lock MERCEDES-BENZ G-CLASS SUV 2015 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2015, Model line: G-CLASS SUV, Model: MERCEDES-BENZ G-CLASS SUV 2015Pages: 274, PDF Size: 31.95 MB

Page 254 of 274

rectly, the jack could tip over with the vehi-cle raised.

R The jack is designed only to raise and hold

the vehicle for a short time while a wheel

is being changed. It is not suited for per-

forming maintenance work under the vehi-

cle.

R Avoid changing the wheel on uphill and

downhill slopes.

R Before raising the vehicle, secure it from

rolling away by applying the parking brake

and inserting wheel chocks. Never disen-

gage the parking brake while the vehicle is

raised.

R The jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a

large, load-bearing underlay must be used.

On a slippery surface, a non-slip underlay

must be used, e.g. rubber mats.

R Do not use wooden blocks or similar

objects as a jack underlay. Otherwise, the

jack will not be able to achieve its load-

bearing capacity due to the restricted

height.

R Make sure that the distance between the

underside of the tires and the ground does

not exceed 1.2 in (3 cm).

R Never place your hands and feet under the

raised vehicle.

R Never lie under the raised vehicle.

R Never start the engine when the vehicle is

raised.

R Never open or close a door or the tailgate

when the vehicle is raised.

R Make sure that no persons are present in

the vehicle when the vehicle is raised.

