clock MERCEDES-BENZ GLE SUV 2019 User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: GLE SUV, Model: MERCEDES-BENZ GLE SUV 2019Pages: 681, PDF Size: 11.7 MB

Page 525 of 681

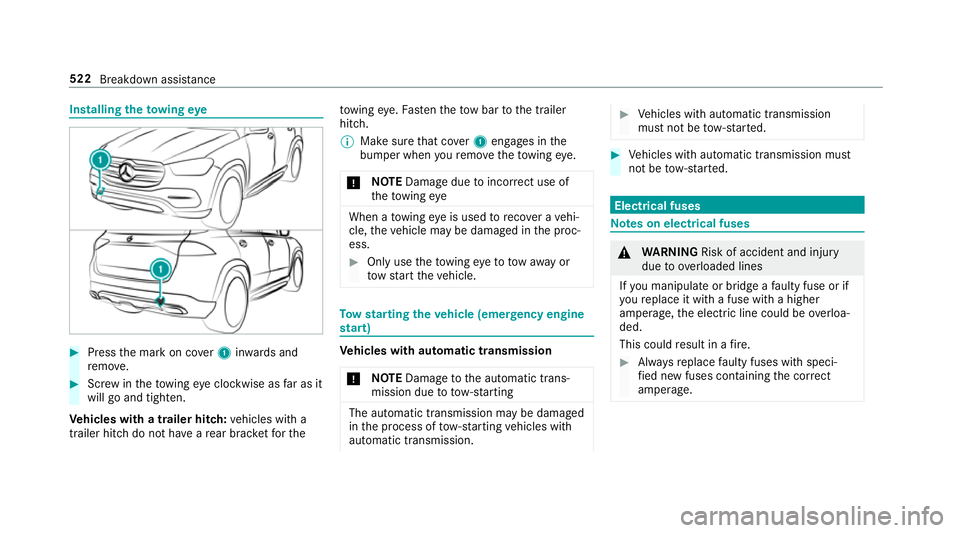

Installing

theto wing eye #

Press the mark on co ver1 inwa rds and

re mo ve. #

Screw intheto wing eyeclockwise as far as it

will go and tighten.

Ve hicles with a trailer hitch: vehicles with a

trailer hitch do not ha veare ar brac ketfo rthe to

wing eye. Fasten theto w bar tothe trailer

hitch.

% Make sure that co ver1 engages in the

bumper when youre mo vetheto wing eye.

* NO

TEDama gedue toincor rect use of

th eto wing eye When a

towing eye is used toreco ver a vehi‐

cle, theve hicle may be damaged in the proc‐

ess. #

Only use theto wing eyeto to waw ay or

to w start theve hicle. To

w starting theve hicle (eme rgency engine

st art) Ve

hicles with automatic transmission

* NO

TEDama getothe automatic trans‐

mission due to tow-starting The automatic transmission may be damaged

in the process of tow- starting vehicles with

automatic transmission. #

Vehicles with automatic transmission

must not be tow- star ted. #

Vehicles with automatic transmission must

not be tow- star ted. Electrical fuses

Note

s on electrical fuses &

WARNING Risk of accident and inju ry

due to ov erloaded lines

If yo u manipulate or bridge a faulty fuse or if

yo ure place it with a fuse with a higher

amperage, the electric line could be overloa‐

ded.

