inflation pressure MERCEDES-BENZ GLC COUPE 2021 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2021, Model line: GLC COUPE, Model: MERCEDES-BENZ GLC COUPE 2021Pages: 481, PDF Size: 9 MB

Page 320 of 481

%

You can find information on the po wer cate‐

gory (LK) and/or electrical data on the back

of the tyre inflation compressor:

R LK3 – 12V/20 A,240W, 1kg

At a dis tance of appr oximately 1 m tothe

tyre inflation compressor and appr oximately

1. 6 m abo vethe ground, thefo llowing sound

pressure le vels apply:

R Emission sound pressure le vel L

PA

84 dB (A)

R Sound po wer le vel L

WA 92 dB (A)

The tyre inflation compressor is mainte‐

nance-free. If there is a malfunction, please

conta ct aqualified specialist workshop. Using

the TIREFIT kit Re

quirements:

R Tyre sealant bottle and tyre inflation com‐

pressor (/ page316).

R TIREFIT sticker

R Gloves (depending on theve hicle equipment) Yo

u can use TIREFIT tyre sealant toseal per fora‐

tion dama geof up to4 mm, particularly those in

th e tyre conta ct surface.You can use TIREFIT in

outside temp eratures down to-20°C. &

WARNING Risk of accident when using

tyre sealant

The tyre sealant may be unable toseal the

tyre properly, especially in thefo llowing

cases:

R there are lar gecuts or punctures in the

tyre (larger than damage pr eviously men‐

tioned)

R the wheel rims ha vebeen damaged

R afte r journe yswith very low tyre pressure

or with flat tyres #

Do not continue driving. #

Consult a qualified specialist workshop. &

WARNING Risk of injury and poisoning

from tyre sealant

Ty re sealant is hazardous tohealth and cau‐

ses ir rita tion. Do not allow it tocome into

contact wi thyour skin, eyes or clo thing, and

do not swallow it. Do not inhale any vapours.

Ke ep the tyre sealant away from children.

