clock MERCEDES-BENZ EQC SUV 2021 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2021, Model line: EQC SUV, Model: MERCEDES-BENZ EQC SUV 2021Pages: 453, PDF Size: 8.68 MB

Page 120 of 453

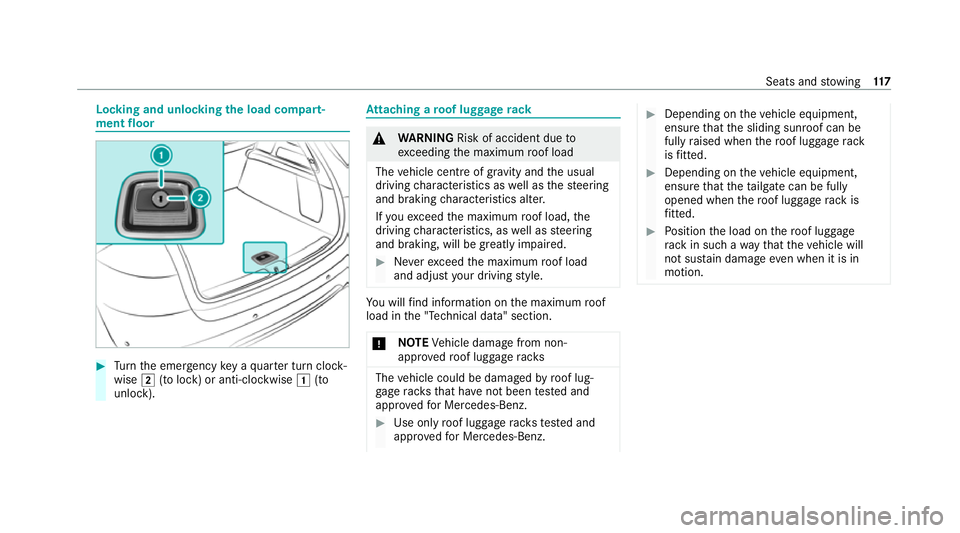

Locking and unlocking

the load compa rt‐

ment floor #

Turn the emer gency key a quarter turn clock‐

wise 2(to lock) or anti-clockwise 1(to

unlock). At

taching a roof luggage rack &

WARNING Risk of accident due to

exc eeding the maximum roof load

The vehicle centre of gravity and the usual

driving characteristics as well as thesteering

and braking characteristics alter.

If yo uexc eed the maximum roof load, the

driving characteristics, as well as steering

and braking, will be greatly impaired. #

Neverexc eed the maximum roof load

and adjust your driving style. Yo

u will find information on the maximum roof

load in the "Technical data" section.

* NO

TEVehicle damage from non-

appr ovedro of luggage racks The

vehicle could be damaged byroof lug‐

ga ge rack sth at ha venot been tested and

appr ovedfo r Mercedes-Benz. #

Use only roof luggage rack ste sted and

appr ovedfo r Mercedes-Benz. #

Depending on theve hicle equipment,

ensure that the sliding sunroof can be

fully raised when thero of luggage rack

is fitted. #

Depending on theve hicle equipment,

ensure that theta ilgate can be fully

opened when thero of luggage rack is

fi tted. #

Position the load on thero of luggage

ra ck in such a wayth at theve hicle will

not sus tain damage even when it is in

motion. Seats and

stowing 117

Page 306 of 453

#

Check the coolant temp erature display in the

instrument clus ter.

