trailer MERCEDES-BENZ G-CLASS SUV 2012 Service Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2012, Model line: G-CLASS SUV, Model: MERCEDES-BENZ G-CLASS SUV 2012Pages: 357, PDF Size: 8.86 MB

Page 320 of 357

Towing the vehicle with both axles on

the ground

It is important tha tyou observe the safety

instructions when towing away your vehicle

(Y page 315).

X Switch on the hazard warning lamps

(Y page 109).

i In order to signal a change of direction

when towing the vehicle with the hazard

warning lamps switched on, use the com-

bination switch as usual.Int his case, only

the turn signals for the desired direction

flash. When you reset the combination

switch, the hazard warning lamps start

flashing again.

X Turn the key to position 2in the ignition

lock (Y page 143).

X When the vehicle is stationary, depress the

brake pedal and keep it depressed.

X Shift the transfer case to neu-

tral(Y page 203).

X Shift the automatic transmission to posi-

tion N.

X Release the brake pedal.

X Release the parking brake (Y page 164).

i The transmission can only change gear

when the battery has sufficient charge.

If you cannot move the selector lever to N,

you must remove the propeller shafts to the

driven axles. Transporting the vehicle

! Only lash the vehicle down by the wheels

or wheel rims, not by parts of the vehicle

such as axle or steering components. Oth-

erwise, the vehicle could be damaged.

Use the towing eyes to pull the vehicle if it

needs to be transported on a trailer or trans-

porter (Y page 316).

X Apply the parking brake.

X Turn the key to position 2in the ignition

lock (Y page 143). X

Move the selector lever to N.

X Shift the transfer case to neu-

tral(Y page 203).

X Secure the towing cable to the towing eyes

(Y page 316).

X Make sure that the vehicle cannot roll

away.

X Release the parking brake.

X Load the vehicle onto the transporter.

As soon as the vehicle is loaded:

X Apply the parking brake.

X Shift the automatic transmission to posi-

tion P.

X Turn the key to position 0in the ignition

lock (Y page 143) and remove it.

X Secure the vehicle. Recovering

avehicle that has become

stuck

! When recovering a trapped vehicle, do not

jerk the vehicle or pull it at an angle. If the

tractive power is too high, the vehicles

could be damaged.

If the drive wheels get trapped on loose or

muddy ground, recover th evehicle with the

utmost care, especially so if the vehicle is

laden.

Never attempt to recover a vehicle with a

trailer attached.

Pull out the vehicle backwards, if possible,

using the tracks it made when it became

stuck. Towing in the event of malfunctions

General notes !

If you are removing the propeller shaft,

use M10 nuts as spacers on the M8 bolts

and secure them with M8 nuts.

New self-locking nuts must be used when

the propeller shafts are refitted. Towing and tow-starting

317Breakdown assistance Z

Page 328 of 357

i

You may wish to deactivate

ESP ®

(Y page 62) when pulling away with

snow chains fitted. This way you can allow

the wheels to spin in a controlled manner,

achieving an increased driving force (cut-

ting action). Tyre pressure

Tyre pressure specifications

Important safety notes G

WARNING

Underinflated or overinflated tyres pose the

following risks:

R the tyres may burst, especially as the load

and vehicle speed increase.

R the tyres may wear excessively and/or

unevenly, which may greatly impair tyre

traction.

R the driving characteristics, as well as steer-

ing and braking, may be greatly impaired.

There is a risk of an accident.

Observe the recommended tyre pressure and

chec kthe tyre pressure of all the tyres includ-

ing the spare wheel:

R at least every two weeks

R when the load changes

R before embarking on a longer journey

R for changed operating conditions, e.g. off-

road driving

If necessary, correct the tyre pressure. G

WARNING

If you fit unsuitable accessories onto tyre

valves, the tyre valves may be overloaded and

malfunction, which can cause tyre pressure

loss. Due to their design, retrofitted tyre pres-

sure monitors keep the tyre valve open. This

can also result in tyre pressure loss. There is

a risk of accident.

Only screw standard valve caps or valve caps

specifically provided by Mercedes-Ben zfor

your vehicle onto the tyre valve. G

WARNING

If the tyre pressure drops repeatedly, the

wheel, valve or tyre may be damaged. Tyre

pressure that is too low may result in a tyre

blow-out. There is a risk of accident.

R Check the tyre for foreign objects.

R Check whether the wheel is losing air or the

valve is leaking.

If you are unable to rectify the damage, con-

tact a qualified specialist workshop. H

Environmental note

Check the tyre pressure regularly, at least

every 14 days.

General notes You will find a table of tyre pressures for var-

ious operating conditions on the inside of

your vehicle's fuel filler flap.

Operation with a trailer:

the applicable

value for the rear tyres is the maximum tyre

pressure value stated in the table inside the

fuel filler flap.

