boot MERCEDES-BENZ E-CLASS COUPE 2015 Owner's Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2015, Model line: E-CLASS COUPE, Model: MERCEDES-BENZ E-CLASS COUPE 2015Pages: 345, PDF Size: 11.42 MB

Page 325 of 345

R

wheel wrench

R centring pin

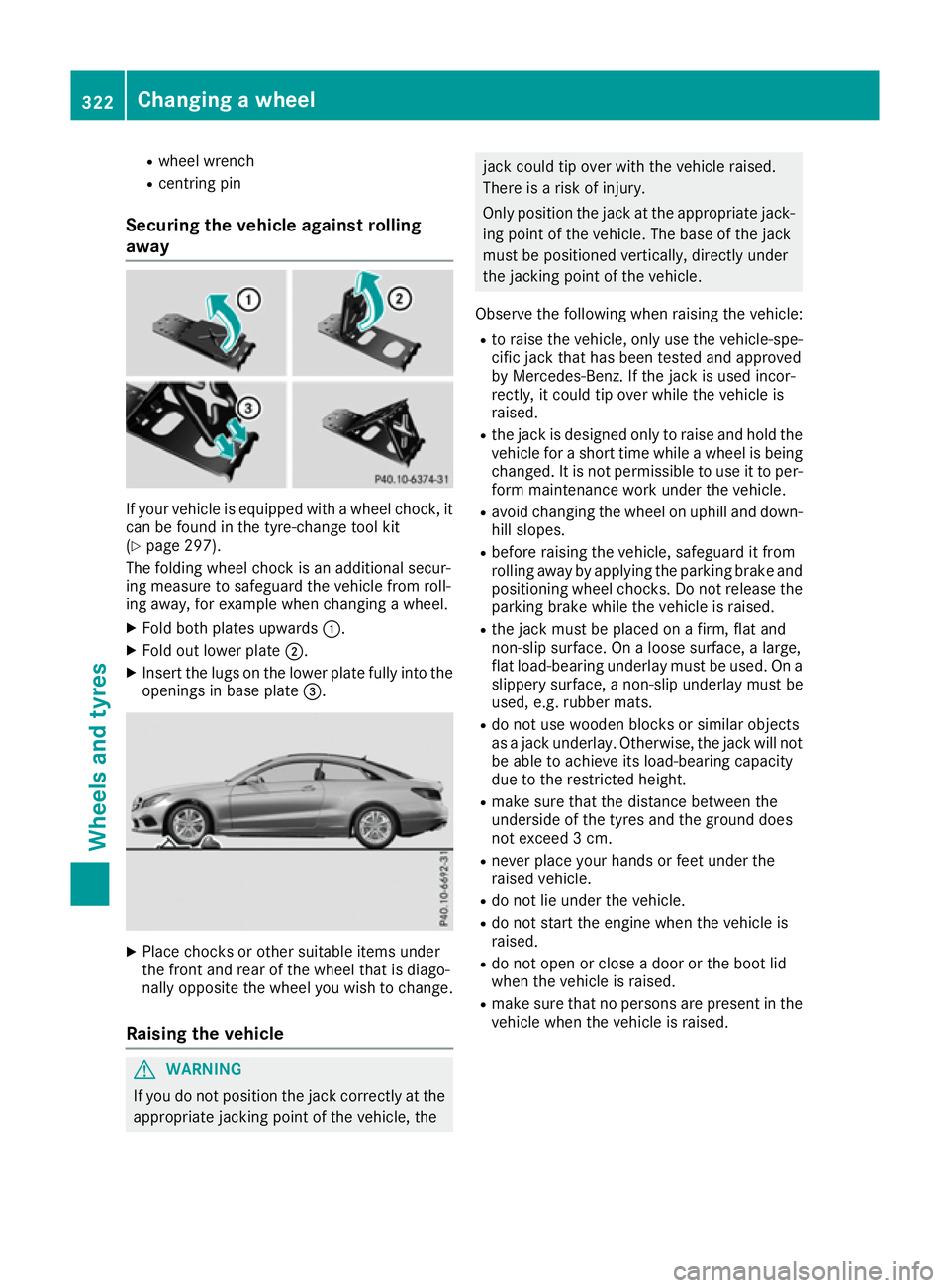

Securing the vehicle against rolling

away If your vehicle is equipped with a wheel chock, it

can be found in the tyre-change tool kit

(Y page 297).

