wheel bolts MERCEDES-BENZ G-CLASS 2019 Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: G-CLASS, Model: MERCEDES-BENZ G-CLASS 2019Pages: 514, PDF Size: 45.22 MB

Page 350 of 514

No

teson car eof vehicl epar ts &

WARNIN GRisk ofentr apment ifth e

winds hieldwiper sar eswit ched on while

th ewindshield isbeing cleaned

If th ewindshield wipersar ese tin mo tion

while youar ecle anin gth ewindshield or

wiper blades, youcan betrapped bythe

wiper arm. #

Alw aysswitc hof fth ewindshield wipers

and theignition beforecleanin gth e

winds hieldorwiper blades. &

WARNIN GRisk ofburning from theta il‐

pipe ortailpipe trim

The tailpipe andtailpipe trim can becom e

ve ry hot.Ifyo uco me intoco ntact withth ese

car parts,youco uld burnyo urself . #

Alw aysbe par ticular lycareful whenin

th evicinit yof theta ilpipe andtailpipe

tr ims and super visechildr envery

clos elywhe nin this area. #

Beforean ycon tact, allo w thecar parts

to cool down. Obs

erve thefo llo wing informa tion: No

teson cleaning andcareA voiding vehicl edamag e

Wheel s/rims

Usewaterand acid-free whee lclea ners. R

Donotuse acidicwhee lclea nersto remo vebrak edus t.

This could damag ewheel boltsandbrak ecom ponen ts.

R Toavoid corrosion ofthebr ak ediscs andbrak epads, drive

th eve hicle fora fe w min utes afte rclea ning beforepar king

it. The brak ediscs andbrak epa dswarm upand dryout .

Wi ndo ws

Cleanthewindo wsontheinside andoutside usingadam p

clo thand cleanin gag ent sre comme ndedbyMer cedes-Ben z.Do

notuse dryclo thsor abr asiv eor sol vent-ba sedcleani ng

ag ents tocle an theinside ofwindo ws. 34

8

Maint enance andcare

Page 367 of 514

Obser

vethefo llo wing during reco very to avo id

damag eto your vehicle:

R Ifth edr iven wheels gettr ap pe don loose or

mu ddygr ou nd, reco verth eve hicle withth e

utm ostcar e,

Es pec iallyso ifth eve hicle isladen.

R Neveratt em pttoreco vera ve hicle that is

st uc kwit hatrailer attached.

R Pull outtheve hicle that isstuc kbac kwards,

if poss ible, usingth etra cksit made beforeit

became stuc k. To

wing vehicl eaw ay intheeve ntofmalf unc‐

tions No

teson towing away intheev ent ofma l‐

fun ctions

* NO

TEDama gedue toinc orrect att ach‐

ment anduseof old nuts The

vehicle andcomponent sof theve hicle

can bedamag eddue toinc orrect att achment

and useof old nuts. #

Ifyo ure mo vethepr opeller shaft,place

th eM1 0nuts ontheM8 bolts as

spacer sand secur eth em withM8 nuts. #

Alw aysuse newself-loc kingnuts when

ins talling thepr opeller shafts. Obser

vetheno teson towing away

( / pag e362).

% Forfur ther information ,con sult anaut hor‐

ized Mercedes- BenzCenter.

To wing away intheev ent ofma lfun ctions

To wing away intheev ent ofdama getothe

engine, transm ission orelectr ics #

Shif tth etra nsmiss iontoposition 005C.

To wing away intheev ent oftransf ercase

da ma ge #

Remo vethepr opeller shaftsbetween the

axle sand thetransf ercase. To

wing away intheev ent offront axle dam‐

ag e #

Remo vethepr opeller shaftbe tween there ar

axle andthetransf ercase. #

Tow aw ay theve hicle withara ised front axle.