The table inside the fuel filler flap may state

tyre pressures for different load conditions.

These are defined in the table as different

numbers of passengers and amounts of lug-

gage. The actual number of seats may vary –

for more information, please refer to the vehi-

cle's registration documents.

If tyre sizes are not specified, the tyre pres-

sures stated on the tyre pressure information

label apply for all tyres approved for this vehi-

cle. Tyre pressure

325Wheels and tyres Z

Page 333 of 357

On vehicles that have the same size front and

rear wheels, you can interchange the wheels

every 5000 km to 10,000 km depending on

the degree of tyre wear. Maintain the direc-

tion of tyre rotation.

Cleant he contact surfaces of the wheel and

the brake disc thoroughly every time a wheel

is interchanged. Check the tyre pressure and

reactivate the tyre pressure monitor

(Y page 327) if necessary. Direction of rotation

Tyres with a specified direction of rotation

have additional benefits, e.g. if there is a risk

of aquaplaning. You will only gain these ben-

efits if the correct direction of rotation is

observed.

An arrow on the sidewall of the tyre indicates

its correct direction of rotation.

You may fit the spare wheel against the direc-

tion of rotation. Observe the time restriction

on use as well as the speed limitation speci-

fied on the spare wheel. Storing wheels

Store tyres that are not being used in a cool,

dry and preferably dark place. Protect the

tyres against oil, grease, petrol and diesel. Cleaning the wheels

G

WARNING

Do not use high-pressure cleaners with circu-

lar-jet nozzles (dirt grinders) to clean your

vehicle, in particular the tyres. You could oth-

erwise damage the tyres and cause an acci-

dent. Fitting

awheel

Preparing the vehicle X

Prepare the vehicle as described

(Y page 309).

X If a trailer is coupled to the vehicle, uncou-

ple it.

X Remove the vehicle tool kit and the jack

(Y page 306).

X Secure the vehicle to prevent it from rolling

away.

X Remove the spare wheel from the spare

wheel bracket (Y page 307).

Securing the vehicle against rolling

away X

On level ground: place chocks or other

suitable items unde rthe front and rear of

the wheel that is diagonally opposite the

wheel you wish to change.

X On downhill gradients: place chocks or

other suitable items in front of the wheels

of the front and rear axle.

Raising the vehicle G

WARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

The following must be observed when raising

the vehicle:

R to raise the vehicle, only use the vehicle-

specific jack that has been tested and

approved by Mercedes-Benz. If the jack is

used incorrectly, it could tip over while the

vehicle is raised.

R the jack is designed only to raise and hold

the vehicle for a short time while a wheel 330

Changing

awheelWheels and tyres

Page 340 of 357

Useful information

............................338

Information on technical data .........338

Genuine Mercedes-Benz parts .........338

Vehicle electronics ...........................339

Identification plates .........................340

Service products and capacities .....341

Vehicle data ...................................... 348

Trailer tow hitch ................................ 350

24 GHz radar sensor system ...........351 337Technical data

Page 343 of 357

quency) transmitters

.Comply with the legal

requirements for add-on parts.

If your vehicle has fittings for two-way radio

equipment, use the power supply or aerial

connections intended for use with the basic

wiring. Be sure to observe the manufacturer's

additional instructions when installing.

Deviations with respect to wavebands, maxi-

mum transmission outputs or aerial positions

must be approved by Mercedes-Benz.

The maximum transmission output (PEAK) at

the base of the aerial must not exceed the

following values: Waveband Maximum

transmission

output( PEAK) Short wave (f < 54 MHz) 100 W

4 m waveband 30 W

2 m waveband 50 W

Trunked radio/Tetra 35 W

70 cm waveband 35 W

GSM/DCS/PCS

850/900/1800/1900 10 W

UMTS/LTE 10 W

The following can be used in the vehicle with-

out restrictions:

R

RF transmitters with amaximum transmis-

sion output of up to 100 mW

R mobile phones (GSM/DCS/PCS/UMTS/

LTE)

There are no restriction swhen positioning the

aerial on the outside of the vehicle for the fol-

lowing wavebands:

R Trunked radio/Tetra

R 70 cm waveband

R GSM/DCS/PCS

R UMTS/LTE Identification plates

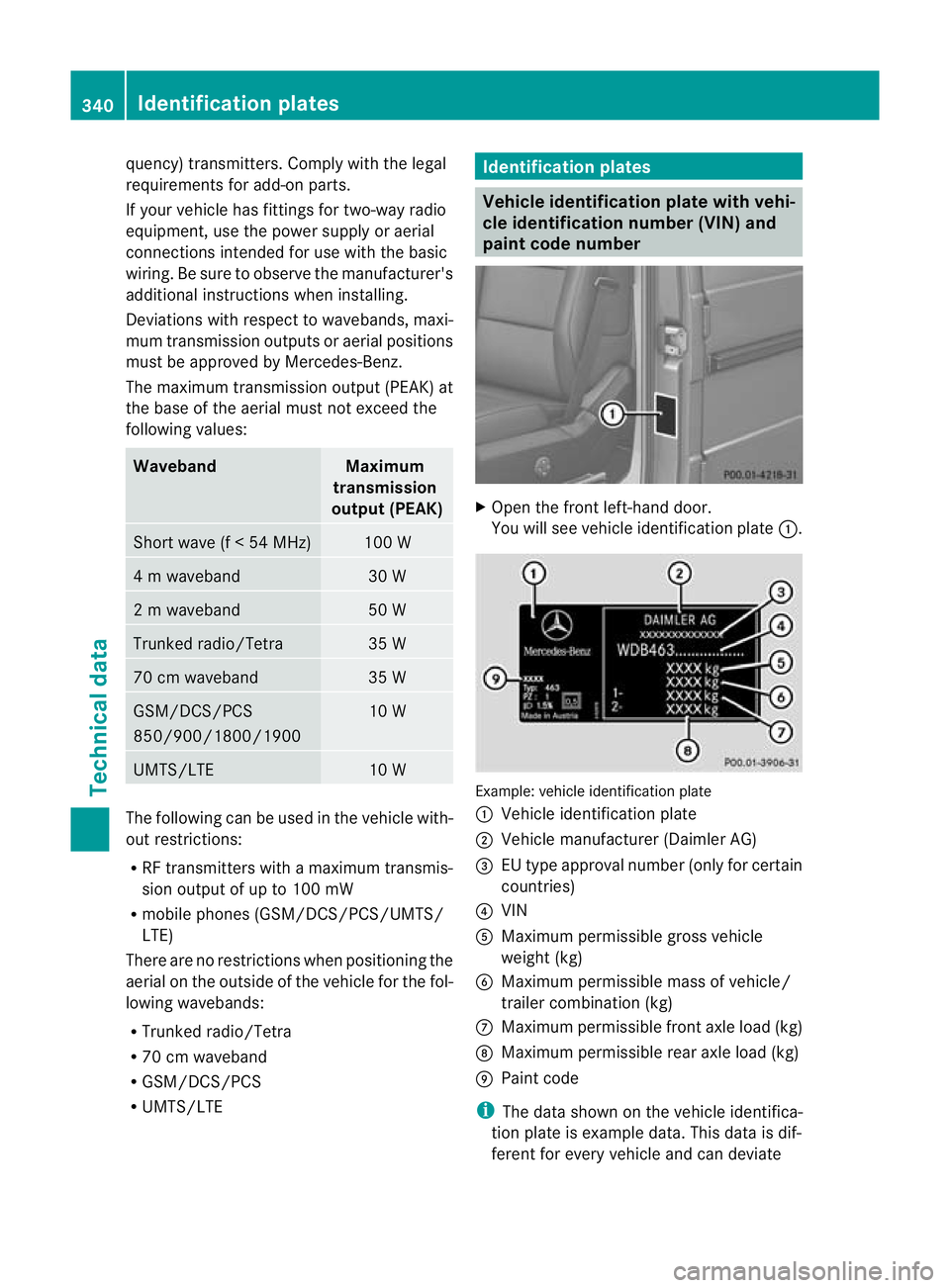

Vehicle identification plate with vehi-

cle identification number (VIN) and

paint code number

X

Open the front left-hand door.

You will see vehicle identification plate :. Example: vehicle identification plate

:

Vehicle identification plate

; Vehicle manufacturer (Daimler AG)

= EU type approval number (only for certain

countries)

? VIN

A Maximum permissible gross vehicle

weight (kg)

B Maximum permissible mass of vehicle/

trailer combination (kg)

C Maximum permissible front axle load (kg)

D Maximum permissible rear axle load (kg)

