MERCEDES-BENZ GLE COUPE 2017 C292 Owner's Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: GLE COUPE, Model: MERCEDES-BENZ GLE COUPE 2017 C292Pages: 366, PDF Size: 8.61 MB

Page 341 of 366

Bar

Metric unit for tire pressure. 14.5038 pounds

per square inch (psi) and 100 kilopascals (kPa)

are the equivalent of 1 bar.

DOT (Department of Transportation)

DOT-marked tires fulfill the requirements of the

U S Department of Transportation.

Normal occupant weight

The number of occupants for which the vehicle

is designed multiplied by 68 kilograms (150 lbs).

Uniform Tire Quality Grading Standards

A uniform standard to grade the quality of tires

with regards to tread quality, tire traction and

temperature characteristics. The quality grad-

ing assessment is made by the manufacturer

following specifications from the U.S. govern-

ment. The ratings are molded into the sidewall of

the tire.

Recommended tire pressures

The recommended tire pressure applies to the

tires mounted at the factory.

The Tire and Loading Information placard con-

tains the recommended tire pressures for cold

tires on a fully loaded vehicle and for the maxi-

mum permissible vehicle speed.

The tire pressure table contains the recommen-

ded pressures for cold tires for various operat-

ing conditions, i.e. differing load and speed con-

ditions.

Increased vehicle weight due to optional

equipment

The combined weight of all standard and

optional equipment available for the vehicle,

regardless of whether it isactua

lly installed on

the vehicle or not.

Rim

This is the part of the wheel on which the tire is

mounted.

GAWR (Gross Axle Weight Rating)

The GAWR is the maximum gross axle weight

rating. The actual load on an axle must never

exceed the gross axle weight rating. The gross

axle weight rating can be found on the vehicle

identification plate on the B-pillar on the driver's

side.

Speed rating

The speed rating is part of the tire identification.

It specifies the speed range for which the tire is

approved.

GTW (Gross Trailer Weight)

The GTW is the weight of a trailer including the

weight of the load, luggage, accessories etc. on

the trailer.

GVW (Gross Vehicle Weight)

The gross vehicle weight includes the weight of the vehicle including fuel, tools, the spare wheel,

accessories installed, occupants, luggage and

the drawbar noseweight, if applicable. The gross

vehicle weight must not exceed the gross vehi-

cle weight rating GVWR as specified on the vehi-

cle identification plate on the B-pillar on the

driver's side.

GVWR (Gross Vehicle Weight Rating)

The GVWR is the maximum permissible gross

weight of a fully loaded vehicle (the weight of the

vehicle including all accessories, occupants,

fuel, luggage and the drawbar nosew

eight, if

applicable). The gross vehicle weight rating is

specified on the vehicle identification plate on

the B-pillar on the driver's side.

Maximum loaded vehicle weight

The maximum weight is the sum of:

Rthe curb weight of the vehicle

Rthe weight of the accessories

Rthe load limit

Rthe weight of the factory installed optional

equipment

Kilopascal (kPa)

Metric unit for tire pressure. 6.9 kPa corre-

sponds to 1 psi. Another unit for tire pressure is

bar. 100 kilopascals (kPa) are the equivalent of

1 bar.

Load index

In addition to the load-bearing index, the load

index may also be imprinted on the sidewall of

the tire. This specifies the load-bearing capacity

more precisely.

Curb weight

The weight of a vehicle with standard equipment

including the maximum capacity of fuel, oil and

coolant. It also includes the air-conditioning sys-

All about wheels and tires339

Wheels and tires

Z

Page 342 of 366

tem and optional equipment if these are instal-

led in the vehicle, but does not include passen-

gers or luggage.

Maximum load rating

The maximum tire load is the maximum permis-

sible weight in kilograms or lbs for which a tire is approved.

Maximum permissible tire pressure

Maximum permissible tire pressure for one tire.

Maximum load on one tire

Maximum load on one tire. This is calculated by

dividing the maximum axle load of one axle by

two.

PSI (pounds per square inch)

A standard unit of measure for tire pressure.

Aspect ratio

Relationship between tire height and tire width

in percent.

Tire pressure

This is pressure inside the tire applying an out-

ward force to each square inch of the tire's sur-

face. The tire pressure is specified in pounds per

square inch (psi), in kilopascal (kPa) or in bar.

The tire pressure should only be corrected whenthe tires are cold.

Cold tire pressure

The tires are cold:

Rif the vehicle has been parked with the tires

out of direct sunlight for at least three hours

and

Rif the vehicle has not been driven further than

1 mile (1.6 km)

Tread

The part of the tire that comes into contact with

the road.

Bead

The tire bead ensures that the tire sits securely

on the wheel. There are several steel wires in the

bead to prevent the tire from coming loose from

the wheel rim.

Sidewall

The part of the tire between the tread and the

bead.

Weight of optional extras

The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 2.3 kg (5 lbs). These

optional extras, such as high-performance

brakes, level control, a roof rack or a high-per-

formance battery, are not included in the curb

weight and the weight of the accessories.

TIN (Tire Identification Number)

This is a unique identifier which can be used by

a tire manufacturer to identify tires, for example

for a product recall, and thus identify the pur-

chasers. The TIN is made up of the manufactur- er's identity code, tire size, tire type code and

the manufacturing date.

Load bearing index

The load bearing index (also load index) is a code

that contains the maximum load bearing capa-

city of a tire.

Traction

Traction is the result of friction between the tires

and the road surface.

TWR (Tongue Weight Rating)

The TWR specifies the maximum permissible

weight that the ball coupling of the trailer tow

hitch can support.

Treadwear indicators

Narrow bars (tread wear bars) that are distrib-

uted over the tire tread. If the tire tread is level

with the bars, the wear limit of áin (1.6 mm)

has been reached.

Occupant distribution

The distribution of occupants in a vehicle at their

designated seating positions.

Total load limit

Nominal load and luggage load plus 68 kg

(150 lbs) multiplied by the number of seats in

the vehicle.

340All about wheels an d tires

Wheels and tires

Page 343 of 366

Changing a wheel

Flat tire

The "Breakdown assistance" section

(Ypage 306) contains information and notes on

how to deal with a flat tire. Information on driv-

ing with MOExtended tires in the event of a flat

tire can be found under "MOExtended tires (tires

with run-flat characteristics" (

Ypage 307).

Vehicles with an emergency spare wheel: in

the event of a flat tire, mount the emergency

spare wheel according to the description under "Mounting a wheel" (

Ypage 341).

Rotating the wheels

GWARNING

Interchanging the front and rear wheels may

severely impair the driving characteristics if

the wheels or tires have different dimensions. The wheel brakes or suspension components

may also be damaged. There is a risk of acci-

dent.

Rotate front and rear wheels only if the wheels and tires are of the same dimensions.

!On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

cialist workshop.

Always observe the instructions and safety

notes in the "Mounting a wheel" section

(

Ypage 341).

The wear patterns on the front and rear tires

differ, depending on the operating conditions.

Rotate the wheels before a clear wear pattern

has formed on the tires. Front tires typically

wear more on the shoulders and the rear tires in

the center.

