light MERCEDES-BENZ E-CLASS WAGON 2001 W210 Workshop Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2001, Model line: E-Class WAGON, Model: MERCEDES-BENZ E-Class WAGON 2001 W210Pages: 345, PDF Size: 16.08 MB

Page 279 of 345

276 Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Spare wheel

Important!

Unidirectional tires must always be mounted with arrow

on tire sidewall pointing in direction of vehicle forward

movement.

If the arrow on tire side wall does not point in direction

of vehicle forward movement when using the spare

wheel, observe the following restrictions:

•Drive to the nearest tire repair facility as soon as

possible.

For rim and tire specifications, see page 320.

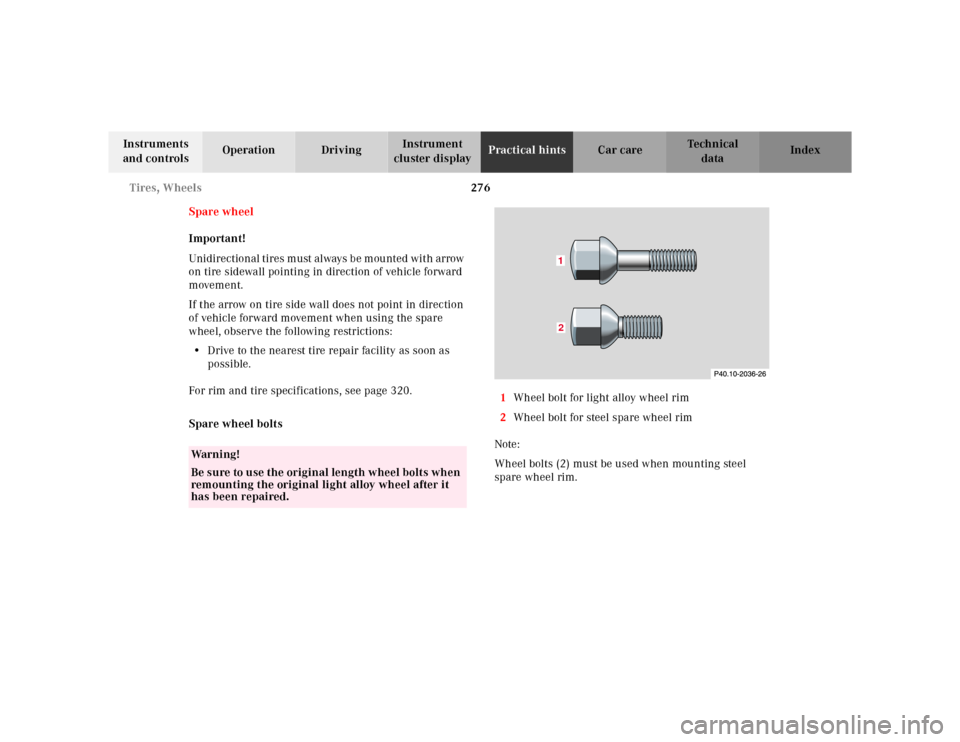

Spare wheel bolts1Wheel bolt for light alloy wheel rim

2Wheel bolt for steel spare wheel rim

Note:

Wheel bolts (2) must be used when mounting steel

spare wheel rim.

Wa r n i n g !

Be sure to use the original length wheel bolts when

remounting the original light alloy wheel after it

has been repaired.

