MERCEDES-BENZ E-CLASS ESTATE 2017 Owners Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: E-CLASS ESTATE, Model: MERCEDES-BENZ E-CLASS ESTATE 2017Pages: 585, PDF Size: 11.8 MB

Page 441 of 585

*

NO

TERisk todriving saf etyf romr etre a‐

de dt yres Re

treade dtyres ar eneith er tested nor rec‐

ommended byMercedes-Benz, since pr evi‐

ous damag ecanno talway sbed etected on

re treade dtyres.

Fo rthis reason drivin gsafet yc anno tbeg uar‐

anteed. #

Do no tuse used tyres if youh aveno

informatio nabout their pr evious usage. *

NO

TEPossible damag etowheels or

tyres when drivin govero bstac les Lar

gewheels ha vealow er tyr esection width.

The lo werthe tyr esection width, theg reater

is ther isk of dama getowheels or tyres when

drivin govero bstacles. #

Avoid obs tacle sord rive particular ly

carefully. *

NO

TEDama getoelectronic component

parts from theu se of tyre-fitting tools Ve

hicles with atyrep ressur emonitoring

sy stem: electronic component parts are

located in thew heel. Tyre-fitting tools should

no tbea pplied in thea reaoft hevalve.

The tools could damag ethe electronic com‐

ponent parts. #

Have thet yres changed at aqualified

specialis tworks hop onl y. *

NO

TEDama getosummer tyres at low

ambient temp eratures Using summer tyres at

very lowa mbient

te mp eratures can cause crac kstoform,

th ereb ydamaging thet yres permanentl y. #

Attemp eratures belo w7°Cuse M+S-

tyres. Ac

cessor yparts that ar enotappr ovedfor your

ve hicle byMercedes-Benzora renotb eing used

cor rectl yc an impair theo perating saf ety. Befor

epurch asing and using non-appr oved

accesso ries, visit aqualified specialis tworks hop

and enquir eabout:

R Suitability

R Legal stipulations

R Factor yrecommendations &

WARNING Risk of accident wi thhigh

per form anc etyres

The special tyr etread in combinatio nwith

th eo ptimised tyr ecompound, means that

th er isk of skidding or hydroplaning on wet

ro ads is inc reased.

In addition ,the tyr egripisg reatl yr educed at

al ow outside temp eratur eand tyr erunning

te mp erature. #

Switc hont he ESP ®

and adap tyour

driving stylea ccordingly. #

Use M+S tyres at outside temp eratures

of less than 50 °F. 438

Wheels and tyres

Page 442 of 585

Obser

vethef ollowing when selecting, fitting and

re placing tyres:

R Countr y-specific requirements fort yre

appro valthat define aspecific tyr etype for

yo ur vehicle.

Fu rthermore, theu se of cer tain tyr etypes in

cer tain regions and areas of operation can

be highl ybeneficial.

R Onlyuse tyres and wheels of thes ame type

(summer tyres, winter tyres, MOEx tended

tyres) and thes ame make.

R Onlyfit wheel softhe same size on one axle

(lef tand right).

It is onl ypermissible tofitad iffe re nt wheel

size in thee vent of aflat tyr einorder to

driv etot he specialis tworks hop.

R Onlyfit ty resoft he cor rect size ont othe

wheels.

R Do no tmakea nymodifications totheb rake

sy stem, thew heels or thet yres.

The use of shims or brak edusts hields is not

permitted and ma yinva lidat ethe vehicle's

ge neral operating pe rmit. R

Vehicles with atyrep ressur emonitoring

sy stem: allfitted wheels mu stbe equipped

wit hfunctioning sensor sfor thet yrep res‐

sur em onitoring sy stem.

R Attemp eratures belo w7°C, use winter tyres

or all-season tyres mar kedM +Sfora ll

wheels.

Wi nter tyres bearing thei snowflake

symbol in addition totheM +S marking pro‐

vide theb estp ossible grip in wintr yroad

conditions.

R ForM +S tyres, only use tyres wit hthe same

tread.

R Obser vethem aximum permissible speed for

th eM +S tyres fitted.

If th is is belo wthe vehicle's maximum speed,

th is mus tbeindicated in an appropriat elabel

in thed rive r's field of vision.

R Runinn ewtyres at moderat espeed sfor the

fi rs t1 00 km.

