flat tire MERCEDES-BENZ GLS SUV 2019 Owners Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: GLS SUV, Model: MERCEDES-BENZ GLS SUV 2019Pages: 729, PDF Size: 12.03 MB

Page 22 of 729

What

todo in theeve nt of an accident

1 QR code for accessing there scue card →

32

2 Safetyve sts →

549

3 Fire extinguisher →

550

4 Buttons forth e SOS emer gency call sy stem

and breakdown assis tance →

480

5 Haza rdwa rning lights →

15 9

6 Tocheck and top up operating fluids →

597

St arting assis tance →

561 7

Totow- start and tow aw ay →

563

8 Flat tyre →

550

9 Totow- start and tow aw ay →

563

A Fuelfiller flap with instruction labels for tyre

pressu re, fuel type and QR code for accessing

th ere scue card →

212

B TIREFIT kit →

553

C Warning triangle →

549

D First-aid kit (so ftsided) →

550 At

aglance – Emer gencies and breakdowns 19

Page 554 of 729

Ty

res without run-flat characteristics: #

Do not drive on with a flat tyre. #

Chan getheflat tyre immediately with

an emer gency spa rewheel or spare

wheel. Alternativel y,consult a qualified

specialist workshop.

Ty res with run-flat characteristics: #

Obse rveth e information and warning

no tes on MOExtended tyres (run-flat

tyres). In

theeve nt of a flat tyre, thefo llowing options

are available depending on your vehicle's equip‐

ment:

R Vehicles with MOExtended tyres: it is pos‐

sible tocontinue the journey for a short

period of time. Make sure you obse rvethe

no tes on MOExtended tyres (run-flat tyres)

(/ page 551).

R Vehicles with a TIREFIT kit: you can repair

th e tyre so that it is possible tocontinue the

jou rney for a short period of time. Todo this,

use the TIREFIT kit (/ page 553). R

Vehicles with Mercedes me connect: you

can make a call for breakdown assi stance via

th eov erhead control panel in the case of a

breakdown (/ page477).

R Allvehicles: change the wheel

(/ page 584).

% The emer gency spa rewheel is only available

in cer tain countries. Note

s on MOExtended tyres (run-flat tyres) &

WARNING Risk of accident when driving

in eme rgency mode

When driving in emer gency mode, the han‐

dling characteristics are impaired. e.g. when

cornering, when accelerating stronglyand

when braking. #

Do not exceed the permissible maxi‐

mum speed. #

Avoid any abrupt steering and driving

maneuvers as well as driving over

obs tacles (curbs, pot holes, off-road). This applies, in pa

rticular, toa loaded

ve hicle. #

Stop driving in the emer gency mode if

yo u notice:

R banging noise

R vehicle vibration

R smoke which smells like rubber

R continuous ESP ®

inter vention

R crac ksin tire side walls #

After driving in emergency mode ha ve

th erims checkedby aqu alified special‐

ist workshop with rega rd totheir fur ther

use. #

The defective tire must be replaced in

eve rycase. Wi

th MOExtended tyres (run-flat tyres), you can

continue todrive your vehicle even if there is a

tot al loss of pressure in one or more tyres. How‐

eve r,th e tyre af fected must not show any clearly

visible damage. Breakdown assis

tance 551

Page 555 of 729

Yo

u can recognise MOExtended tyres bythe

MOExtended marking which appears on the side

wa ll of the tyre.

Ve hicles with tyre pressure loss warning sys‐

te m: MOExtended tyres may only be used in

conjunction wi than activated tyre pressure loss

wa rning sy stem.

Ve hicles with tyre pressure monitoring sys‐

te m: MOExtended tyres may only be used in

conjunction wi than activated tyre pressure mon‐

itoring sy stem.

If a pressure loss warning message appears in

th e multifunction displa y,proceed as follo ws:

R Check the tyre for dama ge.

R If driving on, obser vethefo llowing no tes. Driving distance possible in emer

gency

mode af ter the pressure loss warning: Load condition Driving distance pos‐

sible in emergency

mode

Pa rtially laden 80 km

Fu lly laden 30 km The driving dis

tance possible in emergency

mode may vary depending on the driving style.