On vehicles that have the same size front and

rear wheels, you can rotate the wheels accord-

ing to the intervals in the tire manufacturer's

warranty book in your vehicle documents. If no

warranty book is available, the tires should be

rotated every 3,000 to 6,000 miles (5,000to

10,

000 km). Depending on tire wear, this may be required earlier. Do not change the direction

of wheel rotation.

Clean the contact surfaces of the wheel and the

brake disc thoroughly every time a wheel is rota-

ted. Check the tire pressure and, if necessary,

restart the tire pressure loss warning system or

the tire pressure monitor (

Ypage 328).

Direction of rotation

Tires with a specified direction of rotation have

additional benefits, e.g. if there is a risk of hydro-

planing. These advantages can only be gained if

the tires are installed corresponding to the

direction of rotation.

An arrow on the sidewall of the tire indicates its

correct direction of rotation.

Storing wheels

Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the tires

from oil, grease, gasoline and diesel.

Mounting a wheel

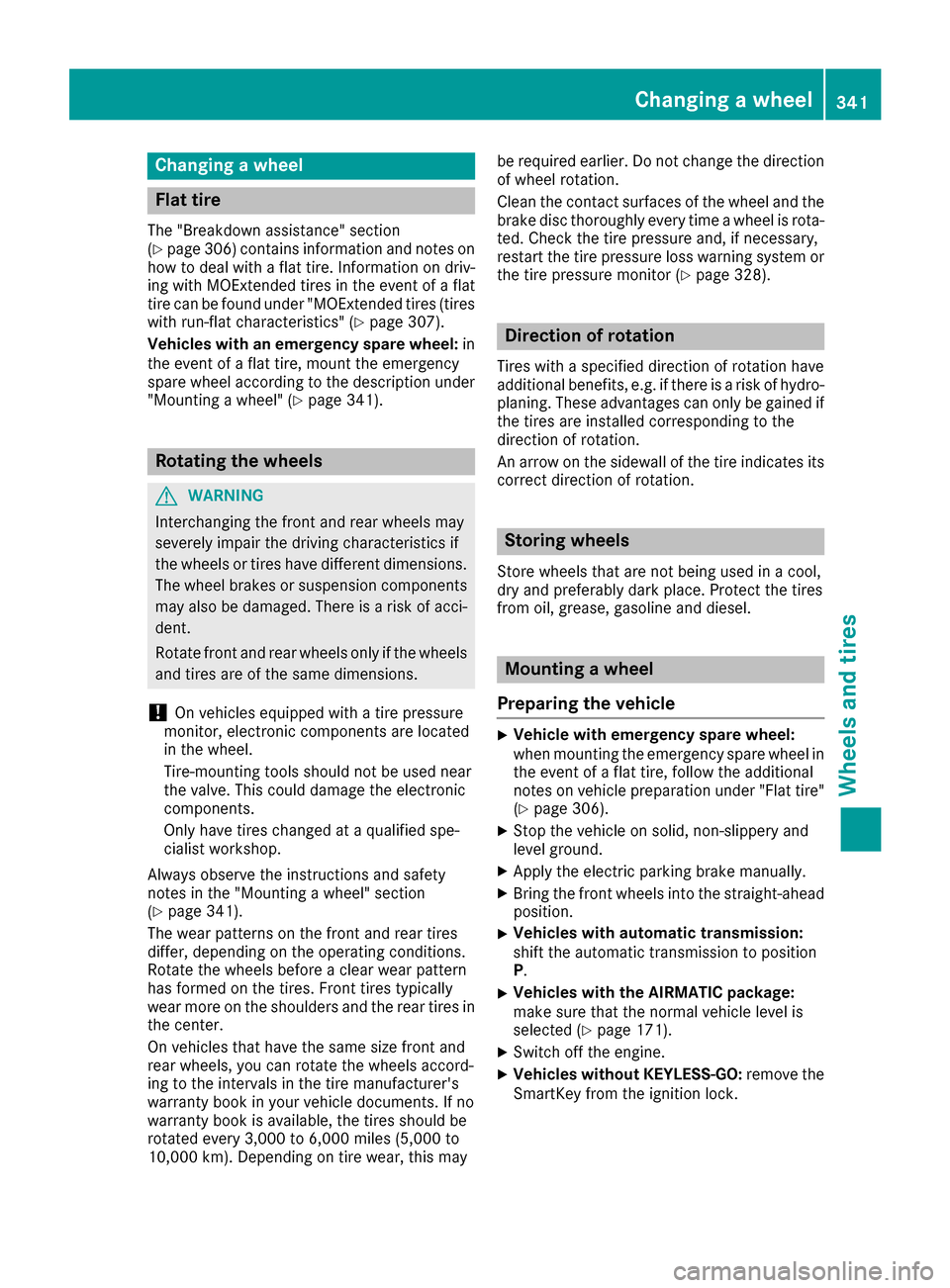

Preparing the vehicle

XVehicle with emergency spare wheel:

when mounting the emergency spare wheel in

the event of a flat tire, follow the additional

notes on vehicle preparation under "Flat tire"

(

Ypage 306).

XStop the vehicle on solid, non-slippery and

level ground.

XApply the electric parking brake manually.

XBring the front wheels into the straight-ahead position.

XVehicles with automatic transmission:

shift the automatic transmission to position

P .

XVehicles with the AIRMATIC package:

make sure that the normal vehicle level is

selected (

Ypage 171).

XSwitch off the engine.

XVehicles without KEYLESS-GO: remove the

SmartKey from the ignition lock.

Changing a wheel341

Wheels an d tires

Z

Page 344 of 366

XVehicles with KEYLESS-GO:open the driv-

er's door.

The on-board electronics now have status 0.

This is the same as the SmartKey having been

removed.

XVehicles with KEYLESS-GO: remove the

Start/Stop button from the ignition lock

(

Ypage 125).

XMake sure that the engine cannot be started

via your smartphone (Ypage 127).

XIf included in the vehicle equipment, remove

the tire-change tool kit from the vehicle.

XSafeguard the vehicle against rolling away.

iApart from certain country-specific varia-

tions, vehicles are not equipped with a tire-

change tool kit. For information on which

tools are required to perform a wheel change

on your vehicle, consult an authorized

Mercedes-Benz Center.

