ECU MERCEDES-BENZ CLS 2017 Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: CLS, Model: MERCEDES-BENZ CLS 2017Pages: 334, PDF Size: 10.18 MB

Page 292 of 334

As soon as the vehicle has been loaded:X

Prevent the veh icle from rolling away by

applyin g the parking brake.X

Sh ift the automat ic transmission to posi-

tion P .X

Turn the Sm artKey to position 0 in the ignition

lock and remove it. X

Secure the veh icle .

Notes on 4MATIC vehicles

! Veh icle s wit h 4MATIC must not be towed

wit h either the front or the rear axle raised, as

doin g so will damage the transmission.

If the veh icle has transmission damage or dam-

age to the front or rear axle, have it transported

on a transporter or trailer.

In the event of da ma ge to the electrical sys-

tem

If the battery is defective, the automat ic trans-

mission will be locked in position P . To shift the

automat ic transmission to position N , you must

pro vide power to the veh icle 's electrical system

in the same way as when jump-starting

( Y

page 285).

Have the veh icle transported on a transporter or

trailer.

Tow-starting (emergency engine

starting)

! Veh icle s wit h automat ic transmission must

not be started by tow-starting. This could oth-

erwise damage the transmission.

i You can find information on "Jump-starting"

under ( Y

page 285).

Fuses

Important safety notes

G WAR NING

If you man ipulat e or brid ge a faulty fuse or if

you replace it wit h a fuse wit h a higher amper-

age, the electr ic cables could be overloaded.

This could result in a fire. There is a risk of an

acc iden t and injury. Alwa ys replace faulty fuses wit h the specified

new fuses having the correct amperage.

Blo wn fuses must be replaced wit h fuses of the

same rating, whic h you can recognize by the

color and value. The fuse ratings are listed in the

fuse allocation chart.

The fuse allocation chart is located in the vehicle

tool kit in the stowage compartment under the

trunk floor ( Y

page 277).

If a ne wly inserted fuse also blows, have the

cause traced and rectified at a qualified special-

ist worksho p, e.g. an authorized Mercedes-Benz

Center.

! Only use fuses that have been appr oved for

Mercedes-Benz vehicles and whic h have the

correct fuse rating for the system concerned.

Otherwise, components or systems could be

damaged.

! Make sure that no moisture can enter the

fuse box when the cover is open.

! When closing the cover, make sure that it is

lying correctly on the fuse box. Moisture seep-

ing in or dirt could otherwise impair the oper-

ation of the fuses.

The fuses in your vehicle ser ve to close down

faulty circuits. If a fuse blows, all the compo-

nents on the circuit and their functions stop

operating.

Before changing a fuse Pay attention to the important safety notes

( Y

page 290). X

Swit ch off the engine. X

Swit ch off all electrical consumers. X

Make sure that the ignition is swit ched off

( Y

page 123).

or X

When using the SmartKey, turn the SmartKey

to position 0 in the ignition lock and remove it

( Y

page 123). X

Secure the vehicle against rolling away

( Y

page 141).

All indicator lamps in the instrument cluster

must be off.290

Fuses

Breakdown assistance

Page 293 of 334

The fuses are located in various fuse boxes: R

Fuse box in the engine compartment on the

left-hand side of the vehicle, when viewed in

the direction of travel R

Fuse box in the trunk on the right-hand side of

the vehicle, when viewed in the direction of

travel

Fuse box in the engine compartment Pay attention to the important safety notes

( Y

page 290).

G WARNING

When the hood is open and the windshield

wipers are set in motion, you can be injured by

the wiper linkage. There is a risk of injury.

Always switch off the windshield wipers and

the ignition before opening the hood.