To wing away intheev ent ofrear axle dam‐

ag e #

Remo vethepr opeller shaftbe tween thefront

axle andthetransf ercase. #

Tow aw ay theve hicle withara ised rear axle

and withwheel roller sunder thefront axle. Loading

theve hicl efo rtr ans port #

Obser vetheno teson towing away

( / pag e362). #

Connec tth eto w bar totheto wing eyein

or der toload theve hicle. #

Shif tth etra nsmiss iontoposition 005C. Br

eakdo wnassis tance 36

5

Page 396 of 514

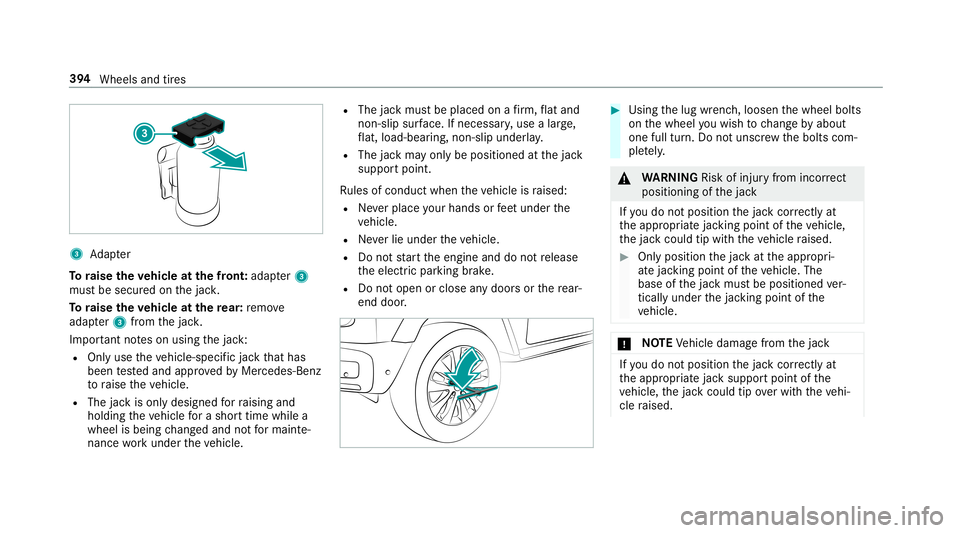

3

Adapter

To raise theve hicl eat thefront :adap ter3

mus tbe secur edon thejac k.

To raise theve hicl eat there ar: remo ve

adap ter3 from thejac k.

Im por tant noteson using thejac k:

R Onlyuse theve hicle-specif icjac kth at has

been tested and appr ovedby Mer cedes-Ben z

to raise theve hicle.

R The jackis onl ydesigned forra ising and

holdin gth eve hicle fora shor ttime whilea

whee lis being chang edand notfo rmaint e‐

nance workund ertheve hicle. R

The jackmus tbe placed onafirm ,fl at and

no n-slip surface. Ifneces sary,use alar ge,

fl at, load- bearing,no n-slip unde rlay .

R The jackma yonl ybe positioned atthejac k

suppor tpoint .

Ru les ofcon duct when theve hicle israised:

R Neverpla ceyour han dsorfeet und erthe

ve hicle.

R Neverlie under theve hicle.

R Donotst ar tth eengine anddonotre lease

th eelectr icpar king brak e.

