MERCEDES-BENZ GLB SUV 2020 Owner's Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2020, Model line: GLB SUV, Model: MERCEDES-BENZ GLB SUV 2020Pages: 602, PDF Size: 45.25 MB

Page 471 of 602

th

ese areins talled ontheve hicle, butdoes not

include passeng ersor lugg age.

Maximum tireload: themaximum tireload is

th emaximum permissible weight inkilog rams or

lbs forwhi chatir eis appr oved.

Maxim umpermissible tirepr essur e:maxi‐

mum permissible tirepr essur efo rone tire.

Maximum loadonone tire: maximu mloa don

one tire. This iscalcu lated bydividing themaxi‐

mum axleload ofone axle bytwo.

PSI (pounds persquar ein ch ):standar dunit of

meas uremen tfo rtir epr essu re.

Aspe ctratio :ra tio betwee ntire height and tire

wi dthin pe rcent .

Ti re pres sur e:press ureinsi dethetir eappl ying

an outw ardfo rc eto eve rysquar einc hof thetir e.

The tirepr essur eis specif iedinpounds per

sq uar einc h(psi), inkilopascals (kPa)or inbar .

The tirepr essur eshould onlybe cor rected whe n

th etir es arecold.

Cold tirepr essur e:thetir es arecold when the

ve hicle hasbeen parkedfo rat lea st3hou rs wit

hout direct sunli ghtonthetir es ortheve hicle

has been driven forless than 1mile (1.6 km ).

Ti re contact surface: thepar tof thetir eth at

com esintocon tact with thero ad.

Ti re bead: thepur pose ofthetir ebead isto

ensur eth at thetir esits secur elyon thewheel

ri m. Ther ear ese veralwir ecor esinthetir ebead

to preve ntthetir efrom chang inglengthon the

wheel rim.

Side wall:thepar tof thetir ebe tween thetread

and thetir ebead.

We ight ofoptiona leq uipm ent:th ecombin ed

we ight oftheop tion aleq uipment weighin gmor e

th an there placed standar dpar tsand moreth an

5 lbs (2.3kg ).This optional equipment, suchas

high-per form anc ebr ak es, leve lcon trol system, a

ro of lugg agera ck orhigh-per form anc ebat teries,

is no tincluded inthecurb weight andthewe ight

of theaccessor ies.

TIN (Tire Identif ication Numbe r):auni que

ident ificat ion numb erwhic hcan beused bya

tir ema nuf actu rerto ident ifytires, forex am ple,

in apr oduc tre cal l,and thus iden tifyth epur‐

ch aser s.The TINismade upofthemanuf actur‐ er's

identit ycode, tiresize, tiretype code and

th emanuf acturingdate.

Load-bear inginde x:theload-bear inginde xis a

code that con tains themaximum load-bearing

capacity ofatir e.

Tr actio n:traction isthegr ip resulting from fric‐

tion between thetir es and thero ad sur face.

We arindi cator:nar row bars(tr ead wearbar s)

th at aredis tribut edove rth etir econ tact surface.

If th etir etread isleve lwit hth ebar s,thewe ar

limit of1/ 16 in(1.6 mm) hasbeen reac hed.

Dis tribut ionofvehicl eoc cupants: distribu tion

of vehicle occupants over designat edseat posi‐

tion sin ave hicle.

Maximum permissible payload weight :nom i‐

nal load andluggageload plus150lb (68 kg)

multip liedby thenumber ofseats intheve hicle. Wheels

andtires 469

Page 472 of 602

Cha

nging awheel No

teson selecting, installing andreplac ing

tir es Yo

ucan askforinf ormation rega rding permitted

wheel/ tirecom binat ionsatan aut hor ized

Mer cede s-Ben zCent er. &

WARNIN GRisk ofacci dent dueto inc or‐

re ct dimensi onsofwhe elsand tires

If whe elsand tires ofthewr ong size are

ins talled, thewheel brak es orwheel suspen‐

sion componen tsma ybe damag ed. #

Alw aysre place wheels andtires wit h

th ose that fulf illthespecif ication sof

th eor iginal part.

