplied with the vehicle tools.

A lways us e a new fus e for re placeme nt. Never atte mp t to

repair or bridge a blown fuse.

A fuse chart can be found inside the corresponding fuse

box cover.Fuse box in engine compartment

1Main fuse box in engine compartment

To gain access to the main fuse box (1), press clamp

(arrow), lift the fuse box cover up and remove it.

To close the main fuse box, engage back end of cover

and let front end snap into place.

1

J_A208.book Seite 252 Donnerstag, 31. Mai 2001 9:35 09

Page 264 of 346

261 Spare wheel, vehicle jack

Technical

data Instruments

and controlsOperation DrivingInstrument

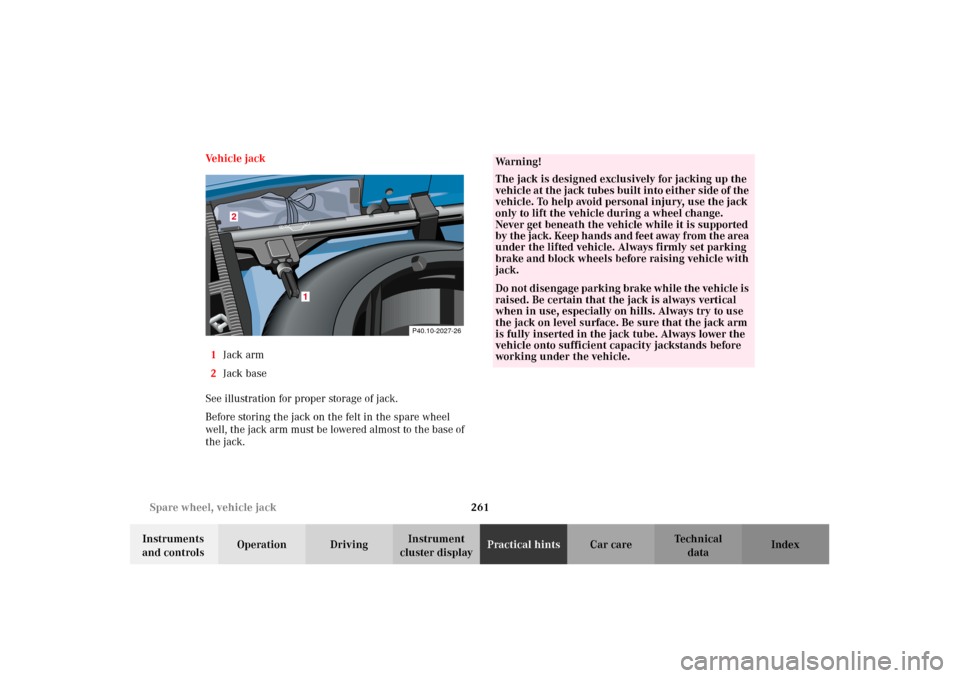

cluster displayPractical hintsCar care Index Ve h i c l e j a c k

1Jack arm

2Jack base

See illustration for proper storage of jack.

Before storing the jack on the felt in the spare wheel

well, the jack arm must be lowered almost to the base of

the jack.

1

2

P40.10-2027-26

Wa r n i n g !

The jack is designed exclusively for jacking up the

vehicle at the jack tubes built into either side of the

vehicle. To help avoid personal injury, use the jack

only to lift the vehicle during a wheel change.

Never get beneath the vehicle while it is supported

by the ja ck. Keep ha nd s an d feet away from the area

under the lifted vehicle. Always firmly set parking

brake and block wheels before raising vehicle with

jack.Do not d i sen ga ge park in g b ra ke whi l e the vehic l e is

raised. Be certain that the jack is always vertical

when in use, especially on hills. Always try to use

the jack on level surface. Be sure that the jack arm

is fully inserted in the jack tube. Always lower the

vehicle onto sufficient capacity jackstands before

working under the vehicle.

