ECU MERCEDES-BENZ GLK-CLASS SUV 2014 Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2014, Model line: GLK-CLASS SUV, Model: MERCEDES-BENZ GLK-CLASS SUV 2014Pages: 384, PDF Size: 48.23 MB

Page 327 of 384

Recovering a vehicle that has become

stuck

! Pull away smoothly, slowly, and in a

straight line when pulling out a vehicle that

has become stuck. Excessive tractive

power could damage the vehicles.

If the drive wheels get trapped on loose or

muddy ground, recover the vehicle with the

utmost care, especially so if the vehicle is

laden.

Never attempt to recover a vehicle with a

trailer attached.

Pull out the vehicle backwards, if possible,

using the tracks it made when it became

stuck. Tow-starting (emergency engine

starting)

! Vehicles with automatic transmission

must not be started by tow-starting. This

could otherwise damage the transmission.

You can find information on "Jump-starting"

at (Y page 320). Fuses

Important safety notes

G

WARNING

If you manipulate or bridge a faulty fuse or if

you replace it with a fuse with a higher

amperage, the electric cables could be

overloaded. This could result in a fire. There

is a risk of an accident and injury.

Always replace faulty fuses with the specified

new fuses having the correct amperage.

! Only use fuses that have been approved

for Mercedes-Benz vehicles and which

have the correct fuse rating for the system

concerned. Otherwise, components or

systems could be damaged.

The fuses in your vehicle serve to close down

faulty circuits. If a fuse blows, all the components on the circuit and their functions

stop operating.

Blown fuses must be replaced with fuses of

the same rating, which you can recognize by

the color and value. The fuse ratings are listed

in the fuse allocation chart.

If a newly inserted fuse also blows, have the

cause traced and rectified at a qualified

specialist workshop, e.g. an authorized

Mercedes-Benz Center. Before changing a fuse

X Secure the vehicle against rolling away

(Y page 164).

X Switch off all electrical consumers.

X Turn the SmartKey to position 0in the

ignition lock and remove it (Y page 145).

or

X On vehicles with KEYLESS-GO, make sure

the ignition is switched off (Y page 145).

All indicator lamps in the instrument cluster

must be off.

The fuses are located in various fuse boxes:

R Fuse box on the driver's side of the

dashboard

R Fuse box in the engine compartment on the

left-hand side of the vehicle, when viewed

in the direction of travel

R Fuse box in the stowage well under the

cargo compartment floor on the right-hand

side of the vehicle, when viewed in the

direction of travel

The fuse allocation chart is located in the

vehicle tool kit in the stowage compartment

under the cargo compartment floor

(Y page 314). Dashboard fuse box

! Do not use a pointed object such as a

screwdriver to open the cover in the

dashboard. You could damage the

dashboard or the cover. Fuses

325Breakdown assistance Z

Page 328 of 384

!

Make sure that no moisture can enter the

fuse box when the cover is open.