When replacing wheels, makesur eto fit th e

cor rect:

R Desi gnati on

R Mod el Whe

nre placing tires, mak esur eto ins tallth e

cor rect:

R Desi gnati on

R Manuf actu rer

R Model &

WARNIN GRisk ofinju rythro ugh exceed‐

ing thespecif iedtireload rating orthe

per missible speedrating

Ex cee ding thespecif iedtireload rating or

th eper missible speedrating mayle ad totire

da ma geand tothetir es bur sting. #

Ther efor e, onl yuse tiretypes andsizes

appr ovedfo ryo ur vehicle model. #

Obser vethetir eload rating andspee d

ra ting requ ired foryo ur vehicle. *

NO

TEVehicle andtiredamag eth ro ugh

tir etyp esand sizes that have notbe en

ap prove d Fo

rsaf etyre ason s,on lyuse tires, wheel s

and accessories whic hha ve been speciall y

appr ovedby Mer cedes-Ben zfo ryo ur vehicle.

These tires arespecially adaptedto thecon ‐

tr ol systems, suchas ABS ,ES P®

and

4MA TIC,andmarkedas follo ws :

R MO =Mer cedes-Ben zOr iginal

R MOE =Mer cedes-Ben zOr iginal Extended

(r un-f lattireonl yfo rcer tain wheels)

R MO1 =Mer cedes -Benz Original (onlycer ‐

ta in AMG tires)

Cer tain charact eristic s,suc has han dling,

ve hicle noise emissions, fuelconsum ption,

et c. ma yot her wise beadv ersel yaf fect ed.

Fu rther mor e,other tiresizes could result in

th etir es rubbing agains tth ebody andaxle

com ponen tswhen loaded. Thiscould result

in damag eto thetir eor theve hicle. 47

0

Wheels andtires

Page 473 of 602

Onl

yuse tires, wheels andaccessor iesthat

ha ve been checkedand recomme ndedby

Mer cedes-Ben z. *

NO

TERisk todriving safetyfrom retrea ‐

de dtir es Re

trea de dtir es arenei ther tested nor recom‐

mend edbyMer cedes-Ben z,since prev ious

damag ecan notalw aysbe detected on

re trea de dtir es .

Fo rth is reason drivin gsaf etycan notbe guar ‐

ant eed. #

Donotuse used tire sif yo uha ve no

inf orma tionab ou tth eir prev ious usage. *

NO

TEPossible damag eto wheels ortires

when drivin gove robs tacle s Larg

ewhe elsha ve alowe rtir esection width.

The lowe rth etir esect ionwidt h,thegr eat er

is therisk ofdamag eto wheels ortires when

dr ivin gove robs tacle s. #

Avoid obstacle sor drive pa rticular ly

car efu lly. *

NO

TEDama getoelectr oniccomponen t

par tsfrom theuse oftire-moun tingtools Ve

hicl eswith atir epr ess uremonit oring

sy stem: Electronic component partsare

locat edinthewheel. Tire -mou nting tools

should notbe used inthear ea oftheva lve.

This could other wise damag eth eelectr onic

com ponen tpar ts. #

Have thetir es chang edataqu alif ied

spec ialistwo rkshop only. *

NO

TEDama getosummer tires atlow

ambient temp eratur es At

low ambien tte mp eratur es,tear scoul d

fo rm when drivin gwit hsumm ertires, caus‐

ing perman entdamag eto thetir es. #

Attemp eratur esbelo w45 °F(7°C),

use M+S tires . Ac

cess orypa rts th at areno tappr ovedfo ryo ur

ve hicle byMer cedes-Ben zor areno tbeing used

cor rectl ycan impairth eoper ating safety.

Bef orepu rchasing andusing non-appr oved

acc esso ries, visit aqu alif ied spec ialistwo rkshop

and inquireabout :

R Suit ability

R Leg alstipulation s

R Factor yre comme ndations &

WARNIN GRisk ofacci dent with high

per form anc etir es

The spec ialtiretread incom binatio nwit hth e

op timized tirecom pound means that therisk

of skidding orhydroplaning onwetro ads is

inc reased.

