MERCEDES-BENZ GLS SUV 2019 Owners Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: GLS SUV, Model: MERCEDES-BENZ GLS SUV 2019Pages: 729, PDF Size: 12.03 MB

Page 591 of 729

Lo

weri ngtheve hicle af ter a wheel change Re

quirements:

R The new wheel has been fitted

(/ page 587).

R Obse rveth e information on tyre pressure

(/ page 571). #

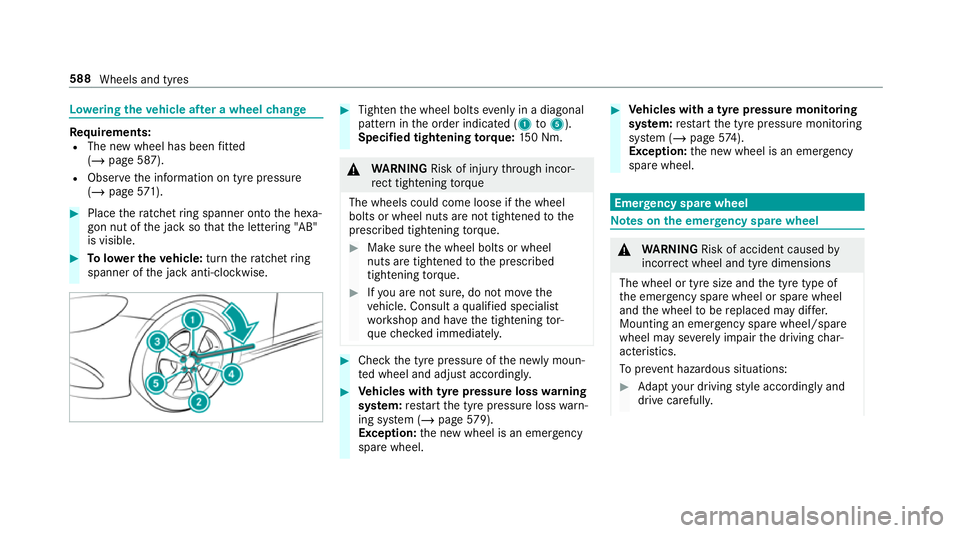

Place thera tchet ring spanner onto the he xa‐

gon nut of the jack so that the lettering "AB"

is visible. #

Tolowe r the vehicle: turnthera tchet ring

spanner of the jack anti-clockwise. #

Tighten the wheel bolts evenly in a diagonal

pattern in the order indicated (1 to5 ).

Specified tightening torq ue: 150 Nm. &

WARNING Risk of inju rythro ugh incor‐

re ct tigh tening torque

The wheels could come loose if the wheel

bolts or wheel nuts are not tightened tothe

prescribed tightening torque. #

Makesure the wheel bolts or wheel

nuts are tightened tothe prescribed

tightening torque. #

Ifyo u are not sure, do not mo vethe

ve hicle. Consult a qualified specialist

wo rkshop and ha vethe tightening tor‐

qu ech ecked immediately. #

Check the tyre pressure of the newly moun‐

te d wheel and adjust according ly. #

Vehicles with tyre pressure loss warning

sy stem: restart the tyre pressure loss warn‐

ing sy stem (/ page579).

Excep tion:the new wheel is an emer gency

spa rewheel. #

Vehicles with a tyre pressure monitoring

sy stem: restart the tyre pressure monitoring

sy stem (/ page574).

Except ion:the new wheel is an emer gency

spa rewheel. Emer

gency spare wheel Note

s onthe emer gency spare wheel &

WARNING Risk of accident caused by

incor rect wheel and tyre dimensions

The wheel or tyre size and the tyre type of

th e emer gency spa rewheel or spare wheel

and the wheel tobe replaced may dif fer.

Mounting an emer gency spa rewheel/spare

wheel may se verely impair the driving char‐

acteristics.

To preve nt hazardous situations: #

Adapt your driving style according lyand

drive carefull y. 588

Wheels and tyres

Page 592 of 729

#

Neverfit more than one emer gency

spa rewheel or spare wheel that dif fers

in size. #

Only use an emer gency spa rewheel or

spare wheel of a dif fere nt size brie fly. #

Do not switch off ESP ®

. #

Have the emer gency spa rewheel or

spare wheel of a dif fere nt size replaced

at the nearest qualified specialist work‐

shop. The new wheel must ha vethe

cor rect dimensions. Check

the tyre pressure of the emer gency spa re

wheel fitted. Co rrect the pressure as necessar y.