! When closing the cover, make sure that it

is lying correctly on the fuse box. Moisture

seeping in or dirt could otherwise impair

the operation of the fuses. X

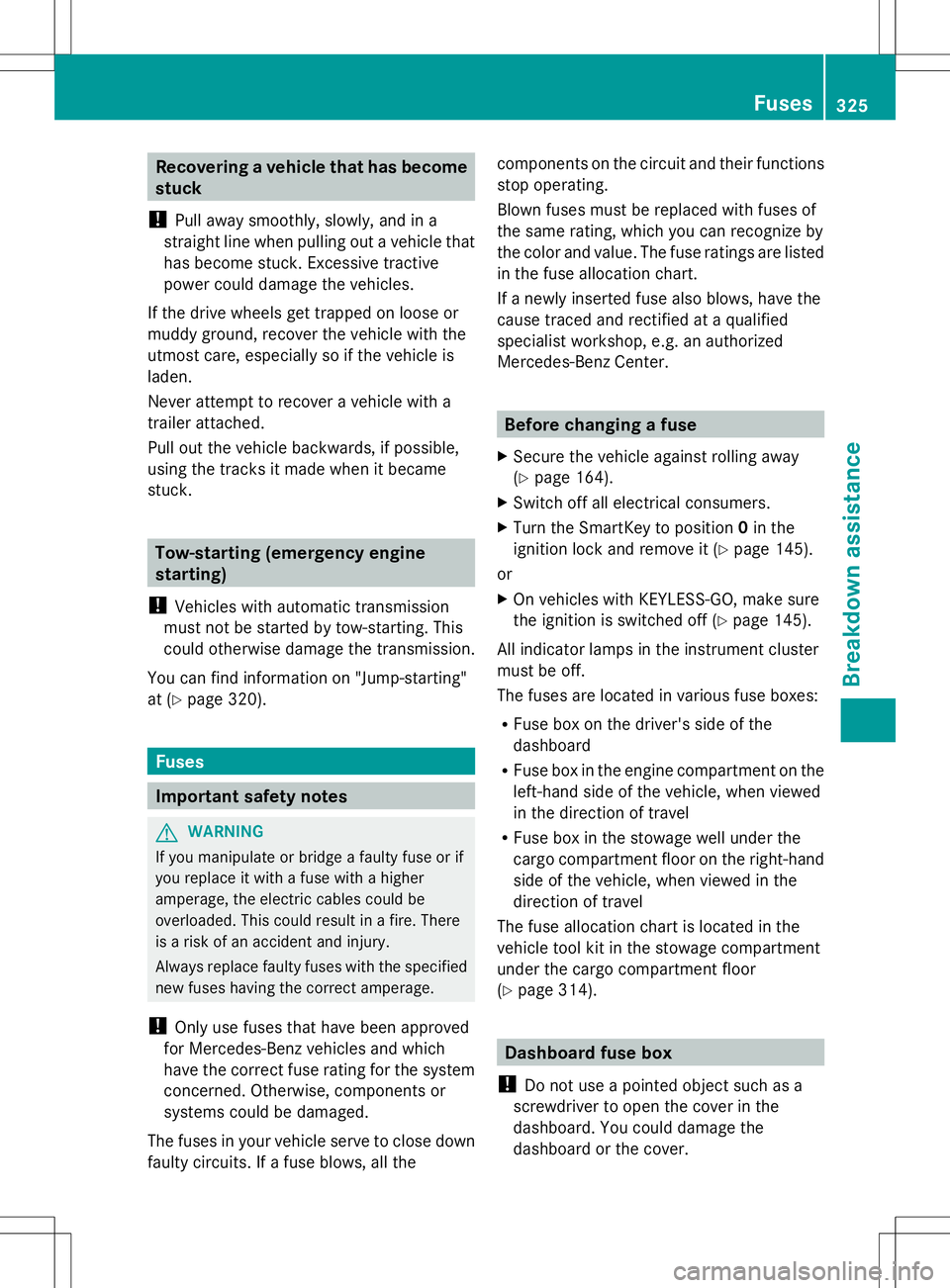

To open: pull out cover :slightly at the

bottom in the direction of arrow =.

X Pull cover :outwards in the direction of

arrow ;and remove it.

X To close: clip in cover :on the front of

the dashboard.

X Fold cover :inwards until it engages. Fuse box in the engine compartment

G

WARNING

When the hood is open and the windshield

wipers are set in motion, you can be injured

by the wiper linkage. There is a risk of injury.

Always switch off the windshield wipers and

the ignition before opening the hood.

! Make sure that no moisture can enter the

fuse box when the cover is open.

! When closing the cover, make sure that it

is lying correctly on the fuse box. Moisture

seeping in or dirt could otherwise impair

the operation of the fuses.

X Make sure that the windshield wipers are

turned off.