J_A208.book Seite 261 Donnerstag, 31. Mai 2001 9:35 09

Page 269 of 346

266 Tires, Wheels

Technical

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Changing wheelsMove vehicle to a level area which is a safe distance

from the roadway.

1. Set parking brake and turn on hazard warning

flasher.

2. Move selector lever to position “P” and turn off

engine.

3. Prevent vehicle from rolling away by blocking

wheels with wheel chocks (not supplied with

vehicle) or sizable wood block or stone. When

changing a wheel on a hill, place chocks on the

downhill side blocking both wheels of the other

axle. On a level road, place one chock in front of and

one behind the wheel that is diagonally opposite to

the wheel being changed.

Wa r n i n g !

The jack is designed exclusively for jacking up the

vehicle at the jack tubes built into either side of the

vehicle. To help avoid personal injury, use the jack

only to lift the vehicle during a wheel change.

Never get beneath the vehicle while it is supported

by t he j ack . Keep han ds a nd feet away from t he a rea

under the lifted vehicle. Always firmly set parking

brake and block wheels before raising vehicle with

jack.Do n ot d is engage parki n g brake w hil e t he vehi c le i s

raised. Be certain that the jack is always vertical

when in use, especially on hills. Always try to use

the jack on level surface. Be sure that the jack arm

is fully inserted in the jack tube. Always lower the

vehicle onto sufficient capacity jackstands before

working under the vehicle.

Wa r n i n g !

Before working on the vehicle, e.g. when changing

wheels, the roll bar should be raised with the

switch, and the electronic key be removed from the

steering lock, to prevent possible injury.

J_A208.book Seite 266 Donnerstag, 31. Mai 2001 9:35 09

Page 274 of 346

271 Tires, Wheels

Technical

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Tire inflation pressure

A table (see fuel filler flap) lists the tire inflation

pressures specified for Mercedes-Benz recommended

tires as well as for the varying operating conditions.

Important!

Tire pressure changes by approx. 1.5 psi (0.1 bar) per

18

°F (10

°C) of air temperature change. Keep this in

mind when checking tire pressure inside a garage –

especially in the winter.

Example:

If garage temperature = approx. +68

°F (+20

°C) and

ambient temperature = approx. +32

°F (0

°C) then the

adjusted air pressure = specified air pressure +3 psi

(+0.2 bar).Tire pressures listed for light loads are minimum values

offering high driving comfort. Increased inflation

pressures for heavy loads produce favorable handling

characteristics with lighter loads and are perfectly

permissible. The ride of the vehicle, however, will

become somewhat harder.

Tire temperature and pressure increase with the vehicle

speed. Tire pressure should therefore only be checked

and corrected on cold tires. Correct tire pressure in

warm tires only if pressure has dropped below the

pressure listed in the table and the respective operating

conditions are taken into consideration.

An underinflated tire due to a slow leak (e.g. due to a

nail in the tire) may cause damage such as tread

separation, bulging etc.. Regular tire pressure checks

(including the spare tire) at intervals of no more than

14 days are therefore essential.

J_A208.book Seite 271 Donnerstag, 31. Mai 2001 9:35 09

Page 276 of 346

273 Battery

Technical

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Therefore, we strongly recommend that you have the

battery charge checked frequently, and corrected if

necessary, especially if you use the vehicle less than

approximately 200 miles (300 km) per month,

mostly for short distance trips, or if it is not used for

long periods of time.

Only charge a battery with a battery charger after the

battery has been disconnected from the vehicle’s

electrical circuit.

Always disconnect the battery negative lead first and

connect last.

When removing and connecting the battery, always

make sure that all electrical consumers are off and the

electronic key is in steering lock position 0. The battery

and its filler caps must always be securely installed

when the vehicle is in operation. During removal and

installation always protect the disconnected battery

positive (+) terminal with the cover attached to the

battery.