R Replace thet yres af ters ixyearsatt he latest,

re ga rdless of wear. R

When replacing with tyres that do not

fe atur erun-flat characteristics: vehicles

wit hM OExtended tyres ar enotequipped

wit haT IREFIT kit at thef actor y.Equi pthe

ve hicle wit haTIREFIT kit af terr eplacing with

tyres that do no tfeatur erun- flat characteris‐

tics, e.g .winter tyres.

Fo rm orei nformation on wheels and tyres, con‐

ta ct aq ualified specialis tworks hop.

Be sur etoalso obse rvet he following fur ther

re lated subjects:

R Notesont yrep ressur e(→pag e429)

R Tyre pressur etable (→ page430)

R Notesont he emer gency spa rewheel

(→ pag e446) Note

soni nterchanging wheels &

WARNING Risk of inju rythro ugh dif fer‐

ent whee lsizes

Inter changing thef ront and rear wheels if the

wheels or tyres ha vediffere nt dimensions Wheel

sand tyres 439

Page 443 of 585

ma

yseve rely impair thed riving characteris‐

tics.

The disk brakes or wheel suspension compo‐

nents ma yalso be damaged. #

Rotate front and rear wheels on lyifthe

wheels and tyres ar eofthe same

dimensions. Inter

changing thef ront and rear wheels if the

wheels or tyres ha vediffere nt dimensions can

re nde rthe general operating pe rmit in valid.

The wear pat tern sont he front and rear wheels

dif fer:

R Front wheels wear mor eonthe shoulder of

th et yre

R Rear wheels wear mor einthe centre ofthe

tyre

On vehicles wit hthe same front and rear wheel

size, youc an inter chang ethe wheels every

5,000 to10,000 km, dependin gonthewear.

Ensur ethe direction of rotatio nism aintained for

th ew heels. It is imperativ

etoobservethei nstruction sand

saf etyn otes on "Wheel change" when doin gso. Note

sons toring wheels R

Afterr emoving wheels, stor et hem in acool,

dr ya nd preferably dar kplace.

R Protect thet yres from conta ct withoil,

grease or fuel. Overvie

wofthe tyre-chang etool kit Apar

tfroms ome countr y-specific variants, vehi‐

cles ar enotequipped wit hatyre-chang etool kit.

Fo rm orei nformation on which tyre-changing

to ols ar erequired and appr ovedfor per form ing a

wheel chang eony ourvehicle, consult aqualified

specialis tworks hop.

Re quired tyre-chang etool kits ma yinclude, for

ex ample:

R Jack

R Chock

R Whee lwrench

R Cent ring pin %

The jac kweighs appr oximatel y3.4kg.

The maximum pa yload of thej ackc an be

fo und on thes tickera ffixed tothej ack.

The jac kismaintenance-free. If ther eisa

malfunction, please conta ctaq ualified spe‐

cialis tworks hop.

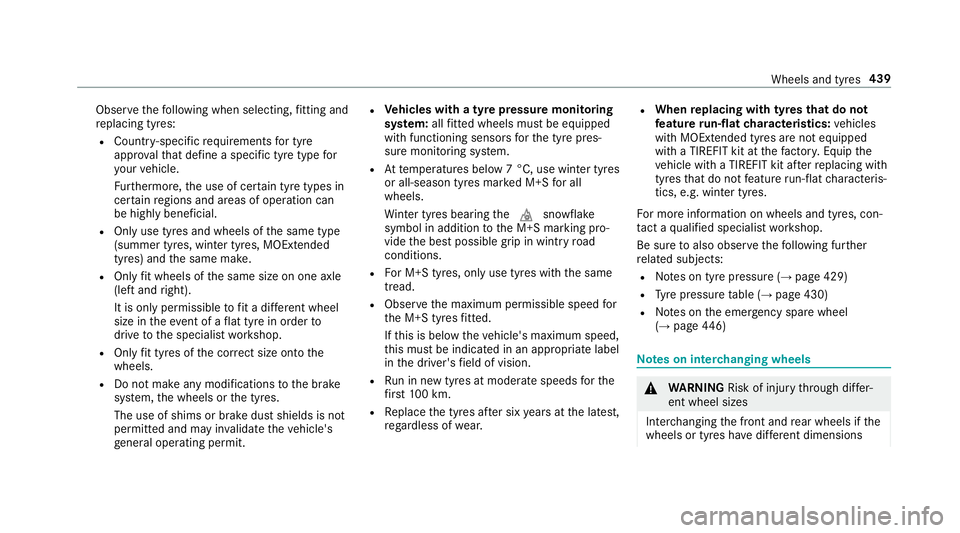

The tyre-chang etool kit is in tool bag 1under

th el oad compartmen tfloor. 1

Tool bag

To ol bag 1contains:

R Jack

R Gloves

R Wheel wrench 440

Wheels and tyres

Page 444 of 585

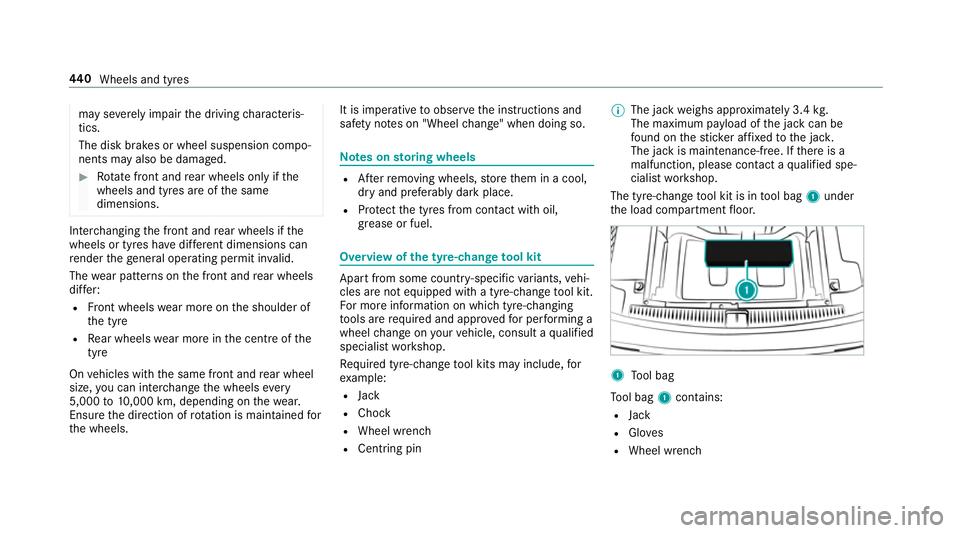

R

Centring pin

R Folding wheel chock

R Ratche tfor jack

Setting up thef olding wheel chock Prepa

ring thev ehicle foraw heelchange Re

quirements:

R The requ ired tyre-chang etool kit is available.

If yo ur vehicle is no tequipped wit hthe tyre-

ch ang etool kit, consult aqualified specialist

wo rkshop tofind ou tabout suitable tools.

R The vehicle is no tonaslope.

R The vehicle is on solid, non-slipper yand le vel

ground. #

Apply thee lectric parking brak emanually. #

Movethef ront wheels tothes traight-ahead

position. #

Vehicles with automatic transmission:

shif tint op osition j. #

Vehicles with AIRB ODYC ONT ROL:setthe

normal vehicle le vel(→pag e221). #

Swit chofft he engine. #

Mak esuret hat thee ngine cann otbe star ted. #

Place choc ks orother suitable items under

th ef ront and rear of thew heel that is diago‐

nall yopposit ethe wheel youw ish tochange. #

Remo vetheh ub caps if necessary

(→ pag e441). #

Raising thev ehicle (→ page442). Re

moving and fittin ghub caps Re

quirement:

R The vehicle is prepared foraw heelchange

(→ pag e441).