Obser vethe maximum permissible speed of

80 km/h.

If a tyre has gone flat and cannot be replaced

with an MOEx tended tyre, you can use a stand‐

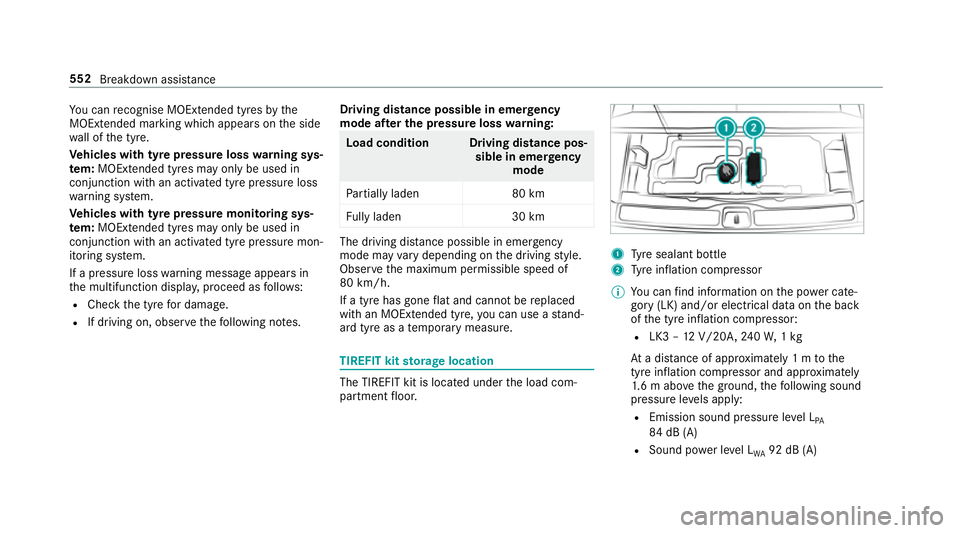

ard tyre as a temp orary measure. TIREFIT kit

storage location The TIREFIT kit is located under

the load com‐

partment floor. 1

Tyre sealant bottle

2 Tyre inflation compressor

% You can find information on the po wer cate‐

gory (LK) and/or electrical data on the back

of the tyre inflation compressor:

R LK3 – 12V/20A, 240W, 1kg

At a dis tance of appr oximately 1 m tothe

tyre inflation compressor and appr oximately

1. 6 m abo vethe ground, thefo llowing sound

pressure le vels apply:

R Emission sound pressure le vel L

PA

84 dB (A)

R Sound po wer le vel L

WA 92 dB (A) 552

Breakd own assi stance

Page 556 of 729

The tyre inflation compressor is mainte‐

nance-free. If

there is a malfunction, please

conta ct aqualified specialist workshop. Using

the TIREFIT kit Re

quirements:

R Tyre sealant bottle

R TIREFIT sticker

R Tyre inflation compressor

R Gloves (depending on theve hicle equipment)

TIREFIT kit storage location: (/ page 552)

Yo u can use TIREFIT tyre sealant toseal per fora‐

tion dama geof up to4 mm, particular lythose in

th e tyre conta ct surface. You can use TIREFIT in

outside temp eratures down to-20 °C. &

WARNING Risk of accident when using

tyre sealant

In thefo llowing situations in particular, the

tyre sealant is unable toprov ide suf ficient breakdown assis

tance, as it is unable toseal

th e tyre properly:

R there are cuts or punctures in the tyre

lar gerth an those pr eviously mentioned.

R the wheel rim is dama ged.

R you ha vedriven at very low tyre pres‐

sures or on a flat tyre. #

Do not drive on. #

Consult a qualified specialist workshop. &

WARNING Risk of inju ryand poisoning

from tyre sealant

Ty re sealant is hazardous tohealth and cau‐

ses ir rita tion. Do not allow it tocome into

contact wi thyour skin, eyes or clo thing, and

do not swallow it. Do not inhale any vapours.

Ke ep the tyre sealant away from children.