Obser vethefo llowing if you come into con‐

ta ct with th e tyre sealant: #

Rinse off the tyre sealant from your skin

using water immediatel y. #

If tyre sealant gets into your eyes, thor‐

oughly rinse them using clean water

immediatel y. #

If tyre sealant has been swallowe d,

th oroughly rinse out your mouth imme‐

diately and drink plenty of water.Do not

induce vomiting and seek medical

attention immediately. #

Change out of clo thing which has come

into con tact with tyre sealant immedi‐

ately. Breakdown assi

stance 317

Page 322 of 481

#

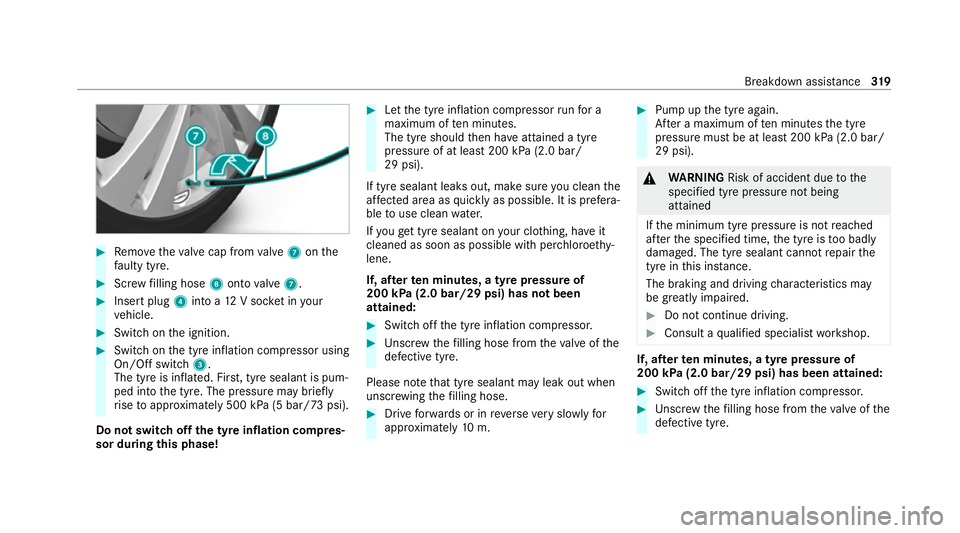

Remo vetheva lve cap from valve 7 onthe

fa ulty tyre. #

Screw filling hose 8onto valve 7. #

Insert plug 4into a 12V soc ket in your

ve hicle. #

Switch on the ignition. #

Switch on the tyre inflation compressor using

On/Off switch 3.

The tyre is inflated. Fir st, tyre sealant is pum‐

ped into the tyre. The pressure may brief ly

ri se toappr oximately 500 kPa (5 bar/73 psi).

Do not switch off the ty reinflation compres‐

sor during this phase! #

Let the tyre inflation compressor runfo r a

maximum of ten minu tes.

The tyre should then ha veattained a tyre

pressure of at least 200 kPa (2.0 bar/

29 psi).

If tyre sealant leaks out, make sure you clean the

af fected area as quickly as possible. It is prefera‐

ble touse clean water.

If yo uge t tyre sealant on your clo thing, ha veit

cleaned as soon as possible with per chloroe thy‐

lene.

If, af terte n minutes, a tyre pressure of

200 kPa (2.0 bar/29 psi) has not been

attained: #

Switch off the tyre inflation compressor. #

Unscr ew thefilling hose from theva lve of the

defective tyre.

Please no tethat tyre sealant may leak out when

unscr ewing thefilling hose. #

Drive forw ards or in reve rseve ry slowly for

appr oximately 10m. #

Pump up the tyre again.

Af ter a maximum of ten minu testh e tyre

pressure must be at least 200 kPa (2.0 bar/

29 psi). &

WARNING Risk of accident due tothe

specified tyre pressure not being

attained

If th e minimum tyre pressure is not reached

af te rth e specified time, the tyre is too badly

damaged. The tyre sealant cannot repair the

tyre in this ins tance.

The braking and driving characteristics may

be great lyimpaired. #

Do not continue driving. #

Consult a qualified specialist workshop. If, af

terte n minutes, a tyre pressure of

200 kPa (2.0 bar/29 psi) has been attained: #

Switch off the tyre inflation compressor. #

Unscr ew thefilling hose from theva lve of the

defective tyre. Breakdown assis

tance 319

Page 323 of 481

&

WARNING Risk of accident from driving

wi th sealed tyres

A tyre temp orarily sealed with tyre sealant

impairs the handling characteristics and is

not suitable for higher speeds. #

Adapt your driving style according lyand

drive carefull y. #

Do not exceed the maximum speed

limit with a tyre that has been repaired

using tyre sealant. #

Obser vethe maximum permissible speed for

a tyre sealed with tyre sealant 80 km/h.

* NO

TEStaining from leaking tyre sealant Af

ter use, excess tyre sealant may leak out

from thefilling hose. #

Therefore, place thefilling hose in the

plastic bag that con tained the TIREFIT

kit. +

ENVIRONMEN

TALNO TEEnvironmental

pollution caused byenvironmen tally ir re‐

sponsible disposal Ty

re sealant contains polluta nts. #

Have the tyre sealant bottle disposed of

professionall y,e.g. at a Mercedes-Benz

Service Centre. #

Stow th e tyre sealant bottle and the tyre

inflation compressor. #

Pull away immediatel y. #

Stop driving af ter appro ximately ten minu tes

and check the tyre pressure using the tyre

inflation compressor.