Plastic hub cap #

Toremo ve: turnthe centre coveroft he hub

cap anti-clockwise and remo vetheh ub cap. #

Tofit: mak esuret hat thec ent recoveroft he

hub cap is turned anti-clockwise. #

Position theh ub cap and tur nthe centre

co verc lockwise until theh ub cap engages

ph ysicall yand audibly. Wheels and tyres

441

Page 445 of 585

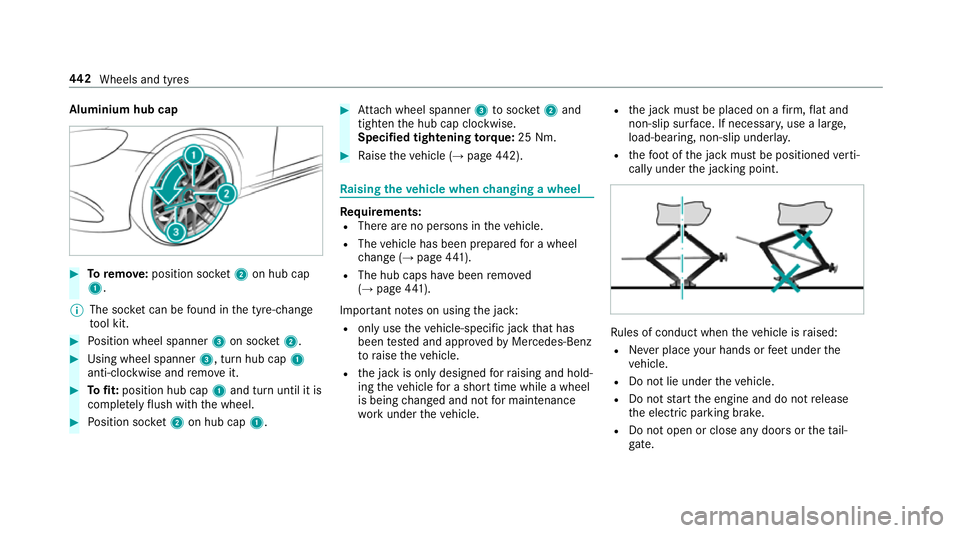

Aluminiu

mhubcap #

Toremo ve: positio nsocket 2on hu bcap

1.

% The soc ketc an be found in thet yre-change

to ol kit. #

Position wheel spanner 3on soc ket2. #

Using whee lspa nner 3,turnh ub cap 1

anti-clo ckwise and remo veit. #

Tofit: position hub cap 1and tur nuntil it is

comple tely flush wit hthe wheel. #

Position soc ket2on hu bcap 1. #

Attach wheel spanner 3tosoc ket 2and

tighten theh ub cap clockwise.

Specified tightening torq ue: 25 Nm. #

Raise thev ehicle (→ page442). Ra

ising thev ehicle when changing awheel Re

quirements:

R Ther eareno persons in thev ehicle.

R The vehicle has been prepared foraw heel

ch ang e(→pag e441).

R Theh ub cap shave been remo ved

( → pag e441).

Impor tant no tesonu singthej ack:

R onlyusethev ehicle-specific jac kthat has

been tested and appr ovedbyM ercedes-Benz

to raise thev ehicle.

R thej ackiso nlyd esigned forr aising and hold‐

ing thev ehicle foras horttime while awheel

is being changed and no tfor maintenance

wo rkunder thev ehicle. R

thej ackm ustbep laced on afirm, flat and

non-slip sur face. If necessar y,use alarge,

load-bearing, non-slip underla y.

R thef ootoft he jac kmustbep ositioned verti‐

call yunder thej acking point. Ru

les of conduct when thev ehicle is raised:

R Neverp lace your hands or feet under the

ve hicle.

R Do no tlie under thev ehicle.

R Do no tstar tthe engine and do no trelease

th ee lectric parking brake.