In addit ion,th etir egr ip isgreatl yre duced at

a low outside temp eratur eand tireru nning

te mp eratur e. #

Switc hon theES P®

and adap tyo ur

dr ivin gst yle accor dingly. #

Use M+S tireat outside temp eratur es

of less than 10 °C (50 °F). Wheels

andtires 47

1

Page 474 of 602

Obser

vethefo llo wing when selecting,ins talling

and replacing tires:

R Onlyuse tires and wheels ofthesame type

(summer tires, wint ertires, MOEx tende d

tir es) and thesame make.

R Onlyins tallwheels ofthesame sizeonone

axle (leftand right).

It is onl yper missible toins talla dif fere nt

wh eelsi ze intheeve ntofaflat tirein order

to drive to thespecialis two rkshop.

R Onlyins talltir es ofthecor rect size ontoth e

wheels.

R Vehicl eswith atir epr ess uremonit oring

sy stem: Allinstalled wheels mustbe equip‐

ped withfunc tioningsensorsfo rth etir e

pr essur emonit oring system.

R Attemp eratur esbelo w45 °F(7°C), usewin‐

te rtir es orall-seaso ntir emar kedM+S forall

whee ls.

Wi nter tires bearing the004D snowflak esym‐

bol inaddition totheM+S marking prov ide

th ebes tpossible grip inwintr yro ad con di‐

tio ns. R

ForM+S tires, only usetires wit hth esame

tr ead.

R Obser vethemaximum permissible speedfor

th eM+S tires installed.

If th is isbelo wtheve hicle's maximum speed,

th is mus tbe indic ated byan appr opriate

label inthedr iver's field ofvision.

R Break inne wtires atmoder atespeeds for

th efirs t60 miles(1 00 km) .

R Replace thetir es afte rsix yearsat thelat est,

re ga rdless ofwe ar.

R Wh enreplac ingwith tires that donotfe a‐

tur eru n-flat charact eristics :ve hicles with

MOExt ended tires areno teq uipped witha

TIREFIT kitatthefa ct or y. Eq uip th eve hicle

wit haTIREFIT kitafte rre placing withtir es

th at do notfe atur eru n-f latch aract eristic s,

e.g .wint ertires.

Fo rmor einf ormation onwhee lsand tires, con‐

tac ta qu alif ied spec ialistwo rkshop.

Be sureto also obse rveth efo llo wing further

re lat ed subje cts:

R Noteson tirepr essur e(/ page45 1) R

Tire and Loadi ngInfo rm atio nplacar d

(/ page45 8)

R Tire size designation, load-bearing cap acity,

spe edrating andload index(/ pag e465)

R Tire pressur eta ble (/ page452 )

R Noteson theemer gency sparewheel

(/ page47 9) No

teson rotat ing whee ls &

WARNIN GRisk ofinju rythro ugh differ‐

ent whee lsizes

Int erch ang ingthefront and rear wheels ifth e

wheels ortires have differe nt dimens ions

ma yse verely im pa irth edr iving charact eris‐

tic s.

The wheel brak es orwheel suspension com ‐

pon entsma yalso bedamag ed. #

Rotate front and rear wheels onlyifth e

wheels andtires areof thesame dimen‐

sions. 47

2

Wheels andtires

Page 475 of 602

The

wearpat tern son thefront and rear wheels

dif fer:

R Front wheels wearmor eon theshoulder of

th etir e

R Rear wheels wearmor eat thecent erofthe

tir e

Do notdr ive wi th tires that have toolittle tread

dep th.Thi ssig nifica ntlyre duces traction onwet

ro ads (hydr oplan ing).

On vehicles that have thesame sizefront and

re ar wheels ,ro tat eth ewheels accordingtothe

int erva ls in thetir emanuf acturer'swarrant y

book inyour vehicle documents. Ifth is isno t

av ailable, rotate thetir es every

3,000 to6,000 miles(5 ,000 to10,000 km),

dependin gon thewe ar.En sur eth at thedir ect ion

of rotatio nis ma intained .

Ob serveth eins truction sand safetyno teson

"Cha nging awheel" whendoing so

(/ page47 4). No

teson sto ring wheels When

stor ing wheels, observethefo llo wing

no tes:

R Afterre mo ving whee ls,stor eth em inacool,

dr yand prefer ably darkplace.