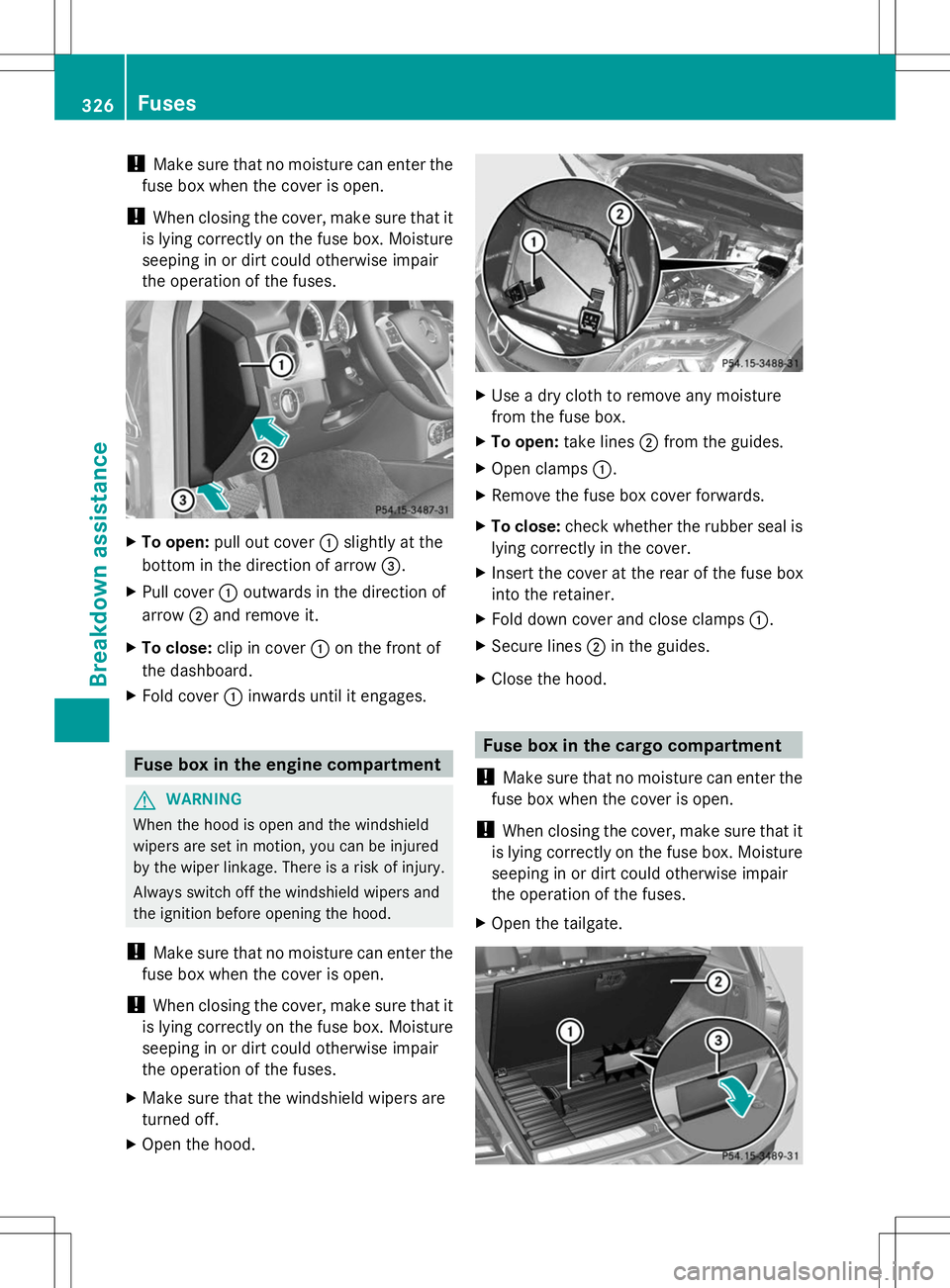

X Open the hood. X

Use a dry cloth to remove any moisture

from the fuse box.

X To open: take lines ;from the guides.

X Open clamps :.

X Remove the fuse box cover forwards.

X To close: check whether the rubber seal is

lying correctly in the cover.

X Insert the cover at the rear of the fuse box

into the retainer.

X Fold down cover and close clamps :.

X Secure lines ;in the guides.

X Close the hood. Fuse box in the cargo compartment

! Make sure that no moisture can enter the

fuse box when the cover is open.

! When closing the cover, make sure that it

is lying correctly on the fuse box. Moisture

seeping in or dirt could otherwise impair

the operation of the fuses.

