oil MERCEDES-BENZ GLE 2019 Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: GLE, Model: MERCEDES-BENZ GLE 2019Pages: 398, PDF Size: 12.25 MB

Page 328 of 398

A qualified specialist workshop will reset the

ASSYST PLUS service interval display after the

service work has been carried out. You can also obtain further information on maintenance

work, for example.

Special service requirements The specified maintenance interval takes only

the normal operation of the vehicle into

account. Under increased load on the vehicle,

maintenance work must be carried out more

frequently, for example:

R Regular city driving with frequent intermedi-

ate stops

R If the vehicle is primarily used to travel short

distances

R Use in mountainous terrain or on poor road

surfaces

R If the engine is often left idling for long periods

Under these or similar conditions, have, for

example, the air filter, engine oil and oil filter

replaced or changed more frequently. Under

arduous operating conditions, the tires must be

checked more often. Further information can be

obtained at a qualified specialist workshop.

Driving abroad An extensive Mercedes-Benz Service network is

also available in other countries. You can obtain further information from any authorized

Mercedes-Benz Center. Care

General notes

H

Environmental note

Dispose of empty packaging and cleaning

cloths in an environmentally responsible man-

ner.

! When cleaning your car, do not use:

R dry, coarse or hard cloths

R abrasive cleaning agents

R solvents

R cleaning agents containing solvents

Do not scrub.

Do not touch the surfaces and films with hard objects, e.g. rings or ice scrapers. Otherwise, you may scratch or damage the surfaces and

films.

! Do not park your vehicle for a long period of

time directly after cleaning, particularly after

cleaning the wheel rim with wheel cleaner.

Wheel cleaner can lead to the increased cor-

rosion of the brake discs and pads. Therefore,

drive for a few minutes after cleaning. By

heating up the brakes, the brake discs and

pads dry. The vehicle can then be parked for a

long period of time.

Regular care of your vehicle is a condition for

retaining the quality in the long term.

Use care products and cleaning agents recom-

mended and approved by Mercedes-Benz. Washing the vehicle and cleaning the

paintwork

Automatic car wash G

WARNING

Braking efficiency is reduced after washing

the vehicle. There is a risk of an accident.

After the vehicle has been washed, brake

carefully while paying attention to the traffic

conditions until full braking power is restored.

! Before driving into an automatic car wash,

make sure that it is suitable for the dimen-

sions of the vehicle. In particular, make sure

that:

R there is enough ground clearance between

the vehicle underbody and the guide rails of the automatic car wash.

R the clearance width of the automatic car

wash is sufficient, particularly the width of

the guide rails.

R you enter the automatic car wash straight

and in the center of the guide rails in order

to avoid damaging the tires or wheel rims.

Fold in the exterior mirrors before the vehicle

is washed. The exterior mirrors could other-

wise be damaged.

! When Active Distance Assist DISTRONIC or

the HOLD function is activated, the vehicle

brakes automatically in certain situations. 326

CareMaintenance and care

Page 330 of 398

tires or chassis components replaced imme-

diately.

! Always maintain a distance of at least 12 in

(30 cm) between the vehicle and the power

washer nozzle. Information about the correct

distance is available from the equipment

manufacturer.

Move the power washer nozzle around when

cleaning your vehicle.

Do not aim directly at any of the following:

R Tires

R Door gaps, roof gaps, joints, etc.

R Electrical components

R Battery

R Plug-type couplings

R Light bulbs

R Seals

R Trim elements

R Ventilation slots

Damaged seals or electrical components can

lead to leaks or failures.

! Vehicles with decorative foil: parts of your

vehicle are covered with decorative foil. Main- tain a distance of at least 27.5 in (70 cm)

between the foil-wrapped parts of the vehicle and the nozzle of the high pressure cleaner.

Information about the correct distance is

available from the equipment manufacturer.

Move the power washer nozzle around when

cleaning your vehicle.

The water temperature of the high-pressure

cleaner must not exceed 140 °F (60 °C).

Cleaning the paintwork !

Do not affix:

R stickers

R films

R magnetic plates or similar items

to painted surfaces. You could otherwise

damage the paintwork.

Scratches, corrosive deposits, areas affected by

corrosion and damage caused by inadequate

care cannot always be completely repaired. In

such cases, visit a qualified specialist workshop. X

Remove dirt immediately, where possible,

while avoiding rubbing too hard.

X Soak insect remains with insect remover and

rinse off the treated areas afterwards.

X Soak bird droppings with water and rinse off

the treated areas afterwards.

X Remove tree resin, oils, fuels and greases by

rubbing gently with a cloth soaked in petro-

leum ether or lighter fluid

X Remove coolant and brake fluid with a moist

cloth and clear water.

X Use tar remover to remove tar stains.

X Use silicone remover to remove wax.

If water no longer forms "beads" on the paint

surface, use the paint care products recommen-

ded and approved by Mercedes-Benz. This is the

case approximately every three to five months,

depending on the climate conditions and the

care product used.

If dirt has penetrated the paint surface or if the

paint has become dull, the paint cleaner recom-

mended and approved by Mercedes-Benz

should be used.

Do not use these care products in the sun or on the hood while the hood is hot.

X Use a suitable touch-up stick, e.g. MB Touch-

Up Stick, to repair slight damage to the paint-

work quickly and provisionally.

Matte finish care !

Never polish the vehicle or the light alloy

wheels. Polishing causes the finish to shine.

! The following can give the paint a glossy

appearance and thus reduce the matt effect:

R Rubbing hard with unsuitable agents

R Washing the vehicle in direct sunlight

! Never use paint cleaner, buffing or polishing

products, or gloss preserver, e.g. wax, for the purpose of paintwork care. These products

are only suitable for high-gloss surfaces. Their

use on vehicles with matte paintwork leads to

considerable surface damage or, more spe-

cifically, to shiny, spotted areas.

Always have paintwork repairs carried out at a

qualified specialist workshop.