The maximum permissible speed with an emer‐

ge ncy spa rewheel fitted is 80 km/h.

Do not fit th e emer gency spa rewheel with sn ow

ch ains.

Re place the emer gency spa rewheel af ter six

ye ars at the latest, rega rdless of wear.

% Ve

hicles with a tyre pressure loss warn‐

ing sy stem: if an emer gency spa rewheel is

fi tted the tyre pressure loss warning sy stem cann

otfunction reliabl y.Only restart the sys‐

te m again when the emer gency spa rewheel

has been replaced with a new wheel.

Ve hicles with a tyre pressure monitoring

sy stem: if an emer gency spa rewheel is fit‐

te dth e tyre pressure monitoring sy stem can‐

not function reliabl y.Only restart the sy stem

again when the emer gency spa rewheel has

been replaced with a new wheel.

Ve hicles with a tyre pressure monitoring

sy stem: for a few minutes af ter an emer‐

ge ncy spa rewheel is fitted, the sy stem may

st ill display the tyre pressure of there mo ved

wheel.

Be sure toalso obse rveth efo llowing fur ther

re lated subjects:

R Notes on tyre pressure (/ page571)

R Tyre pressure table (/ page572) Re

moving the eme rgency spa rewheel The eme

rgency spare wheel is located under the

load compartment floor. #

Obser vethe information on mounting tyres

(/ page 580). #

Open theta ilgate. #

Open the load compartment floor

(/ page 146). #

Remo vethe emer gency spa rewheel bag with

th e emer gency spa rewheel. #

Open the emer gency spa rewheel bag and

re mo vethe emer gency spa rewheel. Collapsible spa

rewheel Note

s onthe collapsible spa rewheel &

WARNING Risk of accident caused by

incor rect wheel and tyre dimensions

The wheel or tyre size and the tyre type of

th e emer gency spa rewheel or spare wheel

and the wheel tobe replaced may dif fer.

Mounting an emer gency spa rewheel/spare

wheel may se verely impair the driving char‐

acteristics.

To preve nt hazardous situations: Wheels and tyres

589

Page 593 of 729

#

Adapt your driving style according lyand

drive carefull y. #

Neverfit more than one emer gency

spa rewheel or spare wheel that dif fers

in size. #

Only use an emer gency spa rewheel or

spare wheel of a dif fere nt size brie fly. #

Do not switch off ESP ®

. #

Have the emer gency spa rewheel or

spare wheel of a dif fere nt size replaced

at the nearest qualified specialist work‐

shop. The new wheel must ha vethe

cor rect dimensions. The collapsible spa

rewheel is an emer gency

wheel which is only suitable for use for a limi ted

period of time and in a restricted manner in the

eve nt of a flat tyre (e.g. until the nearest work‐

shop).

The tyre side walls are folded when in transpo rt

mode. Before use, the collapsible spare wheel

has tobe inflated with the accompanying com‐

pressor. Check

the tyre pressure of the collapsible spare

wheel once fitted. Co rrect the pressure as nec‐

essar y.

The maximum permissible speed with a collapsi‐

ble spare wheel fitted is 80 km/h.

Do not fit snow chains with the collapsible spare

wheel.

Re place the collapsible spare wheel af ter six

ye ars at the latest, rega rdless of wear.

% Ve

hicles with a tyre pressure loss warn‐

ing sy stem: if a collapsible spare wheel is

fi tted, the tyre pressure loss warning sy stem

cann otfunction reliabl y.Only restart the sys‐

te m again when the collapsible spare wheel

has been replaced with a new wheel.

Ve hicles with a tyre pressure monitoring

sy stem: if a collapsible spare wheel is fitted

th e tyre pressure monitoring sy stem cann ot

function reliably. Only restart the sy stem

again when the collapsible spare wheel has

been replaced with a new wheel.

Ve hicles with a tyre pressure monitoring

sy stem: for a few minutes af ter a collapsible

spare wheel is fitted, the sy stem may still display

the tyre pressure of there mo ved

wheel.

Be sure toalso obse rveth efo llowing fur ther

re lated subjects:

R Notes on tyre pressure (/ page571)

R Tyre pressure table (/ page572) Re

moving the collapsible spare wheel Ve

hicles without a Burmes ter sound sy stem

The collapsible spare wheel is located under the

load compartment floor. #

Obser vethe information on mounting tyres

(/ page 580). #

Open theta ilgate. #

Open the load compartment floor

(/ page 146). #

Remo vethe collapsible spare wheel.