12

Page 283 of 345

280 Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

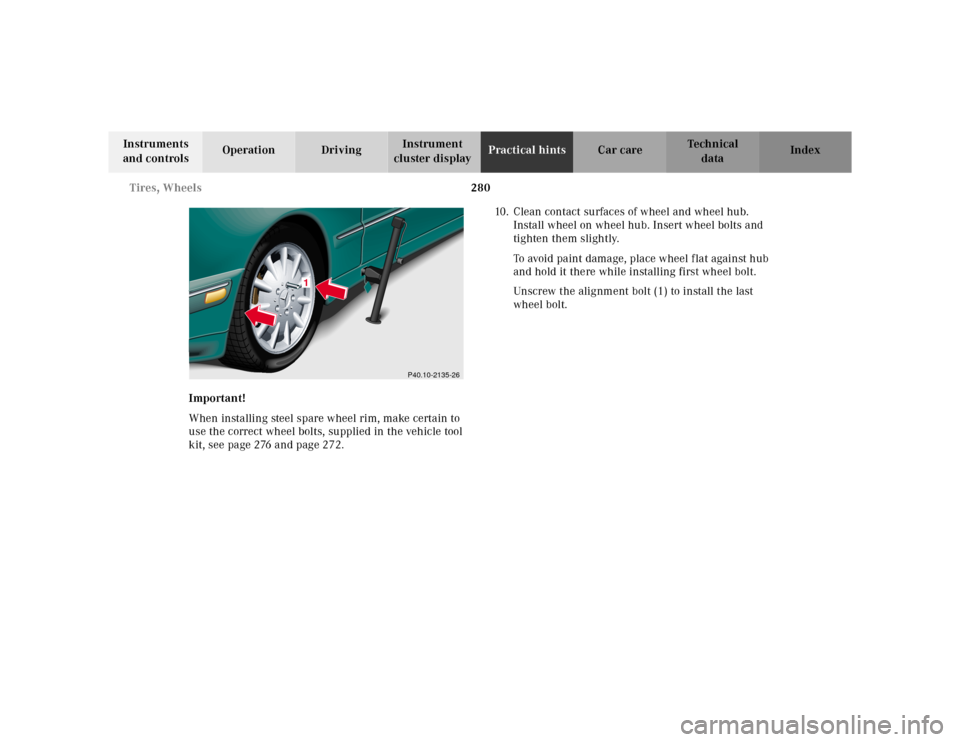

Important!

When installing steel spare wheel rim, make certain to

use the correct wheel bolts, supplied in the vehicle tool

kit, see page 276 and page 272.10. Clean contact surfaces of wheel and wheel hub.

Install wheel on wheel hub. Insert wheel bolts and

tighten them slightly.

To avoid paint damage, place wheel f lat against hub

and hold it there while installing first wheel bolt.

Unscrew the alignment bolt (1) to install the last

wheel bolt.

P40.10-2135-26

1

Page 285 of 345

282 Tires, Wheels

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Tire inflation pressure

A table (see fuel filler flap) lists the tire inflation

pressures specified for Mercedes-Benz recommended

tires as well as for the varying operating conditions.

Important!

Tire pressure changes by approximately 1.5 psi (0.1 bar)

per 18°F (10°C) of air temperature change. Keep this in

mind when checking tire pressure inside a garage -

especially in the winter.

Example:

If garage temperature = approximately +68°F (+20°C)

and ambient temperature = approximately +32°F (0°C)

then the adjusted air pressure = specified air pressure

+3 psi (+0.2 bar).Tire pressures listed for light loads are minimum values

offering high driving comfort. Increased inflation

pressures for heavy loads produce favorable handling

characteristics with lighter loads and are perfectly

permissible. The ride of the vehicle, however, will

become somewhat harder.

Tire temperature and pressure increase with the vehicle

speed. Tire pressure should therefore only be checked

and corrected on cold tires. Correct tire pressure in

warm tires only if pressure has dropped below the

pressure listed in the table and the respective operating

conditions are taken into consideration.

An underinf lated tire due to a slow leak (e.g. due to a

nail in the tire) may cause damage such as tread

separation, bulging etc.. Regular tire pressure checks

(including the spare tire) at intervals of no more than

14 days are therefore essential.