The tyre pressure must now be at least

13 0 kPa (1.3 bar/19 psi). &

WARNING Risk of accident due tothe

specified tyre pressure not being

attained

If th e specified tyre pressure is not reached,

th e tyre is too badly damaged. The tyre seal‐

ant cannot repair the tyre in this ins tance. The braking and driving

characteristics may

be great lyimpaired. #

Do not continue driving. #

Consult a qualified specialist workshop. Countries

that ha veMercedes-Benz

Service24h: you will find a sticke r with thete le‐

phone number, e.g. on the B‑pillar on the driver's

side. #

Cor rect the tyre pressure if it is still at least

13 0 kPa (1.3 bar/19 psi). See the tyre pres‐

sure table on the fuel filler flap forva lues. #

Toincrease the ty repressure: switch on

th e tyre inflation compressor. 320

Breakdown assis tance

Page 324 of 481

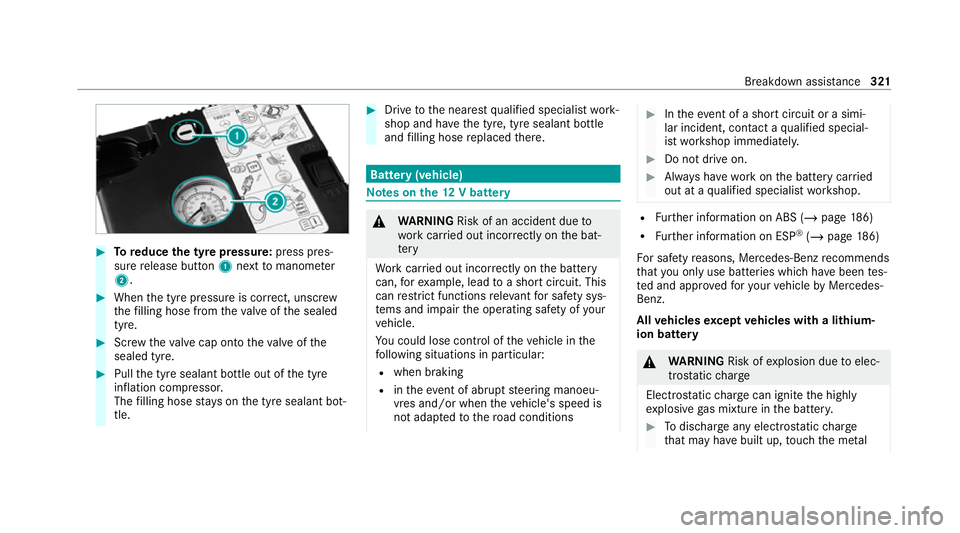

#

Toreduce the tyre pressure: press pres‐

su re re lease button 1next tomanome ter

2 . #

When the tyre pressure is cor rect, unscr ew

th efilling hose from theva lve of the sealed

tyre. #

Screw theva lve cap onto theva lve of the

sealed tyre. #

Pull the tyre sealant bottle out of the tyre

inflation compressor.

The filling hose stay s on the tyre sealant bot‐

tle. #

Drive tothe nearest qualified specialist work‐

shop and ha vethe tyre, tyre sealant bottle

and filling hose replaced there. Batte

ry(vehicle) Note

s onthe12 V battery &

WARNING Risk of an accident due to

wo rkcar ried out incor rectly on the bat‐

te ry

Wo rkcar ried out incor rectly on the battery

can, forex ample, lead toa short circuit. This

can restrict functions releva nt for saf ety sys‐

te ms and impair the operating saf ety of your

ve hicle.

Yo u could lose cont rol of theve hicle in the

fo llowing situations in particular:

R when braking

R intheeve nt of ab rupt steering manoeu‐

vres and/or when theve hicle's speed is

not adap tedto thero ad conditions #

Intheeve nt of a sho rtcircuit or a simi‐

lar incident, contact a qualified special‐

ist workshop immediately. #

Do not drive on. #

Alw ays ha vewo rkon the battery car ried

out at a qualified specialist workshop. R

Further information on ABS (/ page186)

R Further information on ESP ®

(/ page 186)

Fo r saf etyre asons, Mercedes-Benz recommends

th at you on lyuse bat teries which ha vebeen tes‐

te d and appr ovedfo ryo ur vehicle byMercedes-

Benz.