The coolant temp erature must be below

40°C. #

Slowly turn cap 1anti-clockwise torelease

ove rpressure. #

Continue turning cap 1anti-clockwise and

re mo veit. #

Ifth e coolant le vel is below the mar ker bar

2, visit a qualified specialist workshop, e.g.

a Mercedes-Benz Service Centre. Only ha ve

th e coolant checked or refilled at a qualified

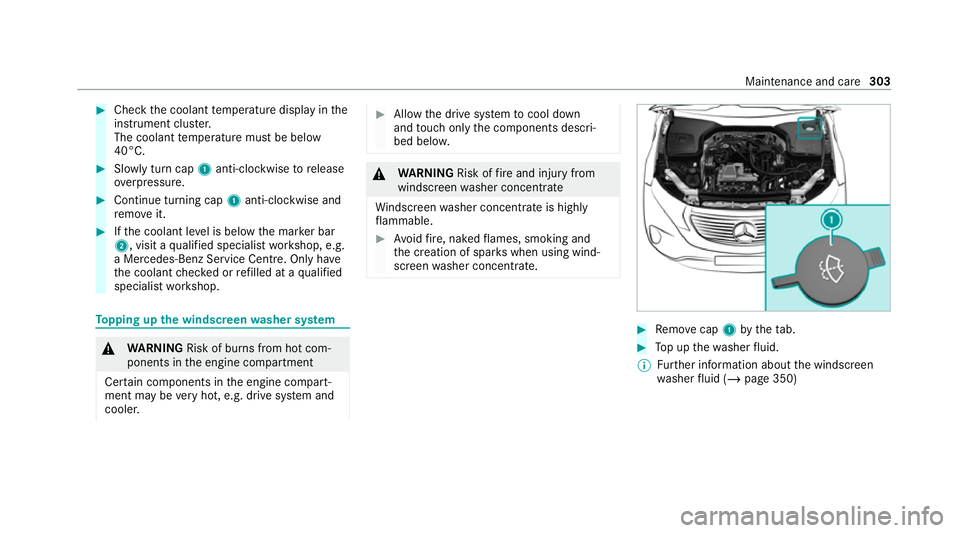

specialist workshop. To

pping up the windsc reen washer sy stem &

WARNING Risk of bu rns from hot com‐

ponents in the engine compartment

Cer tain components in the engine compart‐

ment may be very hot, e.g. drive sy stem and

cooler. #

Allow the drive sy stem tocool down

and touch on lythe components descri‐

bed belo w. &

WARNING Risk offire and injury from

windsc reen washer concentrate

Wi ndsc reen washer concentrate is highly

fl ammable. #

Avoid fire , naked flames, smoking and

th e creation of spar kswhen using wind‐

screen washer concentrate. #

Remo vecap 1bytheta b. #

Top up thewa sher fluid.

% Further information about the windscreen

wa sher fluid (/ page 350) Main

tenance and care 303

Page 326 of 453

%

The transmission may be loc ked in position

j intheeve nt of dama getothe electrics.