Obser vethefo llowing if you come into con‐

ta ct wi th the tyre sealant: #

Rinse off the tyre sealant from your skin

using water immediatel y. #

If tyre sealant gets into your eyes, thor‐

oughly rinse them using clean water

immediatel y. #

If tyre sealant has been swallowe d,

th oroughly rinse out your mouth imme‐

diately and drink plenty of water.Do not

induce vomiting and seek medical

attention immediately. #

Change out of clo thing which has come

into con tact wi thtyre sealant immedi‐

ately. #

If an alle rgic reaction occurs, seek med‐

ical attention immediatel y. *

NO

TEOverheating due tothe tyre infla‐

tion compressor running too long #

Do not runth e tyre inflation compres‐

sor for longer than ten minu tes without

inter ruption. Comply with

the manufacturer's saf ety no tes on

th est icke r on the tyre inflation compressor. Breakdown assis

tance 553

Page 557 of 729

Ha

ve the tyre sealant bottle replaced in a quali‐

fi ed specialist workshop every five years. #

Do not remo veany fore ign objects which

ha ve entered the tyre. #

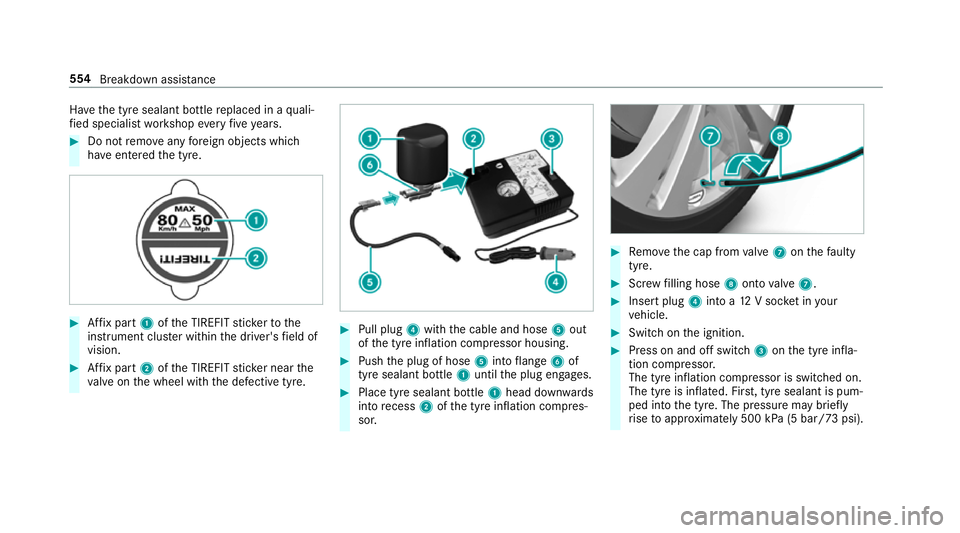

Affix pa rt1 ofthe TIREFIT sticke rto the

instrument clus ter within the driver's field of

vision. #

Affix pa rt2 ofthe TIREFIT sticke r near the

va lve on the wheel with the defective tyre. #

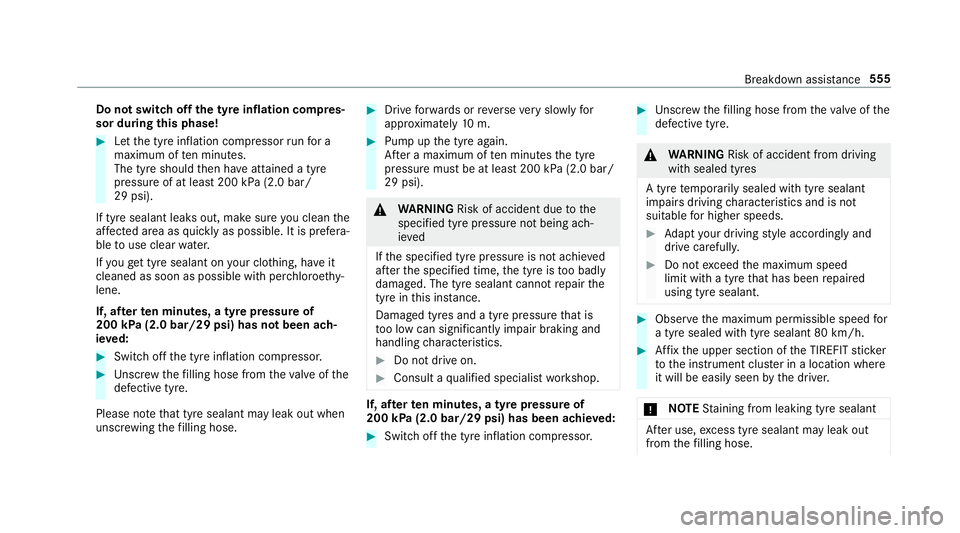

Pull plug 4with the cable and hose 5out

of the tyre inflation compressor housing. #

Push the plug of hose 5into flange 6of