X

Make sure that the windshield wipers are

turned off. X

Open the hood ( Y

page 265).X

Use a dry cloth to remove any moisture from

the fuse box. X

To open: take lines �C out of the guides.X

Move lines �C to one side.X

Open retaining clamps �D .X

Remove the fuse box cover forwards. X

To close: check whether the seal is lying cor-

rectly in the cover. X

Insert the cover at the rear of the fuse box into

the retainer. X

Fold down the cover and close clamps �D .X

Secure lines �C in the guides.X

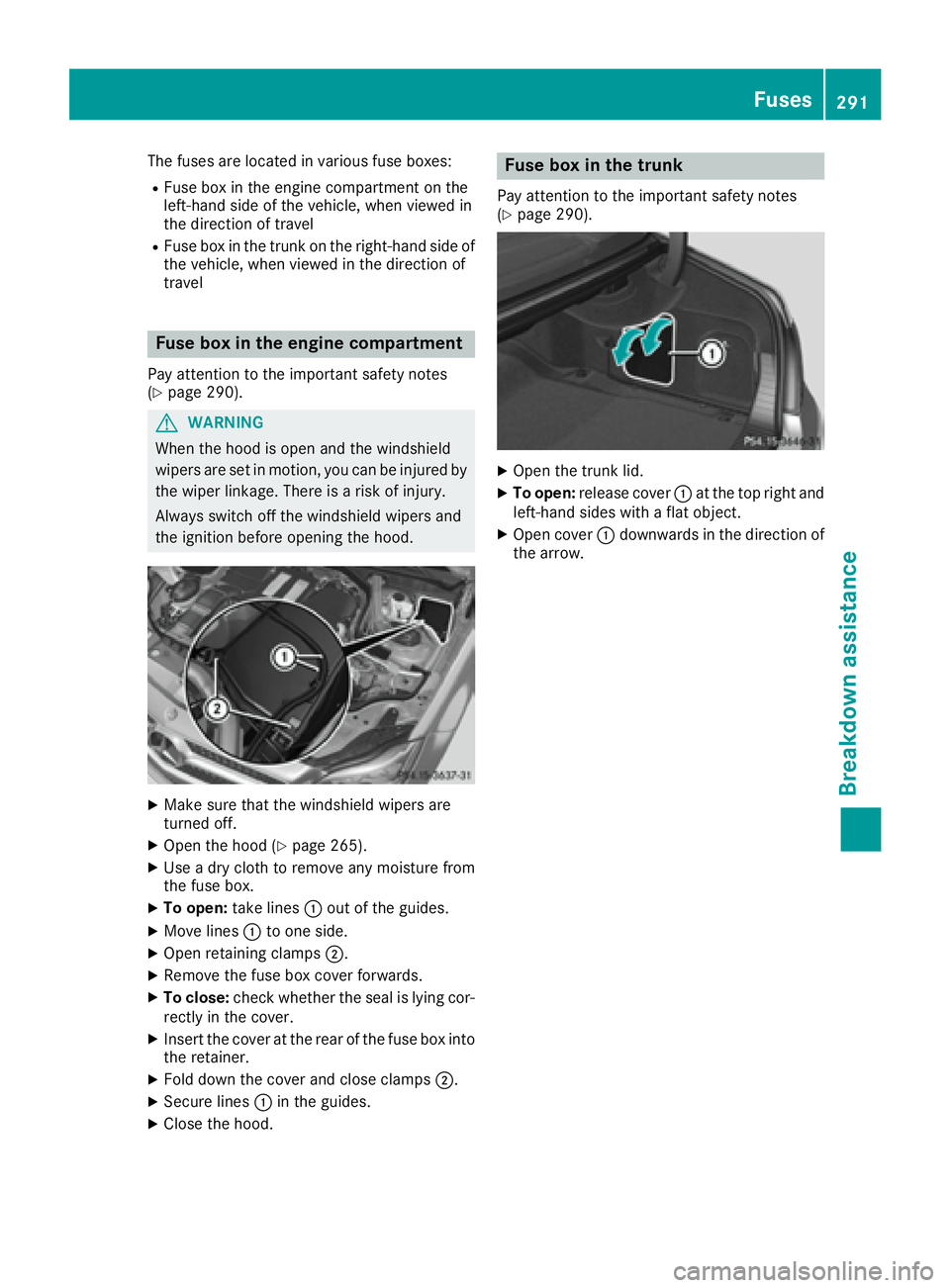

Close the hood. Fuse box in the trunk Pay attention to the important safety notes

( Y

page 290).