All vehicles except vehicles with a lithium-

ion battery &

WARNING Risk ofexplosion due toelec‐

tros tatic charge

Electros tatic charge can igni tethe highly

ex plosive gas mixture in the batter y. #

Todischar geany electros tatic charge

th at may ha vebuilt up, touch the me tal Breakdown assis

tance 321

Page 354 of 481

R

Do not fit th e emer gency spa rewheel with

sn ow chains.

R Replace the emer gency spa rewheel af ter six

ye ars at the latest, rega rdless of wear.

% Ve

hicles with a tyre pressure loss warn‐

ing sy stem: if an emer gency spa rewheel is

fi tted, the tyre pressure loss warning sy stem

cann otfunction reliabl y.Only restart the sys‐

te m again when the emer gency spa rewheel

has been replaced with a new wheel.

Ve hicles with a tyre pressure monitoring

sy stem: if an emer gency spa rewheel is fit‐

te d, the tyre pressure monitoring sy stem

cann otfunction reliabl y.Fo r a few minutes

af te r an emer gency spa rewheel is fitted, the

sy stem may still display the tyre pressure of

th ere mo ved wheel. Only restart the sy stem

again when the emer gency spa rewheel has

been replaced with a new wheel.

Be sure toalso obse rveth efo llowing fur ther

re lated subjects:

R Notes on tyre pressure (/ page 336)

R Tyre pressure table (/ page 337) R

Notes on fitting tyres (/ page 340) Inflating

the emer gency spare wheel *

NO

TEOverheating due tothe tyre infla‐

tion compressor running too long #

Do not runth e tyre inflation compres‐

sor for longer than ten minu tes without

inter ruption. Re

quirements:

Comply with the manufacturer's saf ety no tes on

th est icke r of the emer gency spa rewheel and on

th e tyre inflation compressor. #

Remo vethest icke r with the label 80 km/h

from the tyre inflation compressor housing

and af fix it tothe instrument clus ter within

th e driver's field of vision. #

Remo vethe tyre inflation compressor from

th estow age space under the luggage com‐

partment floor (/ page316). #

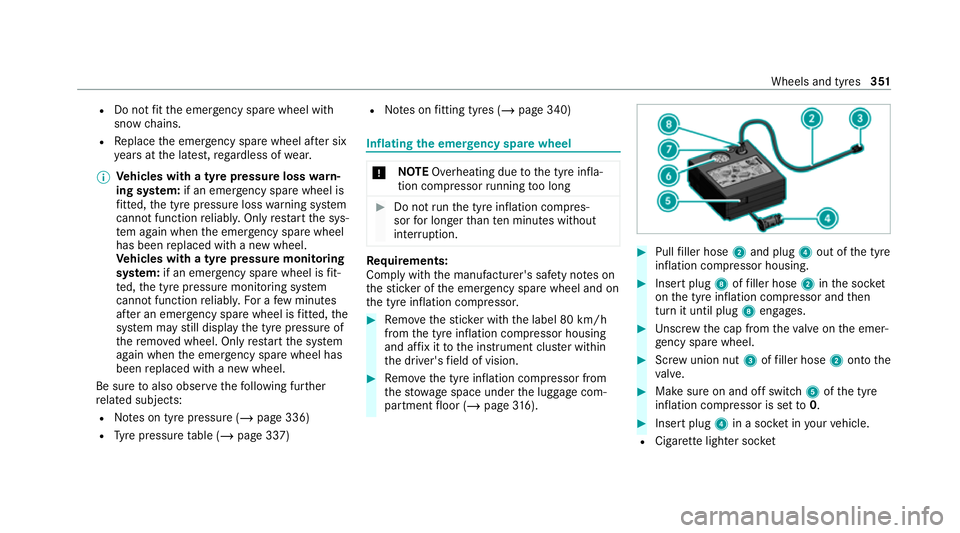

Pull filler hose 2and plug 4out of the tyre

inflation compressor housing. #

Insert plug 8offiller hose 2inthe soc ket

on the tyre inflation compressor and then

turn it until plug 8engages. #

Unscr ew the cap from theva lve on the emer‐

ge ncy spa rewheel. #

Screw union nut 3offiller hose 2onto the

va lve. #

Make sure on and off switch 5ofthe tyre

inflation compressor is set to0. #

Insert plug 4in a soc ket in your vehicle.