! Only use automatic car washes which cor-

respond to the latest technological stand-

ards. Never use wash programs which finish

by treating the vehicle with hot wax. 328

CareMaintenance and care

Page 333 of 398

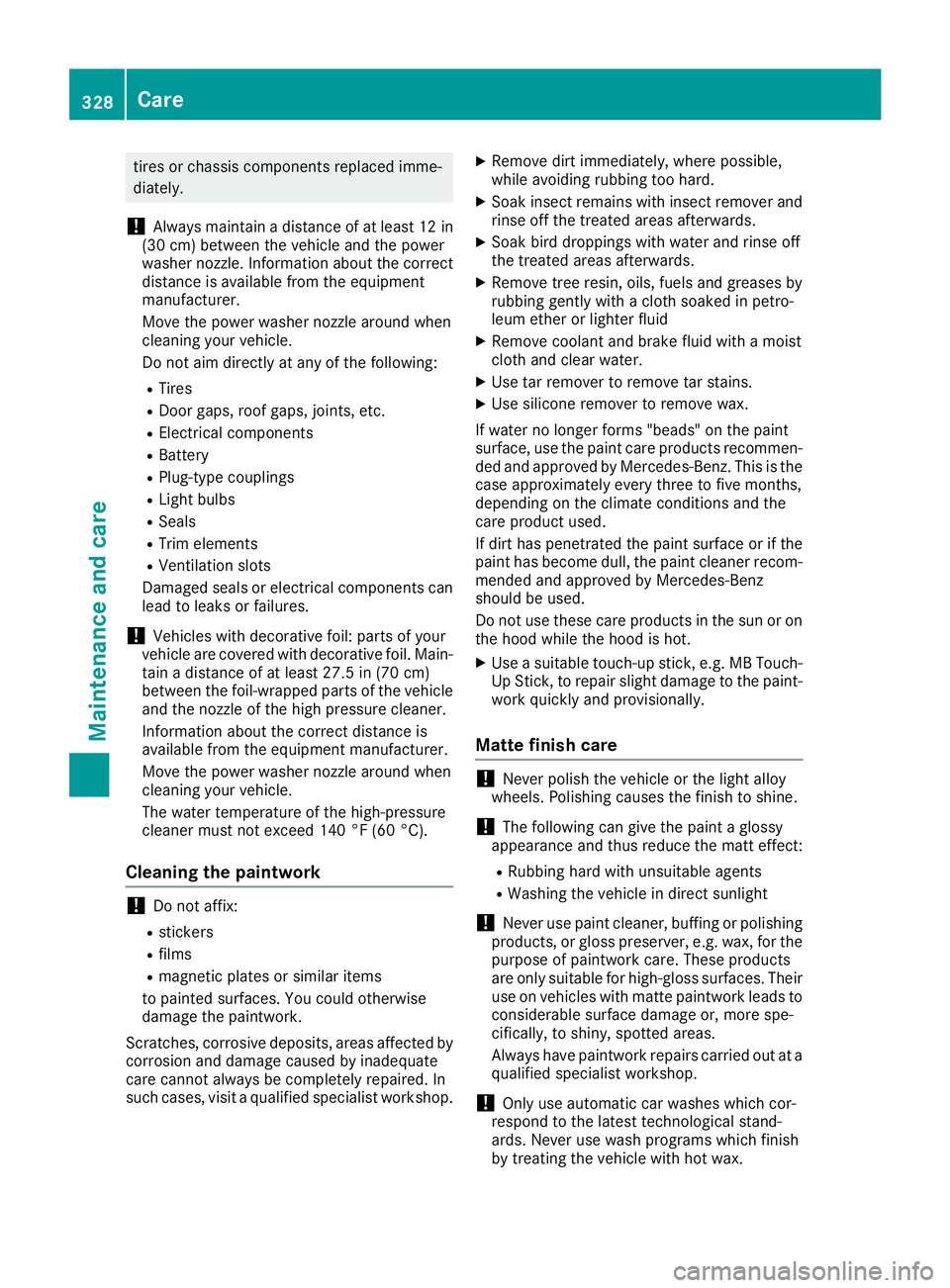

X

Clean sensors 0043of the driving systems with

water, car shampoo and a soft cloth.

Cleaning the rear view camera and 360° camera !

Do not clean the camera lens and the area

around the rear view camera or 360° camera with a power washer. X

Make sure that the vehicle is stationary and

the SmartKey is in position 0048in the ignition

lock.

X Open the camera cover for cleaning via the

multimedia system (see Digital Operator's

Manual).

X To clean the camera: use clean water and a

soft cloth to clean the camera lens 0043.

360° camera: if you drive at speeds above

20 mph (30 km/h) or with the SmartKey in posi- tion 0092or0047 in the ignition lock, the cover of

the 360° camera closes. Cleaning the exhaust pipe G

WARNING

The exhaust tail pipe and tail pipe trim can

become very hot. If you come into contact

with these parts of the vehicle, you could burn

yourself. There is a risk of injury.

Always be particularly careful around the

exhaust tail pipe and the tail pipe trim. Allow

these components to cool down before touch-

ing them.

! Vehicles with black exhaust pipes: black

chromed screens should not be polished with a chrome polish. They will otherwise lose their

black shine. For optimal care, the screens

should be rubbed with a lightly oiled cloth

after every car wash. Commercially available

engine and care oils are suitable for this.

For heavier soiling, you can apply a fine paint- work polish with a microfiber cloth. Remove

the excess polish residue after polishing.

Impurities combined with the effects of road grit and corrosive environmental factors may cause

flash rust to form on the surface. You can

restore the original shine of the exhaust pipe by cleaning it regularly, especially in winter and

after washing.

X Clean the exhaust pipe with a chrome care

product tested and approved by Mercedes-

Benz.

Cleaning the trailer tow hitch H

Environmental note

Dispose of rags soaked in oil and grease in an environmentally responsible manner.

! Do not clean the ball coupling with a power

washer. Do not use solvents.