Page 289 of 345

286 Jump starting

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

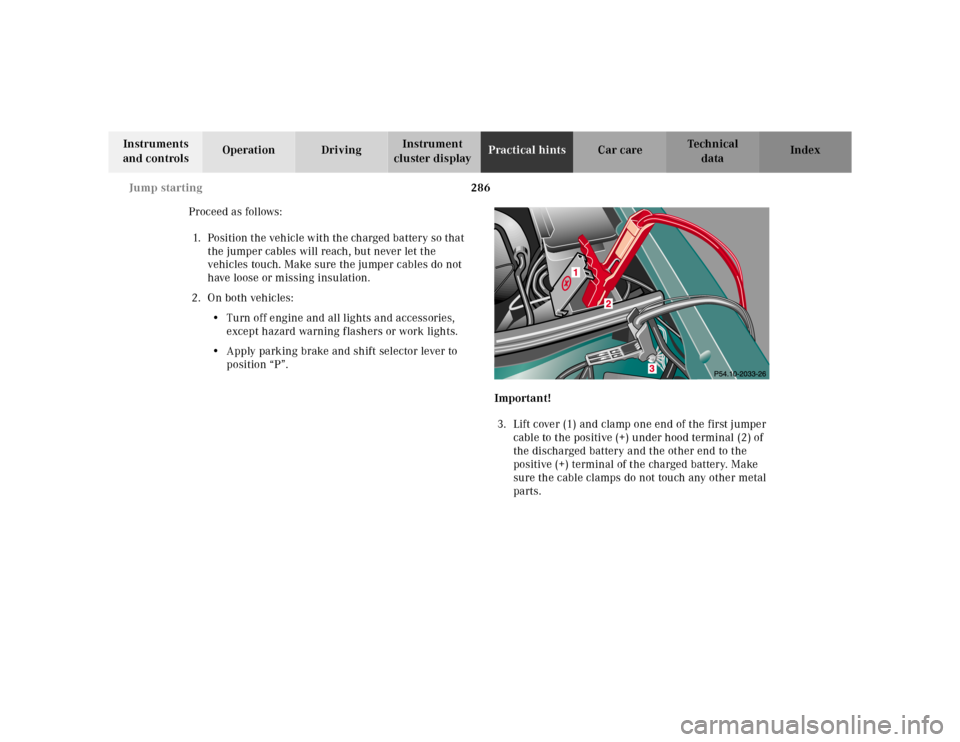

Proceed as follows:

1. Position the vehicle with the charged battery so that

the jumper cables will reach, but never let the

vehicles touch. Make sure the jumper cables do not

have loose or missing insulation.

2. On both vehicles:

•Turn off engine and all lights and accessories,

except hazard warning f lashers or work lights.

•Apply parking brake and shift selector lever to

position “P”.

Important!

3. Lift cover (1) and clamp one end of the first jumper

cable to the positive (+) under hood terminal (2) of

the discharged battery and the other end to the

positive (+) terminal of the charged battery. Make

sure the cable clamps do not touch any other metal

parts.

Page 301 of 345

298 Electronic main key

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

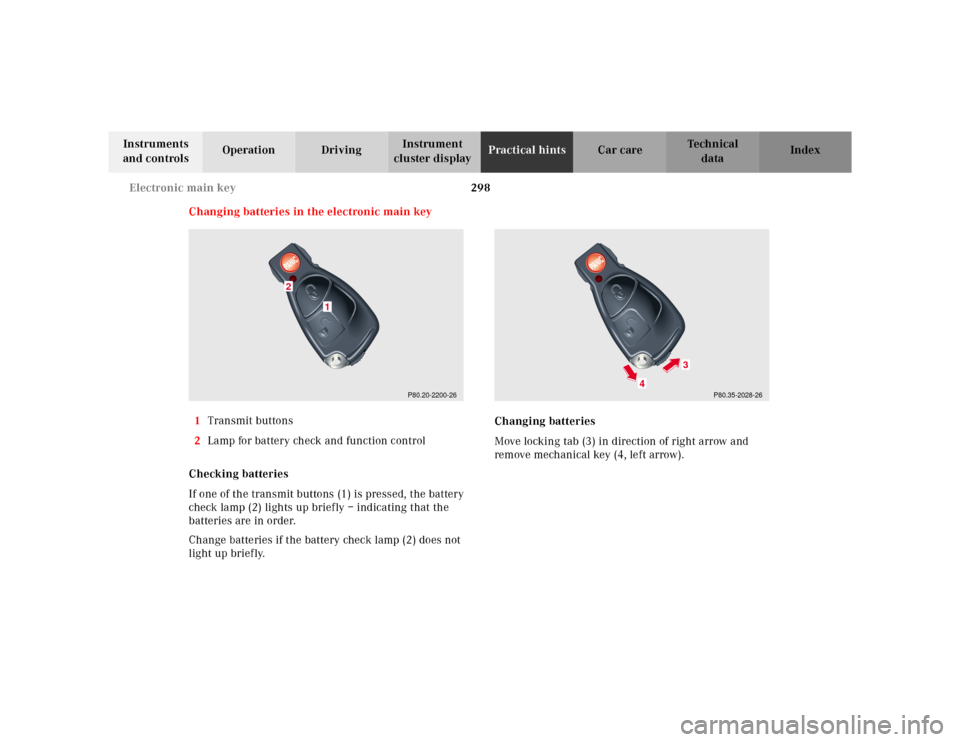

Changing batteries in the electronic main key

1Transmit buttons

2Lamp for battery check and function control

Checking batteries

If one of the transmit buttons (1) is pressed, the battery

check lamp (2) lights up briefly – indicating that the

batteries are in order.