X Open the tailgate. 326

FusesBreakdown assistance

Page 339 of 384

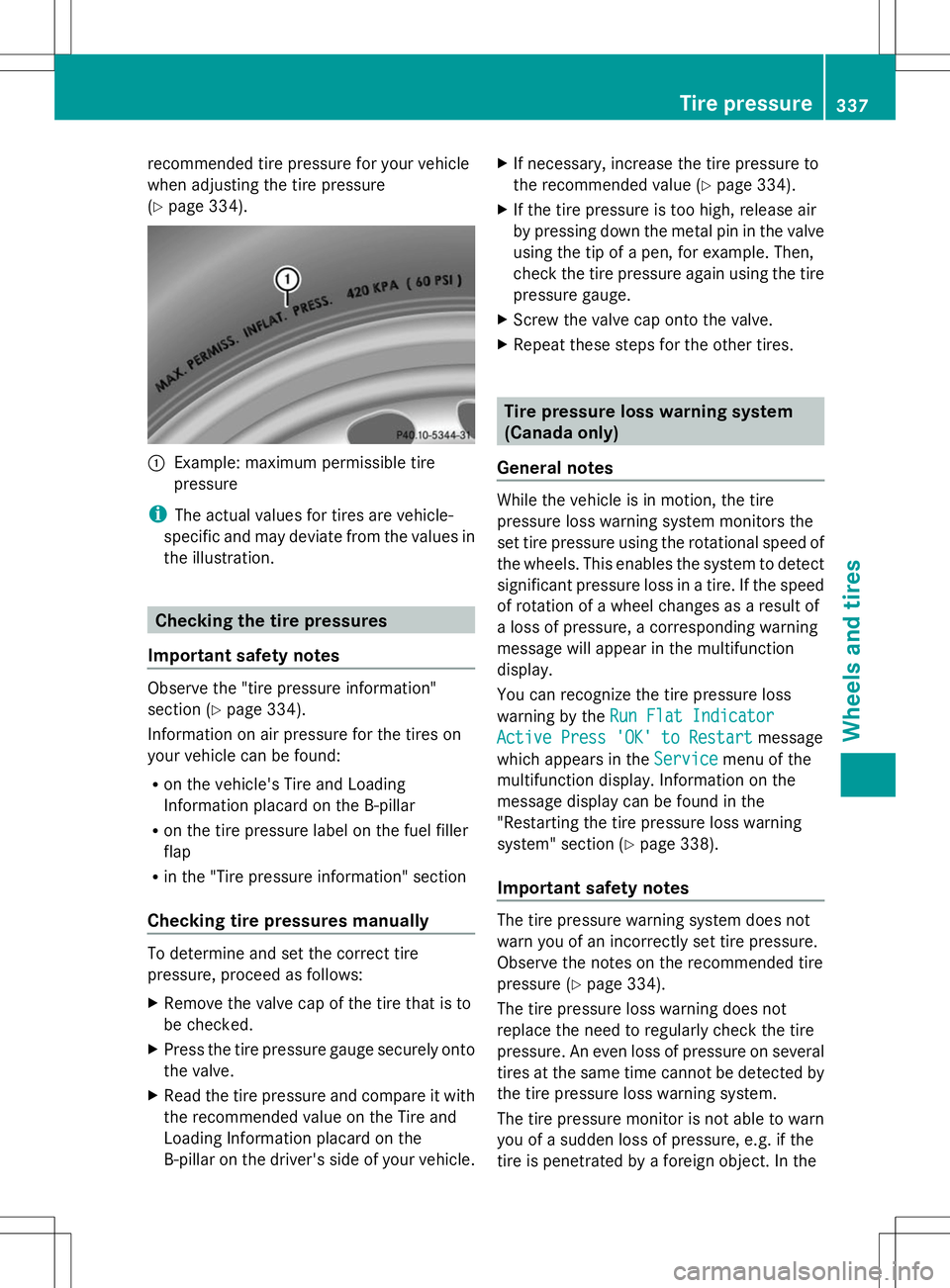

recommended tire pressure for your vehicle

when adjusting the tire pressure

(Y page 334). :

Example: maximum permissible tire

pressure

i The actual values for tires are vehicle-

specific and may deviate from the values in

the illustration. Checking the tire pressures

Important safety notes Observe the "tire pressure information"

section (Y page 334).

Information on air pressure for the tires on

your vehicle can be found:

R on the vehicle's Tire and Loading

Information placard on the B-pillar

R on the tire pressure label on the fuel filler

flap

R in the "Tire pressure information" section

Checking tire pressures manually To determine and set the correct tire

pressure, proceed as follows:

X Remove the valve cap of the tire that is to

be checked.

X Press the tire pressure gauge securely onto

the valve.

X Read the tire pressure and compare it with

the recommended value on the Tire and

Loading Information placard on the

B-pillar on the driver's side of your vehicle. X

If necessary, increase the tire pressure to

the recommended value (Y page 334).

X If the tire pressure is too high, release air

by pressing down the metal pin in the valve

using the tip of a pen, for example. Then,

check the tire pressure again using the tire

pressure gauge.

X Screw the valve cap onto the valve.

X Repeat these steps for the other tires. Tire pressure loss warning system

(Canada only)

General notes While the vehicle is in motion, the tire

pressure loss warning system monitors the

set tire pressure using the rotational speed of

the wheels. This enables the system to detect

significant pressure loss in a tire. If the speed

of rotation of a wheel changes as a result of

a loss of pressure, a corresponding warning

message will appear in the multifunction

display.

You can recognize the tire pressure loss

warning by the

Run Flat Indicator Run Flat Indicator

Active Press 'OK' to Restart

Active Press 'OK' to Restart message

which appears in the Service

Servicemenu of the

multifunction display. Information on the

message display can be found in the

"Restarting the tire pressure loss warning

system" section (Y page 338).

Important safety notes The tire pressure warning system does not

warn you of an incorrectly set tire pressure.

Observe the notes on the recommended tire

pressure (Y

page 334).

The tire pressure loss warning does not

replace the need to regularly check the tire

pressure. An even loss of pressure on several

tires at the same time cannot be detected by

the tire pressure loss warning system.