! Please note the care instructions in the

trailer coupling manufacturer's operating

instructions. Care

331Maintenance and care Z

Page 334 of 398

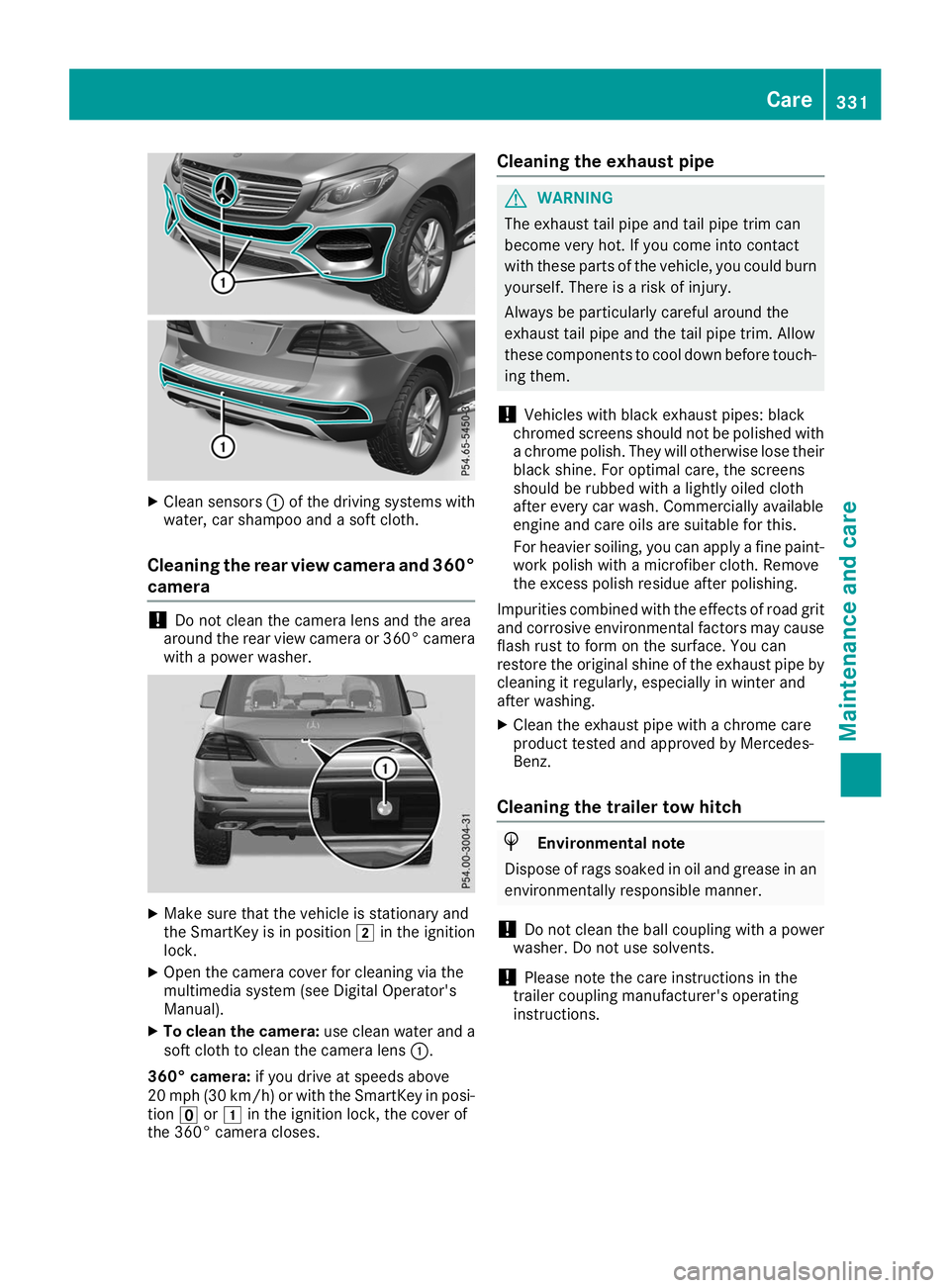

The ball coupling must be cleaned if it becomes

dirty or corroded.

X Remove rust on the ball of the ball coupling,

e.g. with a wire brush.

X Remove dirt with a clean, lint-free cloth or a

brush.

X After cleaning, lightly oil or grease ball cou-

pling 0043.

X Check that the vehicle's trailer tow hitch is

working properly.

i You can also have the maintenance work on

the ball coupling and the trailer tow hitch car-

ried out by a qualified specialist workshop. Interior care

Cleaning the display !

For cleaning, do not use any of the following:

R alcohol-based thinner or gasoline

R abrasive cleaning agents

R commercially-available household cleaning

agents

These may damage the display surface. Do

not put pressure on the display surface when

cleaning. This could lead to irreparable dam-

age to the display.

X Before cleaning the display, make sure that it

is switched off and has cooled down.

X Clean the display surface using a commer-

cially available microfiber cloth and TFT/LCD

display cleaner.

X Dry the display surface using a dry microfiber

cloth. Cleaning the plastic trim G

WARNING

Care products and cleaning agents containing solvents cause surfaces in the cockpit to

become porous. As a result, plastic parts may

come loose in the event of air bag deploy-

ment. There is a risk of injury.

Do not use any care products and cleaning

agents to clean the cockpit.

! Never attach the following to plastic surfa-

ces:

R stickers

R films

R perfume oil container or similar

You could otherwise damage the plastic.

! Do not allow cosmetics, insect repellent or

sunscreen to come into contact with the plas-

tic trim. This maintains the high-quality look of the surfaces.

X Wipe the plastic trim with a damp, lint-free

cloth, e.g. a microfiber cloth.

X Heavy soiling: use care and cleaning prod-

ucts recommended and approved by

Mercedes-Benz.

The surface may change color temporarily.

Wait until the surface is dry again.