R Cigar ette lighter soc ket Wheels and tyres

351

Page 355 of 481

R

Obser vethe no tes on the cigar ette lighter in

th e Digital Owner's Manual

R 12V soc ket: ( / page 121)

R Obse rveth e no tes on soc kets: (/ page 121) #

Turn theke yto position 1inthe ignition

loc k. #

Press on and off switch 5onthe tyre infla‐

tion compressor toI.

The tyre inflation compressor is switched on.

The tyre is inflated. The tyre pressure is

shown on manome ter6. #

Pump the tyre tothe specified tyre pressure.

% The specified tyre pressure is stated on the

label of the emer gency spa rewheel. #

When the specified tyre pressure has been

re ached, press on and off swit ch5 onthe

tyre inflation compressor to0.

The tyre inflation compressor is switched off. #

Turn theke yto position ginthe ignition

loc k. #

Ifth e tyre pressure is higher than the speci‐

fi ed pressure, press pressure release valve bu

tton 7until the cor rect tyre pressure has

been reached. #

Unscr ew union nut 3offiller hose 2from

th eva lve. #

Screw theva lve cap of the emer gency spa re

wheel onto theva lve again. #

Stow filler hose 2and plug 4inthe lo wer

section of the tyre inflation compressor

housing. #

Stow th e tyre inflation compressor in the

ve hicle. 352

Wheels and tyres

Page 472 of 481

Extending/r

etra cting the ball neck

(MBUX multimedia sy stem)...................2 42

No tes....................................................2 39

Soc ket.................................................. .243

Tr ailer stabilisation

Fu nction/no tes..................................... 188

Tr ansmission position display.................. 16 6

Tr anspo rting

Ve hicle..................................................3 29

Tr im element (Care)................................... 310

Tu neIn

Calling up..............................................2 95

Tu rn signal indicator

Ac tivating/deactivating......................... 12 9

TV Information............................................ 292

Tw o-w ayradios

Fr equencies........................................... 354

No tes on ins tallation............................ .353

Tr ansmission output (maximum )........... 354

Ty re inflation compressor

see TIREFIT kit Ty

re pressure

Checking (ty repressure monitoring

sy stem)................................................. 338

No tes....................................................3 36

Re starting the tyre pressure loss

wa rning sy stem..................................... 340

Re starting the tyre pressure monitor‐

ing sy stem.............................................3 39

TIREFIT kit.............................................. 317

Ty re pressure loss warning sy stem

(function)............................................... 339

Ty re pressure monitoring sy stem

(function)............................................... 338

Ty re pressure table................................ 337

Ty re pressure loss warning sy stem

Fu nction................................................ 339

Re starting.............................................. 340

Ty re pressure moni tor

Fu nction................................................ 338

Ty re pressure moni toring sy stem

Checking the tyre pressure...................3 38

Che cking the tyre temp erature............. 338

Re starting............................................. .339

Ty re pressure table ................................... 337 Ty

re temp erature

Checking (tyre pressure monitoring

sy stem)................................................. 338

Ty re pressure monitoring sy stem

(function)............................................... 338

Ty re tread ................................................... 335

Ty re-change tool kit

Overview............................................... 344

Ty res

Checking............................................... 335

Checking the tyre pressure (tyre

pressure monitoring sy stem)................. 338

Fitting.................................................... 348

Flat tyre.................................................3 15

Inter changing........................................ 343

MOExtended tyres................................ .315

No ise.................................................... .335

No tes on fitting..................................... 340

Re moving.............................................. 348

Re placing...................................... 340, 345

Re placing the wheel trim....................... 345

Re starting the tyre pressure loss

wa rning sy stem..................................... 340

Re starting the tyre pressure monitor‐

ing sy stem.............................................3 39 Index

469