The tire pressure monitor is not able to warn

you of a sudden loss of pressure, e.g. if the

tire is penetrated by a foreign object. In the Tire pressure

337Wheels and tires Z

Page 355 of 384

Maximum load on one tire

Maximum load on one tire. This is calculated

by dividing the maximum axle load of one axle

by two. PSI (pounds per square inch)

A standard unit of measure for tire pressure. Aspect ratio

Relationship between tire height and tire

width in percent. Tire pressure

This is pressure inside the tire applying an

outward force to each square inch of the tire's

surface. The tire pressure is specified in

pounds per square inch (psi), in kilopascal

(kPa) or in bar. The tire pressure should only

be corrected when the tires are cold. Tire pressure of cold tires

The tires are cold:

R if the vehicle has been parked without

direct sunlight on the tires for at least three

hours and

R if the vehicle has not been driven further

than 1 mile (1.6 km) Tread

The part of the tire that comes into contact

with the road. Bead

The tire bead ensures that the tire sits

securely on the wheel. There are several steel

wires in the bead to prevent the tire from

coming loose from the wheel rim. Sidewall

The part of the tire between the tread and the

bead. Weight of optional extras

The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 2.3 kg (5 lbs). These

optional extras, such as high-performance

brakes, level control, a roof rack or a high-

performance battery, are not included in the

curb weight and the weight of the

accessories. TIN (Tire Identification Number)

This is a unique identifier which can be used

by a tire manufacturer to identify tires, for

example for a product recall, and thus identify

the purchasers. The TIN is made up of the

manufacturer's identity code, tire size, tire

type code and the manufacturing date. Load bearing index

The load bearing index (also load index) is a

code that contains the maximum load bearing

capacity of a tire. Traction

Traction is the result of friction between the

tires and the road surface. TWR (Tongue Weight Rating)

The TWR specifies the maximum permissible

weight that the ball coupling of the trailer tow

hitch can support. Definition of terms for tires and loading

353Wheels and tires Z

Page 357 of 384

Storing wheels

Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the

tires from oil, grease, gasoline and diesel. Cleaning the wheels

G

WARNING

The water jet from a circular jet nozzle (dirt

blasters) can cause invisible exterior damage

to the tires or chassis components.

Components damaged in this way may fail

unexpectedly. There is a risk of an accident.

Do not use power washers with circular jet

nozzles to clean the vehicle. Have damaged

tires or chassis components replaced

immediately. Mounting a wheel

Preparing the vehicle

X Stop the vehicle on solid, non-slippery and

level ground.

X Apply the parking brake.

X Bring the front wheels into the straight-

ahead position.

X Move the selector lever to position P.

X Switch off the engine.

X Vehicles without KEYLESS-GO: remove

the SmartKey from the ignition lock.

X Vehicles with KEYLESS-GO: open the

driver's door.

The on-board electronics have status 0,

which is the same as the SmartKey having

been removed.

X Vehicles with KEYLESS-GO: remove the

Start/Stop button from the ignition lock

(Y page 145).