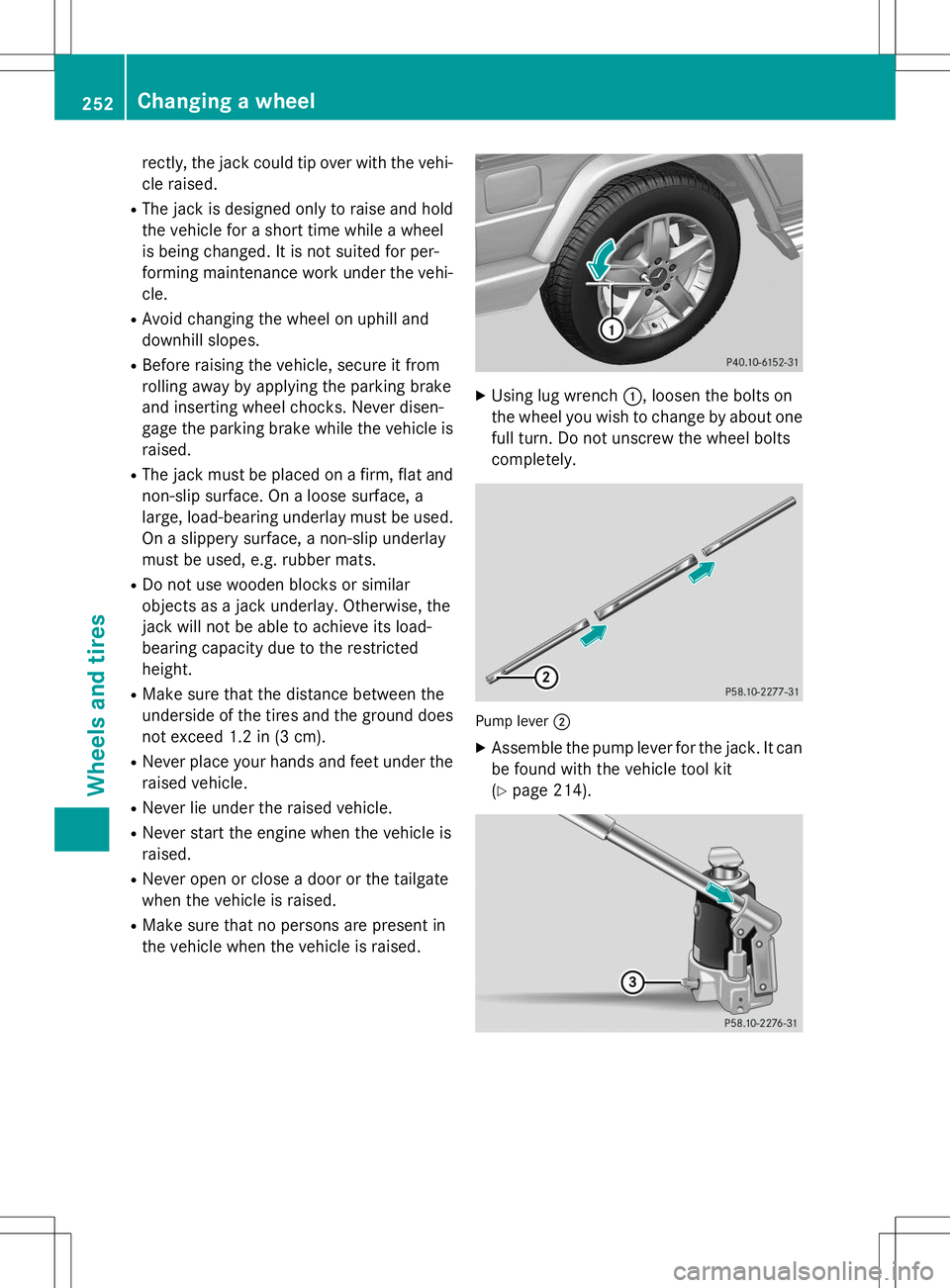

XUsing lug wrench :, loosen the bolts on

the wheel you wish to change by about one full turn. Do not unscrew the wheel bolts

completely.

Pump lever ;

X

Assemble the pump lever for the jack. It can

be found with the vehicle tool kit ( Y page 214).