E Paint code

i The data shown on the vehicle identifica-

tion plate is example data. This data is dif-

ferent for every vehicle and can deviate 340

Identification platesTechnical data

Page 353 of 357

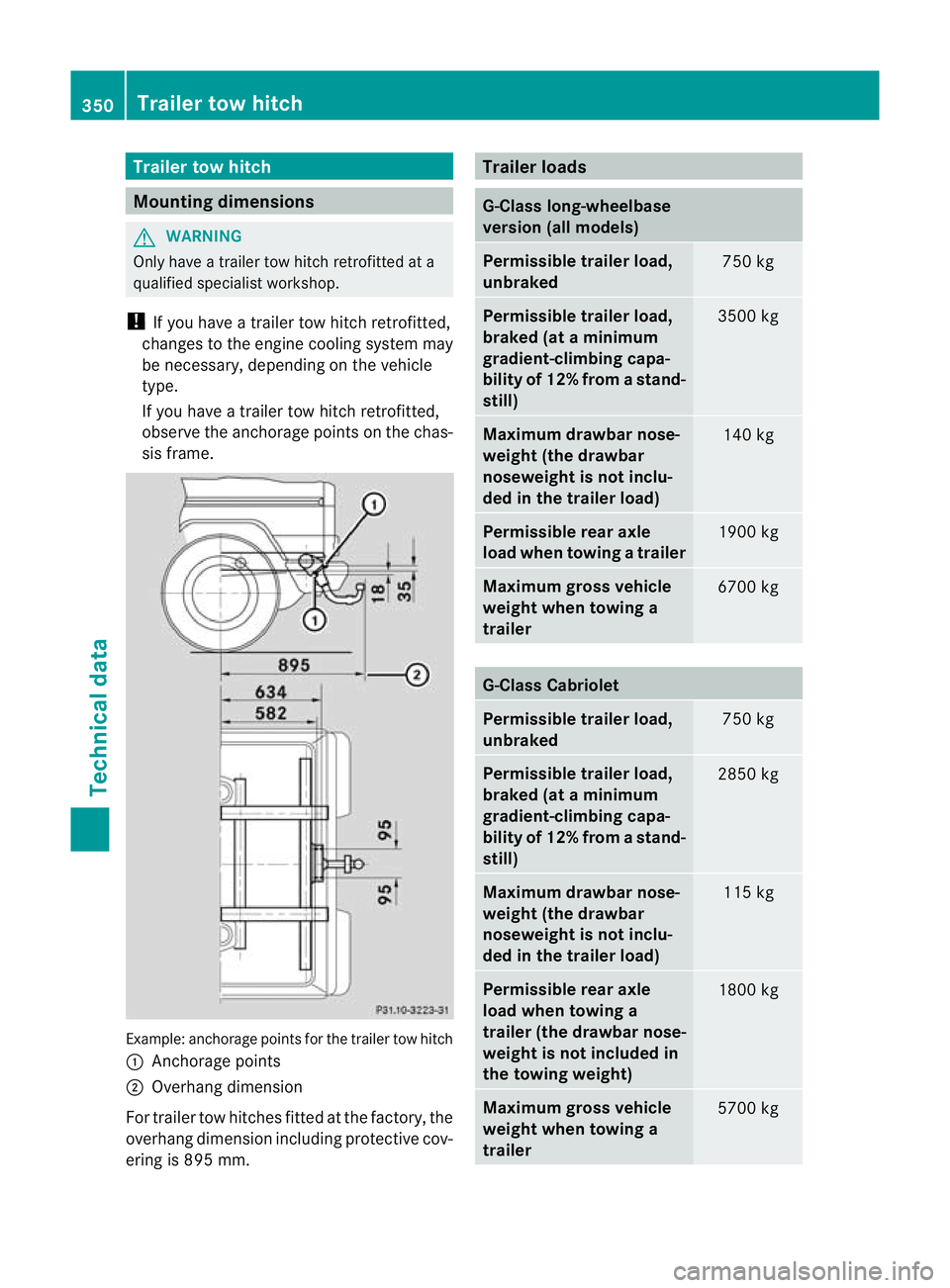

Trailer tow hitch

Mounting dimensions

G

WARNING

Only have a trailer tow hitch retrofitted at a

qualified specialis tworkshop.

! If you have a trailer tow hitch retrofitted,

changes to the engine cooling system may

be necessary, depending on the vehicle

type.

If you have a trailer tow hitch retrofitted,

observe the anchorage points on the chas-

sis frame. Example: anchorage points for the trailer tow hitch

:

Anchorage points

; Overhang dimension

For trailer tow hitches fitted at the factory, the

overhang dimension including protective cov-

ering is 895 mm. Trailer loads

G-Class long-wheelbase

version (all models)

Permissible trailer load,

unbraked

750 kg

Permissible trailer load,

braked (at a minimum

gradient-climbing capa-

bility of 12% from

astand-

still) 3500 kg

Maximum drawbar nose-

weight (the drawbar

noseweight is no tinclu-

ded in the trailer load) 140 kg

Permissible rear axle

load when towing

atrailer 1900 kg

Maximum gross vehicle

weight when towing a

trailer

6700 kg

G-Class Cabriolet

Permissible trailer load,

unbraked

750 kg

Permissible trailer load,

braked (at a minimum

gradient-climbing capa-

bility of 12 %from astand-

still) 2850 kg

Maximum drawbar nose-

weight (the drawbar

noseweight is no tinclu-

ded in the trailer load) 115 kg

Permissible rear axle

load when towing a

trailer (the drawbar nose-

weight is not included in

the towing weight) 1800 kg

Maximum gross vehicle

weight when towing a

trailer 5700 kg350

Trailer tow hitchTechnical data