To shift toi , pr ovide the on-board electri‐

cal sy stem with po wer (/ page 320). #

Load theve hicle onto the transpor ter. #

Shift the transmission toposition j. #

Use the electric parking brake tosecure the

ve hicle against rolling away. #

Only secure theve hicle bythe wheels. #

Make sure that the front and rear axles come

to rest on the same transpor tation vehicle. *

NO

TEDama getothe driv etra in due to

incor rect positioning #

Do not position theve hicle abo vethe

connection point of the transport vehi‐

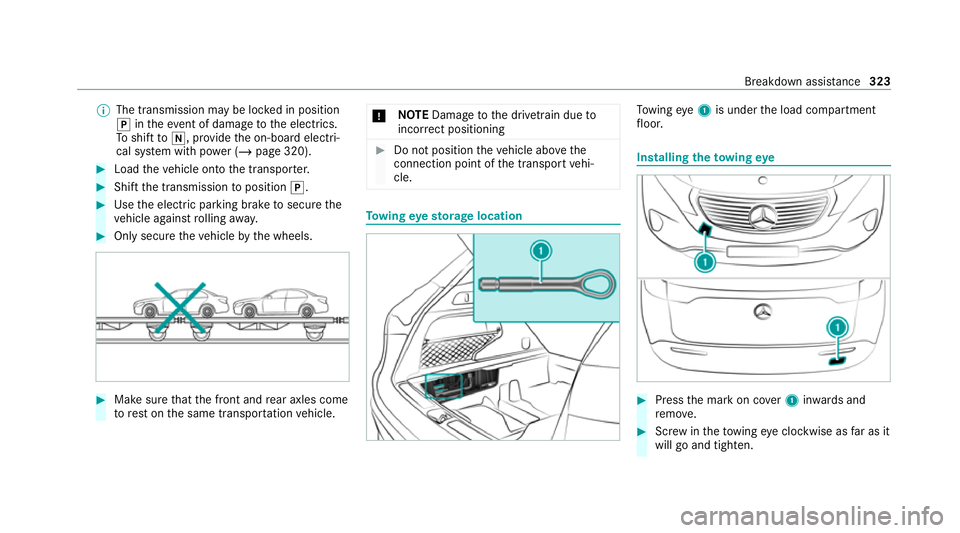

cle. To

wing eyesto rage location To

wing eye1 is under the load compartment

fl oor. Installing

theto wing eye #

Press the mark on co ver1 inwa rds and

re mo ve. #

Screw intheto wing eyeclockwise as far as it

will go and tighten. Breakdown assi

stance 323

Page 343 of 453

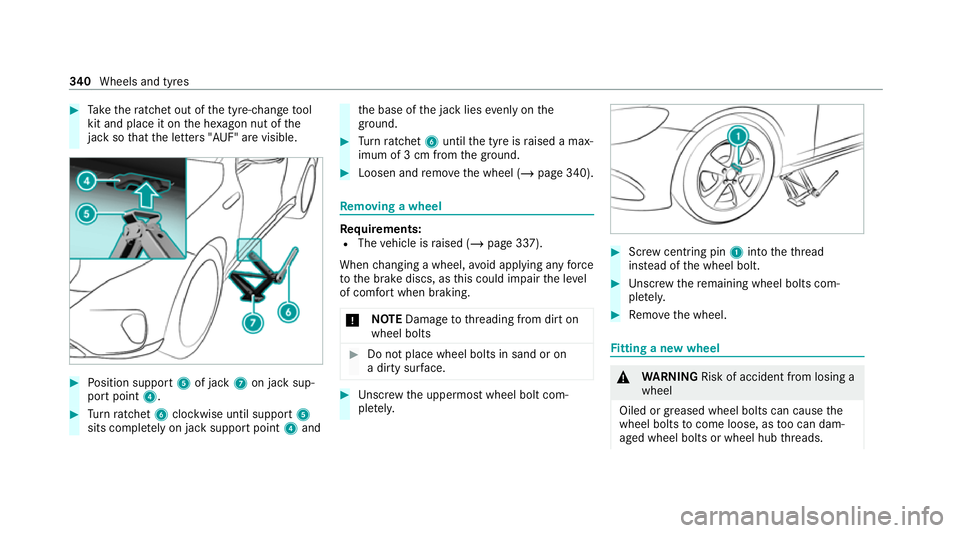

#

Take thera tchet out of the tyre-change tool

kit and place it on the he xagon nut of the

jack so that the letters "AUF" are visible. #

Position support 5of jack 7on jack sup‐

port point 4. #

Turn ratchet 6clockwise until support 5

sits comple tely on jack support point 4and th

e base of the jack lies evenly on the

ground. #

Turn ratchet 6until the tyre is raised a max‐

imum of 3 cm from the ground. #

Loosen and remo vethe wheel (/ page 340). Re

moving a wheel Re

quirements:

R The vehicle is raised (/ page 337).

When changing a wheel, avoid applying any force

to the brake discs, as this could impair the le vel

of comfort when braking.

