tire pressure MERCEDES-BENZ E-CLASS COUPE 2017 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: E-CLASS COUPE, Model: MERCEDES-BENZ E-CLASS COUPE 2017Pages: 541, PDF Size: 10.71 MB

Page 146 of 541

#

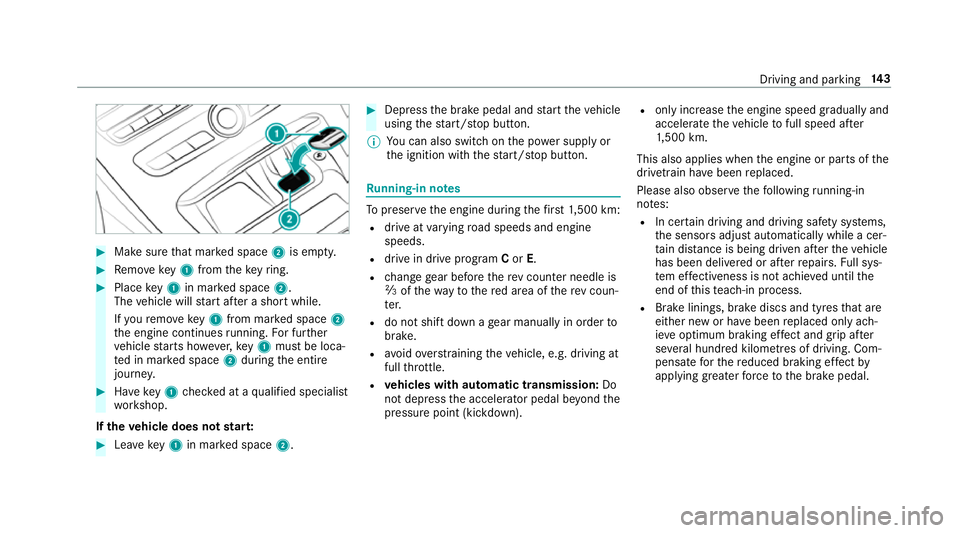

Make sure that mar ked space 2is em pty. #

Remo vekey1 from theke yring. #

Place key1 in mar ked space 2.

The vehicle will start af ter a short while.

If yo ure mo vekey1 from mar ked space 2

th e engine continues running. For fur ther

ve hicle starts ho wever,ke y1 must be loca‐

te d in mar ked space 2during the entire

journe y. #

Have key1 checked at a qualified specialist

wo rkshop.

If th eve hicle does not star t: #

Lea vekey1 in mar ked space 2. #

Depress the brake pedal and start theve hicle

using thest art/ stop button.

% You can also swit chon the po wer supp lyor

th e ignition with thest art/ stop button. Ru

nning-in no tes To

preser vethe engine during thefirs t1, 500 km:

R drive at varying road speeds and engine

speeds.

R drive in drive program Cor E.

R change gear before there v counter needle is

Ô ofthewa yto there d area of there v coun‐

te r.

R do not shift down a gear manually in order to

brake.

R avoidoverstra ining theve hicle, e.g. driving at

full thro ttle.

R vehicles with automatic transmission: Do

not depress the accelera tor pedal be yond the

pressure point (kickdown). R

only increase the engine speed gradually and

accelera tetheve hicle tofull speed af ter

1, 500 km.

This also applies when the engine or parts of the

driv etra in ha vebeen replaced.

Please also obser vethefo llowing running-in

no tes:

R In cer tain driving and driving saf ety sy stems,

th e sensors adjust automatically while a cer‐

ta in dis tance is being driven af terth eve hicle

has been delivered or af terre pairs. Full sys‐

te m ef fectiveness is not achie ved until the

end of this teach-in process.