R Protect thetir es from contact with oil, grease

or fuel. Ov

ervie wof thetir e-c han getool kit Apar

tfr om some country- specif icvariant s,vehi‐

cles areno teq uipped withatir e-c hang eto ol kit.

Fo rmor einf ormation onwhi chtire-c hangeto ols

ar ere qu ired and appr ovedfo rper form ing a

wheel chang eon your vehicle, consult aqu alif ied

spec ialistwo rkshop.

Yo ure qu ire th efo llo wing tools, forins tance, to

ch ang eawheel:

R Jack

R Choc k

R Lugwr enc h

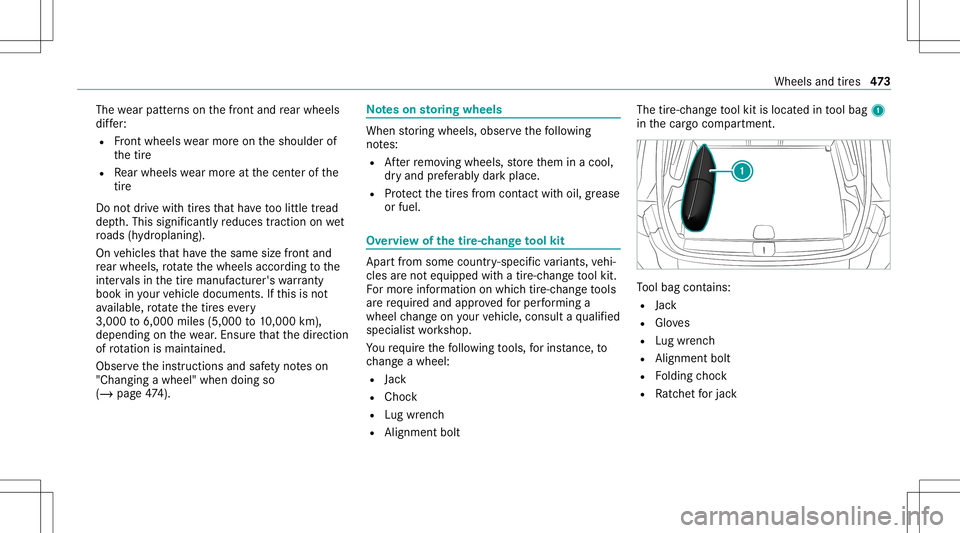

R Alignmen tbolt The

tire-c hang eto ol kit islocat edintool bag 1

in thecar gocom partmen t. To

ol bag cont ains:

R Jack

R Gloves

R Lugwr enc h

R Alignmen tbolt

R Folding choc k

R Ratche tfo rjac k Whee

lsand tires 47

3

Page 476 of 602

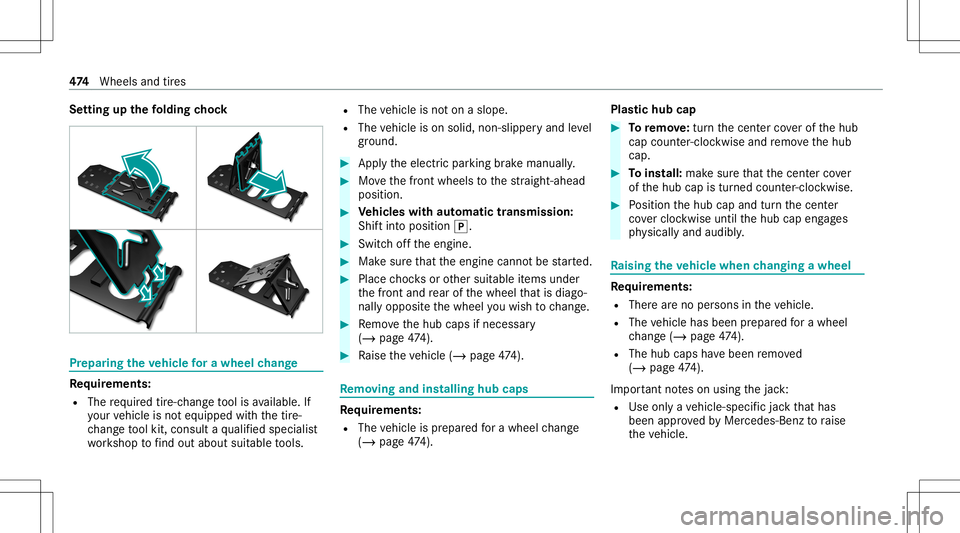

Se

tting upthefo lding chock Pr

epa ring theve hicl efo ra wh eelch ang e Re

quirement s:

R The requ ired tire-c hang eto ol isavailable. If

yo ur vehicle isno teq uipped withth etir e-

ch ang eto ol kit, consult aqu alif ied spec ialist

wo rkshop tofind outab ou tsu itab letools. R

The vehicle isno ton aslope.

R The vehicle ison solid, non-slipper yand leve l

gr ou nd . #

Apply theelectr icpar king brak emanually . #

Movethefront wheels tothest ra ight -ahead

posit ion. #

Vehicl eswith automatic transmiss ion:

Shif tint oposi tion 005D. #

Switc hof fth eengine. #

Mak esur eth at theengine cannotbe star ted. #

Place choc ks orother suitable items under

th efront and rear ofthewheel that isdiago‐

nall yoppos ite th ewheel youwish tochang e. #

Remo vethehub caps ifneces sary

(/ page47 4). #

Raise theve hicle (/page47 4). Re

mo ving and inst alli ng hub caps Re

quirement s:

R The vehicle isprepar edfora whee lch ang e

(/ page47 4). Plas

tichub cap #

Toremo ve:tur nth ecent ercoverof thehub

cap count er-cloc kwise andremo vethehub

cap. #

Toins tall: makesur eth at thecent ercover

of thehub capistur ned count er-cloc kwise. #

Position thehub capand turnth ecent er

co vercloc kwise untilthehub capengages

ph ysicall yand audibly . Ra

ising theve hicl ewhe nch angi ngawhe el Re

quirement s:

R Ther ear eno per sons intheve hicle.

R The vehicle hasbeen prepar edfora whee l

ch ang e(/ page47 4).

R Thehu bcap sha ve been remo ved

( / pag e47 4).

Im po rtant noteson using thejac k:

R Use onlya ve hicle-specif icjac kth at has

been approvedby Mer cedes-Ben zto raise

th eve hicle. 47

4

Wheels andtires

Page 477 of 602

R

The jackis onl ydesigned forra ising and

holdin gth eve hicle fora shor ttime whilea

whee lis being chang edand notfo rmaint e‐

nance workund ertheve hicle.

R The jackmus tbe placed onafirm ,fl at and

no n-slip surface. Ifneces sary,use alar ge,

fl at, load- bearing,no n-slip unde rlay .

R The foot ofthejac kmus tbe position edverti‐

call yunder thejac ksuppor tpoint . Ru

les ofcon duct when theve hicle israised:

R Neverpla ceyour han dsorfeet und erthe

ve hicle.

R Neverlie under theve hicle. R

Donotst ar tth eengine anddonotre lease

th eelectr icpar king brak e.