Cleaning the steering wheel and gear or selector lever X

Thoroughly wipe with a damp cloth or use

leather care agents that have been recom-

mended and approved by Mercedes-Benz.

Cleaning genuine wood and trim ele-

ments !

Do not use solvent-based cleaning agents

such as tar remover, wheel cleaners, polishes

or waxes. There is otherwise a risk of damag- ing the surface.

! Do not use chrome polish on trim pieces.

The trim pieces have a chrome look but are

mostly made of anodized aluminum and can

lose their shine if chrome polish is used. Use

a damp, lint-free cloth instead when cleaning the trim pieces. 332

CareMaintenance and care

Page 335 of 398

If the chrome-plated trim pieces are very

dirty, you can use a chrome polish. If you are

unsure as to whether the trim pieces are

chrome-plated or not, consult an authorized

Mercedes-Benz Center.

X Wipe the wooden trim and trim pieces with a

damp, lint-free cloth, e.g. a microfiber cloth.

X Heavy soiling: use car care and cleaning

products recommended and approved by

Mercedes-Benz.

Cleaning the seat covers General notes

! Do not use a microfiber cloth to clean covers

made out of real leather, artificial leather or

DINAMICA. If used often, these can damage

the cover.

i Note that regular care is essential to ensure

that the appearance and comfort of the cov-

ers is retained over time.

Genuine leather seat covers ! To retain the natural appearance of the

leather, observe the following cleaning

instructions:

R Clean genuine leather covers carefully with

a damp cloth and then wipe the covers

down with a dry cloth.

R Make sure that the leather does not

become soaked. It may otherwise become

rough and cracked.

R Only use leather care agents that have

been tested and approved by Mercedes-

Benz. You can obtain these from a qualified

specialist workshop.

Leather is a natural product.

It exhibits natural surface characteristics, for

example:

R differences in the texture

R marks caused by growth and injury

R slight nuances of color

These are characteristics of leather and not

material defects. Seat covers of other materials

! Observe the following when cleaning:

R clean artificial leather covers with a cloth

moistened with a solution containing 1%

detergent (e.g. dish washing liquid).

R clean cloth covers with a microfiber cloth

moistened with a solution containing 1%

detergent (e.g. dish washing liquid). Rub

carefully and always wipe entire seat sec-

tions to avoid leaving visible lines. Leave

the seat to dry afterwards. Cleaning results

depend on the type of dirt and how long it

has been there.

R clean DINAMICA covers with a damp cloth.

Make sure that you wipe entire seat sec-

tions to avoid leaving visible lines.

Cleaning the seat belts G

WARNING

Seat belts can become severely weakened if

bleached or dyed. This could cause the seat

belts to tear or fail, for instance, in the event of an accident. This poses an increased risk of

injury or fatal injury.

Never bleach or dye the seat belts.

! Do not clean the seat belts using chemical

cleaning agents. Do not dry the seat belts by

heating at temperatures above 176 ‡(80 †)

or in direct sunlight.

X Use clean, lukewarm water and soap solution.

Cleaning the headliner and carpets X

Headliner: if it is very dirty, use a soft brush or

dry shampoo.