Necessary tire-changing tools can include, for example:

RJack

RWheel chock

RLug wrench

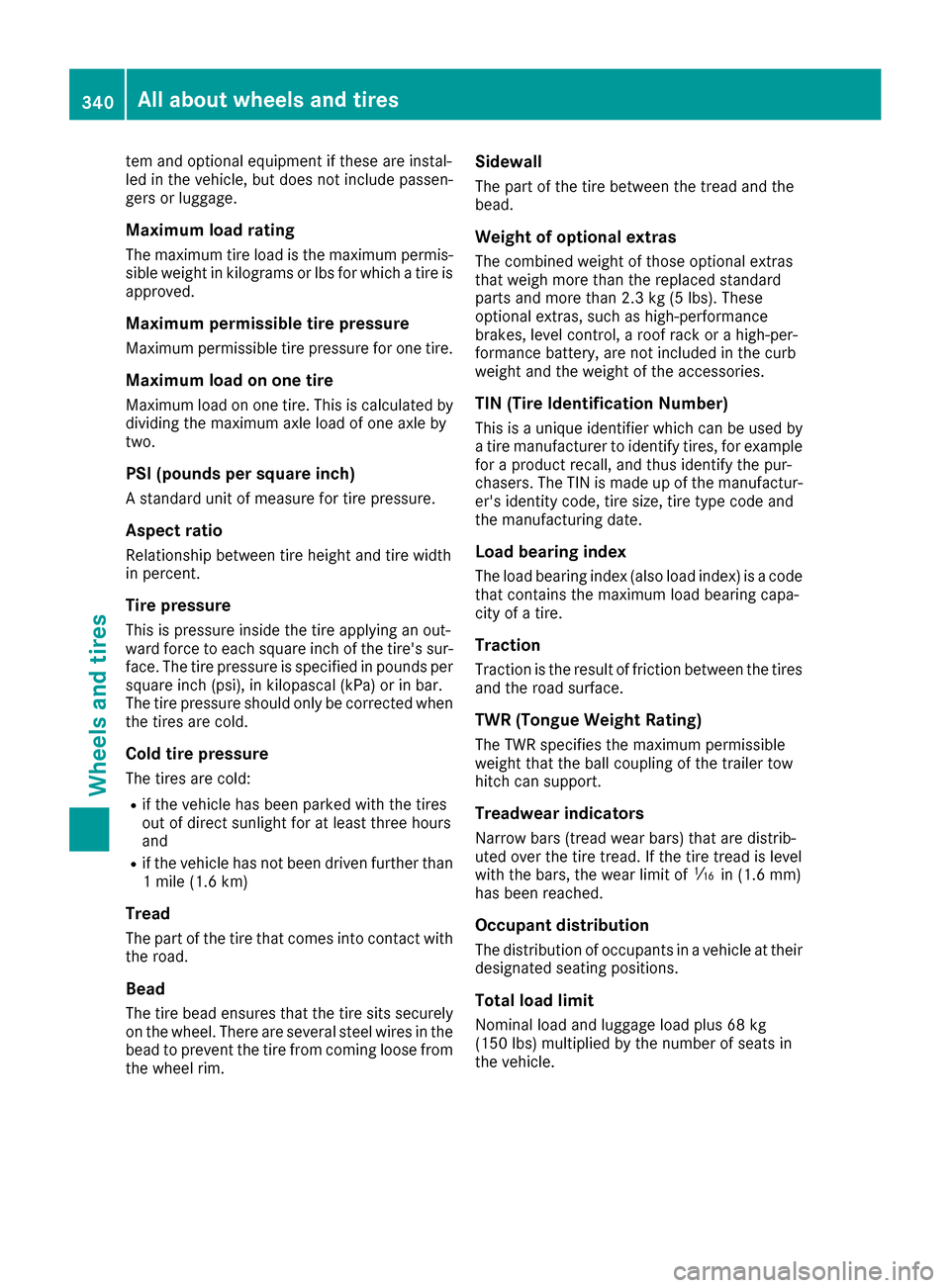

Securing the vehicle to prevent it from

rolling away

If your vehicle is equipped with a wheel chock, itcan be found in the tire-change tool kit

(

Ypage 306).

The folding wheel chock is an additional safety

measure to prevent the vehicle from rolling

away, for example when changing a wheel.

XFold both plates upwards :.

XFold out lower plate;.

XGuide the lugs on the lower plate fully into the

openings in base plate =.

XPlace chocks or other suitable items under

the front and rear of the wheel that is diago-

nally opposite the wheel you wish to change.

Raising the vehicle

GWARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

!The jack is designed exclusively for jacking

up the vehicle at the jacking points. Other-

wise, your vehicle could be damaged.

Observe the following when raising the vehi-

cle:

RTo raise the vehicle, only use the vehicle-spe-

cific jack that has been tested and approved

by Mercedes-Benz. If used incorrectly, the

jack could tip over with the vehicle raised.

RThe jack is designed only to raise and hold the

vehicle for a short time while a wheel is being

changed. It must not be used for performing

maintenance work under the vehicle.

RAvoid changing the wheel on uphill and down- hill slopes.

RBefore raising the vehicle, secure it from roll-

ing away by applying the parking brake and

inserting wheel chocks. Do not disengage the

parking brake while the vehicle is raised.

RThe jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

flat, load-bearing underlay must be use

d. On a

342Changing a wheel

Wheels and tires

Page 345 of 366

slippery surface, a non-slip underlay must be

used, e.g. rubber mats.

RDo not use wooden blocks or similar objects

as a jack underlay. Otherwise, the jack will notbe able to achieve its load-bearing capacity

due to the restricted height.

RMake sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in (3 cm).

RDo not place your hands or feet under the

raised vehicle.

RDo not lie under the vehicle.

RDo not start the engine when the vehicle is

raised.

RNever open or close a door or the tailgate

when the vehicle is raised.

RMake sure that no persons are present in the

vehicle when the vehicle is raised.