X

Open the trunk lid. X

To open: release cover �C at the top right and

left-hand sides with a flat object. X

Open cover �C downwards in the direction of

the arrow. Fuses 291

Breakdown assistance Z

Page 300 of 334

Overinflated tires may: R

increase the braking distance R

adversely affect handling R

wear excessively and/or unevenly R

have an adverse effect on ride comfort R

be more susceptible to damage

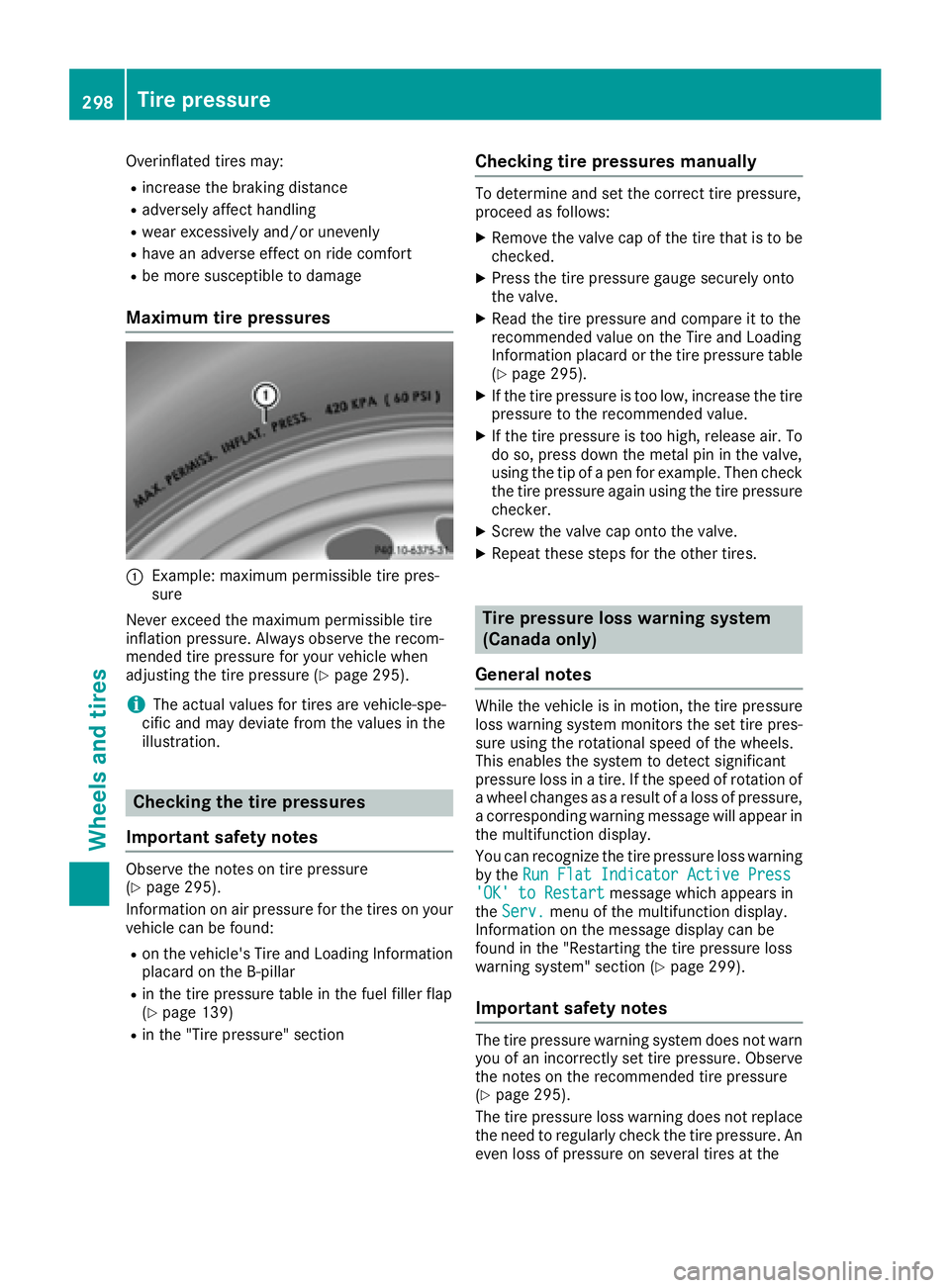

Maximum tire pressures

�C

Example: maximum permissible tire pres-

sure

Never exceed the maximum permissible tire

inflation pressure. Always observe the recom-

mended tire pressure for your vehicle when

adjusting the tire pressure ( Y

page 295).

i The actual values for tires are vehicle-spe-

cific and may deviate from the values in the

illustration.

Checking the tire pressures

Important safety notes Observe the notes on tire pressure

( Y

page 295).