R Brake linings, brake discs and tyres that are

either new or ha vebeen replaced only ach‐

ie ve optimum braking ef fect and grip af ter

se veral hundred kilom etre s of driving. Com‐

pensate forth ere duced braking ef fect by

applying greaterfo rc eto the brake pedal. Driving and parking

14 3

Page 373 of 541

#

After driving in emergency mode ha ve

th erims checkedby aqu alified special‐

ist workshop with rega rd totheir fur ther

use. #

The defective tyre must be replaced in

eve rycase. Wi

th MOExtended tyres (run-flat tyres), you can

continue todrive your vehicle even if there is a

tot al loss of pressure in one or more tyres. How‐

eve r,th e tyre af fected must not show any clearly

visible damage.

Yo u can recognise MOExtended tyres bythe

MOExtended marking which appears on the side

wa ll of the tyre.

Ve hicles with tyre pressure loss warning sys‐

te m: MOExtended tyres may only be used in

conjunction wi than activated tyre pressure loss

wa rning sy stem.

Ve hicles with tyre pressure monitoring sys‐

te m: MOExtended tyres may only be used in

conjunction wi than activated tyre pressure mon‐

itoring sy stem. If a pressure loss

warning message appears in

th e multifunction display:

R Check the tyre for dama ge.

R If driving on, obser vethefo llowing no tes.

Driving distance possible in limp-home mode

af te r the pressure loss warning: Load condition Driving distance pos‐

sible in limp-homemode

Pa rtially laden 80 km

Fu lly laden 30 km R

The driving dis tance possible in li mp-home

mode may vary depending on the driving

st yle.

R Maximum permissible speed 80 km/h.

If a tyre has gone flat and cannot be replaced

with an MOEx tended tyre, you can use a stand‐

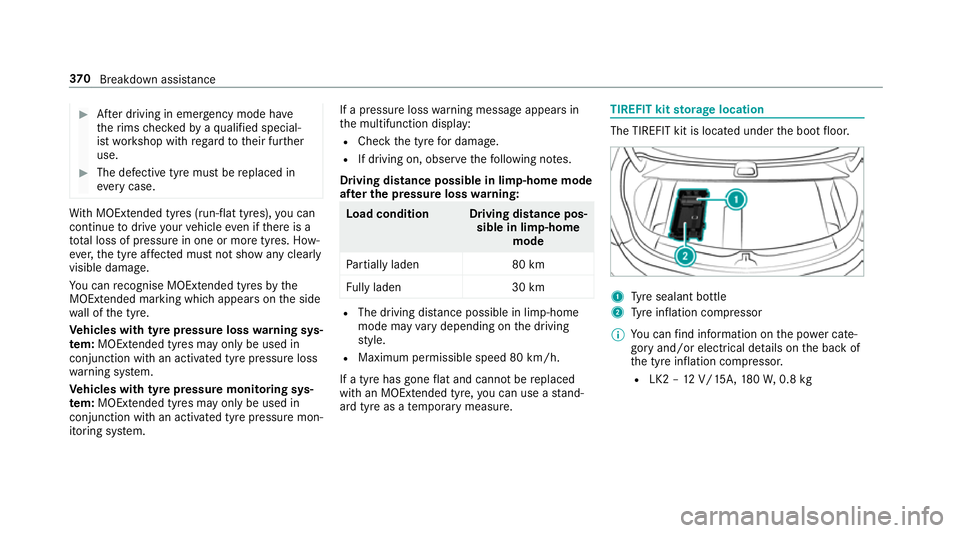

ard tyre as a temp orary measure. TIREFIT kit

storage location The TIREFIT kit is located under

the boot floor. 1

Tyre sealant bottle

2 Tyre inflation compressor

% You can find information on the po wer cate‐

gory and/or electrical de tails on the back of

th e tyre inflation compressor.