X If included in the vehicle equipment,

remove the tire-change tool kit from the

vehicle. X

Secure the vehicle to prevent it from rolling

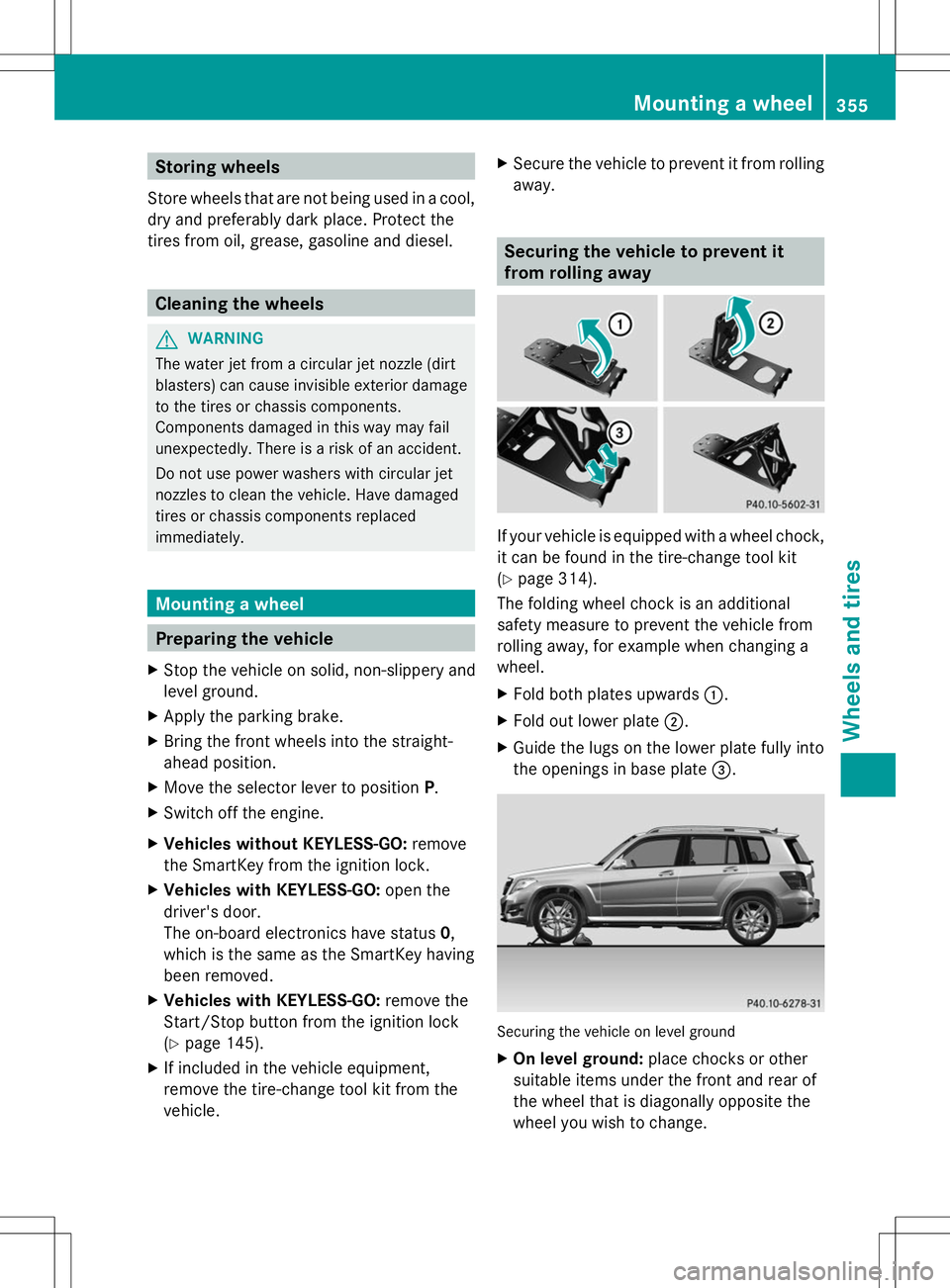

away. Securing the vehicle to prevent it

from rolling away

If your vehicle is equipped with a wheel chock,

it can be found in the tire-change tool kit

(Y

page 314).

The folding wheel chock is an additional

safety measure to prevent the vehicle from

rolling away, for example when changing a

wheel.

X Fold both plates upwards :.

X Fold out lower plate ;.