Information on air pressure for the tires on your

vehicle can be found: R

on the vehicle's Tire and Loading Information

placard on the B-pillar R

in the tire pressure table in the fuel filler flap

( Y

page 139)R

in the "Tire pressure" section Checking tire pressures manually To determine and set the correct tire pressure,

proceed as follows: X

Remove the valve cap of the tire that is to be

checked. X

Press the tire pressure gauge securely onto

the valve. X

Read the tire pressure and compare it to the

recommended value on the Tire and Loading

Information placard or the tire pressure table

( Y

page 295). X

If the tire pressure is too low, increase the tire

pressure to the recommended value. X

If the tire pressure is too high, release air. To

do so, press down the metal pin in the valve,

using the tip of a pen for example. Then check

the tire pressure again using the tire pressure

checker. X

Screw the valve cap onto the valve. X

Repeat these steps for the other tires.

Tire pressure loss warning system

(Canada only)

General notes While the vehicle is in motion, the tire pressure

loss warning system monitors the set tire pres-

sure using the rotational speed of the wheels.

This enables the system to detect significant

pressure loss in a tire. If the speed of rotation of

a wheel changes as a result of a loss of pressure,

a corresponding warning message will appear in

the multifunction display.

You can recognize the tire pressure loss warning

by the Run Flat Indicator Active Press

'OK' to Restart message which appears in

the Serv. menu of the multifunction display.

Information on the message display can be

found in the "Restarting the tire pressure loss

warning system" section ( Y

page 299).

Important safety notes

The tire pressure warning system does not warn

you of an incorrectly set tire pressure. Observe

the notes on the recommended tire pressure

( Y

page 295).

The tire pressure loss warning does not replace

the need to regularly check the tire pressure. An

even loss of pressure on several tires at the298

Tire pressure

Wheels and tires

Page 313 of 334

Speed rating The speed rating is part of the tire identification.

It specifies the speed range for which the tire is

approved.

GVW (Gross Vehicle Weight) The gross vehicle weight includes the weight of

the vehicle including fuel, tools, the spare wheel,

accessories installed, occupants, luggage and

the drawbar noseweight, if applicable. The gross

vehicle weight must not exceed the gross vehi-

cle weight rating GVWR as specified on the vehi-

cle identification plate on the B-pillar on the

driver's side.

GVWR (Gross Vehicle Weight Rating) The GVWR is the maximum permissible gross

weight of a fully loaded vehicle (the weight of the

vehicle including all accessories, occupants,

fuel, luggage and the drawbar noseweight, if

applicable). The gross vehicle weight rating is

specified on the vehicle identification plate on

the B-pillar on the driver's side.

Maximum loaded vehicle weight The maximum weight is the sum of: R

the curb weight of the vehicle R

the weight of the accessories R

the load limit R

the weight of the factory installed optional

equipment

Kilopascal (kPa) Metric unit for tire pressure. 6.9 kPa corre-

sponds to 1 psi. Another unit for tire pressure is

bar. 100 kilopascals (kPa) are the equivalent of

1 bar.

Load index

In addition to the load-bearing index, the load

index may also be imprinted on the sidewall of

the tire. This specifies the load-bearing capacity

more precisely.

Curb weight

The weight of a vehicle with standard equipment

including the maximum capacity of fuel, oil and

coolant. It also includes the air-conditioning sys-

tem and optional equipment if these are instal-

led in the vehicle, but does not include passen-

gers or luggage. Maximum load rating The maximum tire load is the maximum permis-

sible weight in kilograms or lbs for which a tire is

approved.

Maximum permissible tire pressure Maximum permissible tire pressure for one tire.

Maximum load on one tire Maximum load on one tire. This is calculated by

dividing the maximum axle load of one axle by

two.

PSI (pounds per square inch) A standard unit of measure for tire pressure.

Aspect ratio Relationship between tire height and tire width

in percent.

tire pressure Pressure inside the tire applying an outward

force to every square inch of the tire's surface.

The tire pressure is specified in pounds per

square inch (psi), in kilopascal (kPa) or in bar.

The tire pressure should only be corrected when

the tires are cold.

Cold tire pressure The tires are cold: R

if the vehicle has been parked with the tires

out of direct sunlight for at least three hours

and R

if the vehicle has not been driven further than

1 mile (1.6 km)

Tread

The part of the tire that comes into contact with

the road.