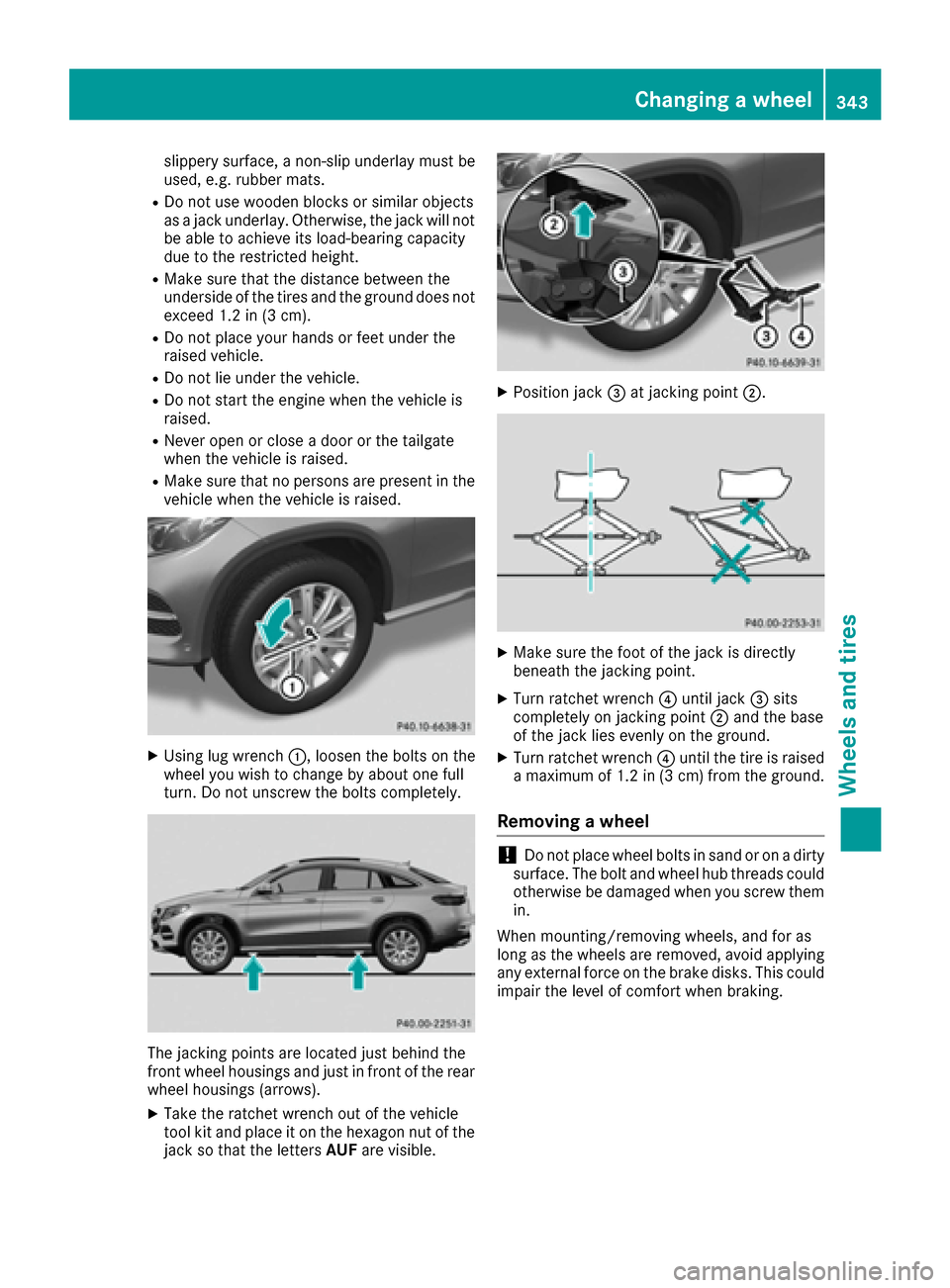

XUsing lug wrench :, loosen the bolts on the

wheel you wish to change by about one full

turn. Do not unscrew the bolts completely.

The jacking points are located just behind the

front wheel housings and just in front of the rear

wheel housings (arrows).

XTake the ratchet wrench out of the vehicle

tool kit and place it on the hexagon nut of the

jack so that the letters AUFare visible.

XPosition jack =at jacking point ;.

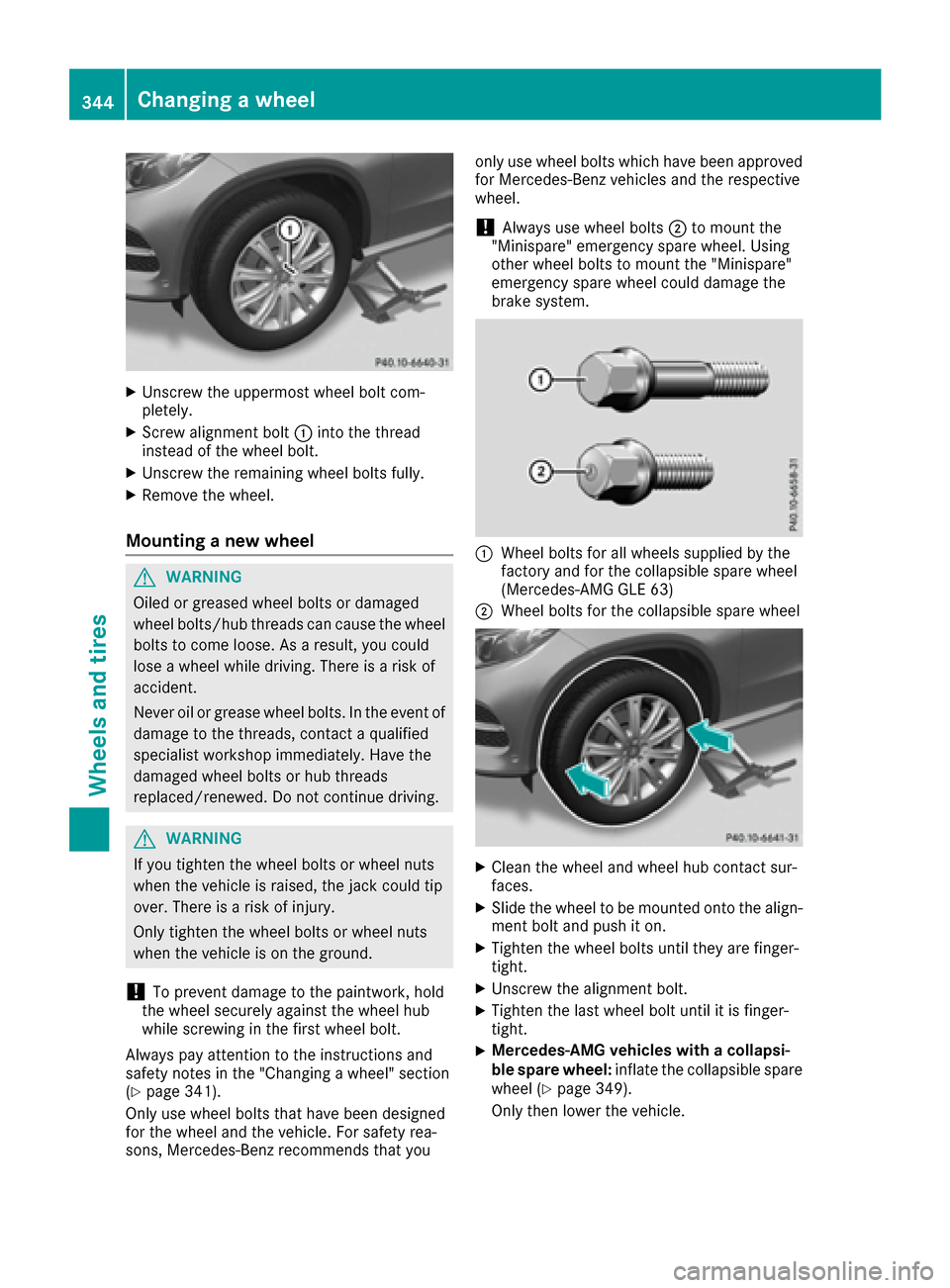

XMake sure the foot of the jack is directly

beneath the jacking point.

XTurn ratchet wrench ?until jack =sits

completely on jacking point ;and the base

of the jack lies evenly on the ground.

XTurn ratchet wrench ?until the tire is raised

a maximum of 1.2 in (3 cm) from the ground.

Removing a wheel

!Do not place wheel bolts in sand or on a dirty

surface. The bolt and wheel hub threads could

otherwise be damaged when you screw them

in.

When mounting/removing wheels, and for as

long as the wheels are removed, avoid applying

any external force on the brake disks. This could impair the level of comfort when braking.

Changing a wheel343

Wheels and tires

Z

Page 346 of 366

XUnscrew the uppermost wheel bolt com-

pletely.

XScrew alignment bolt:into the thread

instead of the wheel bolt.

XUnscrew the remaining wheel bolts fully.

XRemove the wheel.