tyre sealant bottle 1until the plug engages. #

Place tyre sealant bottle 1head down wards

into recess 2ofthe tyre inflation compres‐

sor. #

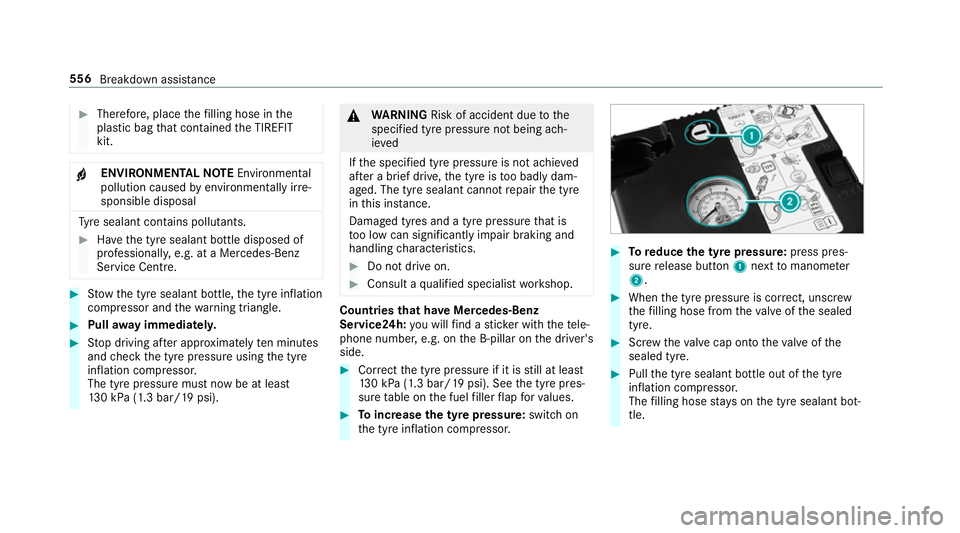

Remo vethe cap from valve 7 onthefa ulty

tyre. #

Screw filling hose 8onto valve 7. #

Insert plug 4into a 12V soc ket in your

ve hicle. #

Switch on the ignition. #

Press on and off switch 3onthe tyre infla‐

tion compressor.

The tyre inflation compressor is switched on.

The tyre is inflated. Fir st, tyre sealant is pum‐

ped into the tyre. The pressure may brief ly

ri se toappr oximately 500 kPa (5 bar/73 psi). 554

Breakdown assis tance

Page 558 of 729

Do not swit

choff the ty reinflation compres‐

sor during this phase! #

Let the tyre inflation compressor runfo r a

maximum of ten minu tes.

The tyre should then ha veattained a tyre

pressure of at least 200 kPa (2.0 bar/

29 psi).

If tyre sealant leaks out, make sure you clean the

af fected area as quickly as possible. It is prefera‐

ble touse clear water.

If yo uge t tyre sealant on your clo thing, ha veit

cleaned as soon as possible with per chloroe thy‐

lene.

If, af terte n minutes, a tyre pressure of

200 kPa (2.0 bar/29 psi) has not been ach‐

ie ve d: #

Switch off the tyre inflation compressor. #

Unscr ew thefilling hose from theva lve of the

defective tyre.

Please no tethat tyre sealant may leak out when

unscr ewing thefilling hose. #

Drive forw ards or reve rseve ry slowly for

appr oximately 10m. #

Pump up the tyre again.