Bead

The tire bead ensures that the tire sits securely

on the wheel. There are several steel wires in the

bead to prevent the tire from coming loose from

the wheel rim.

Sidewall

The part of the tire between the tread and the

bead.All about wheels and tires 311

Wheels and tires Z

Page 315 of 334

Direction of rotation Tires wit h a specifie d direction of rotation hav e

additional benefits, e.g. if there is a ris k of hydro-

planing. These advantages can only be gained if

th e tires are installed correspondin g to th e

direction of rotation .

An arrow on th e sidewall of th e tire indicates it s

correc t direction of rotation .

Storing wheel sStor e wheels that are no t bein g used in a cool,

dry and preferably dar k place. Protec t th e tires

from oil, grease , gasolin e and diesel.

Mounting a wheel

Preparing th e vehicleX

Stop th e vehicle on solid, non-slipper y and

level ground. X

Apply th e parking brake .X

Brin g th e fron t wheels into th e straight-ahead

position .X

Shift th e transmissio n to position P .X

Vehicles wit h AIRMATIC : mak e sur e that "nor-

mal" level is selecte d ( Y

page 159).X

Switc h of f th e engine.X

Remov e th e SmartKey from th e ignition lock.

or , on vehicles wit h KEYLESS ‑ GO :X

Ope n th e driver's door.

The vehicle electronic s no w hav e status 0 .