Ve hicles with a Burmes ter sound sy stem

The collapsible spare wheel is secured in the col‐

lapsible spare wheel bag in the load compart‐

ment. 590

Wheels and tyres

Page 594 of 729

#

Obser vethe information on mounting tyres

(/ page 580). #

Open the load compartment. #

Detach the securing stra ps. #

Unhook there taining spring hooks of the

securing stra ps from the brac kets. #

Remo vethe emer gency spa rewheel bag

to ge ther with the collapsible spare wheel. #

Open the emer gency spa rewheel bag and

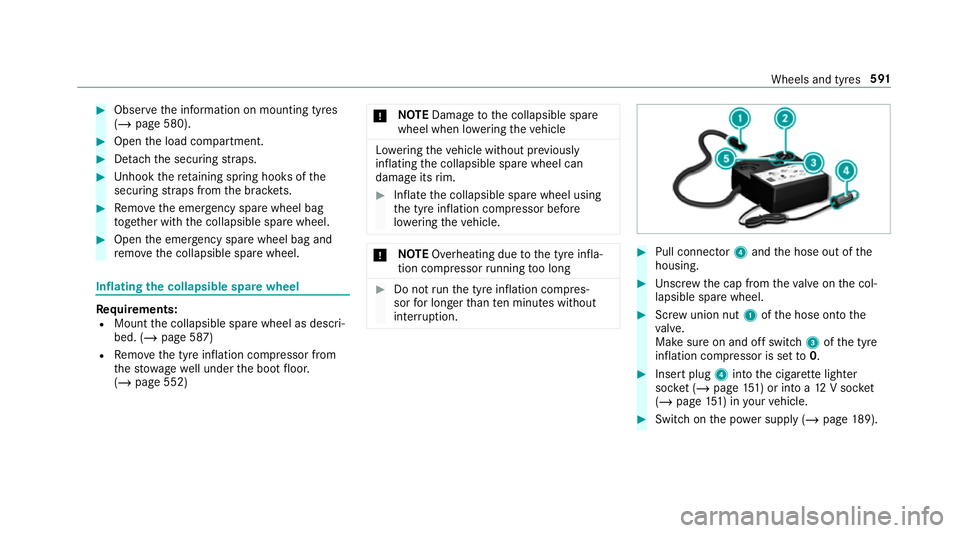

re mo vethe collapsible spare wheel. Inflating

the collapsible spa rewheel Re

quirements:

R Mount the collapsible spare wheel as descri‐

bed. (/ page 587)

R Remo vethe tyre inflation compressor from

th estow agewell under the boot floor.

(/ page 552) *

NO

TEDama getothe collapsible spare

wheel when lo wering theve hicle Lo

we ring theve hicle without pr eviously

inflating the collapsible spare wheel can

damage its rim. #

Inflate the collapsible spare wheel using

th e tyre inflation compressor before

lo we ring theve hicle. *

NO

TEOverheating due tothe tyre infla‐

tion compressor running too long #

Do not runth e tyre inflation compres‐

sor for longer than ten minu tes without

inter ruption. #

Pull connec tor4 and the hose out of the

housing. #

Unscr ew the cap from theva lve on the col‐

lapsible spare wheel. #

Screw union nut 1ofthe hose onto the

va lve.

Make sure on and off switch 3ofthe tyre

inflation compressor is set to0. #

Insert plug 4into the cigar ette lighter

soc ket (/ page 151) or in toa12 V soc ket

( / page 151) in your vehicle. #

Switch on the po wer supp ly (/ page 189). Wheels and

tyres591

Page 595 of 729

#

Press on and off switch 3onthe tyre infla‐

tion compressor toI.

The tyre inflation compressor is switched on.

The tyre is inflated. The tyre pressure is

shown on manome ter2. #

Pump the tyre tothe specified tyre pressure.

The specified tyre pressure is printed on the

ye llow label of the collapsible spare wheel. #

When the specified tyre pressure has been

re ached, press on and off swit ch3 onthe

tyre inflation compressor to0. #

Ifth e tyre pressure is higher than the speci‐

fi ed pressure, press pressure release valve

bu tton 5until the cor rect tyre pressure has

been reached. 592

Wheels and tyres

Page 596 of 729

Note

s ontech nical data

The tech nical da tawa s de term ined in accord‐

ance with EU Directives. The data stated on ly

applies tovehicles with standard equipment. Yo u

can obtain fur ther information from a Mercedes-

Benz Service Centre.