X Carpets: use the carpet and textile cleaning

agents recommended and approved by

Mercedes-Benz. Care

333Maintenance and care Z

Page 336 of 398

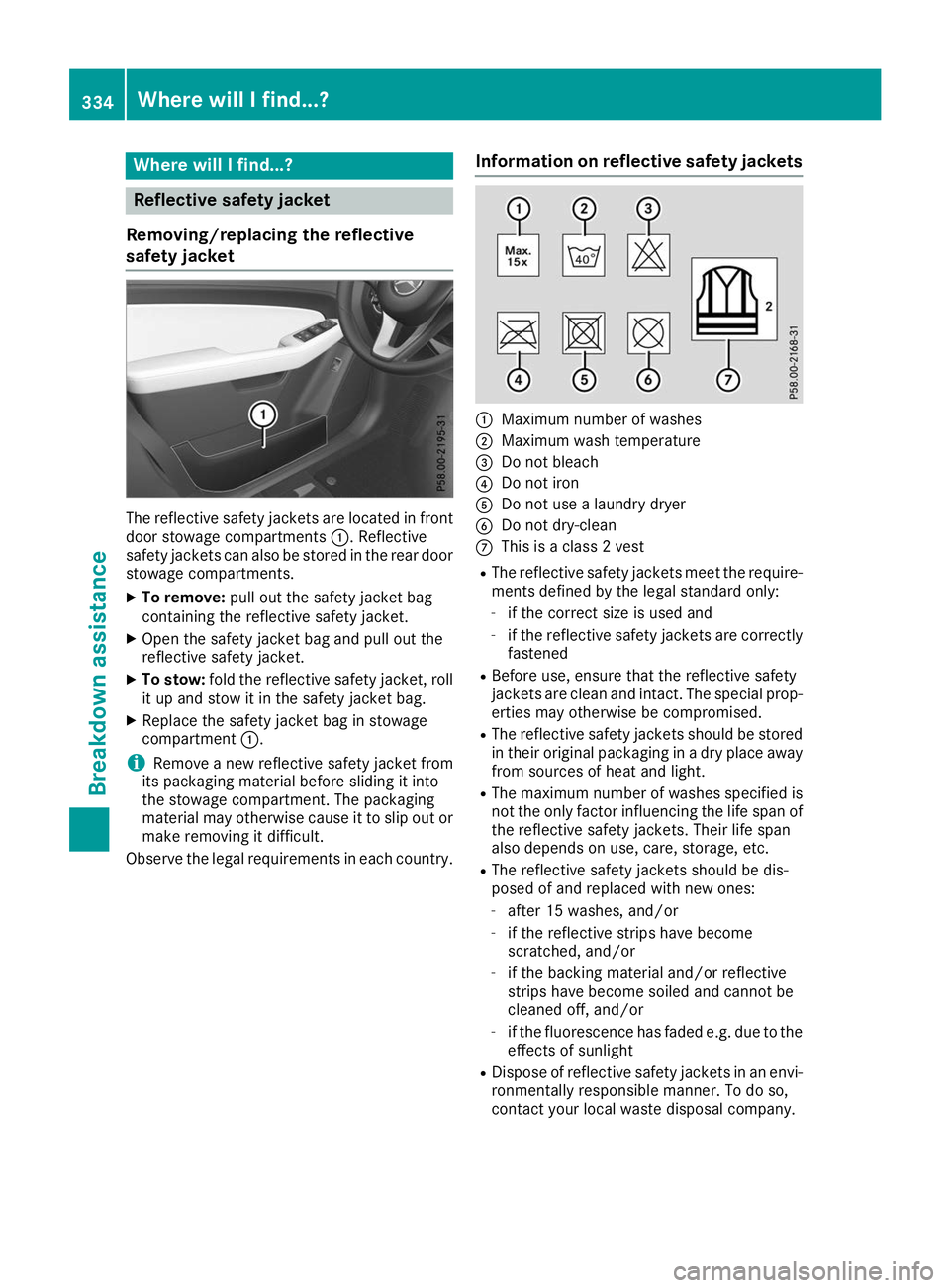

Where will I find...?

Reflective safety jacket

Removing/replacing the reflective

safety jacket The reflective safety jackets are located in front

door stowage compartments 0043. Reflective

safety jackets can also be stored in the rear door stowage compartments.

X To remove: pull out the safety jacket bag

containing the reflective safety jacket.

X Open the safety jacket bag and pull out the

reflective safety jacket.

X To stow: fold the reflective safety jacket, roll

it up and stow it in the safety jacket bag.

X Replace the safety jacket bag in stowage

compartment 0043.

i Remove a new reflective safety jacket from

its packaging material before sliding it into

the stowage compartment. The packaging

material may otherwise cause it to slip out or

make removing it difficult.

Observe the legal requirements in each country. Information on reflective safety jackets 0043

Maximum number of washes

0044 Maximum wash temperature

0087 Do not bleach

0085 Do not iron

0083 Do not use a laundry dryer

0084 Do not dry-clean

006B This is a class 2 vest

R The reflective safety jackets meet the require-

ments defined by the legal standard only:

- if the correct size is used and

- if the reflective safety jackets are correctly

fastened

R Before use, ensure that the reflective safety

jackets are clean and intact. The special prop-

erties may otherwise be compromised.

R The reflective safety jackets should be stored

in their original packaging in a dry place away

from sources of heat and light.

R The maximum number of washes specified is

not the only factor influencing the life span of

the reflective safety jackets. Their life span

also depends on use, care, storage, etc.

R The reflective safety jackets should be dis-

posed of and replaced with new ones:

- after 15 washes, and/or

- if the reflective strips have become

scratched, and/or

- if the backing material and/or reflective

strips have become soiled and cannot be

cleaned off, and/or

- if the fluorescence has faded e.g. due to the

effects of sunlight

R Dispose of reflective safety jackets in an envi-

ronmentally responsible manner. To do so,

contact your local waste disposal company. 334

Where will I find...?Breakdown assistance

Page 340 of 398

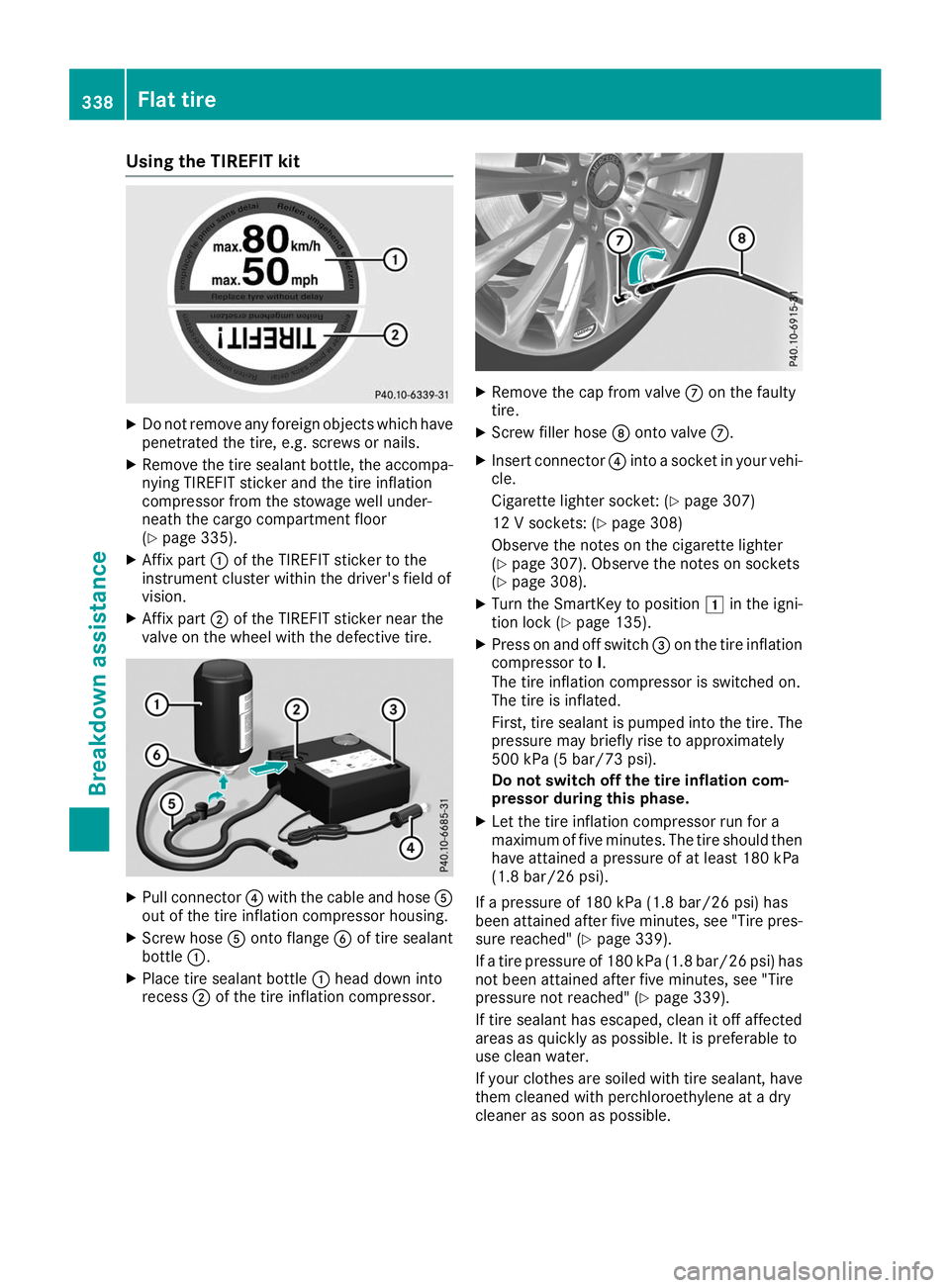

Using the TIREFIT kit

X

Do not remove any foreign objects which have

penetrated the tire, e.g. screws or nails.

X Remove the tire sealant bottle, the accompa-

nying TIREFIT sticker and the tire inflation

compressor from the stowage well under-

neath the cargo compartment floor

(Y page 335).

X Affix part 0043of the TIREFIT sticker to the

instrument cluster within the driver's field of

vision.

X Affix part 0044of the TIREFIT sticker near the

valve on the wheel with the defective tire. X

Pull connector 0085with the cable and hose 0083

out of the tire inflation compressor housing.

X Screw hose 0083onto flange 0084of tire sealant

bottle 0043.

X Place tire sealant bottle 0043head down into

recess 0044of the tire inflation compressor. X

Remove the cap from valve 006Bon the faulty

tire.

X Screw filler hose 006Conto valve 006B.

X Insert connector 0085into a socket in your vehi-

cle.

Cigarette lighter socket: (Y page 307)

12 V sockets: (Y page 308)

Observe the notes on the cigarette lighter

(Y page 307). Observe the notes on sockets

(Y page 308).

X Turn the SmartKey to position 0047in the igni-

tion lock (Y page 135).

X Press on and off switch 0087on the tire inflation

compressor to I.

The tire inflation compressor is switched on.

The tire is inflated.

First, tire sealant is pumped into the tire. The

pressure may briefly rise to approximately

500 kPa (5 bar/73 psi).

Do not switch off the tire inflation com-

pressor during this phase.

X Let the tire inflation compressor run for a

maximum of five minutes. The tire should then

have attained a pressure of at least 180 kPa

(1.8 bar/26 psi).

If a pressure of 180 kPa (1.8 bar/26 psi) has

been attained after five minutes, see "Tire pres- sure reached" (Y page 339).

If a tire pressure of 180 kPa (1.8 bar/26 psi) has not been attained after five minutes, see "Tire

pressure not reached" (Y page 339).

If tire sealant has escaped, clean it off affected

areas as quickly as possible. It is preferable to

use clean water.

If your clothes are soiled with tire sealant, have

them cleaned with perchloroethylene at a dry

cleaner as soon as possible. 338

Flat tireBreakdown assistance

Page 372 of 398

Speed rating

The speed rating is part of the tire identification. It specifies the speed range for which the tire is

approved.

GTW (Gross Trailer Weight)

The GTW is the weight of a trailer including the

weight of the load, luggage, accessories etc. on

the trailer.

GVW (Gross Vehicle Weight) The gross vehicle weight includes the weight of

the vehicle including fuel, tools, the spare wheel, accessories installed, occupants, luggage and

the drawbar noseweight, if applicable. The gross

vehicle weight must not exceed the gross vehi-

cle weight rating GVWR as specified on the vehi- cle identification plate on the B-pillar on the

driver's side.

GVWR (Gross Vehicle Weight Rating)

The GVWR is the maximum permissible gross

weight of a fully loaded vehicle (the weight of the

vehicle including all accessories, occupants,

fuel, luggage and the drawbar noseweight, if

applicable). The gross vehicle weight rating is

specified on the vehicle identification plate on

the B-pillar on the driver's side.

Maximum loaded vehicle weightThe maximum weight is the sum of:

R the curb weight of the vehicle

R the weight of the accessories

R the load limit

R the weight of the factory installed optional

equipment

Kilopascal (kPa) Metric unit for tire pressure. 6.9 kPa corre-

sponds to 1 psi. Another unit for tire pressure is

bar. 100 kilopascals (kPa) are the equivalent of

1 bar.

Load index

In addition to the load-bearing index, the load

index may also be imprinted on the sidewall of

the tire. This specifies the load-bearing capacity

more precisely.

Curb weight The weight of a vehicle with standard equipment

including the maximum capacity of fuel, oil and

coolant. It also includes the air-conditioning sys- tem and optional equipment if these are instal-

led in the vehicle, but does not include passen-

gers or luggage.

Maximum load rating The maximum tire load is the maximum permis-

sible weight in kilograms or lbs for which a tire is approved.

Maximum permissible tire pressure Maximum permissible tire pressure for one tire.

Maximum load on one tire

Maximum load on one tire. This is calculated by

dividing the maximum axle load of one axle by

two.

PSI (pounds per square inch) A standard unit of measure for tire pressure.

Aspect ratio Relationship between tire height and tire width

in percent.

Tire pressure

This is pressure inside the tire applying an out-

ward force to each square inch of the tire's sur-

face. The tire pressure is specified in pounds per

square inch (psi), in kilopascal (kPa) or in bar.

The tire pressure should only be corrected when the tires are cold.

Cold tire pressure

The tires are cold:

R if the vehicle has been parked with the tires

out of direct sunlight for at least three hours

and

R if the vehicle has not been driven further than

1 mile (1.6 km)

Tread The part of the tire that comes into contact with

the road.