The folding wheel chock is an additional secur-

ing measure to safeguard the vehicle from roll-

ing away, for example when changing a wheel.

X Fold both plates upwards :.

X Fold out lower plate ;.

X Insert the lugs on the lower plate fully into the

openings in base plate =.X

Place chocks or other suitable items under

the front and rear of the wheel that is diago-

nally opposite the wheel you wish to change.

Raising the vehicle G

WARNING

If you do not position the jack correctly at the appropriate jacking point of the vehicle, the jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack- ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

Observe the following when raising the vehicle:

R to raise the vehicle, only use the vehicle-spe-

cific jack that has been tested and approved

by Mercedes-Benz. If the jack is used incor-

rectly, it could tip over while the vehicle is

raised.

R the jack is designed only to raise and hold the

vehicle for a short time while a wheel is being

changed. It is not permissible to use it to per- form maintenance work under the vehicle.

R avoid changing the wheel on uphill and down-

hill slopes.

R before raising the vehicle, safeguard it from

rolling away by applying the parking brake and

positioning wheel chocks. Do not release the parking brake while the vehicle is raised.

R the jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

flat load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats.

R do not use wooden blocks or similar objects

as a jack underlay. Otherwise, the jack will not

be able to achieve its load-bearing capacity

due to the restricted height.

R make sure that the distance between the

underside of the tyres and the ground does

not exceed 3 cm.

R never place your hands or feet under the

raised vehicle.

R do not lie under the vehicle.

R do not start the engine when the vehicle is

raised.

R do not open or close a door or the boot lid

when the vehicle is raised.

R make sure that no persons are present in the

vehicle when the vehicle is raised. 322

Changing a wheelWheels and tyres

Page 327 of 345

X

Unscrew the uppermost wheel bolt com-

pletely.

X Screw centring pin :into the thread instead

of the wheel bolt.

X Unscrew the remaining wheel bolts fully.

X Remove the wheel.

Fitting a new wheel G

WARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event ofdamage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving. G

WARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

It is imperative to observe the instructions and

safety notes on "Changing a wheel"

(Y page 321).

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been approved for Mercedes-Benz vehicles and the respective

wheel. X

Clean the wheel and wheel hub contact sur-

faces.

X Slide the wheel to be mounted onto the cen-

tring pin and push it on.

X Tighten the wheel bolts until they are finger-

tight.

X Unscrew the centring pin.

X Tighten the last wheel bolt until it is finger-

tight.

Lowering the vehicle G

WARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

X Turn the crank of the jack anti-clockwise until

the vehicle is once again standing firmly on

the ground.