R LK2 – 12V/15A, 180W, 0.8 kg 37 0

Breakdown assis tance

Page 374 of 541

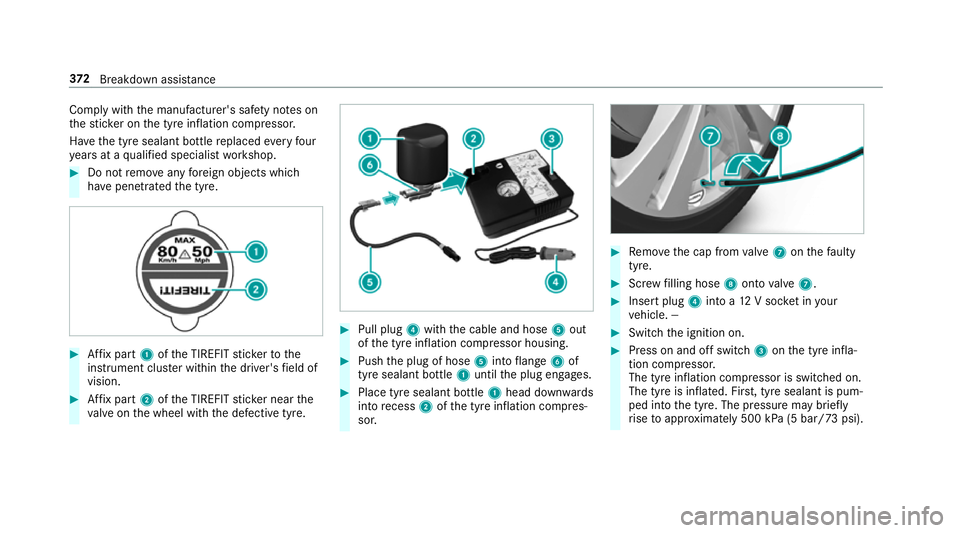

At

a distance of appr oximately 1 m tothe

tyre inflation compressor and appr oximately

1. 6 m abo vethe ground, thefo llowing sound

pressure le vels apply:

R Sound po wer le vel L

LA 74

.8 dB (A)

The tyre inflation compressor is mainte‐

nance-free. If there is a malfunction, please

conta ct aqualified specialist workshop. Using

the TIREFIT kit Ha

ve thefo llowing readily available:

R tyre sealant bottle

R enclosed TIREFIT sticker

R tyre inflation compressor

Yo u can use TIREFIT tyre sealant toseal punctu‐

re s of up to4 mm, particularly those in the tyre

conta ct surface. You can use TIREFIT in outside

te mp eratures down to-20 °C. &

WARNING Risk of accident when using

tyre sealant

In thefo llowing situations, the tyre sealant is

unable toprov ide suf ficient breakdown assis‐

ta nce, as it is unable toseal the tyre prop‐

er ly:

R there are cuts or punctures in the tyre

lar gerth an those pr eviously mentioned.

R the wheel rim is dama ged.

R you ha vedriven at very low tyre pres‐

sures or on a flat tyre. #

Do not drive on. #

Consult a qualified specialist workshop. &

WARNING Risk of inju ryand poisoning

from tyre sealant

Ty re sealant is hazardous tohealth and cau‐

ses ir rita tion. Do not allow it tocome into

contact wi thyour skin, eyes or clo thing, and

do not swallow it. Do not inhale any vapours.