While the engine is running the battery terminal clamps

must not be loosened or detached, otherwise the

generator and other electronic components would be

damaged.Notes:

After reconnecting the battery also set the clock (see

page 106) resynchronize the front seats (see page 49),

front seat head restraints (see page 49), the express

feature of the power windows (see page 147), and the

electronic stability program (ESP) (see page 221).

If the soft top is in a half open position, it also has to be

synchronized. To do so, raise and lock soft top manually

(see page 291).

Battery recycling

Batteries contain material that can harm the

environment with improper disposal.

Large 12 Volt storage batteries contain lead.

Recycling of batteries is the preferred method of

disposal.

Many states require sellers of batteries to accept old

batteries for recycling.

J_A208.book Seite 273 Donnerstag, 31. Mai 2001 9:35 09

Page 281 of 346

278 Towing

Technical

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

We recommend that the vehicle be transported using

flat bed equipment. This method is preferable to other

types of towing.

The vehicle may be towed with all wheels on the ground

and the selector lever in position “N” for distances up to

30 miles (50 km) and at a speed not to exceed 30 mph

(50 km/h). The electronic key must be in steering lock

position 2.

To be certain to avoid a possibility of damage to the

transmission, however, we recommend the drive shaft

be disconnected at the rear axle drive flange for any

towing beyond a short tow to a nearby garage.

Do not tow with sling-type equipment. Towing with

sling-type equipment over bumpy roads will damage

radiator and supports.

Use wheel lift, dolly, or flat bed equipment, with

electronic key in steering lock turned to position 0.Note:

To signal turns while being towed with hazard warning

flasher in use, turn electronic key in steering lock to

position 2 and activate combination switch for left or

right turn signal in usual manner – only the selected

turn signal will operate.

Upon canceling the turn signal, the hazard warning

flasher will operate again.

Caution!

If the vehicle is towed with the front axle raised, the

engine must be shut off (electronic key in steering lock

position 0 or 1). Otherwise, the ESP will immediately be

engaged and will apply the rear wheel brakes. Switch off

the tow-away alarm (see page 44) as well as the ESP (see

page 222).

Wa r n i n g !

With the engine not running, there is no power

assistance for the braking and steering systems. In

this case, it is important to keep in mind that a

considerably higher degree of effort is necessary to

brake and steer the vehicle.

J_A208.book Seite 278 Donnerstag, 31. Mai 2001 9:35 09

Page 316 of 346

313 Technical data

Technical

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hints Car care Index Technical data