* NO

TEDama getothre ading from dirt on

wheel bolts #

Do not place wheel bolts in sand or on

a dirty sur face. #

Unscr ew the uppermost wheel bolt com‐

ple tely. #

Screw centring pin 1into theth re ad

ins tead of the wheel bolt. #

Unscr ew there maining wheel bolts com‐

ple tely. #

Remo vethe wheel. Fi

tting a new wheel &

WARNING Risk of accident from losing a

wheel

Oiled or greased wheel bolts can cause the

wheel bolts tocome loose, as too can dam‐

aged wheel bolts or wheel hub thre ads. 340

Wheels and tyres

Page 344 of 453

#

Never oil or grease theth re ads. #

Intheeve nt of damage totheth re ads,

con tact a qualified specialist workshop

immediatel y. #

Have the damaged wheel bolts or dam‐

aged hub thre ads replaced. #

Do not continue driving. #

Obser vethe information on thech oice of

tyres (/ page 332).

Fo r tyres with a specified direction of rotation,

an ar row on the side wall of the tyre indicates

th e cor rect di rection of rotation. Obse rvethe

direction of rotation when fitting. #

Slide the wheel tobe mounted onto the cen‐

tring pin and push it on. &

WARNING Risk of inju ryfrom tightening

wheel bolts and nuts

If yo u tighten the wheel bolts or wheel nuts

when theve hicle is raised, the jack could tip. #

Only tighten wheel bolts or wheel nuts

when theve hicle is on the ground. #

Be sure toobser vethe instructions and

saf ety no tes on "Changing a wheel"

(/ page 332). #

For saf etyre asons, on lyuse wheel bolts

which ha vebeen appr ovedby Mercedes-

Benz and forth e wheel in question. #

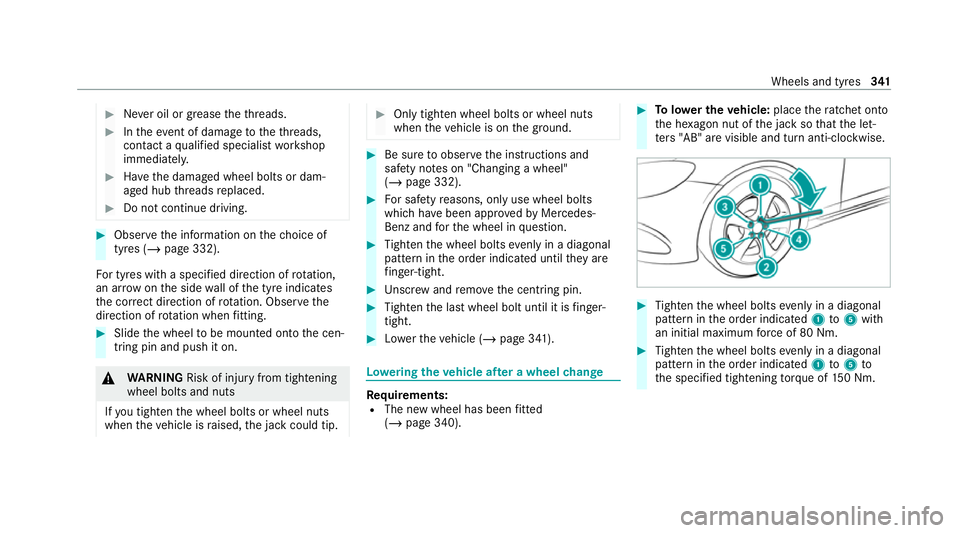

Tighten the wheel bolts evenly in a diagonal

pattern in the order indicated until they are

fi nger-tight. #

Unscr ew and remo vethe cent ring pin. #

Tighten the last wheel bolt until it is finger-

tight. #

Lowe rth eve hicle (/ page 341). Lo

weri ngtheve hicle af ter a wheel change Re

quirements:

R The new wheel has been fitted

(/ page 340). #

Tolowe r the vehicle: placethera tchet onto

th e he xagon nut of the jack so that the let‐

te rs "AB" are visible and turn anti-clockwise. #

Tighten the wheel bolts evenly in a diagonal

pattern in the order indicated 1to5 with

an initial maximum forc e of 80 Nm. #

Tighten the wheel bolts evenly in a diagonal

pattern in the order indicated 1to5 to

th e specified tightening torque of 150 Nm. Wheels and tyres

341