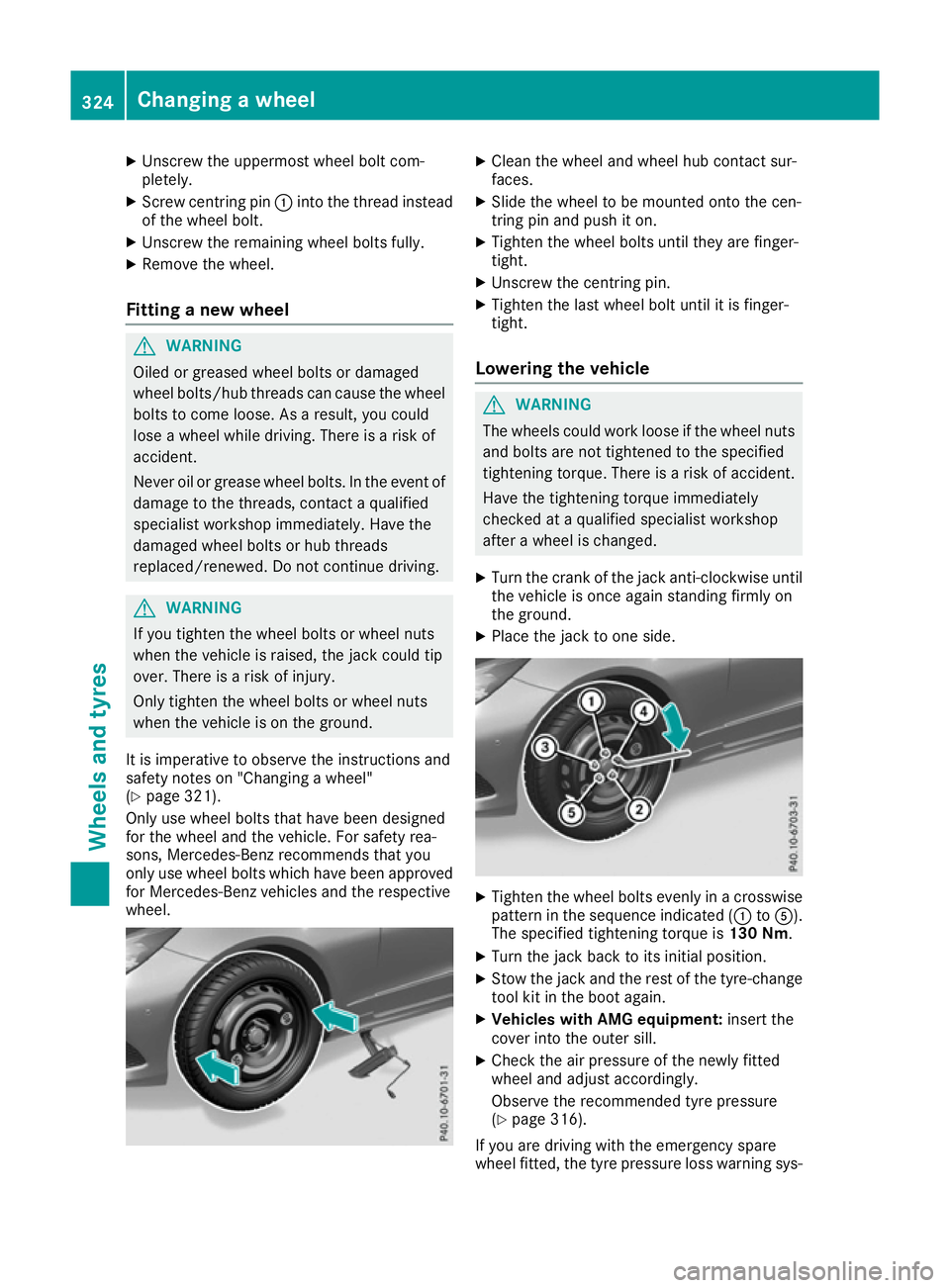

X Place the jack to one side. X

Tighten the wheel bolts evenly in a crosswise

pattern in the sequence indicated (: toA).

The specified tightening torque is 130 Nm.

X Turn the jack back to its initial position.

X Stow the jack and the rest of the tyre-change

tool kit in the boot again.

X Vehicles with AMG equipment: insert the

cover into the outer sill.

X Check the air pressure of the newly fitted

wheel and adjust accordingly.

Observe the recommended tyre pressure

(Y page 316).

If you are driving with the emergency spare

wheel fitted, the tyre pressure loss warning sys- 324

Changing a wheelWheels and tyres

Page 329 of 345

To prevent hazardous situations:

R Adapt your driving style accordingly and

drive carefully.

R Never fit more than one spare wheel/emer-

gency spare wheel if the dimensions are

different to those of the wheel being

replaced.

R Only use a spare wheel/emergency spare

wheel briefly if the dimensions are different

to those of the wheel being replaced.

R Do not switch off ESP ®

.

R Have the spare wheel/emergency spare

wheel in question replaced at the nearest

qualified specialist workshop. Make sure

that the wheel/tyre dimensions and tyre

type are correct.

When using an emergency spare wheel or spare wheel of a different size, you must not exceed

the maximum speed of 80 km/h.

Snow chains must not be fitted to emergency

spare wheels. General notes

You can ask for information regarding permitted

emergency spare wheels at a Mercedes-Benz

Service Centre.

You should regularly check the pressure of all

your tyres, including the emergency spare

wheel, particularly prior to long trips, and cor-

rect the pressure as necessary (Y page 316).

The value on the wheel is valid.

An emergency spare wheel may also be fitted

against the direction of rotation. Observe the

time restriction on use as well as the speed lim- itation specified on the emergency spare wheel.