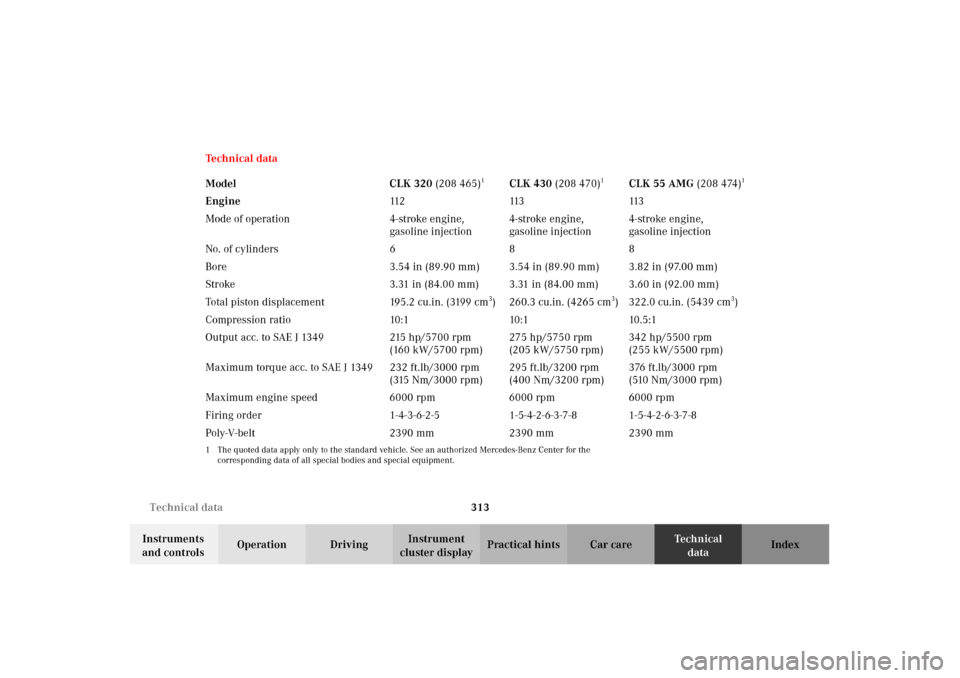

Model CLK 320 (208 465)

1

CLK 430 (208 470)

1

CLK 55 AMG (208 474)

1

Engine11 2 113 113

Mode of operation 4-stroke engine,

gasoline injection4-stroke engine,

gasoline injection4-stroke engine,

gasoline injection

No. of cylinders688

Bore 3.54 in (89.90 mm) 3.54 in (89.90 mm) 3.82 in (97.00 mm)

Stroke 3.31 in (84.00 mm) 3.31 in (84.00 mm) 3.60 in (92.00 mm)

Total piston displacement 195.2 cu.in. (3199 cm

3) 260.3 cu.in. (4265 cm

3) 322.0 cu.in. (5439 cm

3)

Compression ratio 10:1 10:1 10.5:1

Output acc. to SAE J 1349 215 hp/5700 rpm

(160 kW/5700 rpm)275 hp/5750 rpm

(205 kW/5750 rpm)342 hp/5500 rpm

(255 kW/5500 rpm)

Maximum torque acc. to SAE J 1349 232 ft.lb/3000 rpm

(315 Nm/3000 rpm)295 ft.lb/3200 rpm

(400 Nm/3200 rpm)376 ft.lb/3000 rpm

(510 Nm/3000 rpm)

Maximum engine speed 6000 rpm 6000 rpm 6000 rpm

Firing order 1-4-3-6-2-5 1-5-4-2-6-3-7-8 1-5-4-2-6-3-7-8

Poly-V-belt 2390 mm 2390 mm 2390 mm

1 The quoted data apply only to the standard vehicle. See an authorized Mercedes-Benz Center for the

corresponding data of all special bodies and special equipment.