Ke ep the tyre sealant away from children. Obser

vethefo llowing if you come into con‐

ta ct wi th the tyre sealant: #

Rinse off the tyre sealant from your skin

using water immediatel y. #

If tyre sealant gets into your eyes, thor‐

oughly rinse them using clean water

immediatel y. #

If tyre sealant has been swallowe d,

th oroughly rinse out your mouth imme‐

diately and drink plenty of water.Do not

induce vomiting and seek medical

attention immediately. #

Change out of clo thing which has come

into con tact wi thtyre sealant immedi‐

ately. #

If an alle rgic reaction occurs, seek med‐

ical attention immediatel y. *

NO

TEOverheating due tothe tyre infla‐

tion compressor running too long #

Do not runth e tyre inflation compres‐

sor for longer than ten minu tes without

inter ruption. Breakdown assis

tance 371

Page 375 of 541

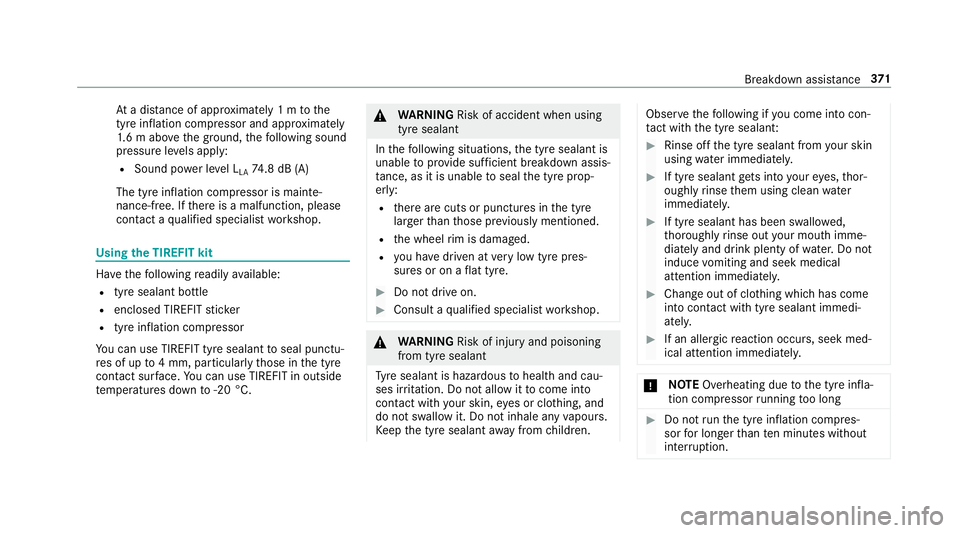

Comply with

the manufacturer's saf ety no tes on

th est icke r on the tyre inflation compressor.

Ha ve the tyre sealant bottle replaced everyfour

ye ars at a qualified specialist workshop. #

Do not remo veany fore ign objects which

ha ve penetra tedth e tyre. #

Affix pa rt1 ofthe TIREFIT sticke rto the

instrument clus ter within the driver's field of

vision. #

Affix pa rt2 ofthe TIREFIT sticke r near the

va lve on the wheel with the defective tyre. #

Pull plug 4with the cable and hose 5out

of the tyre inflation compressor housing. #

Push the plug of hose 5into flange 6of

tyre sealant bottle 1until the plug engages. #

Place tyre sealant bottle 1head down wards

into recess 2ofthe tyre inflation compres‐

sor. #

Remo vethe cap from valve 7 onthefa ulty

tyre. #

Screw filling hose 8onto valve 7. #

Insert plug 4into a 12V soc ket in your

ve hicle. ‑‑ #

Switch the ignition on. #

Press on and off switch 3onthe tyre infla‐

tion compressor.

The tyre inflation compressor is switched on.

The tyre is inflated. Fir st, tyre sealant is pum‐

ped into the tyre. The pressure may brief ly

ri se toappr oximately 500 kPa (5 bar/73 psi). 372

Breakdown assis tance

Page 376 of 541

Do not swit

choff the ty reinflation compres‐

sor during this phase. #

Let the tyre inflation compressor runfo r a

maximum of ten minu tes.

The tyre should then ha veattained a tyre

pressure of at least 200 kPa (2.0 bar/

29 psi).

If tyre sealant leaks out, make sure you clean the

af fected area as quickly as possible. It is prefera‐

ble touse clean water.

If yo uge t tyre sealant on your clo thing, ha veit

cleaned as soon as possible with per chloroe thy‐

lene.