Replace the tyres after six years at the latest,

regardless of wear. This also applies to the

emergency spare wheel.

i If you are driving with the emergency spare

wheel fitted, the tyre pressure loss warning

system or the tyre pressure monitor cannot

function reliably. Only restart the tyre pres-

sure loss warning system or tyre pressure

monitor when the defective wheel has been

replaced with a new wheel.

Vehicles with a tyre pressure monitor: for a

few minutes after an emergency spare wheel is fitted, the system may still display the tyre

pressure of the removed wheel. The value dis-

played for the position where the emergency

spare wheel is fitted is not the same as the

current tyre pressure of the emergency spare

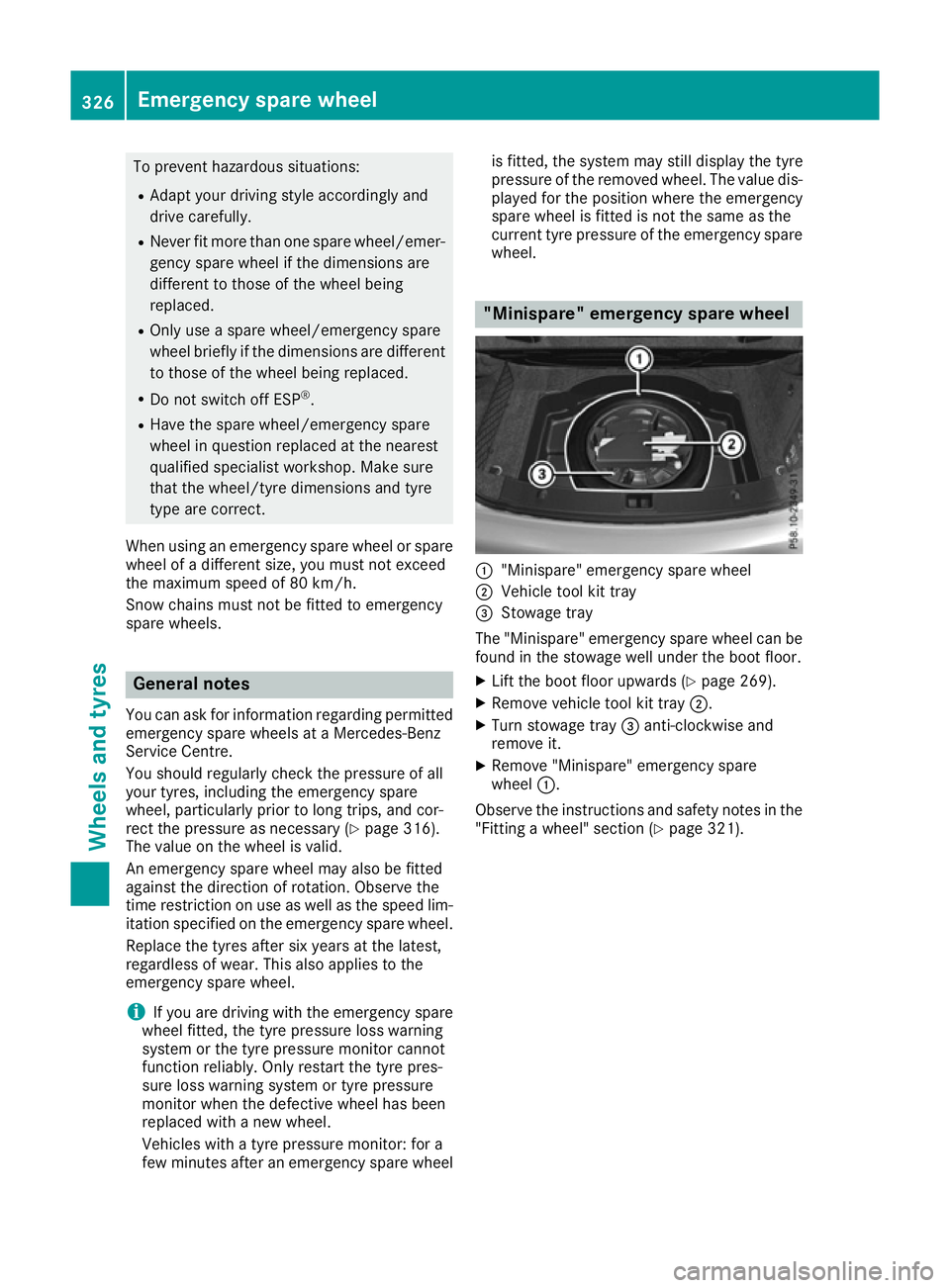

wheel. "Minispare" emergency spare wheel

:

"Minispare" emergency spare wheel

; Vehicle tool kit tray

= Stowage tray

The "Minispare" emergency spare wheel can be found in the stowage well under the boot floor.