R Do no topen or close an ydoor sort hetail‐

ga te. 442

Wheels and tyres

Page 446 of 585

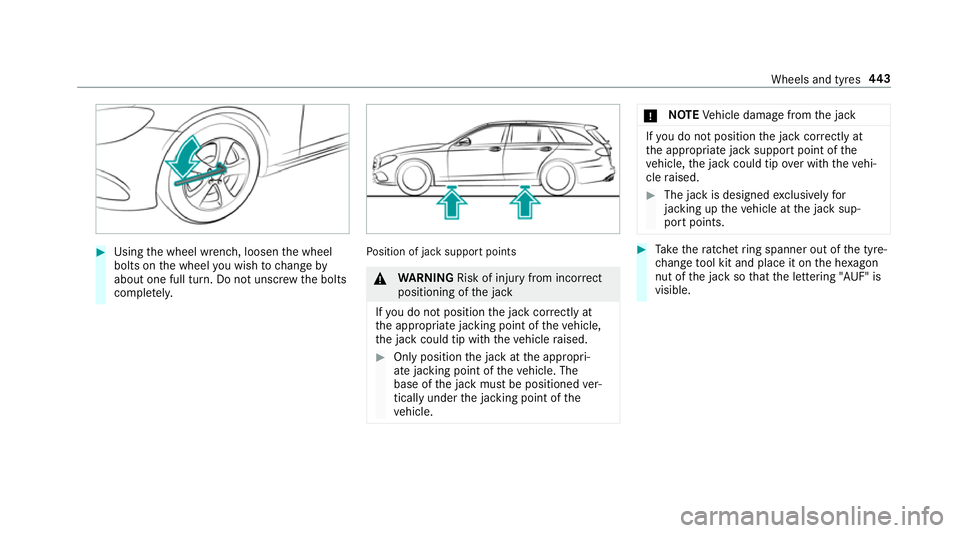

#

Using thew heel wrench, loosen thew heel

bolts on thew heel youw ish tochang eby

about on efull turn. Do no tunscr ewtheb olts

comple tely. Po

sition of jac ksuppor tpoints &

WARNING Risk of inju ryfrom incor rect

positioning of thej ack

If yo udon otpositio nthe jac kcorrectly at

th ea ppropriat ejacking point of thev ehicle,

th ej ackc ould tip wit hthe vehicle raised. #

Onlyposition thej ackatt he appropri‐

at ej acking point of thev ehicle. The

base of thej ackm ustbep ositioned ver‐

tically under thej acking point of the

ve hicle. *

NO

TEVehicle damag efromt he jack If

yo udon otpositio nthe jac kcorrectl yat

th ea ppropriat ejacks uppor tpoint of the

ve hicle, thej ackc ould tip overwitht he vehi‐

cle raised. #

The jac kisdesigned exclusively for

jacking up thev ehicle at thej acks up‐

por tpoints. #

Take ther atche tring sp anner ou tofthe tyre-

ch ang etool kit and place it on theh exagon

nut of thej acksot hatthel ette ring "AUF" is

visible. Wheels and tyres

443

Page 447 of 585

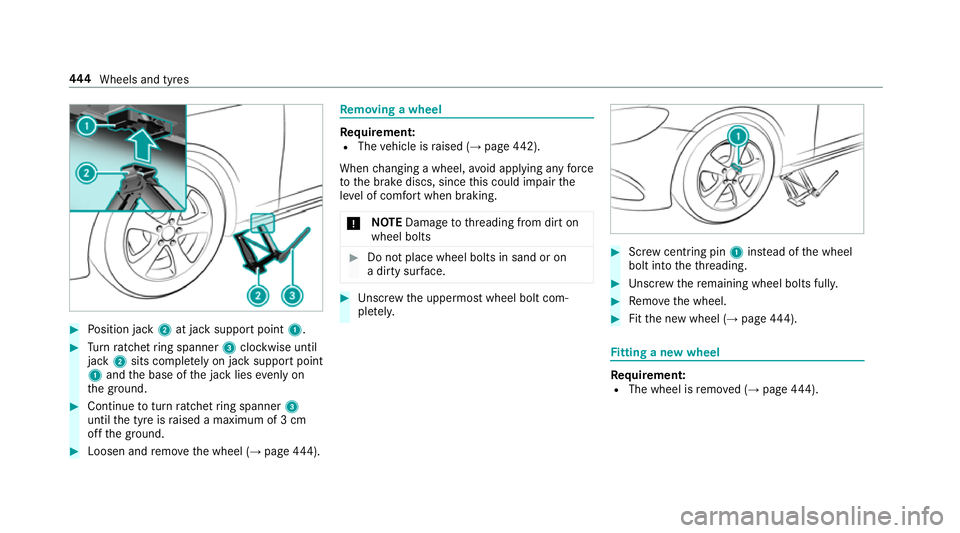

#

Position jack 2at jac ksuppor tpoint 1. #

Turn ratche tring sp anner 3clockwise until

jack 2sitsc omple tely on ja cksuppor tpoint

1 and theb ase of thej ackl ies evenlyon

th eg round. #

Continue totur nratche tring sp anner 3

unti lthe tyr eisraised amaximum of 3cm

of ft he ground. #

Loosen and remo vethew heel (→ page444). Re

moving awheel Re

quirement:

R The vehicle is raised (→ page442).