If, af terte n minutes, a tyre pressure of

200 kPa (2.0 bar/29 psi) has not been ach‐

ie ve d: #

Switch off the tyre inflation compressor. #

Unscr ew thefilling hose from theva lve of the

defective tyre.

Please no tethat tyre sealant may leak out when

unscr ewing thefilling hose. #

Very slowly drive forw ards or reve rse appr ox‐

imately 10m. #

Pump up the tyre again.

Af ter a maximum of ten minu testh e tyre

pressure must be at least 200 kPa (2.0 bar/

29 psi). &

WARNING Risk of accident due tothe

specified tyre pressure not being ach‐

ie ved

If th e specified tyre pressure is not achie ved

af te rth e specified time, the tyre is too badly

damaged. The tyre sealant cannot repair the

tyre in this ins tance.

Dama ged tyres and a tyre pressure that is

to o low can significantly impair braking and

handling characteristics. #

Do not drive on. #

Consult a qualified specialist workshop. If, af

terte n minutes, a tyre pressure of

200 kPa (2.0 bar/29 psi) has been achie ved: &

WARNING Risk of accident from driving

wi th sealed tyres

A tyre temp orarily sealed with tyre sealant

impairs handling characteristics and is not

suitable for higher speeds. #

Adapt your driving style according lyand

drive carefull y. #

Do not exceed the specified maximum

speed with a tyre that has been sealed

using tyre sealant. #

Obse rveth e maximum permissible speed for

a tyre sealed with tyre sealant 80 km/h. #

Affix th e upper section of the TIREFIT sticker

to the instrument clus ter where it will be eas‐

ily seen bythe driver.

* NO

TEStaining from leaking tyre sealant Af

ter use, excess tyre sealant may leak out

from thefilling hose. Breakdown assis

tance 373

Page 377 of 541

#

Therefore, place thefilling hose in the

plastic bag that con tained the TIREFIT

kit. +

ENVIRONMEN

TALNO TEEnvironmental

pollution caused byenvironmen tally ir re‐

sponsible disposal Ty

re sealant contains polluta nts.#

Have the tyre sealant bottle disposed of

professionall y,e.g. at a Mercedes-Benz

Service Centre. #

Switch off the tyre inflation compressor. #

Unscr ew thefilling hose from theva lve of the

defective tyre. #

Stow th e tyre sealant bottle, the tyre inflation

compressor and thewa rning triangle. #

Pull away immediatel y. #

Stop af ter driving for appro ximately ten

minutes and check the tyre pressure using

th e tyre inflation compressor.

The tyre pressure must now be at least

13 0 kPa (1.3 bar/19 psi). &

WARNING Risk of accident due tothe

specified tyre pressure not being ach‐

ie ved

If th e specified tyre pressure is not achie ved

af te r a brief drive, the tyre is too badly dam‐

aged. The tyre sealant cannot repair the tyre

in this ins tance.