Mounting a new wheel

GWARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event of

damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving.

GWARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

!To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt.

Always pay attention to the instructions and

safety notes in the "Changing a wheel" section

(

Ypage 341).

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you only use wheel bolts which have been approved

for Mercedes-Benz vehicles and the respective

wheel.

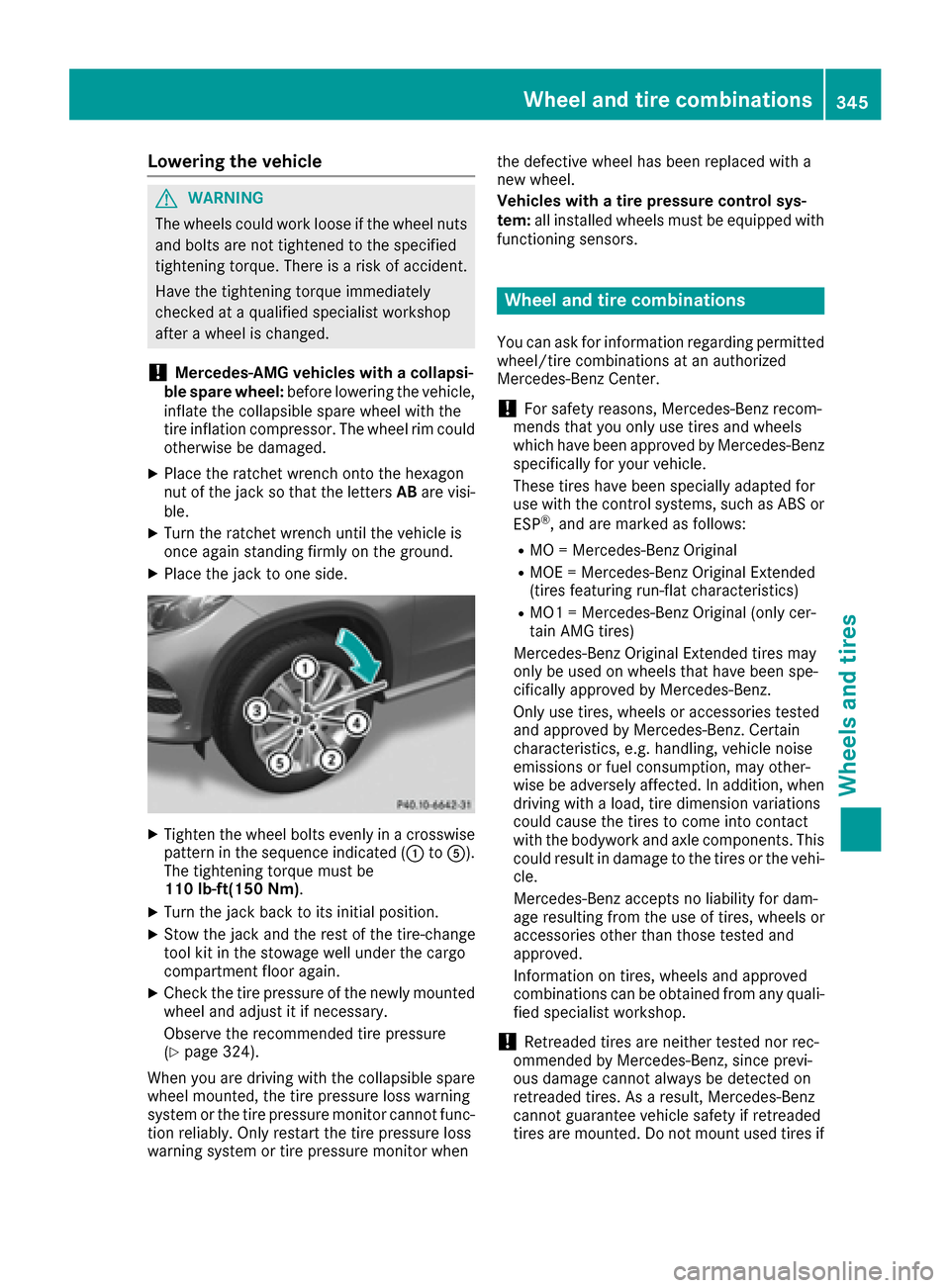

!Always use wheel bolts

;to mount the

"Minispare" emergency spare wheel. Using

other wheel bolts to mount the "Minispare"

emergency spare wheel could damage the

brake system.

:Wheel bolts for all wheels supplied by the

factory and for the collapsible spare wheel

(Mercedes-AMG GLE 63)

;Wheel bolts for the collapsible spare wheel

XClean the wheel and wheel hub contact sur-

faces.

XSlide the wheel to be mounted onto the align-

ment bolt and push it on.

XTighten the wheel bolts until they are finger-

tight.

XUnscrew the alignment bolt.

XTighten the last wheel bolt until it is finger-

tight.

XMercedes-AMG vehicles with a collapsi-

ble spare wheel: inflate the collapsible spare

wheel (

Ypage 349).

Only then lower the vehicle.

344Changing a wheel

Wheels and tires

Page 347 of 366

Lowering the vehicle

GWARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

!Mercedes-AMG vehicles with a collapsi-

ble spare wheel: before lowering the vehicle,

inflate the collapsible spare wheel with the

tire inflation compressor. The wheel rim could

otherwise be damaged.

XPlace the ratchet wrench onto the hexagon

nut of the jack so that the letters ABare visi-

ble.

XTurn the ratchet wrench until the vehicle is

once again standing firmly on the ground.

XPlace the jack to one side.