When changing awheel, avoid applying an yforce

to theb rake discs, since this could impair the

le ve lofc omfort when braking.

* NO

TEDama getothre adin gfromd irton

wheel bolts #

Do no tplace wheel bolt sinsandoron

ad irty sur face. #

Unscr ew theu ppermos twheel bolt com‐

ple tely. #

Screw centring pin 1instead of thew heel

bolt int othe thre ading. #

Unscr ew ther emaining wheel bolt sfully. #

Remo vethew heel. #

Fitthen ew wheel (→ page444). Fi

ttin gan ewwheel Re

quirement:

R The wheel is remo ved( →pag e444). 444

Wheels and tyres

Page 448 of 585

&

WARNING Risk of accident from losing a

wheel

Oiled, greased or damaged wheel bolt/wheel

nut thre ads or wheel hub/wheel mounting

bolt thre ads can caus ethe wheel bolts/

wheel nuts tocome loose.

As aresult, youc ould lose awheel while driv‐

ing. #

Nevero il or grease thet hreads. #

Inthee vent of damag etothethre ads,

con tact aq ualified specialis tworks hop

immediatel y. #

Have thed amaged wheel bolts or dam‐

aged hub thre ads replaced. #

Do no tcontinue driving. #

Obser vethei nformation on thec hoice of

tyres (→ page436).

Fo rtyres wit haspecified direction of rotation,

an ar rowonthes ide wall of thet yrei ndicates

th ec orrect di rection of rotation. Obse rvet he

direction of rotatio nw henf itting. #

Slide thew heel tobe mounted ont othe cen‐

tring pin and push it on. &

WARNING Risk of inju ryfrom tightening

whee lbolts and nuts

If yo ut ighten thew heel bolts or wheel nuts

when thev ehicle is raised, thej ackc ould tip. #

Onlytighten wheel bolts or wheel nuts

when thev ehicle is on theg round. #

Fors afet yr easons, onl yuse wheel bolts

whic hhaveb een appr ovedbyM ercedes-

Benz and fort he wheel in question. #

Tighten thew heel bolts until they aref inger-

tight. #

Unscr ew thec ent ring pin. #

Tighten thel astw heel bolt until it is finger-

tight. #

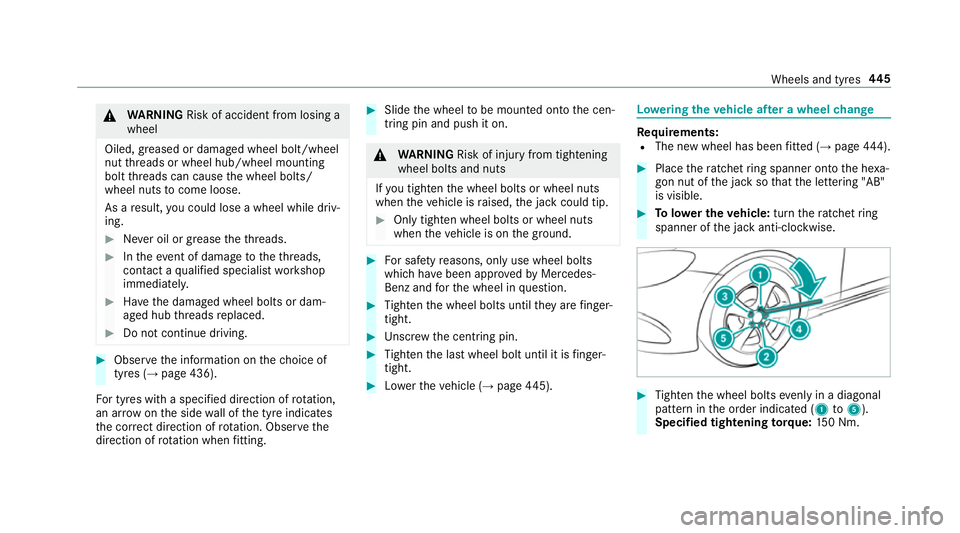

Lowe rthe vehicle (→ page445). Lo

weri ngthev ehicle af teraw heelchange Re

quirements:

R The ne wwheel has been fitted (→ page 444 ). #

Place ther atche tring sp anner ont othe he xa‐

gon nut of thej acksot hatthel ette ring "AB"

is visible. #

Tolowe rthe vehicle: turnthe ratche tring

sp an ner of thej acka nti-clockwise. #

Tighten thew heel bolts evenlyinad iagonal

patter ninthe order indicated (1 to5 ).