Thi s is th e sam e as th e SmartKey havin g bee n

removed. X

Remov e th e Start/Sto p butto n from th e igni-

tion loc k ( Y

page 123).X

If included in th e vehicle equipment, remov e

th e tire-chang e tool ki t from th e vehicle

( Y

page 277). X

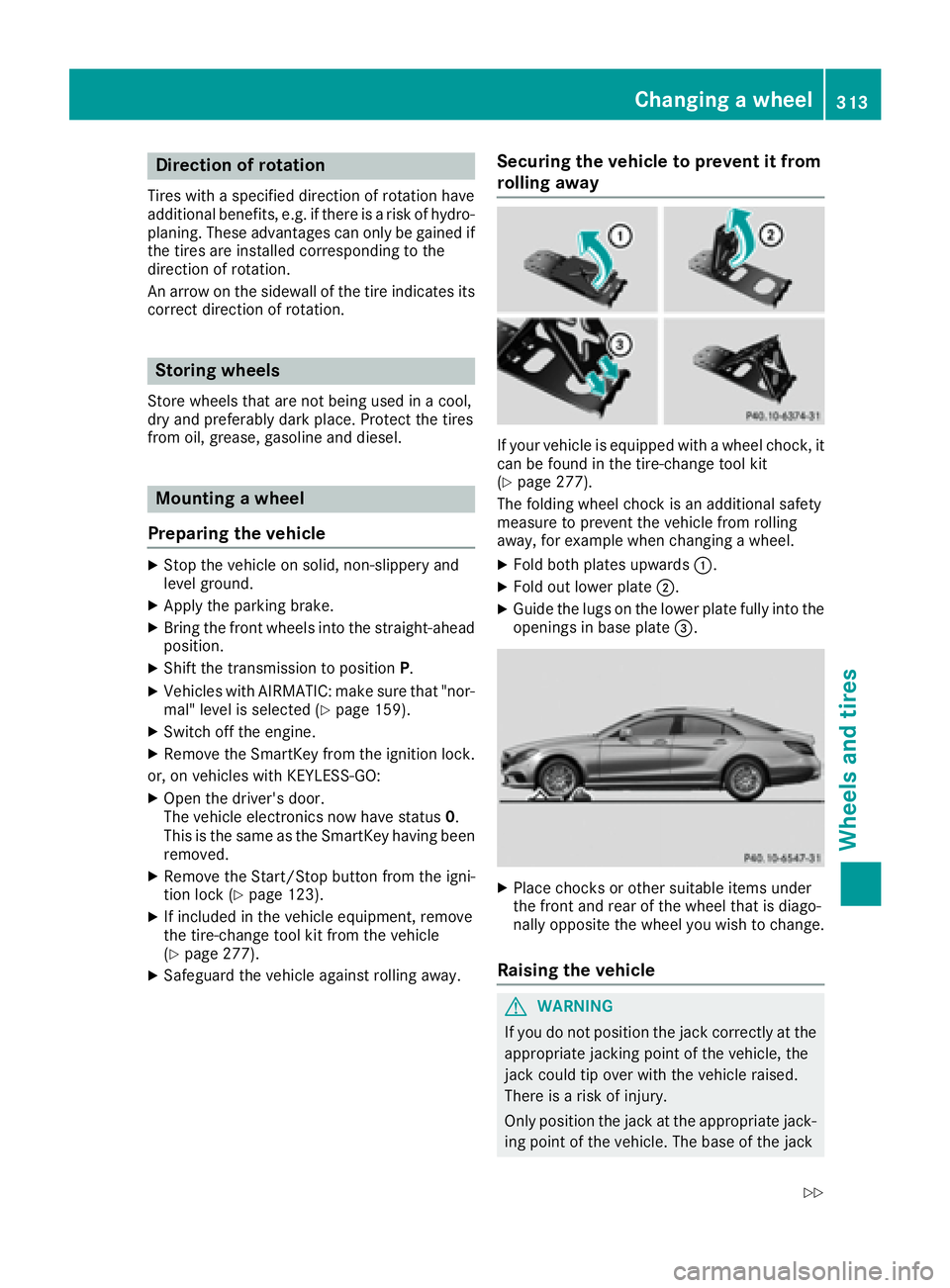

Safeguar d th e vehicle against rollin g away. Securing th e vehicle to preven t it from

rollin g awa y

If your vehicle is equipped wit h a whee l chock, it

can be found in th e tire-chang e tool ki t

( Y

page 277).

The foldin g whee l choc k is an additional safet y

measur e to preven t th e vehicle from rollin g

away, fo r example when changin g a wheel.X

Fold bot h plates upwards �C .X

Fold out lowe r plat e �D .X

Guide th e lugs on th e lowe r plat e full y into th e

opening s in base plat e �

Page 316 of 334

must be positioned vertically, directly under

the jacking point of the vehicle.

! The jack is designed exclusively for jacking

up the vehicle at the jacking points. Other-

wise, your vehicle could be damaged.

Observe the following when raising the vehicle: R

To raise the vehicle, only use the vehicle-spe-

cific jack that has been tested and approved

by Mercedes-Benz. If used incorrectly, the

jack could tip over with the vehicle raised. R

The jack is designed only to raise and hold the

vehicle for a short time while a wheel is being

changed. It must not be used for performing

maintenance work under the vehicle. R

Avoid changing the wheel on uphill and down-

hill slopes. R

Before raising the vehicle, secure it from roll-

ing away by applying the parking brake and

inserting wheel chocks. Do not disengage the

parking brake while the vehicle is raised. R

The jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

flat, load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats. R

Do not use wooden blocks or similar objects

as a jack underlay. Otherwise, the jack will not

be able to achieve its load-bearing capacity

due to the restricted height. R

Make sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in (3 cm). R

Never place your hands and feet under the

raised vehicle. R

Do not lie under the vehicle. R

Do not start the engine when the vehicle is

raised. R

Do not open or close a door or the trunk lid

when the vehicle is raised. R

Make sure that no persons are present in the

vehicle when the vehicle is raised.