X Lift the boot floor upwards (Y page 269).

X Remove vehicle tool kit tray ;.

X Turn stowage tray =anti-clockwise and

remove it.

X Remove "Minispare" emergency spare

wheel :.

Observe the instructions and safety notes in the "Fitting a wheel" section (Y page 321).326

Emergency spare wheelWheels and tyres

Page 330 of 345

Information on technical data

i The technical data was determined in

accordance with EU Directives. All data

applies to the vehicle's standard equipment.

The data may therefore differ for vehicles with

optional equipment. You can obtain further

information from a Mercedes-Benz Service

Centre. Vehicle electronics

Tampering with the engine electron-

ics

! Only have work carried out on the engine

electronics and its associated parts, such as

control units, sensors, actuating components

and connector leads, at a qualified specialist

workshop. Vehicle components may other-

wise wear more quickly and the vehicle's

operating permit may be invalidated. Retrofitting two-way radios and

mobile phones (RF transmitters)

G

WARNING

If RF transmitters are tampered with or not

properly retrofitted, the electromagnetic radi- ation they emit can interfere with the vehicle

electronics. This may jeopardise the opera-

tional safety of the vehicle. There is a risk of an

accident.

You should have all work on electrical and

electronic components carried out at a quali-

fied specialist workshop. G

WARNING

If you operate RF transmitters incorrectly in

the vehicle, the electromagnetic radiation

could interfere with the vehicle electronics,

e.g.:

R if the RF transmitter is not connected to an

exterior aerial

R the exterior aerial has been fitted incor-

rectly or is not a low-reflection type This could jeopardise the operating safety of

the vehicle. There is a risk of an accident.

Have the low-reflection exterior aerial fitted at

a qualified specialist workshop. When oper-

ating RF transmitters in the vehicle, always

connect them to the low-reflection exterior

aerial.

! The operating permit may be invalidated if

the instructions for installation and use of RF

transmitters are not observed.

In particular, the following conditions must be complied with:

R only approved wavebands may be used.

R observe the maximum permissible output

in these wavebands.

R only approved aerial positions may be

used.

Excessive levels of electromagnetic radiation

may cause damage to your health and to the

health of others. The use of an exterior aerial

takes into consideration the scientific discus-

sion surrounding the possible health risk posed

by electromagnetic fields.

Observe the notes on operating mobile phones

(Y page 275).