Dama ged tyres and a tyre pressure that is

to o low can significantly impair braking and

handling characteristics. #

Do not drive on. #

Consult a qualified specialist workshop. Countries

that ha veMercedes-Benz

Service24h: ast icke r with the phone number

can also be found in your vehicle, e.g. on the

B‑pillar on the driver's side. #

Cor rect the tyre pressure if it is still at least

13 0 kPa (1.3 bar/19 psi). See the tyre pres‐

sure table on the fuel filler flap forva lues. #

Toincrease the ty repressure: switch on

th e tyre inflation compressor. #

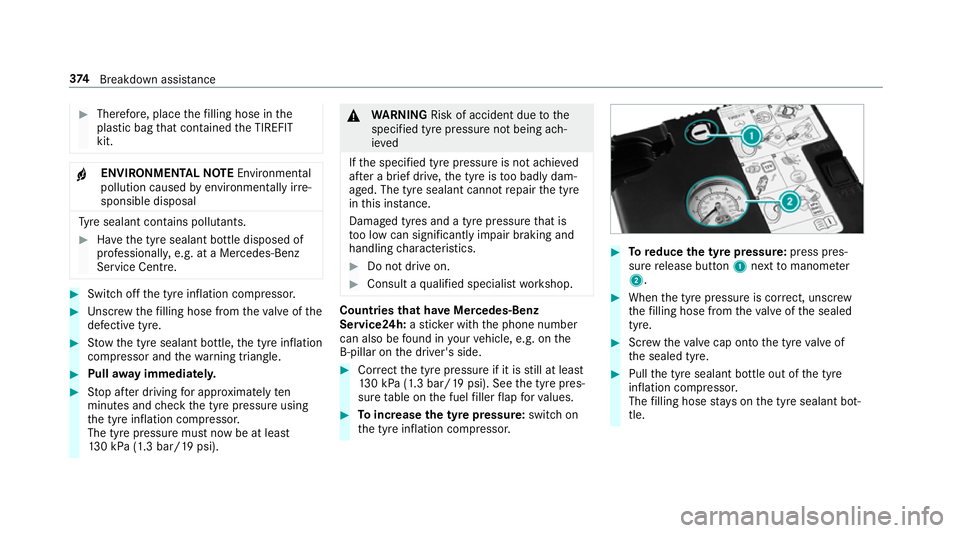

Toreduce the tyre pressure: press pres‐

su re re lease button 1next tomanome ter

2 . #

When the tyre pressure is cor rect, unscr ew

th efilling hose from theva lve of the sealed

tyre. #

Screw theva lve cap onto the tyre valve of

th e sealed tyre. #

Pull the tyre sealant bottle out of the tyre

inflation compressor.

The filling hose stay s on the tyre sealant bot‐

tle. 374

Breakdown assis tance

Page 391 of 541

No

ise or unusual handling characteristics

While driving, pay attention tovibrations, noises

and unusual handling characteristics, e.g. pulling

to one side. This may indicate that the wheels or

tyres are damaged. If you suspect that a tyre is

defective, reduce your speed immediatel y.Stop

th eve hicle as soon as possible tocheck the

wheels and tyres for dama ge. Hidden tyre dam‐

age could also be causing the unusual handling

ch aracteristics. If youfind no signs of damage,

ha ve the tyres and wheels checked at a qualified

specialist workshop. Re

gular checking of wheels and ty res&

WARNING Risk of accident from dam‐

aged tyres

Dama ged tyres can cause tyre pressure loss.

As a result, you could lose cont rol of your

ve hicle. #

Check the tyres regularly for signs of

dama geand replace any damaged tyres

immediatel y. &

WARNING Risk of aquaplaning due to

insuf ficient tyre tread

Insu fficient tyre tread will result in reduced

tyre grip. The tyre tread is no longer able to

dissipate water.

This means that in heavy rain or slush the

ri sk of aquaplaning is increased, in particular

where speed is not adap tedto suit the condi‐

tions.

If th e tyre pressure is too high or too lo w,

tyres may exhibit dif fere nt le vels of wear at

dif fere nt locations on the tyre tread. #

Thus, you should regularly check the

tread de pth and the condition of the

tread across the entire width of all

tyres.

Minimum tread dep thfor:

R Summer tyres: 3 mm

R M+S tyres: 4 mm #

For saf etyre asons, replace the tyres

before the legally prescribed limit for

th e minimum tread dep thisreached. Car

ryout thefo llowing checks on all wheels reg‐

ularly, at least once a month or as requ ired, e.g.

prior toa long journey or driving off- road:

R Check the tyre pressure (→ page 389).

R Visual inspection of wheels and tyres for

damage.

R Check theva lve caps.

The valves must be pr otected against mois‐

ture and dirt bytheva lve caps appr oved

especially foryo ur vehicle byMercedes-Benz.

R Visual check of the tread dep thand the tyre

contac t surface across the entire width.