R Donotopen orclose anydoor sor theta il‐

ga te. #

Using thelug wrenc h,loosen thewheel bolts

on thewheel youwish tochang eby about

on efull turn.Do notuns crew thebolts com‐

ple tely. Po

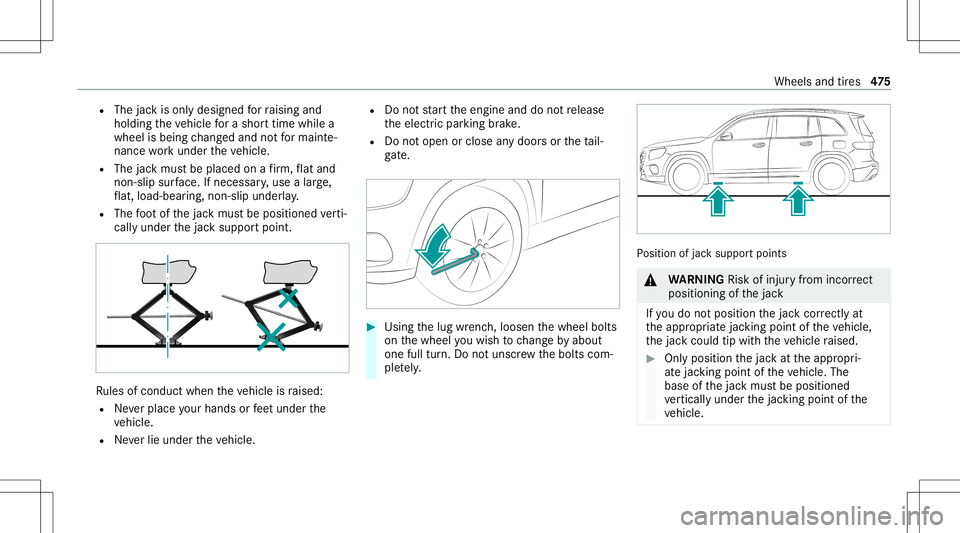

sition ofjac ksuppor tpoints &

WARNIN GRisk ofinju ryfrom incor rect

pos itioning ofthejac k

If yo udo notposi tionth ejac kcor rectl yat

th eappr opriatejac king point oftheve hicle,

th ejac kcould tipwithth eve hicle raised. #

Onlyposit ionthejac kat theappr opri‐

at ejac king point oftheve hicle. The

base ofthejac kmus tbe position ed

ve rticall yunder thejac king point ofthe

ve hicle. Wheels

andtires 47

5

Page 478 of 602

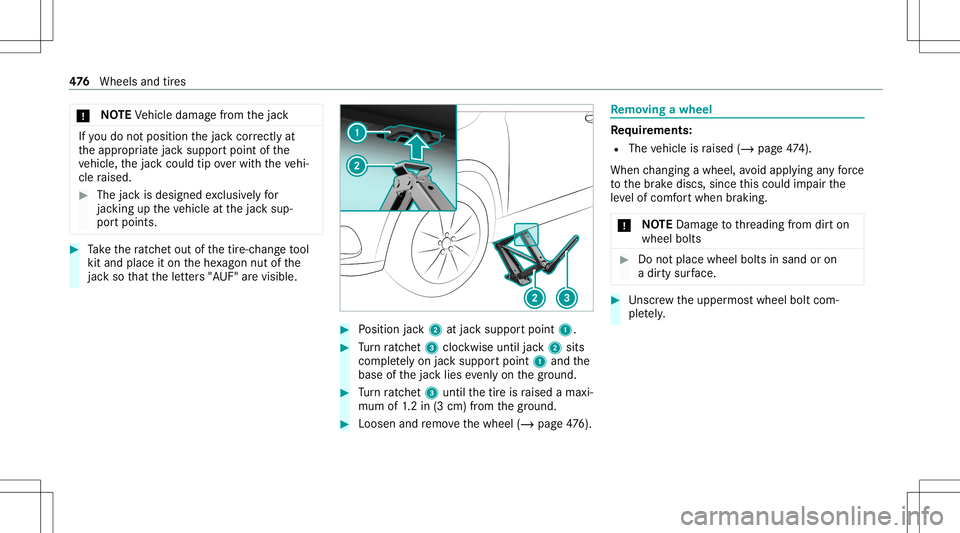

*

NO

TEVehicle damag efrom thejac k If

yo udo notposi tionth ejac kcor rectl yat

th eappr opriatejac ksuppor tpoint ofthe

ve hicle, thejac kcould tipove rwit hth eve hi‐

cle raised. #

The jackis design edexclu sively for

jac king uptheve hicle atthejac ksup‐

por tpoint s. #

Take thera tche tou tof thetir e-c hang eto ol

kit and place iton thehe xagon nutofthe

jac kso that theletter s"A UF" arevisible. #

Position jack2 atjac ksuppor tpoint 1. #

Turn ratche t3 clockwise untiljac k2 sits

com pletely on jacksuppor tpoint 1and the

base ofthejac klies evenlyon thegr ound. #

Turn ratche t3 unti lth etir eis raised amaxi‐

mum of1.2 in (3 cm) from thegr ound. #

Loosen andremo vethewheel (/page47 6). Re

mo ving awh eel Re

quirement s:

R The vehicle israised (/page47 4).