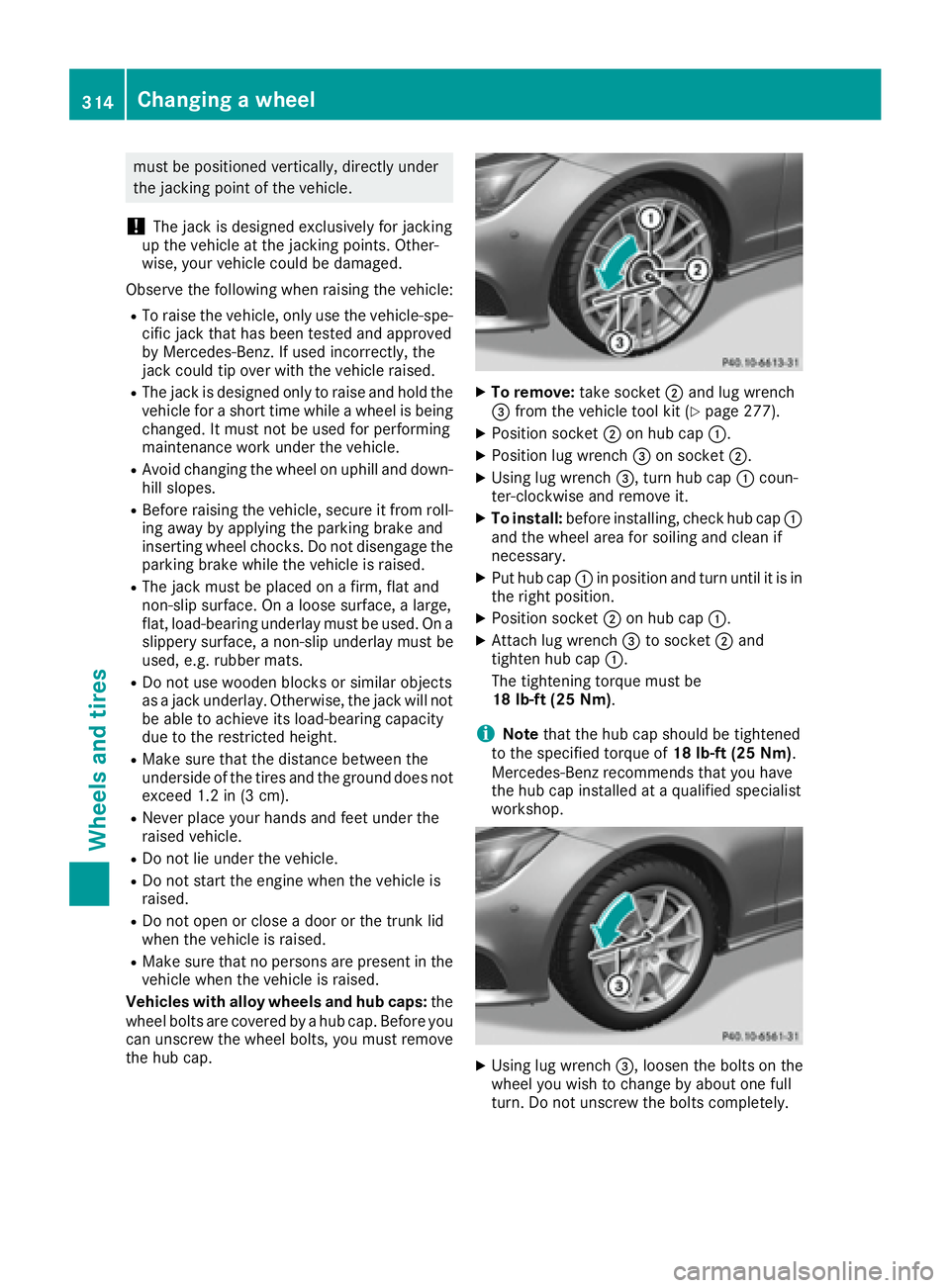

Vehicles with alloy wheels and hub caps: the

wheel bolts are covered by a hub cap. Before y ou

ca n unscrew the wheel bolts, you must remove

the hub cap. X

To remove: take socket �D and lug wrench

�

Page 318 of 334

Always pay attention to the instructions and

safety notes in the "Changing a wheel" section

( Y

page 312).

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been approved

for Mercedes-Benz vehicles and the respective

wheel.

! Mercedes-AMG vehicles with ceramic-

brake disc: during removal and repositioning

of the wheel, the wheel rim can strike the

ceramic-brake disc and damage it. Therefore,

you should proceed carefully and get a sec-

ond person assist to you. Alternatively, you

can use a second alignment bolt.

! To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt.

X

Clean the wheel and wheel hub contact sur-

faces. X

Slide the wheel to be mounted onto the align-

ment bolt and push it on. X

Tighten the wheel bolts until they are finger-

tight. X

Unscrew the alignment bolt. X

Tighten the last wheel bolt until it is finger-

tight. X

Vehicles with a collapsible spare wheel:

inflate the collapsible spare wheel

( Y

page 319).

Only then lower the vehicle. Lowering the vehicle

G WARNING

The wheels could work loose if the wheel nuts

and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

! Vehicles with a collapsible spare wheel:

before lowering the vehicle, inflate the col-

lapsible spare wheel with the tire inflation

compressor. The wheel rim could otherwise

be damaged. X

Turn the crank of the jack counter-clockwise

until the vehicle is once again standing firmly

on the ground. X

Place the jack to one side.

X

Tighten the wheel bolts evenly in a crosswise

pattern in the sequence indicated ( �C to �