X Guide the lugs on the lower plate fully into

the openings in base plate =. Securing the vehicle on level ground

X

On level ground: place chocks or other

suitable items under the front and rear of

the wheel that is diagonally opposite the

wheel you wish to change. Mounting a wheel

355Wheels and tires Z

Page 358 of 384

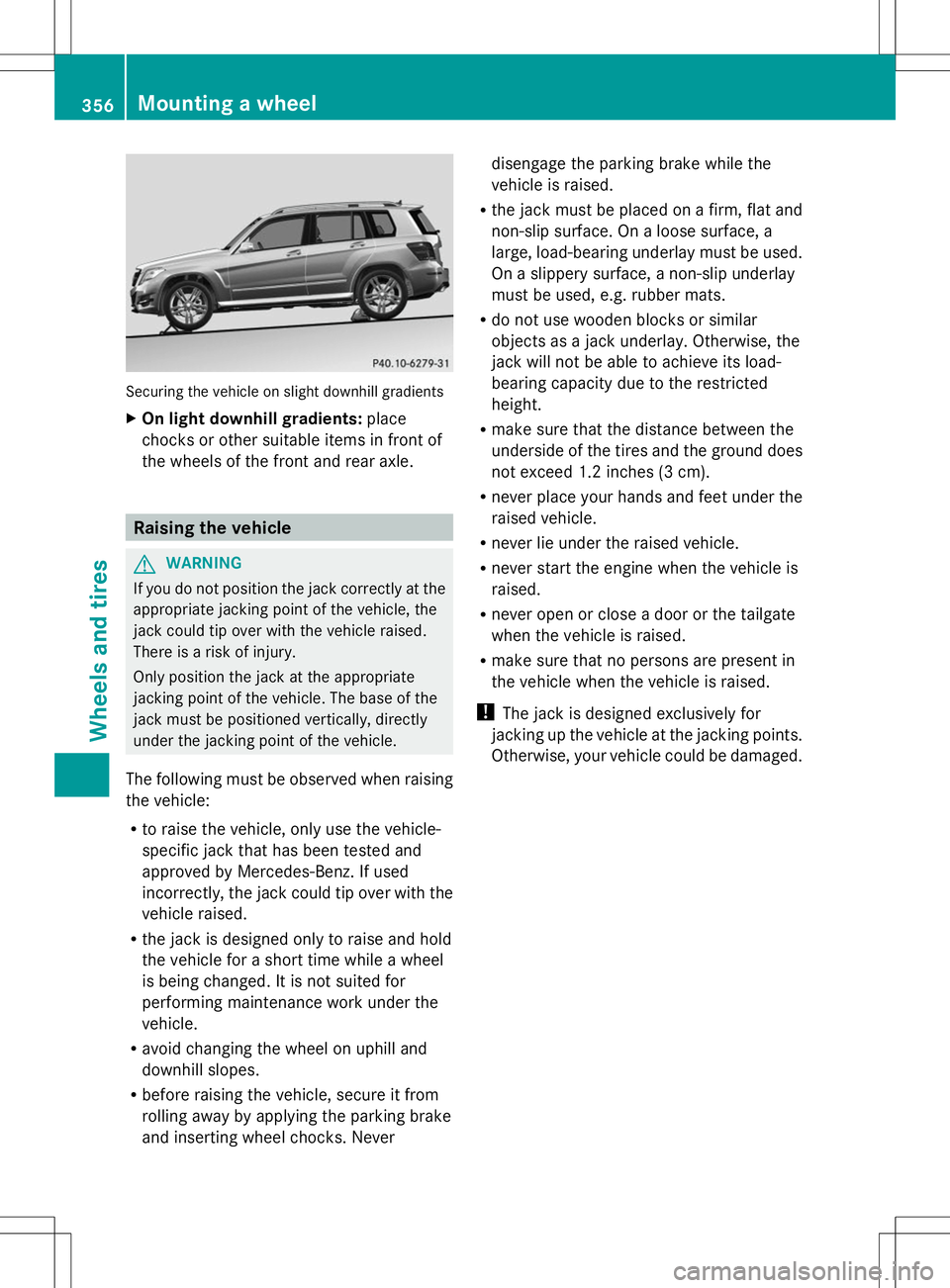

Securing the vehicle on slight downhill gradients

X On light downhill gradients: place

chocks or other suitable items in front of

the wheels of the front and rear axle. Raising the vehicle

G

WARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate

jacking point of the vehicle. The base of the

jack must be positioned vertically, directly

under the jacking point of the vehicle.

The following must be observed when raising

the vehicle:

R to raise the vehicle, only use the vehicle-

specific jack that has been tested and

approved by Mercedes-Benz. If used

incorrectly, the jack could tip over with the

vehicle raised.

R the jack is designed only to raise and hold

the vehicle for a short time while a wheel

is being changed. It is not suited for

performing maintenance work under the

vehicle.

R avoid changing the wheel on uphill and

downhill slopes.

R before raising the vehicle, secure it from

rolling away by applying the parking brake

and inserting wheel chocks. Never disengage the parking brake while the

vehicle is raised.

R the jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a

large, load-bearing underlay must be used.

On a slippery surface, a non-slip underlay

must be used, e.g. rubber mats.

R do not use wooden blocks or similar

objects as a jack underlay. Otherwise, the

jack will not be able to achieve its load-

bearing capacity due to the restricted

height.

R make sure that the distance between the

underside of the tires and the ground does

not exceed 1.2 inche s (3cm).

R never place your hands and feet under the

raised vehicle.

R never lie under the raised vehicle.

R never start the engine when the vehicle is

raised.

R never open or close a door or the tailgate

when the vehicle is raised.

R make sure that no persons are present in

the vehicle when the vehicle is raised.

! The jack is designed exclusively for

jacking up the vehicle at the jacking points.

Otherwise, your vehicle could be damaged. 356

Mounting a wheelWheels and tires

Page 360 of 384

bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event

of damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving. G

WARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always pay attention to the instructions and

safety notes in the "Changing a wheel"

section (Y page 354).