Wh enchang ingawheel, avoid applying anyfo rc e

to thebr ak ediscs, sincethis could impair the

le ve lof com fort when brakin g.

* NO

TEDama getothre adin gfrom dirton

wheel bolts #

Donotplace wheel boltsin san dor on

a dir tysur face. #

Unscr ew theupper mostwheel boltcom‐

ple tely. 47

6

Wheels andtires

Page 479 of 602

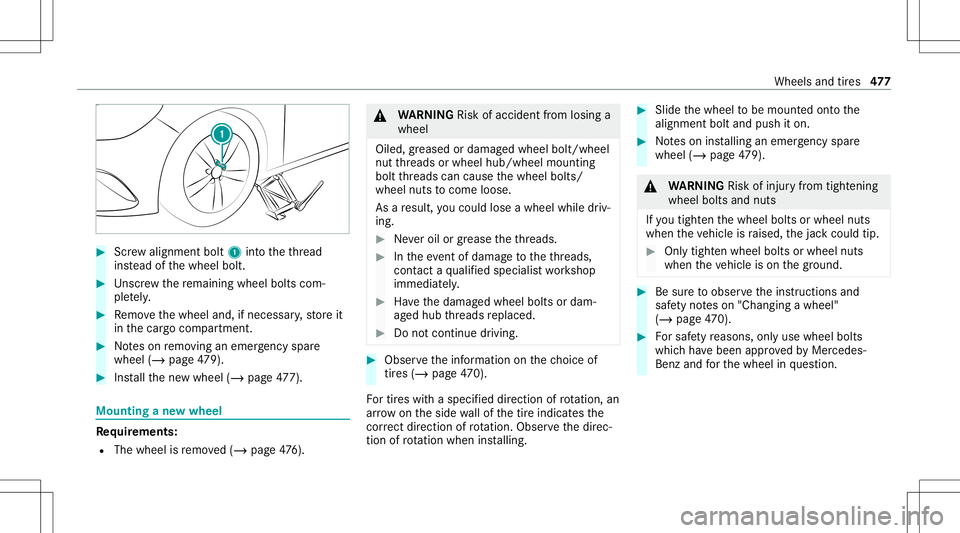

#

Screw align mentbolt 1intoth eth re ad

ins tead ofthewheel bolt. #

Unscr ew there maini ngwhee lbolts com‐

ple tely. #

Remo vethewheel and,ifneces sary,stor eit

in thecar gocom partmen t. #

Noteson remo ving anemer gency spare

wheel (/page47 9). #

Install thene wwheel (/page47 7). Mo

untin gane wwh eel Re

quirement s:

R The wheel isremo ved(/ page47 6). &

WARNIN GRisk ofacci dent from losing a

whe el

Oil ed, grea sed ordamag edwhe elbol t/whe el

nut thre ads orwheel hub/wheel mounting

bolt thre ads can caus eth ewheel bolts/

wheel nutstocome loose.

As are sult, youco uld lose awheel whiledriv‐

ing . #

Neveroil orgrease theth re ads. #

Intheeve ntofdama getotheth re ads,

con tact aqu alif ied spec ialistwo rkshop

immediat ely. #

Have thedamag edwheel boltsordam‐

ag ed hub thre ads replaced. #

Donotcon tinue driving. #

Obser vetheinf ormation onthech oice of

tir es (/ page47 0).

Fo rtir es wit haspecif ieddirection ofrotatio n,an

ar ro w on theside wallof thetir eindicat esthe

cor rect dire ction ofrotatio n.Ob serveth edir ec‐

tion ofrotatio nwh en installing. #

Slide thewheel tobe mount edont oth e

align mentbolt andpush iton . #

Noteson installing anemer gency spare

wheel (/page47 9). &

WARNIN GRisk ofinju ryfrom tight ening

whee lbol tsand nuts

If yo utig hten thewheel boltsorwheel nuts

when theve hicle israised, thejac kcould tip. #

Onlytight enwheel boltsorwheel nuts

when theve hicle ison thegr ound. #

Besureto obser vetheins truction sand

saf etyno teson "Cha nging awheel"