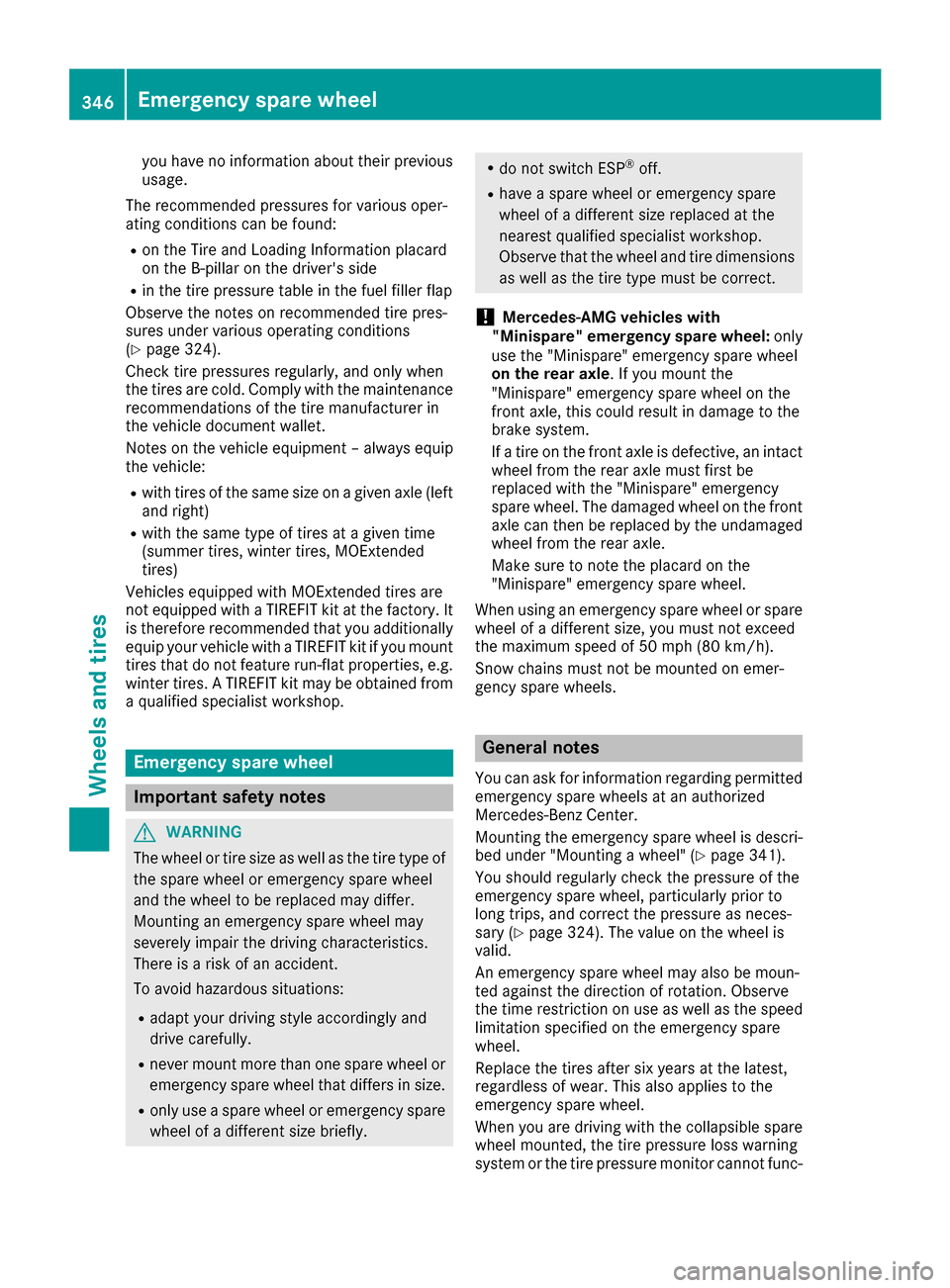

XTighten the wheel bolts evenly in a crosswise pattern in the sequence indicated (: toA).

The tightening torque must be

110 lb-f t(150 Nm).

XTurn the jack back to its initial position.

XStow the jack and the rest of the tire-change

tool kit in the stowage well under the cargo

compartment floor again.

XCheck the tire pressure of the newly mounted

wheel and adjust it if necessary.

Observe the recommended tire pressure

(

Ypage 324).

When you are driving with the collapsible spare

wheel mounted, the tire pressure loss warning

system or the tire pressure monitor cannot func-

tion reliably. Only restart the tire pressure loss

warning system or tire pressure monitor when the defective wheel has been replaced with a

new wheel.

Vehicles with a tire pressure control sys-

tem:

all installed wheels must be equipped with

functioning sensors.

Wheel and tire combinations

You can ask for information regarding permitted

wheel/tire combinations at an authorized

Mercedes-Benz Center.

!For safety reasons, Mercedes-Benz recom-

mends that you only use tires and wheels

which have been approved by Mercedes-Benz

specifically for your vehicle.

These tires have been specially adapted for

use with the control systems, such as ABS or

ESP

®, and are marked as follows:

RMO = Mercedes-Benz Original

RMOE = Mercedes-Benz Original Extended

(tires featuring run-flat characteristics)

RMO1 = Mercedes-Benz Original (only cer-

tain AMG tires)

Mercedes-Benz Original Extended tires may

only be used on wheels that have been spe-

cifically approved by Mercedes-Benz.

Only use tires, wheels or accessories tested

and approved by Mercedes-Benz. Certain

characteristics, e.g. handling, vehicle noise

emissions or fuel consumption, may other-

wise be adversely affected. In addition, when

driving with a load, tire dimension variations

could cause the tires to come into contact

with the bodywork and axle components. This

could result in damage to the tires or the vehi- cle.

Mercedes-Benz accepts no liability for dam-

age resulting from the use of tires, wheels or

accessories other than those tested and

approved.

Information on tires, wheels and approved

combinations can be obtained from any quali-

fied specialist workshop.

!Retreaded tires are neither tested nor rec-

ommended by Mercedes-Benz, since previ-

ous damage cannot always be detected on

retreaded tires. As a result, Mercedes-Benz

cannot guarantee vehicle safety if retreaded

tires are mounted. Do not mount used tires if

Wheel and tire combinations345

Wheels and tires

Z

Page 348 of 366

you haveno information about their previous

usage .

The recommended pressures for various oper -

ating condition scan be found :

Ron theTir eand Loadin gInformation placard

on th eB-pillar on th edriver's side

Rin th etire pressur etable in th efuel filler flap

Observ eth enote son recommended tire pres-

sures under various operating condition s

(

Ypage 324).

Chec ktire pressures regularly, and only when

th etires are cold. Comply wit hth emaintenance

recommendation sof th etire manufacturer in

th evehicl edocumen twallet .

Notes on th evehicl eequipmen t –always equip

th evehicle:

Rwit htires of th esam esiz eon agiven axl e(lef t

and right )

Rwithth esam etyp eof tires at agiven time

(summer tires ,winte rtires ,MOExtended

tires )

Vehicles equipped wit hMOExtended tires are

no tequipped wit h aTIREFI Tki tat th efactory. It

is therefor erecommended that you additionally

equip your vehicl ewit h a TIREFI Tki tif you moun t

tires that do no tfeature run-flat properties, e.g.

winte rtires . ATIREFI Tki tmay be obtained from

a qualified specialist workshop .

Emergency spare wheel

Impor tant safety notes

GWARNIN G

The whee lor tire siz eas well as th etire typ eof

th espar ewhee lor emergenc yspar ewhee l

and th ewhee lto be replaced may differ .

Mounting an emergenc yspar ewhee lmay

severely impair th edrivin gcharacteristics .

There is aris kof an accident.

To avoid hazardous situations:

Radapt your drivin gstyle accordingly and

drive carefully.

Rnever moun tmor ethan on espar ewhee lor

emergenc yspar ewhee lthat differ sin size.

Ronly use aspar ewhee lor emergenc yspar e

whee lof adifferen tsiz ebriefly.

Rdo no tswitch ES P®off.

Rhav e a spar ewhee lor emergenc yspar e

whee lof adifferen tsiz ereplaced at th e

neares tqualified specialist workshop .

Observ ethat th ewhee land tire dimension s

as well as th etire typ emus tbe correct.

!Mercedes-AMG vehicles wit h

"Minispare" emergency spar ewheel :only

use th e"Minispare" emergenc yspar ewhee l

on th erea raxle .If you moun tth e

"Minispare" emergenc yspar ewhee lon th e

fron taxle, this could result in damage to th e

brak esystem.