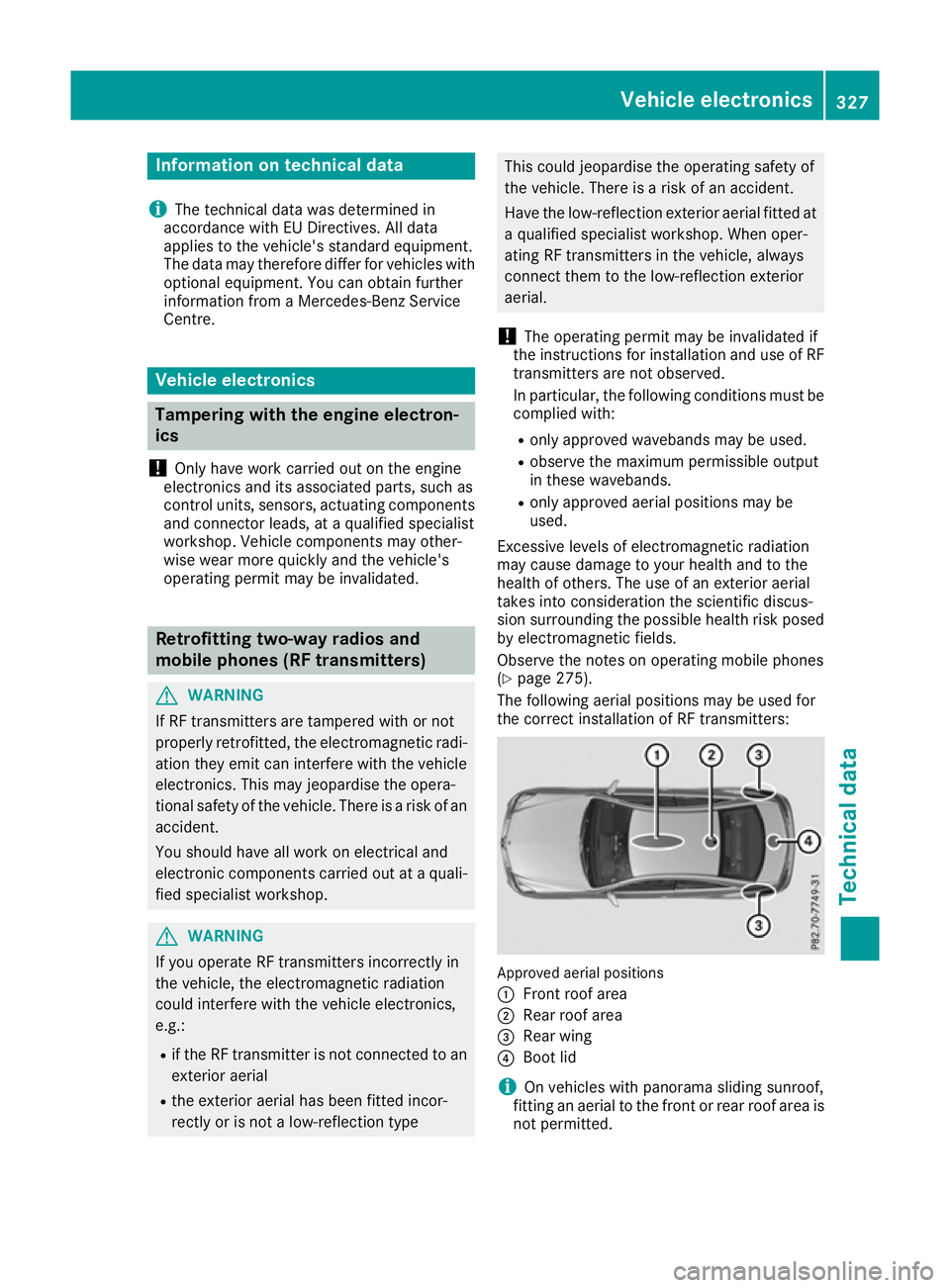

The following aerial positions may be used for

the correct installation of RF transmitters: Approved aerial positions

:

Front roof area

; Rear roof area

= Rear wing

? Boot lid

i On vehicles with panorama sliding sunroof,

fitting an aerial to the front or rear roof area is

not permitted. Vehicle electronics

327Technical data Z

Page 338 of 345

For the correct mixing ratio refer to the infor-

mation on the antifreeze reservoir.

i Add washer fluid concentrate, e.g. MB Sum-

merFit or MB WinterFit, to the washer fluid all

year round. Vehicle data

General notes

Please note that for the specified vehicle data:

R the heights specified may vary as a result of:

- tyres

- load

- condition of the suspension

- optional equipment

R optional equipment reduces the maximum

payload

R vehicle-specific weight information can be

found on the vehicle identification plate

(Y page 328)

R only for certain countries: you can find vehi-

cle-specific vehicle data in the COC docu-

ments (CERTIFICATE OF CONFORMITY).