Af ter a maximum of ten minu testh e tyre

pressure must be at least 200 kPa (2.0 bar/

29 psi). &

WARNING Risk of accident due tothe

specified tyre pressure not being ach‐

ie ved

If th e specified tyre pressure is not achie ved

af te rth e specified time, the tyre is too badly

damaged. The tyre sealant cannot repair the

tyre in this ins tance.

Dama ged tyres and a tyre pressure that is

to o low can significantly impair braking and

handling characteristics. #

Do not drive on. #

Consult a qualified specialist workshop. If, af

terte n minutes, a tyre pressure of

200 kPa (2.0 bar/29 psi) has been achie ved: #

Switch off the tyre inflation compressor. #

Unscr ew thefilling hose from theva lve of the

defective tyre. &

WARNING Risk of accident from driving

wi th sealed tyres

A tyre temp orarily sealed with tyre sealant

impairs driving characteristics and is not

suitable for higher speeds. #

Adapt your driving style according lyand

drive carefull y. #

Do not exceed the maximum speed

limit with a tyre that has been repaired

using tyre sealant. #

Obser vethe maximum permissible speed for

a tyre sealed with tyre sealant 80 km/h. #

Affix th e upper section of the TIREFIT sticker

to the instrument clus ter in a location where

it will be easi lyseen bythe driver.

* NO

TEStaining from leaking tyre sealant Af

ter use, excess tyre sealant may leak out

from thefilling hose. Breakdown assis

tance 555

Page 559 of 729

#

Therefore, place thefilling hose in the

plastic bag that con tained the TIREFIT

kit. +

ENVIRONMEN

TALNO TEEnvironmental

pollution caused byenvironmen tally ir re‐

sponsible disposal Ty

re sealant contains polluta nts.#

Have the tyre sealant bottle disposed of

professionall y,e.g. at a Mercedes-Benz

Service Centre. #

Stow th e tyre sealant bottle, the tyre inflation

compressor and thewa rning triangle. #

Pull away immediatel y. #

Stop driving af ter appro ximately ten minu tes

and check the tyre pressure using the tyre

inflation compressor.

The tyre pressure must now be at least

13 0 kPa (1.3 bar/19 psi). &

WARNING Risk of accident due tothe

specified tyre pressure not being ach‐

ie ved

If th e specified tyre pressure is not achie ved

af te r a brief drive, the tyre is too badly dam‐

aged. The tyre sealant cannot repair the tyre

in this ins tance.