Only for ce rtain countries: you can find vehi‐

cle-specific vehicle data in the EC-Certificate of

Conformity (CERTIFIC ATE OF CONFORMITY).

These documents are deli vered with your vehi‐

cle. On-board electronics

Note

s on tampering with the engine elec‐

tronics *

NO

TEPremature wearthro ugh improper

main tenance Improper maintenance may cause

vehicle

components towe ar more quickly and the

ve hicle's operating permit may be in valida‐

te d. #

Alw ays ha vewo rkon the engine elec‐

tronics and related components car ried

out at a qualified specialist workshop. Tw

o-w ayradios Note

s onfitting two-w ayradios &

WARNING Risk of accident due to

improper workon two-w ayradios

The elect romagnetic radiation from two-w ay

ra dios can inter fere with the on-board elec‐

tronics if RF transmit ters are manipulated or

re trofitted inco rrectly.

This could jeopardise the operating saf ety of

th eve hicle. #

You should ha veall workon electrical

and electronic components car ried out

at a qualified specialist workshop. &

WARNING Risk of accident from incor‐

re ct ope ration of two-w ayradios

If yo u operate two- wayra dios inco rrectly in

th eve hicle, the electromagnetic radiation

could inter fere with the on-board electronics,

e.g.:

R ifth e two-w ayradio is not connec tedto

an exterior aerial

R ifth eex terior aerial is not cor rectly

mounted or is not of low reflection

This could jeopardise the operating saf ety of

th eve hicle. #

Have the lo w-reflection exterior aerial

fi tted at a qualified specialist workshop. #

When operating two-w ayradios in the

ve hicle, alw ays connect them tothe

lo w- reflection exterior aerial. Te

ch nical da ta593

Page 597 of 729

*

NO

TEInva lidation of the operating per‐

mit due tofailure tocomply wi th the

instructions for ins tallation and use The operating permit may be in

validated if

th e instructions for ins tallation and use of

two-w ayradios are not obser ved. #

Only use appr oved frequency bands. #

Obser vethe maximum permissible out‐

put po wer in these frequency bands. #

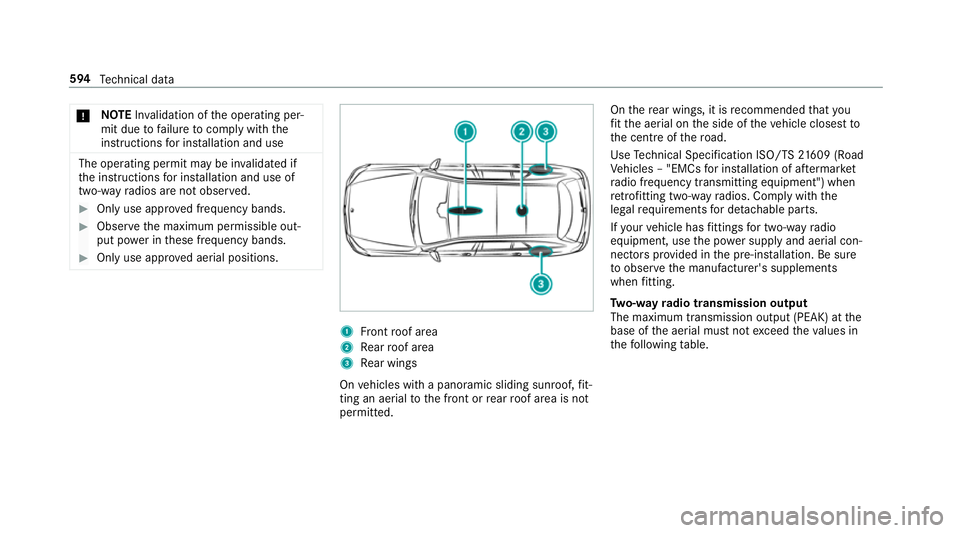

Only use appr oved aerial positions. 1

Front roof area

2 Rear roof area

3 Rear wings

On vehicles with a panoramic sliding sunroof, fit‐

ting an ae rial to the front or rear roof area is not

permitted. On

there ar wings, it is recommended that you

fi t th e aerial on the side of theve hicle closest to

th e cent reofthero ad.