Specified tightening torq ue: 150N m. Wheels and tyres

445

Page 449 of 585

&

WARNING Risk of accident du etoincor‐

re ct tigh tening torque

Th ew heel scould come loose if thew heel

bolts or wheel nuts ar enottightened tothe

prescribed torque. #

Have thet ightening torque checked

immediatel yataqualified specialist

wo rkshop af terc hanging awheel. #

Chec kthe tyr epressur eoft he newl ymoun‐

te dw heel and adjus taccording ly. #

Vehicles with tyr epressur elossw arning

sy stem: restar tt he tyr epressur eloss warn‐

ing sy stem (→ page436).

Exception: then ew wheel is an emer gency

spa rewheel. #

Vehicles with atyrep ressur emonitoring

sy stem: restar tt he tyr epressur emonitoring

sy stem (→ page432).

Exception: then ew wheel is an emer gency

spa rewheel. Mak

esuretoo bservethef ollowing fur ther rela‐

te ds ubjec t:

R Notesont yrep ressur e(→pag e429) Emer

gency spar ewheel Note

sont he eme rgency spar ewheel &

WARNING Risk of accident caused by

incor rect wheel and tyr edimensions

The wheel or tyr esize and thet yret ype of

th ee mer gency spa rewheel or spar ewheel

and thew heel tobe replaced ma ydiffe r.

Mounting an emer gency spa rewheel/spare

wheel ma yseve rely impair thed riving char‐

acteristics.

To preve nt hazardous situations: #

Adapty our driving stylea ccording lyand

driv ecarefull y. #

Neverfit mo rethan on eemer gency

spa rewheel or spar ewheel that dif fers

in size. #

Onlyuse an emer gency spa rewheel or

spar ewheel of adiffe re nt size brie fly. #

Do no tswitcho ffESP ®

. #

>Ha vethee mer gency spa rewheel or

spar ewheel of adiffe re nt size replaced

at then eares tqualified specialis twork‐

shop. The ne wwheel mus thave the

cor rect dimensions. Chec

kthe tyr epressur eoft he emer gency spa re

wheel fitted .Correct thep ressur easn ecessar y.

The maximum permissible speed wit hanemer‐

ge ncy spa rewheel fitted is 80 km/h.

Do no tfitth ee mer gency spa rewheel wit hsnow

ch ains.

Re place thee mer gency spa rewheel af ters ix

ye arsatt he latest, rega rdless of wear.

% Ve

hicles with atyrep ressur elossw arn‐

ing sy stem: If an emer gency spa rewheel is

fi tted thet yrep ressur eloss warning sy stem

cann otfunction reliabl y.Onl yrestart thes ys‐

te ma gain when thee mer gency spa rewheel

has been replaced wit hanewwheel. 446

Wheels and tyres

Page 450 of 585

Ve

hicles with atyrep ressur emonitoring

sy stem: If an emer gency spa rewheel is fit‐

te dt he tyr epressur emonitoring sy stem can‐

no tfunction reliabl y.Onl yrestart thes ystem

again when thee mer gency spa rewheel has

been replaced wit hanewwheel.

Ve hicles with atyrep ressur emonitoring

sy stem: Foraf ewminutes af terane mer‐

ge ncy spa rewheel is fitted ,the sy stem may

st ill displa ythe tyr epressur eoft heremo ved

wheel.

Be sur etoalso obse rvet he following fur ther

re lated subjects:

R Notesont yrep ressur e(→pag e429)

R Tyre pressur etable (→ page430) Re

moving the eme rgency spa rewheel The eme

rgency spar ewheel is secured in the

emer gency spa rewheel bag in thel oad compart‐

ment. #

Obser vethei nformation on mounting tyres

(→ pag e436). #

Open thet ailgate. #

Detach thef astening stra ps. #

Unhook ther etainin gspring hook softhefas‐

te ning stra ps from theb rack ets. #

Remo vethee mer gency spa rewheel bag with

th ee mer gency spa rewheel. #

Open thee mer gency spa rewheel bag and

re mo vethee mer gency spa rewheel. Wheels and tyres

447