252Changing a wheel

Wheels and tires

Page 255 of 274

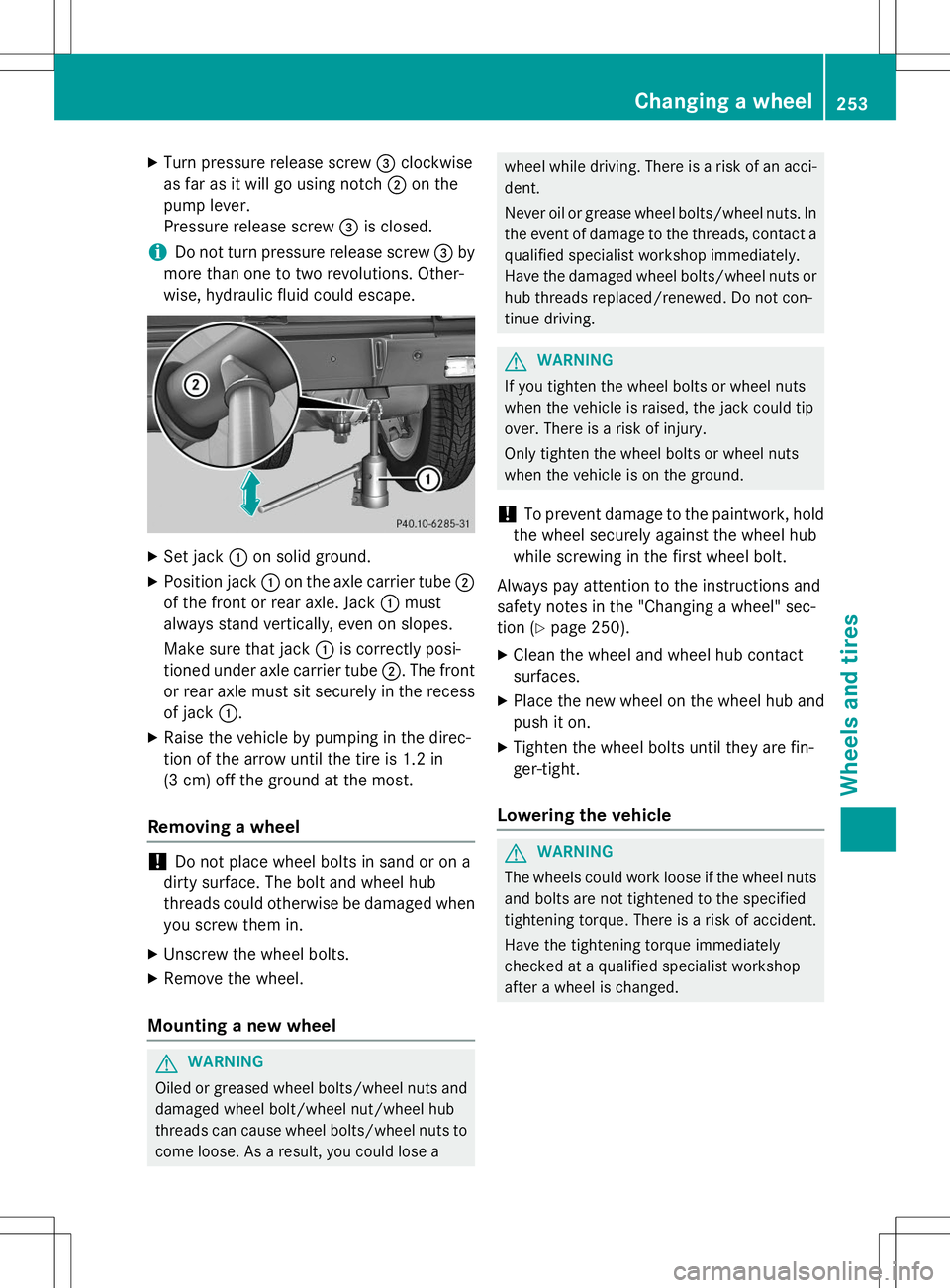

XTurn pressure release screw =clockwise

as far as it will go using notch ;on the

pump lever.

Pressure release screw =is closed.

iDo not turn pressure release screw =by

more than one to two revolutions. Other-

wise, hydraulic fluid could escape.

X Set jack :on solid ground.

X Position jack :on the axle carrier tube ;

of the front or rear axle. Jack :must

always stand vertically, even on slopes.

Make sure that jack :is correctly posi-

tioned under axle carrier tube ;. The front

or rear axle must sit securely in the recess of jack :.

X Raise the vehicle by pumping in the direc-

tion of the arrow until the tire is 1.2 in

(3 cm) off the ground at the most.

Removing a wheel

!Do not place wheel bolts in sand or on a

dirty surface. The bolt and wheel hub

threads could otherwise be damaged when you screw them in.

X Unscrew the wheel bolts.

X Remove the wheel.

Mounting a new wheel

GWARNING

Oiled or greased wheel bolts/wheel nuts and

damaged wheel bolt/wheel nut/wheel hub

threads can cause wheel bolts/wheel nuts to come loose. As a result, you could lose a

wheel while driving. There is a risk of an acci- dent.

Never oil or grease wheel bolts/wheel nuts. In the event of damage to the threads, contact a

qualified specialist workshop immediately.

Have the damaged wheel bolts/wheel nuts or hub threads replaced/renewed. Do not con-

tinue driving.

GWARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

!To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt.

Always pay attention to the instructions and

safety notes in the "Changing a wheel" sec-

tion ( Ypage 250).

X Clean the wheel and wheel hub contactsurfaces.

X Place the new wheel on the wheel hub and

push it on.

X Tighten the wheel bolts until they are fin-

ger-tight.

Lowering the vehicle

GWARNING

The wheels could work loose if the wheel nuts

and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

Changing a wheel253

Wheels and tires

Z

Page 267 of 274

iThe coolant is checked with every main-

tenance interval at a qualified specialist workshop.

The engine cooling system is filled with cool-

ant at the factory which contains antifreeze/

corrosion inhibitor that ensures protection

down to approximately -35 ‡ (-37 †).

Your vehicle has a range of aluminum com-

ponents. Aluminum components in the

engine make it necessary to use antifreeze/

corrosion inhibitor that has been specifically

formulated to protect the aluminum parts.

Failure to use such anticorrosion/antifreeze

coolant will result in a significantly shortened service life.

The coolant must be used throughout the year

in order to maintain the necessary corrosion

protection and to provide protection from

overheating. In the Maintenance Booklet, you

can find information on the intervals forrenewal.

The renewal interval is determined by the

coolant type and the engine cooling system

design. The renewal interval in the Mainte-

nance Booklet is only valid if the coolant is

renewed or added to with Mercedes-Benz

approved products. Therefore, only use MB

326.0 antifreeze/corrosion inhibitor or

another Mercedes-Benz approved product of the same specification.

Information on other products with the same

specifications that are approved by

Mercedes-Benz can be obtained at an author- ized Mercedes-Benz Center or on the Internet

at http://bevo.mercedes-benz.com .

If the coolant level is too low, MB 325.0 anti-

freeze/corrosion inhibitor should be added.