If atire on th efron taxl eis defective, an intac t

whee lfrom th erear axl emus tfirst be

replaced wit hth e"Minispare" emergenc y

spar ewheel. The damaged whee lon th efron t

axl ecan then be replaced by th eundamaged

whee lfrom th erear axle.

Mak esur eto note th eplacard on th e

"Minispare" emergenc yspar ewheel.

Whe nusin gan emergenc yspar ewhee lor spar e

whee lof adifferen tsize, you mus tno texceed

th emaximum speed of 50 mph (80 km/h).

Snow chain smus tno tbe mounte don emer-

gency spar ewheels.

Gene ral notes

You can ask for information regarding permitte d

emergenc yspar ewheels at an authorized

Mercedes-Ben zCenter.

Mounting th eemergenc yspar ewhee lis descri-

bed under "Mounting awheel" (

Ypage 341).

You should regularl ychec kth epressur eof th e

emergenc yspar ewheel, particularly prior to

lon gtrips, and correc tth epressur eas neces-

sar y (

Ypage 324). The value on th ewhee lis

valid.

An emergenc yspar ewhee lmay also be moun -

te dagainst th edirection of rotation .Observ e

th etime restriction on use as well as th espeed

limitation specified on th eemergenc yspar e

wheel.

Replac eth etires after six years at th elatest ,

regardless of wear .This also applie sto th e

emergenc yspar ewheel.

Whe nyou are drivin gwit hth ecollapsible spar e

whee lmounted, th etire pressur eloss warnin g

system or th etire pressur emonitor canno tfunc-

346Emergency spare wheel

Wheels and tires

Page 349 of 366

tion reliably. Only restart the tire pressure loss

warning system or tire pressure monitor when

the defective wheel has been replaced with a

new wheel.

Vehicles with tire pressure monitor:after

mounting an emergency spare wheel, the sys-

tem may still display the tire pressure of the

removed wheel for a few minutes. The value dis-

played for the mounted emergency spare wheel

is not the same as the current tire pressure of

the emergency spare wheel.

Removing/stowing the emergency

spare wheel

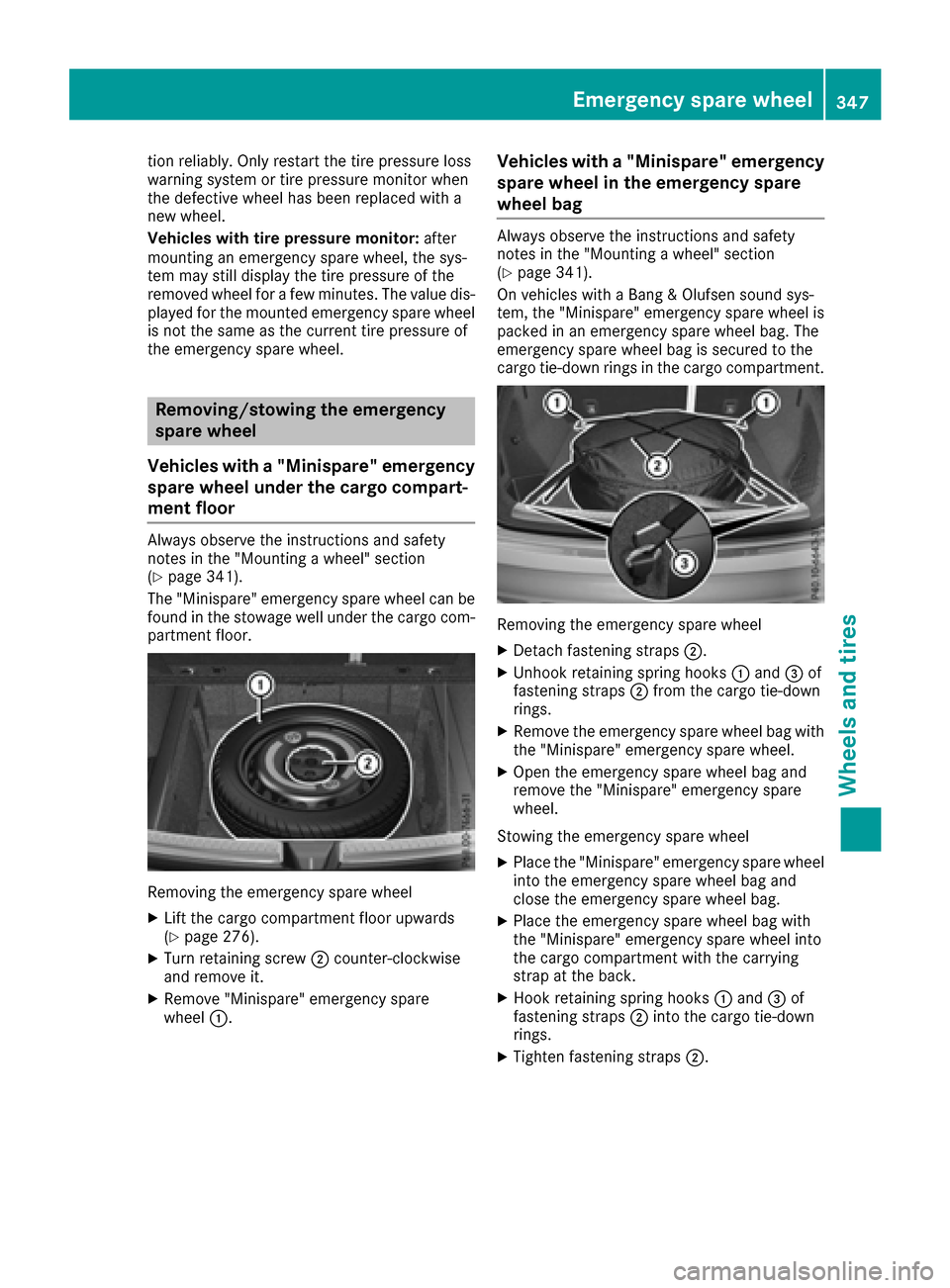

Vehicles with a "Minispare" emergency

spare wheel under the cargo compart-

ment floor

Always observe the instructions and safety

notes in the "Mounting a wheel" section

(

Ypage 341).

The "Minispare" emergency spare wheel can be

found in the stowage well under the cargo com-

partment floor.

Removing the emergency spare wheel

XLift the cargo compartment floor upwards

(Ypage 276).

XTurn retaining screw ;counter-clockwise

and remove it.

XRemove "Minispare" emergency spare

wheel :.