R Donotopen orclose anydoor sor there ar-

end door . #

Usin gth elug wrenc h,loosen thewheel bolts

on thewheel youwish tochang eby about

on efull turn.Do notuns crew thebolts com‐

ple tely. &

WARNIN GRisk ofinju ryfrom incor rect

pos itioning ofthejac k

If yo udo notposi tionth ejac kcor rectl yat

th eappr opriatejac king point oftheve hicle,

th ejac kcould tipwithth eve hicle raised. #

Onlyposit ionthejac kat theappr opri‐

at ejac king point oftheve hicle. The

base ofthejac kmus tbe position edver‐

tically underthejac king point ofthe

ve hicle. *

NO

TEVehicle damag efrom thejac k If

yo udo notposi tionth ejac kcor rectl yat

th eappr opriatejac ksuppor tpoint ofthe

ve hicle, thejac kcould tipove rwit hth eve hi‐

cle raised. 39

4

Wheels andtires

Page 397 of 514

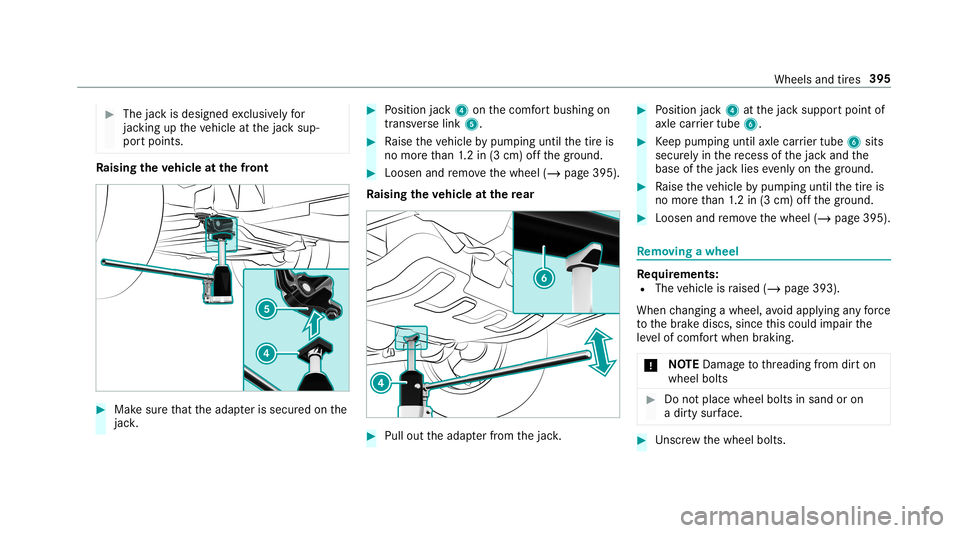

#

The jackis designed exclu sively for

jac king uptheve hicle atthejac ksup‐

por tpoint s. Ra

ising theve hicl eat thefront #

Mak esur eth at theadap teris secur edon the

jac k. #

Position jack4 onthecomf ortbushing on

tra nsv erse link 5. #

Raise theve hicle bypum ping until thetir eis

no mor eth an 1.2 in (3 cm) offth egr ound. #

Loosen andremo vethewheel (/page395).

Ra ising theve hicl eat there ar #

Pullout theadap terfr om thejac k. #

Position jack4 atthejac ksuppor tpoint of

axle carrier tube 6. #

Keep pum ping until axlecarrier tube 6sits

secur elyinthere cess ofthejac kand the

base ofthejac klies evenlyon thegr ound. #

Raise theve hicle bypum ping until thetir eis

no mor eth an 1.2 in (3 cm) offth egr ound. #

Loosen andremo vethewheel (/page395). Re

mo ving awh eel Re

quirement s:

R The vehicle israised (/page393).

When chang ingawheel, avoid applying anyfo rc e

to thebr ak ediscs, sincethis could impair the

le ve lof com fort when brakin g.

* NO

TEDama getothre adin gfrom dirton

wheel bolts #

Donotplace wheel boltsin san dor on

a dir tysur face. #

Unscr ew thewheel bolts. Wheels

andtires 395

Page 398 of 514

#

Remo vethewheel. #

Installth ene wwheel (/page396). Mounting

ane wwheel Re

quirement s:

R The wheel isremo ved(/ page395 ). &

WARNIN GRisk ofacci dent from losing a

whe el

Oil ed, grea sed ordamag edwhe elbol t/whe el

nut thre ads orwheel hub/wheel mounting

bolt thre ads can caus eth ewheel bolts/

wheel nutstocome loose.

As are sult, youco uld lose awheel whiledriv‐

ing . #

Neveroil orgrease theth re ads. #

Intheeve ntofdamag eto theth re ads,

con tact aqu alif ied spec ialistwo rkshop

immediat ely. #

Have thedamag edwheel boltsordam‐

ag ed hub thre ads replaced. #

Donotcon tinue driving. #

Obser vetheinf ormation onthech oice of

tir es (/ page389).

Fo rtir es wit haspecif ieddirection ofrotatio n,an

ar ro w on theside wallof thetir eindicat esthe

cor rect dire ction ofrotatio n.Ob serveth edir ec‐

tion ofrotatio nwh en installing. #

Place thewheel tobe installed onthewheel

hub andpush iton. &

WARNIN GRisk ofinju ryfrom tight ening

whee lbol tsand nuts

If yo utig hten thewheel boltsorwheel nuts

when theve hicle israised, thejac kcould tip. #

Onlytight enwheel boltsorwheel nuts

when theve hicle ison thegr ound. #

Forsaf etyre ason s,on lyuse wheel bolts

whic hha ve been approvedby Mer cedes-

Benz andforth ewheel inqu estion . *

NO

TEDama getopaintw orkof thewheel

ri m when screwing onthefirs twh eelbo lt If

th ewheel hastoomuc hpla ywhen screw‐

ing inthefirs twh eelbo lt, thewheel rim pai nt

can bedama ged. #

Press thewheel firm lyag ains tth e

wheel hubwhen screwing onthefirs t

wheel bolt. #

Tight enthewheel boltsevenlyin adi ag ona l

pa tter nin theor der indicat eduntil they are

fi ng er-tig ht. #

Lowe rth eve hicle (/page396). Lo

we ring theve hicl eaf te ra wh eelch ang e Re

quirement s:

R The newwheel hasbeen installed

(/ page396) . #

Place thera tche tont oth ehe xagon nutofthe

jac kso that theletter s"AB" arevisible. #

Tolowe rthe vehicl e:tur nth era tche tof the

jac kcou nter-clo ckwise. 396

Wheels andtires

Page 399 of 514

#

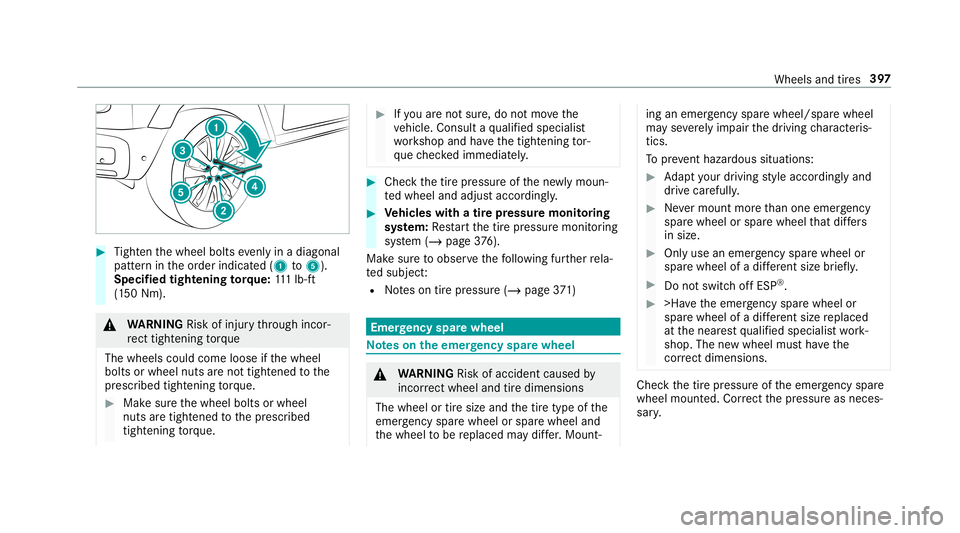

Tight enthewheel boltsevenlyin adi ag ona l

pa tter nin theor der indicat ed(1 to5 ).

Specif iedtight ening torq ue: 111 lb-ft

(1 50 Nm). &

WARNIN GRisk ofinju rythro ugh incor‐

re ct tigh tening torq ue

Th ewh eelscou ldcome looseifth ewheel

bolts orwheel nutsareno ttight ened tothe

pr escr ibed tighteningto rq ue. #

Makesur eth ewheel boltsorwheel

nuts aretight ened tothepr escr ibed

tight ening torq ue. #

Ifyo uar eno tsur e,do notmo vethe

ve hicle. Consult aqu alif ied spec ialist

wo rkshop andhave thetight ening tor‐

qu ech eckedimmediat ely. #

Chec kth etir epr essur eof thene wlymoun‐

te dwheel andadjus taccor dingly. #

Vehicl eswith atir epr ess uremonit oring

sy stem: Restar tth etir epr essur emonit oring

sy stem (/ page37 6).

Mak esur eto obser vethefo llo wing further rela‐

te dsubjec t:

R Noteson tirepr essur e(/ page37 1) Emer

gency spar ewheel No

teson the emer gency spar ewheel &

WARNIN GRisk ofacci dent caused by

inc orrect whe eland tiredimensi ons

The wheelor tiresize andthetir etype ofthe

emer gency sparewheel orspar ewheel and

th ewheel tobe replaced maydif fer. Mount‐ ing

anemer gency sparewheel/ sparewheel

ma yse verely im pair thedr iving charact eris‐

tic s.

To preve nthazardous situa tions: #

Adaptyo ur drivin gst yle accor dinglyand

dr ive car efull y. #

Nevermount moreth an oneemer gency

spa rewheel orspar ewheel that dif fers

in size . #

Onlyuse anemer gency sparewheel or

spar ewheel ofadif fere nt size briefly. #

Donotsw itchof fESP ®

. #

>Ha vetheemer gency sparewheel or

spar ewheel ofadif fere nt size replaced

at thenear estqu alif ied spec ialistwo rk‐

shop. Thenewwheel mustha ve the

cor rect dimensi ons. Ch

eckth etir epr essur eof theemer gency spare

wheel mounted. Cor rect thepr essur eas neces ‐

sar y. Wheels

andtires 39

7