J_A208.book Seite 313 Donnerstag, 31. Mai 2001 9:35 09

Page 321 of 346

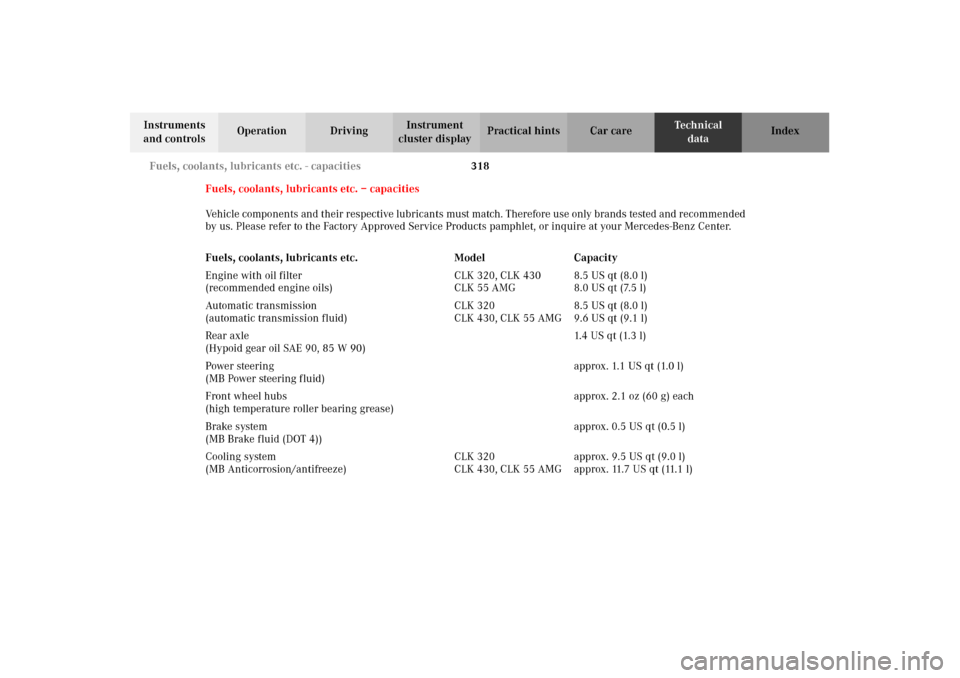

318 Fuels, coolants, lubricants etc. - capacities

Technical

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hints Car care Index

Fuels, coolants, lubricants etc. – capacities

Vehicle components and their respective lubricants must match. Therefore use only brands tested and recommended

by us. Please refer to the Factory Approved Service Products pamphlet, or inquire at your Mercedes-Benz Center.

Fuels, coolants, lubricants etc. Model Capacity

Engine with oil filter

(recommended engine oils)CLK 320, CLK 430

CLK 55 AMG8.5 US qt (8.0 l)

8.0 US qt (7.5 l)

Automatic transmission

(automatic transmission fluid)CLK 320

CLK 430, CLK 55 AMG8.5 US qt (8.0 l)

9.6 US qt (9.1 l)

Rear axle

(Hypoid gear oil SAE 90, 85 W 90)1.4 US qt (1.3 l)

Power steering

(MB Power steering fluid)approx. 1.1 US qt (1.0 l)

Front wheel hubs

(high temperature roller bearing grease)approx. 2.1 oz (60 g) each

Brake system

(MB Brake fluid (DOT 4))approx. 0.5 US qt (0.5 l)

Cooling system

(MB Anticorrosion/antifreeze)CLK 320

CLK 430, CLK 55 AMGapprox. 9.5 US qt (9.0 l)

approx. 11.7 US qt (11.1 l)

J_A208.book Seite 318 Donnerstag, 31. Mai 2001 9:35 09

Page 325 of 346

322 Fuels, coolants, lubricants etc.

Technical

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hints Car care Index

Gasoline additives

A major concern among engine manufacturers is carbon

build up caused by gasoline. Mercedes-Benz

recommends the use of only quality gasoline containing

additives that prevent the build up of carbon deposits.

After an extended period of using fuels without such

ad ditives , car bon d ep osits c an bui ld up esp eci ally on t he

intake valves and in the combustion area, leading to

engine performance problems such as:

•warm-up hesitation,

•unstable idle,

•knocking/pinging,

•misfire,

•power loss.

Do not blend other specific fuel additives with fuel.

They only result in unnecessary cost, and may be

harmful to the engine operation.

Damage or malfunctions resulting from poor fuel

quality or from blending specific fuel additives are not

covered by the Mercedes-Benz Limited Warranty.Coolants

The engine coolant is a mixture of water and

anticorrosion/antifreeze, which provides:

•corrosion protection,

•freeze protection,

•boiling protection (by increasing the boiling point).

The cooling system was filled at the factory with a

coolant providing freeze protection to approximately

-22

°F (-30

°C) and corrosion protection.

If the antifreeze mixture is effective to -22

°F (-30

°C), the

boiling point of the coolant in the pressurized cooling

system is reached at approximately 266

°F (130

°C).

The coolant solution must be used year round to provide

the necessary corrosion protection and increase in the

boil-over protection. You should have it replaced every

3years.

To provide the important corrosion protection, the

solution must be at least 45% anticorrosion/antifreeze

(equals a freeze protection to approx. - 22

°F [-30

°C]). If

you use a solution that is more than 55% anticorrosion/

antifreeze (freeze protection to approx. - 49

°F [-45

°C]),

J_A208.book Seite 322 Donnerstag, 31. Mai 2001 9:35 09