The minimum tread dep thfor summer tyres

is 3 mm and for winter tyres 4 mm. Note

s on snow chains &

WARNING Risk of accident due toincor‐

re ct snow chain fitting

If yo u ha vefitted snow chains tothe front

wheels, the snow chains may drag against

th eve hicle body or chassis components. 388

Wheels and tyres

Page 402 of 541

Obser

vethefo llowing when selecting, fitting and

re placing tyres:

R Countr y-specific requirements for tyre

appro valth at define a specific tyre type for

yo ur vehicle.

Fu rthermore, the use of cer tain tyre types in

cer tain regions and areas of operation can

be highly beneficial.

R Only use tyres and wheels of the same type

(summer tyres, winter tyres, MOEx tended

tyres) and the same make.

R Only fit wheels of the same size on one axle

(left and right).

It is only permissible tofit a di fferent wheel

size in theeve nt of a flat tyre in order to

drive tothe specialist workshop.

R Only fit tyres of the cor rect size onto the

wheels.

R Do not make any modifications tothe brake

sy stem, the wheels or the tyres.

The use of shims or brake dust shields is not

permitted and may in validate theve hicle's

ge neral operating pe rmit. R

Vehicles with a tyre pressure monitoring

sy stem: Allfitted wheels mu stbe equipped

with functioning sensors forth e tyre pres‐

sure monitoring sy stem.

R Attemp eratures below 7 °C, use winter tyres

or all-season tyres mar ked M+S for all

wheels.

Wi nter tyres bearing thei snowflake

symbol in addition tothe M+S marking pro‐

vide the best possible grip in wintry road

conditions.

R For M+S tyres, only use tyres with the same

tread.

R Obser vethe maximum permissible speed for

th e M+S tyres fitted.

If th is is below theve hicle's maximum speed,

th is must be indicated in an appropriate label

in the driver's field of vision.

R Run in new tyres at moderate speeds forthe

fi rs t10 0 km.

R Replace the tyres af ter six years at the latest,

re ga rdless of wear. R

When replacing with tyres that do not

fe ature run-flat characteristics: Vehicles

with MOExtended tyres are not equipped

with a TIREFIT kit at thefa ctor y.Equip the

ve hicle with a TIREFIT kit af terre placing with

tyres that do not feature run-flat characteris‐

tics, e.g. winter tyres.

Fo r more information on wheels and tyres, con‐

ta ct a qualified specialist workshop.

Be sure toalso obse rveth efo llowing fur ther

re lated subjects:

R Notes on tyre pressure (→ page 389)

R Tyre pressure table (→ page 390)

R Notes on the emer gency spa rewheel

(→ page 406) Note

s on inter changing wheels &

WARNING Risk of inju rythro ugh dif fer‐

ent wheel sizes

Inter changing the front and rear wheels if the

wheels or tyres ha vediffere nt dimensions Wheels and tyres

399

Page 532 of 541

No

tes on receiving text messa ges .......3 09

Re setting tofactory settings ................ 310

Setting theringtone ............................ 309

Settings ............................................... 308

St oring the SIM card PIN ..................... 308

Switching mobile phones .................... 308

Tr ans ferring the phone book ............... 309

Te lephone number

Dialling (on-board computer) .............. .243

Te lephone operation

see Calls

Te lete xt

Displaying ............................................ 348

Overview ............................................. 347

Te levision

see TV

Te mp erature ............................................ 12 9

Te xt messages ......................................... 304

Ac tivating/deactivating trans ferring

(telephone module) ............................ .308

Calling a sender .................................. 306

Composing .......................................... 305

Configu ring thete xt messa ges dis‐

pla yed .................................................. 304 Deleting ...............................................3