Dama ged tyres and a tyre pressure that is

to o low can significantly impair braking and

handling characteristics. #

Do not drive on. #

Consult a qualified specialist workshop. Countries

that ha veMercedes-Benz

Service24h: you will find a sticke r with thete le‐

phone number, e.g. on the B‑pillar on the driver's

side. #

Cor rect the tyre pressure if it is still at least

13 0 kPa (1.3 bar/19 psi). See the tyre pres‐

sure table on the fuel filler flap forva lues. #

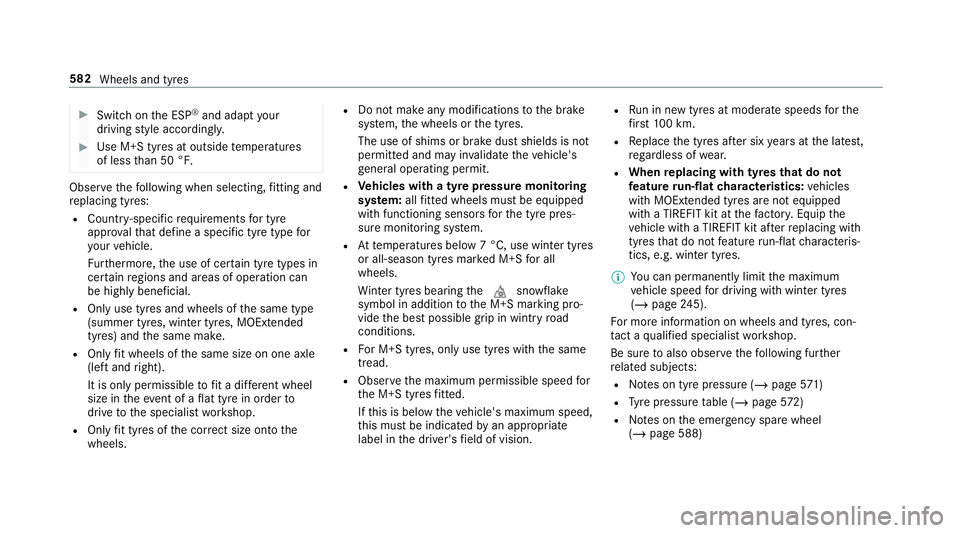

Toincrease the ty repressure: switch on

th e tyre inflation compressor. #

Toreduce the tyre pressure: press pres‐

su re re lease button 1next tomanome ter

2 . #

When the tyre pressure is cor rect, unscr ew

th efilling hose from theva lve of the sealed

tyre. #

Screw theva lve cap onto theva lve of the

sealed tyre. #

Pull the tyre sealant bottle out of the tyre

inflation compressor.

The filling hose stay s on the tyre sealant bot‐

tle. 556

Breakdown assis tance

Page 585 of 729

#

Switch on the ESP ®

and adapt your

driving style accordingly. #

Use M+S tyres at outside temp eratures

of less than 50 °F. Obse

rveth efo llowing when selecting, fitting and

re placing tyres:

R Countr y-specific requirements for tyre

appro valth at define a specific tyre type for

yo ur vehicle.

Fu rthermore, the use of cer tain tyre types in

cer tain regions and areas of operation can

be highly beneficial.

R Only use tyres and wheels of the same type

(summer tyres, winter tyres, MOEx tended

tyres) and the same make.

R Only fit wheels of the same size on one axle

(left and right).

It is only permissible tofit a di fferent wheel

size in theeve nt of a flat tyre in order to

drive tothe specialist workshop.

R Only fit tyres of the cor rect size onto the

wheels. R

Do not make any modifications tothe brake

sy stem, the wheels or the tyres.

The use of shims or brake dust shields is not

permitted and may in validate theve hicle's

ge neral operating pe rmit.

R Vehicles with a tyre pressure monitoring

sy stem: allfitted wheels mu stbe equipped

with functioning sensors forth e tyre pres‐

sure monitoring sy stem.

R Attemp eratures below 7 °C, use winter tyres

or all-season tyres mar ked M+S for all

wheels.

Wi nter tyres bearing thei snowflake

symbol in addition tothe M+S marking pro‐

vide the best possible grip in wintry road

conditions.

R For M+S tyres, only use tyres with the same

tread.

R Obser vethe maximum permissible speed for

th e M+S tyres fitted.

If th is is below theve hicle's maximum speed,

th is must be indicated byan appropriate

label in the driver's field of vision. R

Run in new tyres at moderate speeds forthe

fi rs t10 0 km.

R Replace the tyres af ter six years at the latest,

re ga rdless of wear.

R When replacing with tyres that do not

fe ature run-flat characteristics: vehicles

with MOExtended tyres are not equipped

with a TIREFIT kit at thefa ctor y.Equip the

ve hicle with a TIREFIT kit af terre placing with

tyres that do not feature run-flat characteris‐

tics, e.g. winter tyres.

% You can permanently limit the maximum

ve hicle speed for driving with winter tyres

(/ page 245).

Fo r more information on wheels and tyres, con‐

ta ct a qualified specialist workshop.

Be sure toalso obse rveth efo llowing fur ther

re lated subjects:

R Notes on tyre pressure (/ page571)

R Tyre pressure table (/ page572)

R Notes on the emer gency spa rewheel

(/ page 588) 582

Wheels and tyres

Page 699 of 729

EQ Boost

Operating saf ety .................................... 24

ERA-GLONASS test mode

St arting/ending .................................. 485

ESC (Elect ronic Stability Control)

see ESP ®

(Electronic Stability Prog ram)