Have the engine cooling system checked for

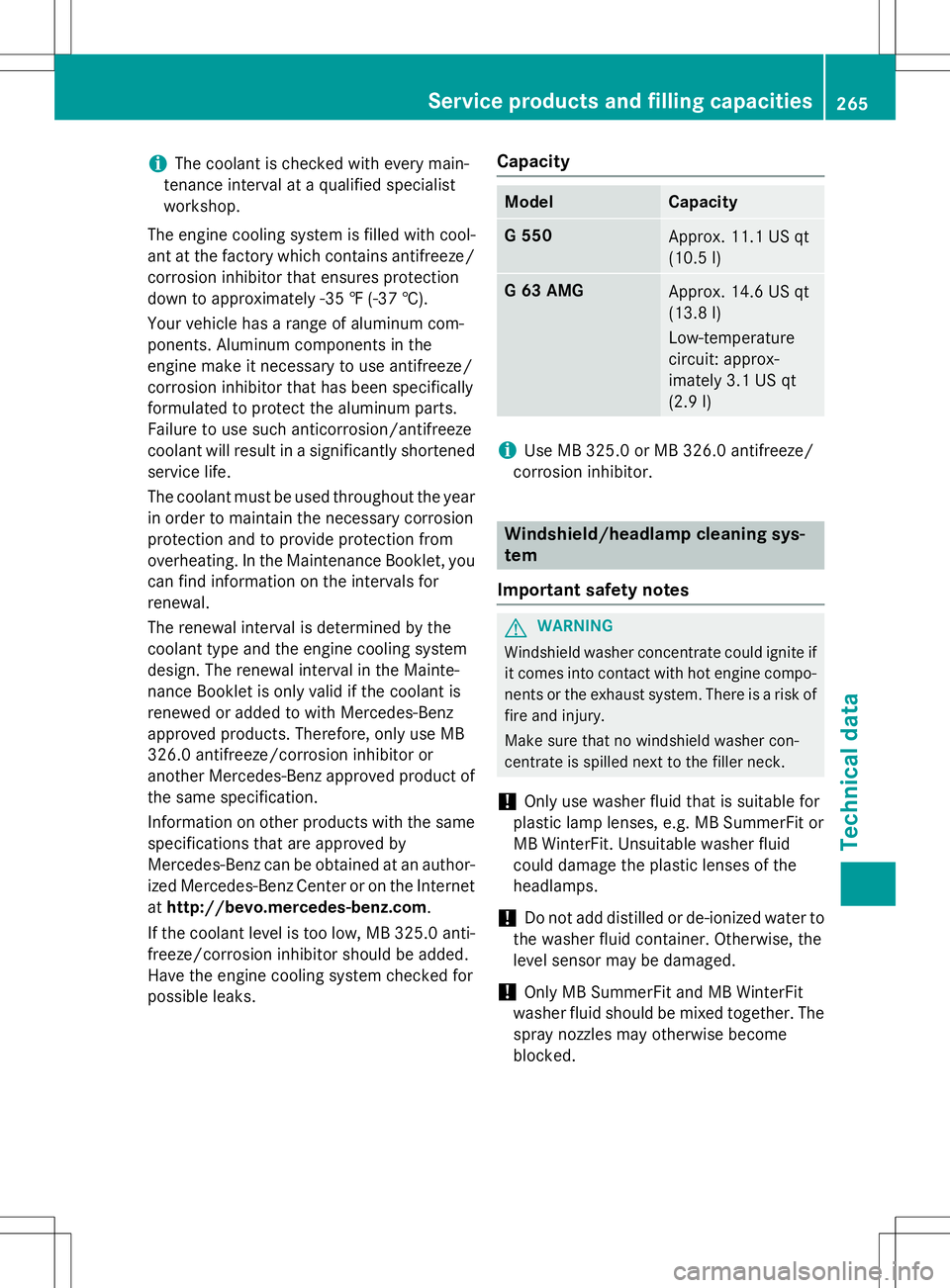

possible leaks.Capacity

ModelCapacity

G 550Approx. 11.1 US qt

(10.5 l)

G 63 AMGApprox. 14.6 US qt

(13.8 l)

Low-temperature

circuit: approx-

imately 3.1 US qt

(2.9 l)

iUse MB 325.0 or MB 326.0 antifreeze/

corrosion inhibitor.

Windshield/headlamp cleaning sys- tem

Important safety notes

GWARNING

Windshield washer concentrate could ignite if it comes into contact with hot engine compo-

nents or the exhaust system. There is a risk of

fire and injury.

Make sure that no windshield washer con-

centrate is spilled next to the filler neck.

!Only use washer fluid that is suitable for

plastic lamp lenses, e.g. MB SummerFit or

MB WinterFit. Unsuitable washer fluid

could damage the plastic lenses of theheadlamps.

!Do not add distilled or de-ionized water to

the washer fluid container. Otherwise, the

level sensor may be damaged.

!Only MB SummerFit and MB WinterFit

washer fluid should be mixed together. The spray nozzles may otherwise becomeblocked.

Service products and filling capacities265

Technical data

Z