(/ page47 0). #

Forsaf etyre ason s,on lyuse wheel bolts

whic hha ve been approvedby Mer cedes-

Benz andforth ewheel inqu estion . Wheels

andtires 47

7

Page 480 of 602

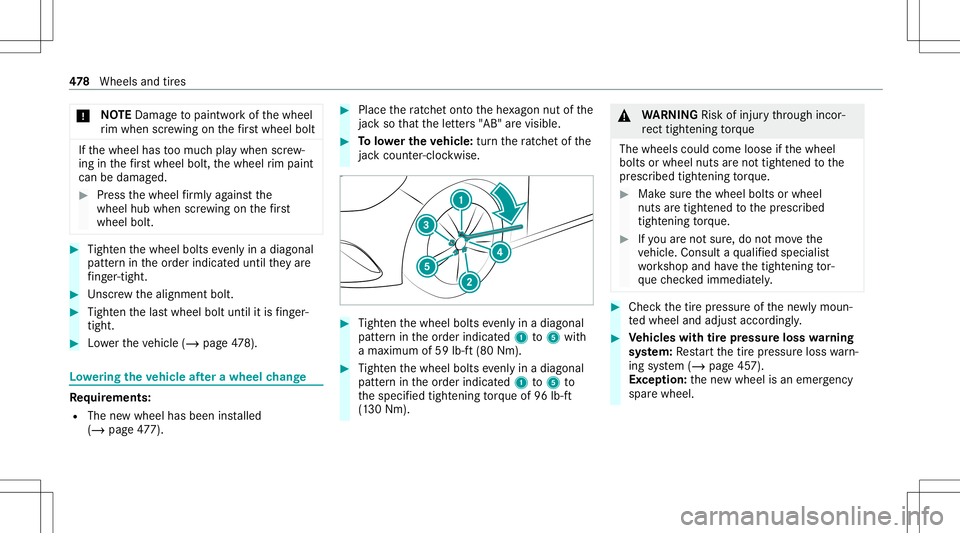

*

NO

TEDama getopaintw orkof thewheel

ri m when screwing onthefirs twh eelbo lt If

th ewheel hastoomuc hpla ywhen screw‐

ing inthefirs twh eelbo lt, thewheel rim pai nt

can bedama ged. #

Press thewheel firm lyag ains tth e

wheel hubwhen screwing onthefirs t

wheel bolt. #

Tight enthewheel boltsevenlyin adi ag ona l

pa tter nin theor der indicat eduntil they are

fi ng er-tig ht. #

Unscr ew thealignment bolt. #

Tight enthelas twheel boltuntil itis fing er-

tig ht. #

Lowe rth eve hicle (/page47 8). Lo

we ring theve hicl eaf te ra wh eelch ang e Re

quirement s:

R The newwheel hasbeen installed

(/ page47 7). #

Placethera tche tont oth ehe xagon nutofthe

jac kso that theletter s"AB" arevisible. #

Tolowe rthe vehicl e:tur nth era tche tof the

jac kcou nter-clo ckwise. #

Tight enthewheel boltsevenlyin adi ag ona l

pa tter nin theor der indicat ed1 to5 with

a max imum of59 lb-ft(80 Nm). #

Tight enthewheel boltsevenlyin adi ag ona l

pa tter nin theor der indicat ed1 to5 to

th especif iedtight ening torq ue of96 lb-ft

(1 30 Nm) . &

WARNIN GRisk ofinju rythro ugh incor‐

re ct tigh tening torq ue

Th ewh eelscou ldcome looseifth ewheel

bolts orwheel nutsareno ttight ened tothe

pr escr ibed tighteningto rq ue. #

Makesur eth ewheel boltsorwheel

nuts aretight ened tothepr escr ibed

tight ening torq ue. #

Ifyo uar eno tsur e,do notmo vethe

ve hicle. Consult aqu alif ied spec ialist

wo rkshop andhave thetight ening tor‐

qu ech eckedimmediat ely. #

Chec kth etir epr essur eof thene wlymoun‐

te dwheel andadjus taccor dingly. #

Vehicl eswith tirepr ess urelos swa rning

sy stem: Restar tth etir epr essur eloss warn‐

ing system (/ page45 7).

Ex cep tion: thene wwheel isan emer gency

spa rewheel. 47

8

Wheels andtires