ESP ®

Crosswind Assist ................................. 234

Tr ailer stabilisation .............................. 234

ESP ®

(Elect ronic Stability Prog ram) ...... 230

Ac tivating/deactivating ...................... .234

Fu nction/no tes ................................... 230

EU general operating permit number ....595

Exhaust pipes (Care) ...............................545

Exterior lighting Care .................................................... 545

Exterior lighting see Lights

External device Locking (child saf ety lock) .................. .394 F

Fa tigue de tection

see ATTENTION ASSIST

Fa ult message

see Displ aymessa ge

Favo urites

Ad ding .................................................3 73

Ad ding a destination ............................ 414

Calling up ............................................ 373

Del eting .............................................. .374

Home address ...................................... 414

Moving .................................................3 73

Overview ............................................. 372

Re naming ............................................ 373

Wo rkaddress ...................................... .414

Fi ll le vel

Ad Blue ®

............................................... 325

Fi lling station sear ch

St arting automatic sear ch................... 422

Switching au tomatic search on/off ..... 422

Fire extinguisher ..................................... 550

Fi rs t-aid kit (soft sided) .......................... 550 Flacon

Inse rting/ removing ............................. 180

Flat towing

see Tow- bar sy stem

Flat tyre ....................................................5 50

MOExtended tyres ............................... 551

No tes .................................................. 550

TIREFIT kit ...........................................5 53

Wheel change ...................................... 584

Floor mats ................................................ 15 6

Fo g light (extended range) ......................1 61

Fo il co vering

Ra dar sensors .....................................2 28

Fr ag rance

see Fragrance sy stem

Fr ag rance sy stem .................................... 180

Inserting/removing theflacon ............ .180

Setting ................................................. 180

Fr ee driving mode

St arting .............................................. .278

Fr ee software ............................................ 35696

Index

Page 723 of 729

Showing/hiding full screen ..................

51 0

Te lete xt overview ................................. 514

Vo ice commands (LINGU ATRO NIC) .....3 43

TV channel

Ac tivating/deactivating channel fix ..... 512

Channel fix ........................................... 511

Channel list overview .......................... .512

Countr y-specific character set ............ .512

EPG (electronic prog ramme guide) ....... 511

Overview of favo urites ........................ .512

Selecting from thech annel list ............ 51 0

Selecting from the control menu ......... 51 0

Selecting from thefa vo urites .............. .511

Selecting in the bac kground ................ .511

St oring .................................................5 12

Tw o phone mode

see Second telephone

Tw o-w ayradios

Fr equencies ......................................... 594

No tes on ins tallation .......................... .593

Tr ansmission output (maximum) ........ .594

Ty re inflation compressor

see TIREFIT kit Ty

re pressure ........................................... 572

Checking (tyre pressure monitoring

sy stem) ................................................ 573

No tes ................................................... 571

Re starting the tyre pressure loss

wa rning sy stem ................................... 579

Re starting the tyre pressure monitor‐

ing sy stem ...........................................5 74

TIREFIT kit ...........................................5 53

Ty re pressure loss warning sy stem

(function) ............................................. 578

Ty re pressure monitoring sy stem

(function) ............................................. 573

Ty re pressure table .............................. 572

Ty re pressure loss warning sy stem

Fu nction .............................................. 578

Re starting ............................................ 579

Ty re pressure moni toring sy stem

Checking the tyre pressure .................. 573

Checking the tyre temp erature ............ 573

Fu nction .............................................. 573

Re starting ............................................ 574

Te ch nical da ta..................................... 575

Ty re pressure table ................................. 572Ty

re temp erature

Checking (tyre pressure monitoring

sy stem) ................................................ 573

Ty re pressure monitoring sy stem

(function) ............................................. 573

Ty re tread ................................................. 570

Ty re-change tool kit

Overview ............................................ .583

Ty res

Checking ............................................ .570

Che cking the tyre pressure (tyre

pressure monitoring sy stem) ............... 573

Fitting .................................................. 587

Flat tyre ............................................... 550

Inter changing ...................................... 583

MOExtended tyres .............................. .551

No ise .................................................. .570

No tes on fitting ................................... 580

Re moving ............................................ 587

Re placing .................................... 580, 584

Re starting the tyre pressure loss

wa rning sy stem ................................... 579

Re starting the tyre pressure monitor‐

ing sy stem ...........................................5 74

Selection ............................................. 580 720

Index