This could result in a fire. #

Alw aysre place faulty fuses with speci‐

fi ed new fuses conta iningthe cor rect

amperage. 522

Breakdown assis tance

Page 544 of 681

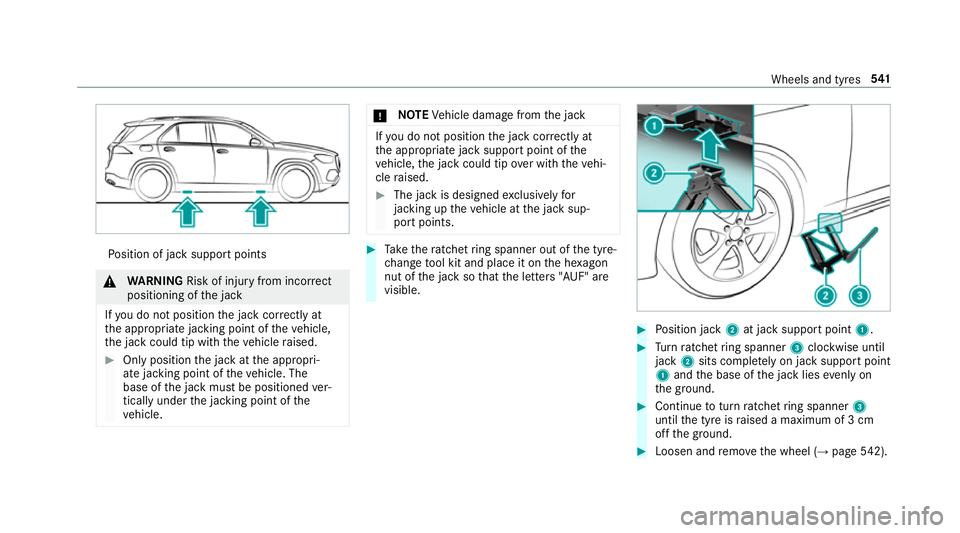

Po

sition of jack support points &

WARNING Risk of inju ryfrom incor rect

positioning of the jack

If yo u do not position the jack cor rectly at

th e appropriate jacking point of theve hicle,

th e jack could tip with theve hicle raised. #

Only position the jack at the appropri‐

ate jacking point of theve hicle. The

base of the jack must be positioned ver‐

tically under the jacking point of the

ve hicle. *

NO

TEVehicle damage from the jack If

yo u do not position the jack cor rectly at

th e appropriate jack support point of the

ve hicle, the jack could tip over with theve hi‐

cle raised. #

The jack is designed exclusively for

jacking up theve hicle at the jack sup‐

port points. #

Take thera tchet ring spanner out of the tyre-

ch ange tool kit and place it on the he xagon

nut of the jack so that the letters "AUF" are

visible. #

Position jack 2at jack support point 1. #

Turn ratchet ring spanner 3clockwise until

jack 2sits comple tely on ja cksupport point

1 and the base of the jack lies evenly on

th e ground. #

Continue toturn ratchet ring spanner 3

until the tyre is raised a maximum of 3 cm

off the ground. #

Loosen and remo vethe wheel (→ page542). Wheels and tyres

541

Page 546 of 681

#

Slide the wheel tobe mounted onto the cen‐

tring pin and push it on. &

WARNING Risk of inju ryfrom tightening

wheel bolts and nuts

If yo u tighten the wheel bolts or wheel nuts

when theve hicle is raised, the jack could tip. #

Only tighten wheel bolts or wheel nuts

when theve hicle is on the ground. #

Be sure toobser vethe instructions and

saf ety no tes on "Changing a wheel"

(→ page 535). #

For saf etyre asons, on lyuse wheel bolts

which ha vebeen appr ovedby Mercedes-

Benz and forth e wheel in question. #

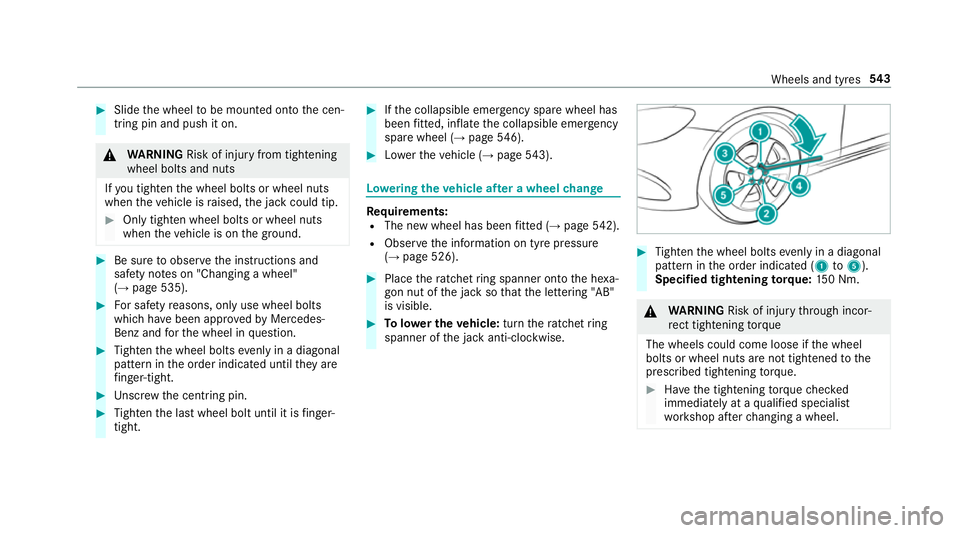

Tighten the wheel bolts evenly in a diagonal

pattern in the order indicated until they are

fi nger-tight. #

Unscr ew the cent ring pin. #

Tighten the last wheel bolt until it is finger-

tight. #

Ifth e collapsible emer gency spa rewheel has

been fitted, infla tethe collapsible emer gency

spa rewheel (→ page546). #

Lowe rth eve hicle (→ page543). Lo

weri ngtheve hicle af ter a wheel change Re

quirements:

R The new wheel has been fitted (→ page 542).

R Obse rveth e information on tyre pressure

(→ page 526). #

Place thera tchet ring spanner onto the he xa‐

gon nut of the jack so that the lettering "AB"

is visible. #

Tolowe r the vehicle: turnthera tchet ring

spanner of the jack anti-clockwise. #

Tighten the wheel bolts evenly in a diagonal

pattern in the order indicated (1 to5 ).

Specified tightening torq ue: 150 Nm. &

WARNING Risk of inju rythro ugh incor‐

re ct tigh tening torque

The wheels could come loose if the wheel

bolts or wheel nuts are not tightened tothe

prescribed tightening torque. #

Have the tightening torque checked

immediately at a qualified specialist

wo rkshop af terch anging a wheel. Wheels and tyres

543