These documents are delivered with your

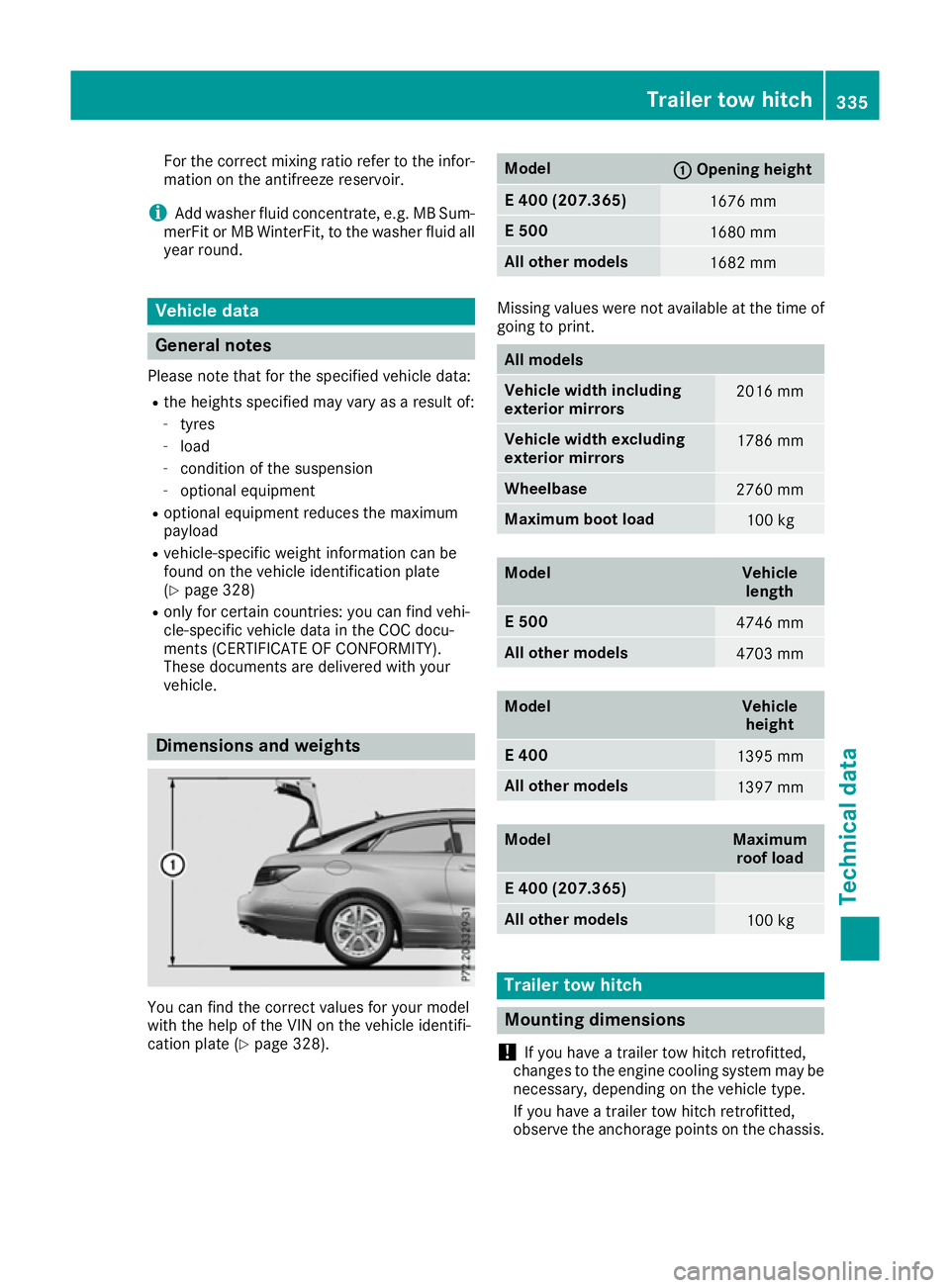

vehicle. Dimensions and weights

You can find the correct values for your model

with the help of the VIN on the vehicle identifi-

cation plate (Y page 328). Model

: :

Opening height E 400 (207.365)

1676 mm

E 500

1680 mm

All other models

1682 mm

Missing values were not available at the time of

going to print. All models

Vehicle width including

exterior mirrors

2016 mm

Vehicle width excluding

exterior mirrors

1786 mm

Wheelbase

2760 mm

Maximum boot load

100 kg

Model Vehicle

length E 500

4746 mm

All other models

4703 mm

Model Vehicle

height E 400

1395 mm

All other models

1397 mm

Model Maximum

roof load E 400 (207.365)

All other models

100 kg

Trailer tow hitch

Mounting dimensions

! If you have a trailer tow hitch retrofitted,

changes to the engine cooling system may be necessary, depending on the vehicle type.

If you have a trailer tow hitch retrofitted,

observe the anchorage points on the chassis. Trailer tow hitch

335Technical data Z