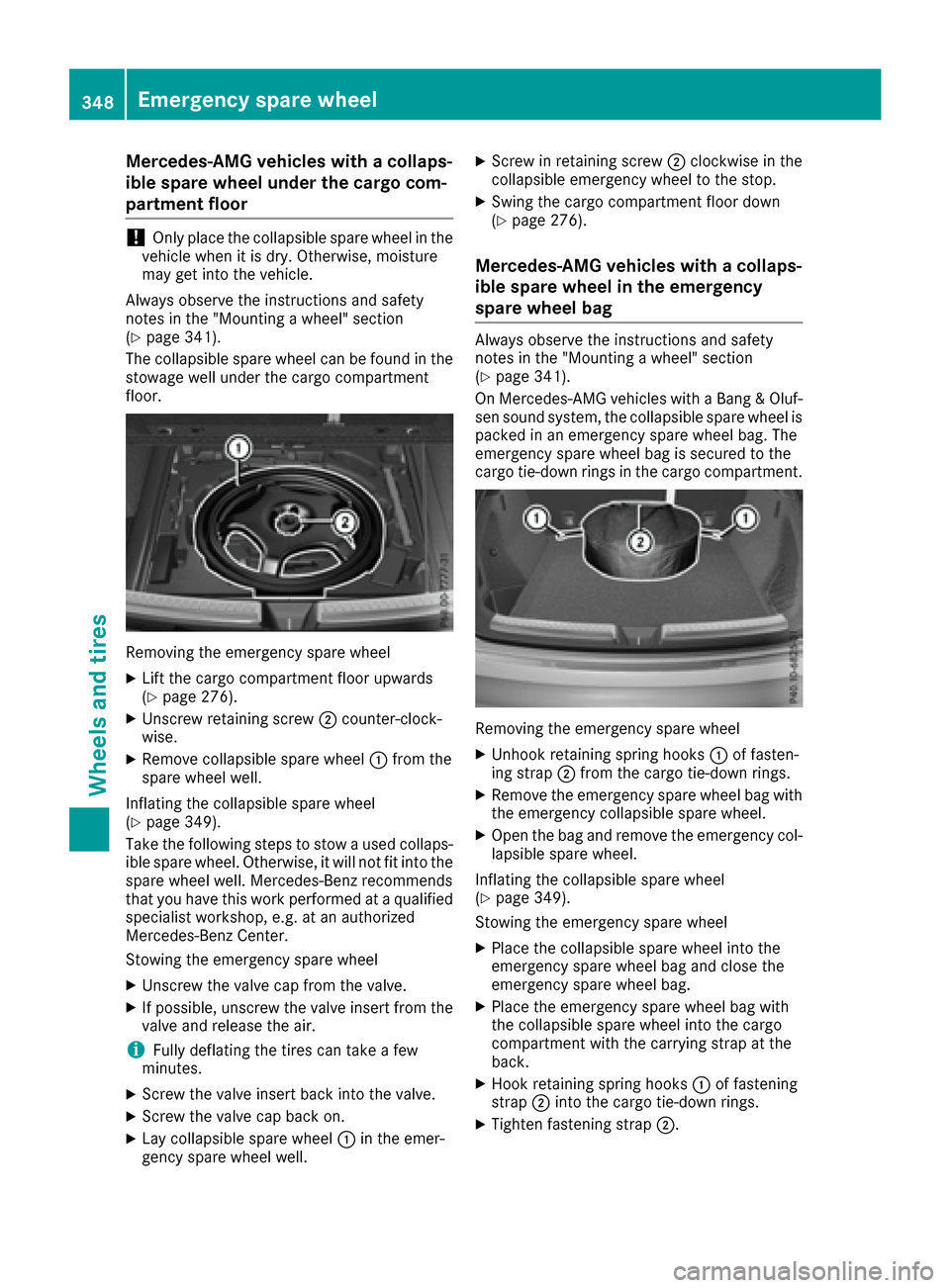

Vehicles with a "Minispare" emergency

spare wheel in the emergency spare

wheel bag

Always observe the instructions and safety

notes in the "Mounting a wheel" section

(

Ypage 341).

On vehicles with a Bang & Olufsen sound sys-

tem, the "Minispare" emergency spare wheel is packed in an emergency spare wheel bag. The

emergency spare wheel bag is secured to the

cargo tie-down rings in the cargo compartment.

Removing the emergency spare wheel

XDetach fastening straps ;.

XUnhook retaining spring hooks :and =of

fastening straps ;from the cargo tie-down

rings.

XRemove the emergency spare wheel bag with

the "Minispare" emergency spare wheel.

XOpen the emergency spare wheel bag and

remove the "Minispare" emergency spare

wheel.

Stowing the emergency spare wheel

XPlace the "Minispare" emergency spare wheel

into the emergency spare wheel bag and

close the emergency spare wheel bag.

XPlace the emergency spare wheel bag with

the "Minispare" emergency spare wheel into

the cargo compartment with the carrying

strap at the back.

XHook retaining spring hooks :and =of

fastening straps ;into the cargo tie-down

rings.

XTighten fastening straps ;.

Emergency sparewheel347

Wheels an d tires

Z

Page 350 of 366

Mercedes-AMG vehicles with a collaps-

ible spare wheel under the cargo com-

partment floor

!Only place the collapsible spare wheel in the

vehicle when it is dry. Otherwise, moisture

may get into the vehicle.

Always observe the instructions and safety

notes in the "Mounting a wheel" section

(

Ypage 341).

The collapsible spare wheel can be found in the

stowage well under the cargo compartment

floor.

Removing the emergency spare wheel

XLift the cargo compartment floor upwards

(Ypage 276).

XUnscrew retaining screw ;counter-clock-

wise.

XRemove collapsible spare wheel :from the

spare wheel well.

Inflating the collapsible spare wheel

(

Ypage 349).

Take the following steps to stow a used collaps- ible spare wheel. Otherwise, it will not fit into the

spare wheel well. Mercedes-Benz recommends

that you have this work performed at a qualified

specialist workshop, e.g. at an authorized

Mercedes-Benz Center.

Stowing the emergency spare wheel

XUnscrew the valve cap from the valve.

XIf possible, unscrew the valve insert from the

valve and release the air.

iFully deflating the tires can take a few

minutes.

XScrew the valve insert back into the valve.

XScrew the valve cap back on.

XLay collapsible spare wheel :in the emer-

gency spare wheel well.

XScrew in retaining screw ;clockwise in the

collapsible emergency wheel to the stop.

XSwing the cargo compartment floor down

(Ypage 276).

Mercedes-AMG vehicles with a collaps-

ible spare wheel in the emergency

spare wheel bag

Always observe the instructions and safety

notes in the "Mounting a wheel" section

(

Ypage 341).

On Mercedes-AMG vehicles with a Bang & Oluf-

sen sound system, the collapsible spare wheel is packed in an emergency spare wheel bag. The

emergency spare wheel bag is secured to the

cargo tie-down rings in the cargo compartment.

Removing the emergency spare wheel

XUnhook retaining spring hooks :of fasten-

ing strap ;from the cargo tie-down rings.

XRemove the emergency spare wheel bag with

the emergency collapsible spare wheel.

XOpen the bag and remove the emergency col-

lapsible spare wheel.

Inflating the collapsible spare wheel

(

Ypage 349).

Stowing the emergency spare wheel

XPlace the collapsible spare wheel into the

emergency spare wheel bag and close the

emergency spare wheel bag.

XPlace the emergency spare wheel bag with

the collapsible spare wheel into the cargo

compartment with the carrying strap at the

back.

XHook retaining spring hooks :of fastening

strap ;into the cargo tie-down rings.

XTighten fastening strap ;.

348Emergency spare wheel

Wheels and tires