Change batteries if the battery check lamp (2) does not

light up briefly.Changing batteries

Move locking tab (3) in direction of right arrow and

remove mechanical key (4, left arrow).

P80.20-2200-26

1

2

P80.35-2028-26

4

3

Page 310 of 345

307 Contents - Vehicle care

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar careIndex

Vehicle careCleaning and care of

the vehicle .................................. 308

Power washer ..............................309

Tar stains .....................................309

Paintwork, painted body

components .................................309

Engine cleaning .......................... 310Vehicle washing ..........................310

Ornamental moldings ................310

Headlamps, taillamps,

turn signal lenses .......................310

Cleaning the parktronic

system sensors ............................ 311

Window cleaning ........................ 311

Wiper blades ............................... 311

Light alloy wheels ......................312Instrument cluster ..................... 312

Steering wheel and

gear selector lever ...................... 312

Cup holder ................................... 312

Seat belts ..................................... 312

Headliner ..................................... 312

Upholstery ................................... 313

Hard plastic trim items ............. 313

Plastic and rubber parts ............ 313

Page 313 of 345

310 Cleaning and care of the vehicle

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar careIndex

Engine cleaning

Prior to cleaning the engine compartment make sure to

protect electrical components and connectors from the

intrusion of water and cleaning agents.

Corrosion protection, such as MB Anticorrosion Wax

should be applied to the engine compartment after

every engine cleaning. Before applying, all control

linkage bushings and joints should be lubricated. The

poly-V-belt and all pulleys should be protected from any

wax.

Ve h i c l e w a s h i n g

Do not use hot water or wash your vehicle in direct

sunlight. Use only a mild car wash detergent, such as

Mercedes-Benz approved Car Shampoo.

Thoroughly spray the vehicle with a diffused jet of

water. Direct only a very weak spray towards the

ventilation intake. Use plenty of water and rinse the

sponge and chamois frequently.

Rinse with clear water and thoroughly wipe dry with a

chamois. Do not allow cleaning agents to dry on the

finish.Due to the width of the vehicle, prior to running the

vehicle through an automatic car wash, fold back the

outside mirrors to prevent them from getting damaged.

In the winter, thoroughly remove all traces of road salt

as soon as possible.

When washing the underbody, do not forget to clean the

inner sides of the wheels.

Ornamental moldings

For regular cleaning and care of very dirty chrome-

plated parts, use a chrome cleaner.

Headlamps, taillamps, turn signal lenses

Use a mild car wash detergent, such as Mercedes-Benz

approved Car Shampoo, with plenty of water.

To prevent scratches, never apply strong force and use

only a soft, non-scratchy cloth when cleaning the lenses.

Do not attempt to wipe dirty lenses with a dry cloth or

sponge.

Page 315 of 345

312 Cleaning and care of the vehicle

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar careIndex

Light alloy wheels

Mercedes-Benz approved Wheel Care should be used for

regular cleaning of the light alloy wheels.

If possible, clean wheels once a week with

Mercedes-Benz approved Wheel Care, using a soft

bristle brush and a strong spray of water.

Follow instructions on container.

Note:

Use only acid-free cleaning materials. The acid could

lead to corrosion.

Instrument cluster

Use a gentle dishwashing detergent or mild detergent

for delicate fabrics as a washing solution. Wipe with a

cloth moistened in lukewarm solution. Do not use

scouring agents.

Steering wheel and gear selector lever

Wipe with a damp cloth and dry thoroughly or clean

with Mercedes-Benz approved Leather Care.Cup holder

Use a gentle dishwashing detergent or mild detergent

for delicate fabrics as a washing solution. Wipe with a

cloth moistened in lukewarm solution. Do not use

scouring agents.

Seat belts

The webbing must not be treated with chemical

cleaning agents. Use only clear, lukewarm water and

soap. Do not dry the webbing at temperatures above

176°F (80°C) or in direct sunlight.

Headliner

Clean with soft bristle brush, or use a dry-shampoo

cleaner in case of excessive dirt.

Wa r n i n g !

Do not bleach or dye seat belts as this may severely

weaken them. In a crash they may not be able to

provide adequate protection.