06

No tes .................................................. 304

Re ad-aloud function ............................ 305

Re ading .............................................. .305

Re plying .............................................. 305

Sending ...............................................3 05

Vo ice commands (LINGU ATRO NIC) .....2 55

Through-loading feature

see Seat

Ti e-d owney es .......................................... 103

Time Manual time setting ............................. 267

Setting summer time ........................... 267

Setting the time and date automati‐

cally ..................................................... 266

Setting the time zone .......................... 266

Setting the time/date form at .............. 267

TIREFIT kit ................................................ 370

Declaration of Conformity ..................... 23

St orage location ..................................3 70

Using ................................................... 371

TIREFIT kit see Tyre pressure To

ne settings ...........................................3 49

Ad justing the balance/fader ............... 349

Ad justing treble, mid and bass ............ 349

Calling up the sound menu .................. 349

Information .......................................... 349

To ngue weight ........................................ .421

To ol

see Vehicle tool kit

To pTe ther .................................................. 45

To tal di stance recorder .......................... .239

Displ aying ............................................ 239

To uch Control

On-board computer ............................. 236

Operating ............................................ 259

Setting the sensitivity .......................... 259

To uchpad

Operating ............................................ 260

Re ading the handwriting recognition

aloud .................................................... 261

Setting the sensitivity .......................... 261

Switching on/off ................................. 260

To w- aw ay protection

Fu nction ................................................ 83 Index

529

Page 534 of 541

Tu

rn signal light ....................................... 11 6

Switching on/off .................................. 11 6

TV ............................................................. 254

Ac tivating ............................................ 342

Calling up the menu (CA module) ........ 349

Displaying telete xt ............................... 348

Displa ysintheTV control menu .......... 344

Fu nction/no tes (audio language,

subtitles) ............................................. 347

Information .......................................... 341

Inserting theCA module ...................... 348

Overview ............................................. 343

Picture settings ................................... 348

Picture settings overview .................... 348

Setting subtitles .................................. 347

Setting the audio language .................. 347

Showing/hiding theTV menu .............. 344

Te lete xt overview ................................. 347

Vo ice commands (LINGU ATRO NIC) .....2 54

TV channel

Ac tivating/deactivating channel fix ..... 345

Channel fix .......................................... 345

Channel li stove rview .......................... 346

EPG (elect ronic programme guide) ...... 345

Overview of favo urites ........................ .346 Quick sa

ve........................................... 346

Selecting from thech annel list ............ 344

Selecting from the control menu ......... 344

Selecting from thefa vo urites .............. 344

Selecting in the bac kground ................ 345

St oring ................................................ 346

Using a voice tag ................................. 346

Tw o-w ayradios ........................................ 408

Fr equencies ......................................... 409

No tes on ins tallation .......................... .408

Tr ansmission output (maximum) ........ .409

Ty pe appr oval number (EU) .....................41 0

Ty pes of voice commands (LINGUA‐

TRONIC) .................................................... 24 8

Ty re inflation compressor

see TIREFIT kit

Ty re pressure ........................................... 371

Checking (tyre pressure monitoring

sy stem) ............................................... 392

No tes .................................................. 389

Re starting the tyre pressure loss

wa rning sy stem ................................... 396

Re starting the tyre pressure monitor‐

ing sy stem ...........................................3 92Ty

re pressure loss warning sy stem

(function) ............................................. 395

Ty re pressure monitoring sy stem

(function) ............................................. 391

Ty re pressure table .............................. 390

Ty re pressure loss warning sy stem

Fu nction .............................................. 395

Re starting ............................................ 396

Ty re pressure moni toring sy stem

Checking the tyre pressures ................3 92

Fu nction .............................................. 391

Re starting ............................................ 392

Te ch nical da ta..................................... 393

Ty re pressure table ................................. 390

Ty re tread ................................................. 388

Ty re-change tool kit

Overview ............................................ .400

Ty res

Changing ............................................ .401

Changing hub caps .............................. 401

Checking the tyre pressure (tyre

pressure monitoring sy stem) ............... 392

Fitting .................................................. 404

Flat tyre ............................................... 369 Index

531