BeadThe tire bead ensures that the tire sits securely

on the wheel. There are several steel wires in the

bead to prevent the tire from coming loose from

the wheel rim. 370

All about wheels and tiresWheels and tires

Page 374 of 398

be required earlier. Do not change the direction

of wheel rotation.

Clean the contact surfaces of the wheel and the

brake disc thoroughly every time a wheel is rota- ted. Check the tire pressure and, if necessary,

restart the tire pressure loss warning system or

the tire pressure monitor (Y page 358).Direction of rotation

Tires with a specified direction of rotation have

additional benefits, e.g. if there is a risk of hydro-

planing. These advantages can only be gained if the tires are installed corresponding to the

direction of rotation.

An arrow on the sidewall of the tire indicates itscorrect direction of rotation. Storing wheels

Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the tires

from oil, grease, gasoline and diesel. Mounting a wheel

Preparing the vehicle X

Vehicle with emergency spare wheel:

when mounting the emergency spare wheel in

the event of a flat tire, follow the additional

notes on vehicle preparation under "Flat tire"

(Y page 335).

X Stop the vehicle on solid, non-slippery and

level ground.

X Apply the electric parking brake manually.

X Bring the front wheels into the straight-ahead

position.

X Vehicles with automatic transmission:

shift the transmission to position

005D.

X Vehicles with the AIRMATIC package:

make sure that the normal vehicle level is

selected (Y page 185).

X Vehicles with the Off-Road Engineering

package:

make sure that the normal vehicle

level is selected (Y page 179).

X Switch off the engine.

X Vehicles without KEYLESS-GO: remove the

SmartKey from the ignition lock. X

Vehicles with KEYLESS-GO: open the driv-

er's door.

The vehicle electronics are now in position

0092. This means no SmartKey is in the ignition

lock.

X Vehicles with KEYLESS-GO: remove the

Start/Stop button from the ignition lock

(Y page 135).

X Make sure that the engine cannot be started

via your smartphone (Y page 137).

X If included in the vehicle equipment, remove

the tire-change tool kit from the vehicle.

X Safeguard the vehicle against rolling away.

i Apart from certain country-specific varia-

tions, vehicles are not equipped with a tire-

change tool kit. For more information on

which tools are required to perform a wheel

change on your vehicle, consult a qualified

specialist workshop.

Necessary tire-changing tools can include, for

example:

R Jack

R Wheel chock

R Lug wrench

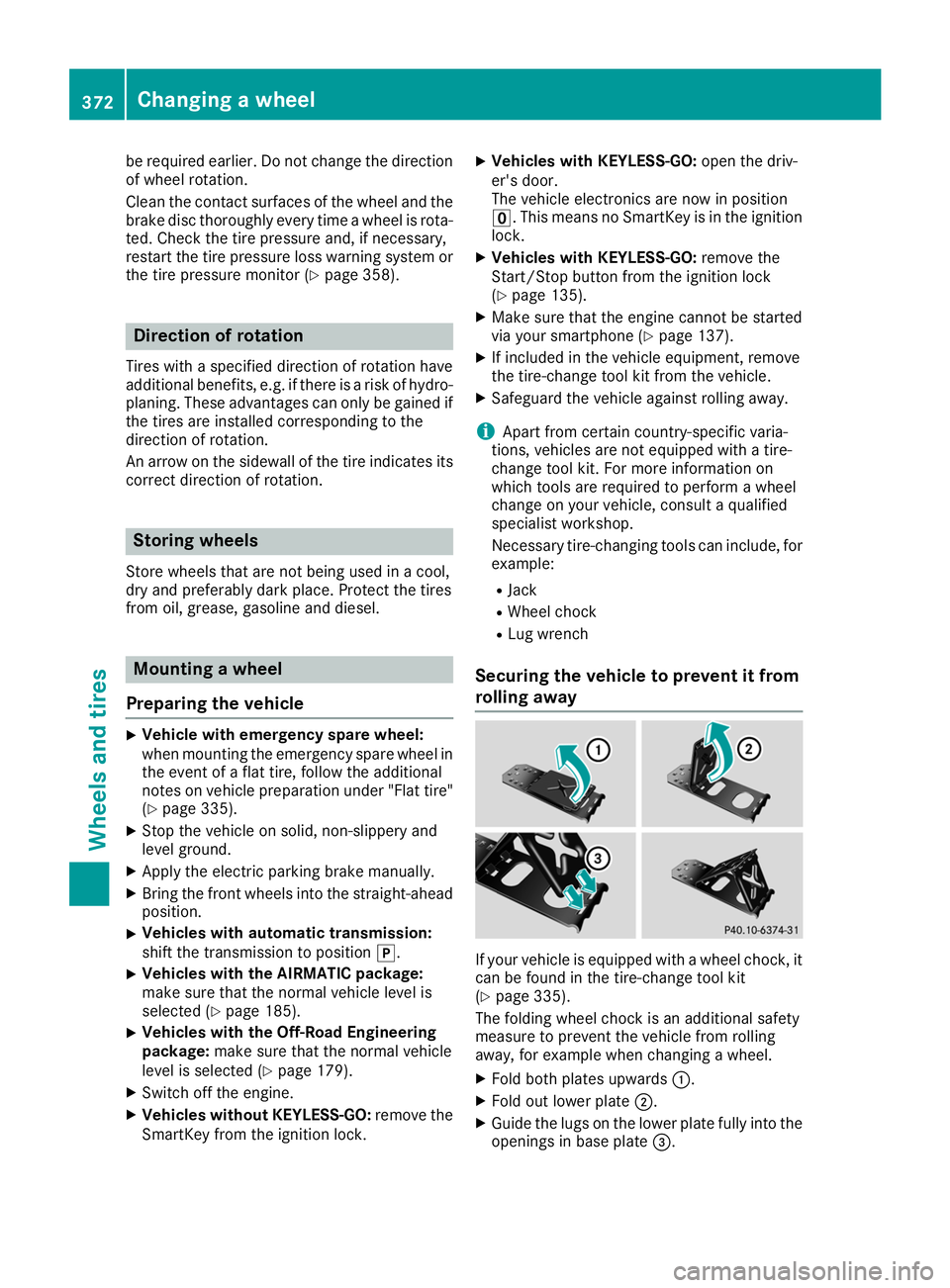

Securing the vehicle to prevent it from

rolling away If your vehicle is equipped with a wheel chock, it

can be found in the tire-change tool kit

(Y page 335).