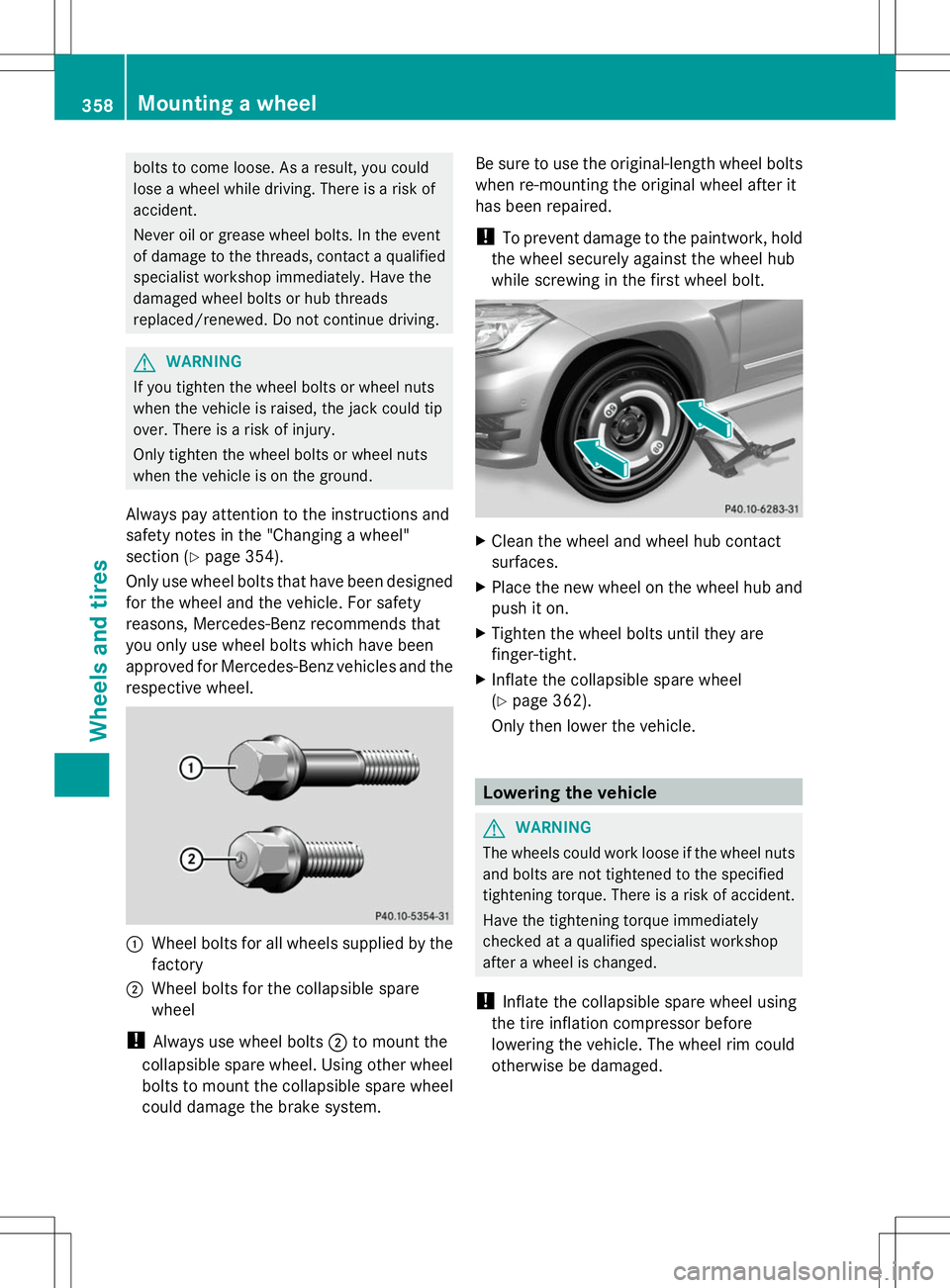

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety

reasons, Mercedes-Benz recommends that

you only use wheel bolts which have been

approved for Mercedes-Benz vehicles and the

respective wheel. :

Wheel bolts for all wheels supplied by the

factory

; Wheel bolts for the collapsible spare

wheel

! Always use wheel bolts ;to mount the

collapsible spare wheel. Using other wheel

bolts to mount the collapsible spare wheel

could damage the brake system. Be sure to use the original-length wheel bolts

when re-mounting the original wheel after it

has been repaired.

!

To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt. X

Clean the wheel and wheel hub contact

surfaces.

X Place the new wheel on the wheel hub and

push it on.

X Tighten the wheel bolts until they are

finger-tight.

X Inflate the collapsible spare wheel

(Y page 362).

Only then lower the vehicle. Lowering the vehicle

G

WARNING

The wheels could work loose if the wheel nuts

and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

! Inflate the collapsible spare wheel using

the tire inflation compressor before

lowering the vehicle. The wheel rim could

otherwise be damaged. 358

Mounting a wheelWheels and tires