Use Tech nical Specification ISO/TS 21609 (Road

Ve hicles – "EMCs for ins tallation of af term arket

ra dio frequency transmitting equipment") when

re trofitting two-w ayradios. Comply with the

legal requirements for de tach able parts.

If yo ur vehicle has fittings for two-w ayradio

equipment, use the po wer supp lyand aerial con‐

nec tors prov ided in the pre-ins tallation. Be sure

to obser vethe manufacturer's supplements

when fitting.

Tw o-w ayradio transmission output

The maximum transmission output (PEAK) at the

base of the aerial must not exceed theva lues in

th efo llowing table. 594

Tech nical da ta

Page 598 of 729

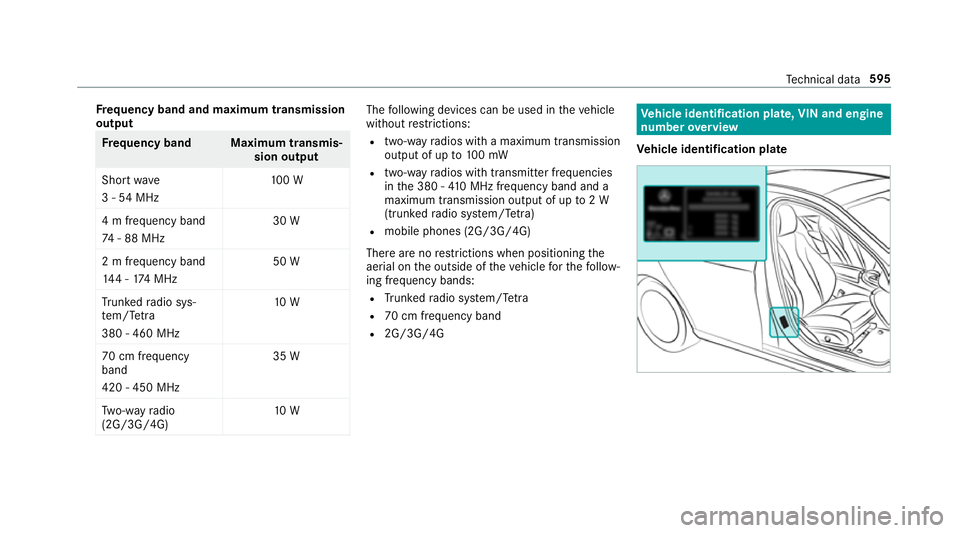

Fr

equency band and maximum transmission

output Fr

equency band Maximum transmis‐

sion output

Sho rtwa ve

3 - 54 MHz 10

0 W

4 m frequency band

74 - 88 MHz 30 W

2 m frequency band

14 4 - 174 MHz 50 W

Tr unked radio sys‐

te m/T etra

380 - 460 MHz 10 W

70 cm frequency

band

420 - 450 MHz 35 W

Tw o-w ayradio

(2G/3G/4G) 10 W The

following devices can be used in theve hicle

without restrictions:

R two-w ayradios with a maximum transmission

output of up to100 mW

R two-w ayradios with transmit ter frequencies

in the 380 - 410 MHz frequency band and a

maximum transmission output of up to2 W

(trunked radio sy stem/T etra)

R mobile phones (2G/3G/4G)

There are no restrictions when positioning the

aerial on the outside of theve hicle forth efo llow‐

ing frequency bands:

R Trunked radio sy stem/T etra

R 70 cm frequency band

R 2G/3G/4G Ve

hicle identification plate, VIN and engine

number overview

Ve hicle identification plate Te

ch nical da ta595

Page 599 of 729

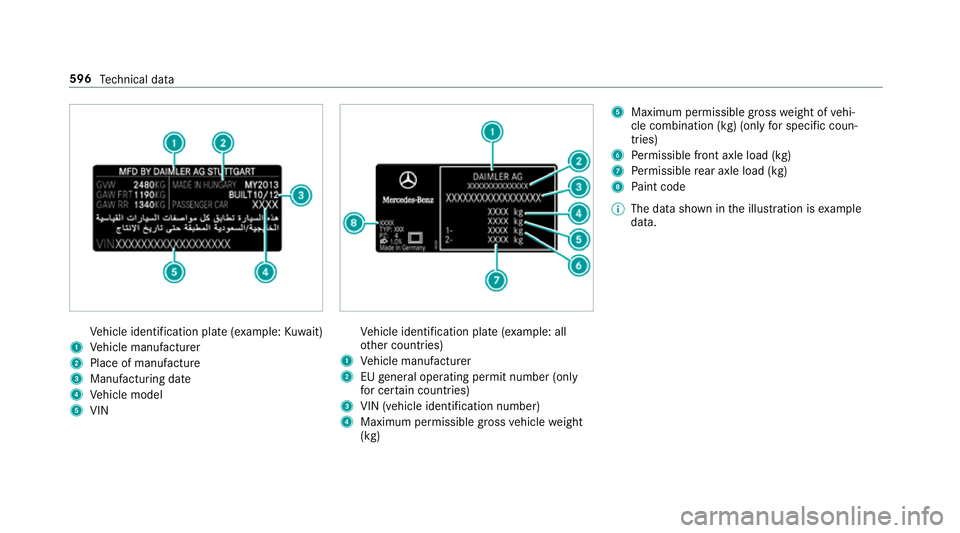

Ve

hicle identification plate (e xample:Kuwa it)

1 Vehicle manufacturer

2 Place of manufacture

3 Manufacturing date

4 Vehicle model

5 VIN Ve

hicle identification plate (e xample: all

ot her countries)

1 Vehicle manufacturer

2 EUgeneral operating pe rmit number (only

fo r cer tain countries)

3 VIN (vehicle identification number)

4 Maximum permissible gross vehicle weight

(kg) 5

Maximum permissible gross weight of vehi‐

cle combination (kg) (only for specific coun‐

tries)

6 Perm issible front axle load (kg)

7 Perm issible rear axle load (kg)

8 Paint code

% The data shown in the illustration is example

data. 596

Tech nical da ta

Page 600 of 729

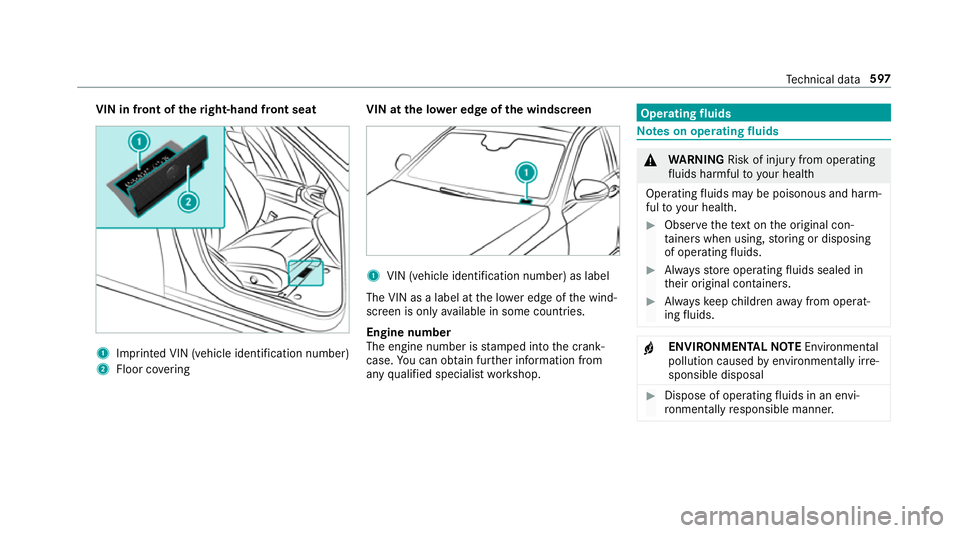

VIN in front of the

right-hand front seat 1

Imprinted VIN (vehicle identification number)

2 Floor co vering VIN at the lo

wer edge of the windscreen 1

VIN (vehicle identi fication number) as label

The VIN as a label at the lo wer edge of the wind‐

screen is only available in some countries.

Engine number

The engine number is stamped into the crank‐

case. You can obtain fur ther information from

any qualified specialist workshop. Operating

fluids Note

s on operating fluids &

WARNING Risk of inju ryfrom operating

fl uids harmful to your health

Operating fluids may be poisonous and harm‐

ful to yo ur health. #

Obser vethete xt on the original con‐

ta iners when using, storing or disposing

of operating fluids. #

Alw aysst ore operating fluids sealed in

th eir original conta iners. #

Alw ayske ep children away from operat‐

ing fluids. +

ENVIRONMEN

TALNO TEEnvironmental

pollution caused byenvironmen tally ir re‐

sponsible disposal #

Dispose of operating fluids in an envi‐

ro nmentally responsible manner. Te

ch nical da ta597