The folding wheel chock is an additional safety

measure to prevent the vehicle from rolling

away, for example when changing a wheel.

X Fold both plates upwards 0043.

X Fold out lower plate 0044.

X Guide the lugs on the lower plate fully into the

openings in base plate 0087.372

Changing a wheelWheels and tires

Page 376 of 398

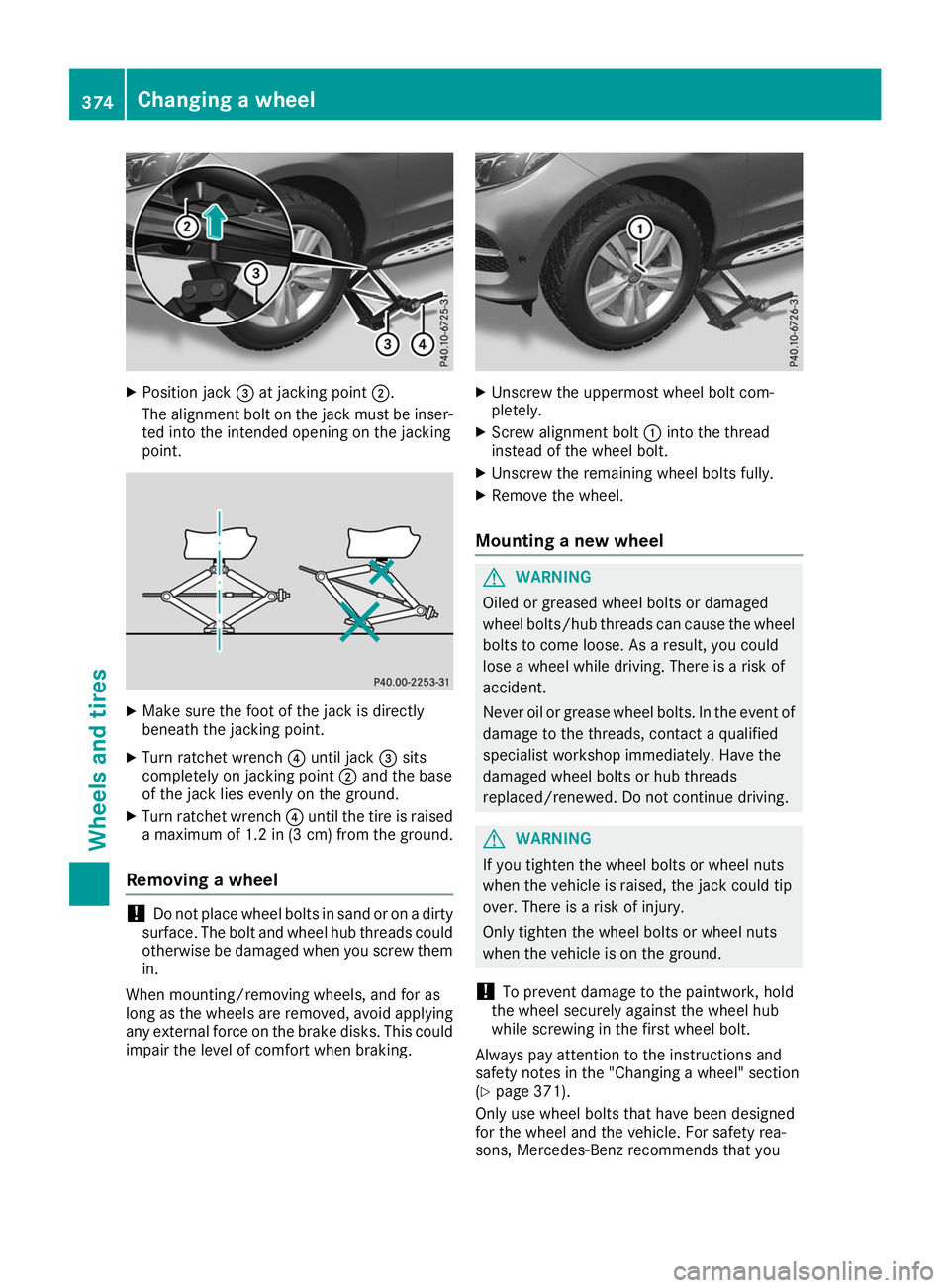

X

Position jack 0087at jacking point 0044.

The alignment bolt on the jack must be inser- ted into the intended opening on the jacking

point. X

Make sure the foot of the jack is directly

beneath the jacking point.

X Turn ratchet wrench 0085until jack 0087sits

completely on jacking point 0044and the base

of the jack lies evenly on the ground.

X Turn ratchet wrench 0085until the tire is raised

a maximum of 1.2 in (3 cm) from the ground.

Removing a wheel !

Do not place wheel bolts in sand or on a dirty

surface. The bolt and wheel hub threads could

otherwise be damaged when you screw them

in.

When mounting/removing wheels, and for as

long as the wheels are removed, avoid applying any external force on the brake disks. This could impair the level of comfort when braking. X

Unscrew the uppermost wheel bolt com-

pletely.

X Screw alignment bolt 0043into the thread

instead of the wheel bolt.

X Unscrew the remaining wheel bolts fully.

X Remove the wheel.

Mounting a new wheel G

WARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event ofdamage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving. G

WARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

! To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt.

Always pay attention to the instructions and

safety notes in the "Changing a wheel" section

(Y page 371).

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you 374

Changing a wheelWheels and tires