Page 316 of 345

313 Cleaning and care of the vehicle

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar careIndex Upholstery

Using aftermarket seat covers or wearing clothing that

have the tendency to give off coloring (e.g. when wet

etc.) may cause the upholstery to become permanently

discolored. By lining the seats with a proper

intermediate cover, contact-discoloration will be

prevented.

Leather Upholstery

Wipe leather upholstery with a damp cloth and dry

thoroughly or clean with Mercedes-Benz approved

Leather Care. Exercise particular care when cleaning

perforated leather as its underside should not become

wet.

Cloth Upholstery

Clean with soft bristle brush, or use a dry-shampoo

cleaner in case of excessive dirt.

MB Tex Upholstery

Pour Mercedes-Benz approved Interior Care onto soft

lint-free cloth and apply with light pressure.Hard plastic trim items

Pour Mercedes-Benz approved Interior Care onto soft

lint-free cloth and apply with light pressure.

Plastic and rubber parts

Do not use oil or wax on these parts.

Page 323 of 345

320 Technical data

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hints Car care Index

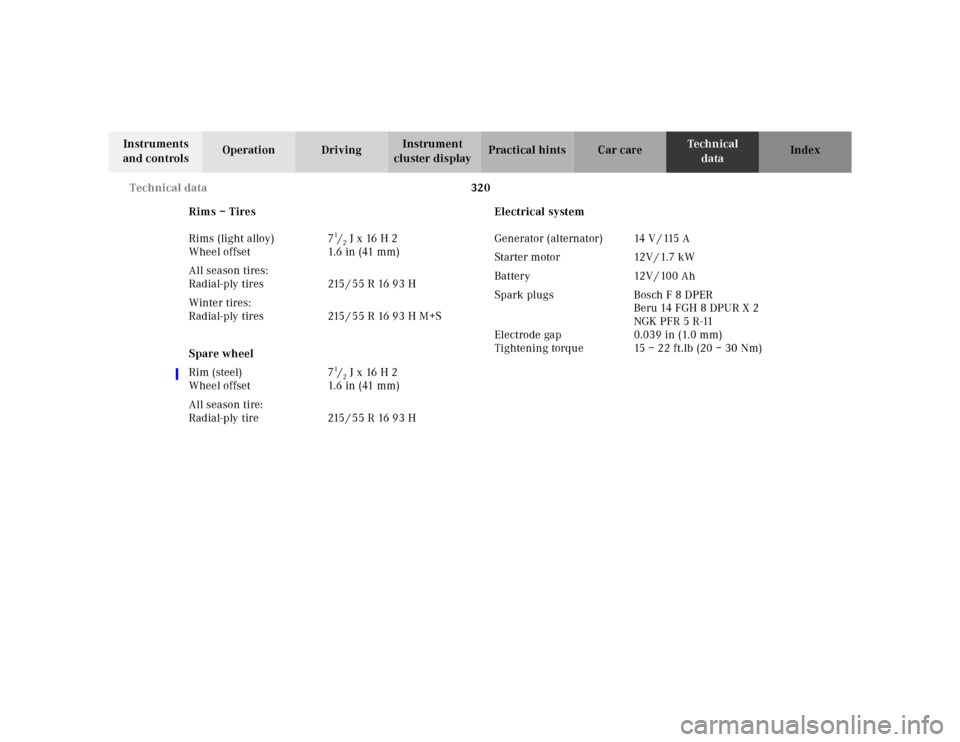

Rims – Tires Electrical system

Rims (light alloy)

Wheel offset7

1/2 J x 16 H 2

1.6 in (41 mm)

All season tires:

Radial-ply tires 215 / 55 R 16 93 H

Winter tires:

Radial-ply tires 215 / 55 R 16 93 H M+S

Spare wheel

Rim (steel)

Wheel offset7

1/2 J x 16 H 2

1.6 in (41 mm)

All season tire:

Radial-ply tire 215 / 55 R 16 93 HGenerator (alternator) 14 V / 115 A

Starter motor 12V / 1.7 kW

Battery 12V / 100 Ah

Spark plugs

Electrode gap

Tightening torqueBosch F 8 DPER

Beru 14 FGH 8 DPUR X 2

NGK PFR 5 R-11

0.039 in (1.0 mm)

15 – 22 ft.lb (20 – 30 Nm)