MERCEDES-BENZ GLS SUV 2020 Owner's Manual

Manufacturer: MERCEDES-BENZ, Model Year: 2020, Model line: GLS SUV, Model: MERCEDES-BENZ GLS SUV 2020Pages: 682, PDF Size: 53.88 MB

Page 541 of 682

Re

mo ving and inst alli ng hub caps Re

quirement s:

R The vehicle isprepar edfora whee lch ang e

(/ page53 8).

Pla stic hub cap #

Toremo ve:tur nth ecent ercoverof thehub

cap count er-cloc kwise andremo vethehub

cap. #

Toins tall: makesur eth at thecent ercover

of thehub capistur ned count er-cloc kwise. #

Position thehub capand turnth ecent er

co vercloc kwise untilthehub capengages

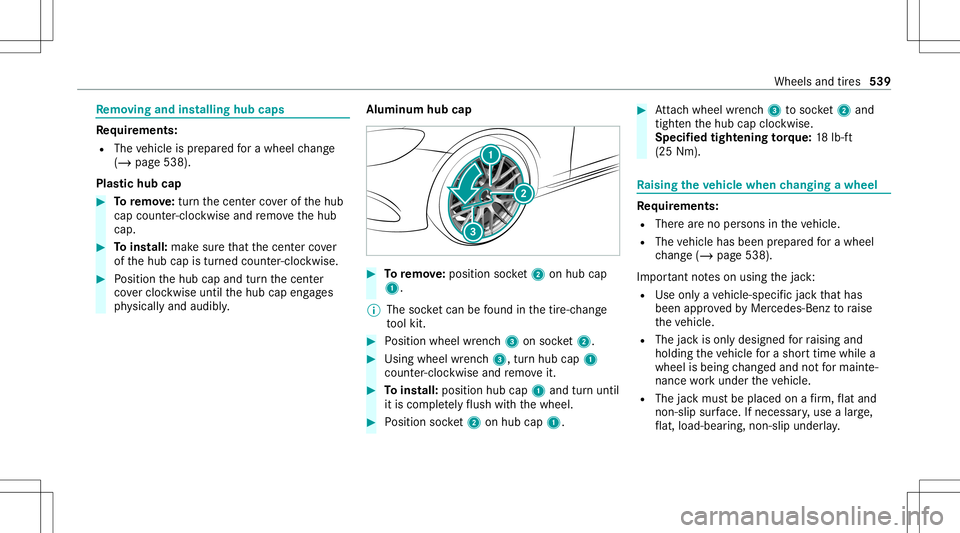

ph ysicall yand audibly . Alum

inum hubcap #

Toremo ve:po sitio nsoc ket2 onhubcap

1.

% The socketcan befound inthetir e-c hang e

to ol kit. #

Position wheel wrenc h3 onsoc ket2. #

Usingwheelwr enc h3, turnhu bcap 1

cou nter-clo ckwise andremo veit. #

Toins tall: posit ionhub cap1and turnunt il

it is com pletely flush withth ewheel. #

Position socket2 onhubcap 1. #

Attach wheel wrenc h3 tosoc ket2 and

tig hten thehub capclockwise.

Specif iedtight ening torq ue: 18lb-f t

(25 Nm). Ra

ising theve hicl ewhe nch angi ngawhe el Re

quirement s:

R Ther ear eno per sons intheve hicle.

R The vehicle hasbeen prepar edfora whee l

ch ang e(/ page53 8).

Im por tant noteson using thejac k:

R Use onlya ve hicle-specif icjac kth at has

been approvedby Mer cedes-Ben zto raise

th eve hicle.

R The jackis onl ydesigned forra ising and

holdin gth eve hicle fora shor ttime whilea

whee lis being chang edand notfo rmaint e‐

nance workund ertheve hicle.

R The jackmus tbe placed onafirm ,fl at and

no n-slip surface. Ifneces sary,use alar ge,

fl at, load- bearing,no n-slip unde rlay . Wheels

andtires 539

Page 542 of 682

R

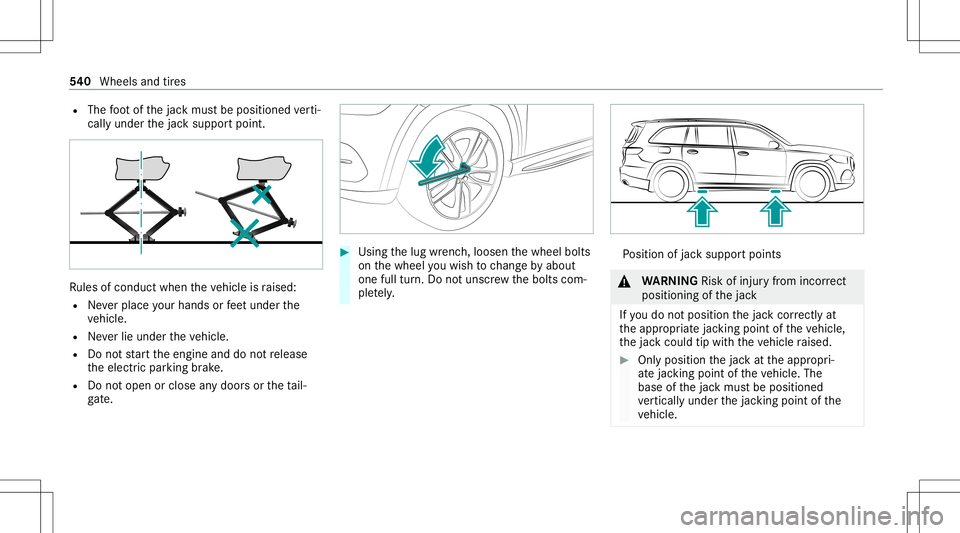

The foot ofthejac kmus tbe position edverti‐

call yunder thejac ksuppor tpoint . Ru

les ofcon duct when theve hicle israised:

R Neverpla ceyour han dsorfeet und erthe

ve hicle.

R Neverlie under theve hicle.

R Donotst ar tth eengine anddonotre lease

th eelectr icpar king brak e.

R Donotopen orclose anydoor sor theta il‐

ga te. #

Using thelug wrenc h,loosen thewheel bolts

on thewheel youwish tochang eby about

on efull turn.Do notuns crew thebolts com‐

ple tely. Po

sition ofjac ksuppor tpoints &

WARNIN GRisk ofinju ryfrom incor rect

pos itioning ofthejac k

If yo udo notposi tionth ejac kcor rectl yat

th eappr opriatejac king point oftheve hicle,

th ejac kcould tipwithth eve hicle raised. #

Onlyposit ionthejac kat theappr opri‐

at ejac king point oftheve hicle. The

base ofthejac kmus tbe position ed

ve rticall yunder thejac king point ofthe

ve hicle. 54

0

Wheels andtires

Page 543 of 682

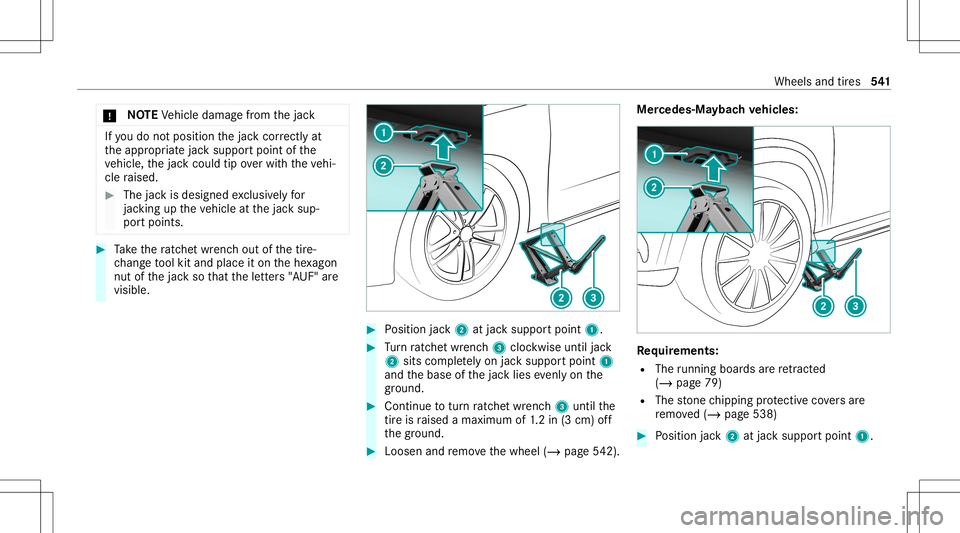

*

NO

TEVehicle damag efrom thejac k If

yo udo notposi tionth ejac kcor rectl yat

th eappr opriatejac ksuppor tpoint ofthe

ve hicle, thejac kcould tipove rwit hth eve hi‐

cle raised. #

The jackis design edexclu sively for

jac king uptheve hicle atthejac ksup‐

por tpoint s. #

Take thera tche twrenc hou tof thetir e-

ch ang eto ol kit and place iton thehe xagon

nut ofthejac kso that theletter s"A UF" are

visible. #

Position jack2 atjac ksuppor tpoint 1. #

Turn ratche twr enc h3 clockwise untiljac k

2 sitscom pletely on jacksuppor tpoint 1

and thebase ofthejac klies evenlyon the

gr ou nd . #

Con tinue totur nra tche twr enc h3 unti lth e

tir eis raised amaxim umof1.2 in (3 cm) off

th egr ound. #

Loosen andremo vethewheel (/page54 2). Mer

cedes-Ma ybachve hicl es: Re

quirement s:

R The running boards arere tract ed

(/ page 79)

R The stone chipping protect ive co vers are

re mo ved(/ page538 ) #

Position jack2 atjac ksuppor tpoint 1. Wheels

andtires 54

1

Page 544 of 682

#

Turn ratche twr enc h3 clockwise untiljac k

2 sitscom pletely on jacksuppor tpoint 1

and thebase ofthejac klies evenlyon the

gr ou nd . #

Con tinue totur nra tche twr enc h3 unti lth e

tir eis raised amaxim umof1.2 in (3 cm) off

th egr ound. #

Loosen andremo vethewheel (/page54 2). Re

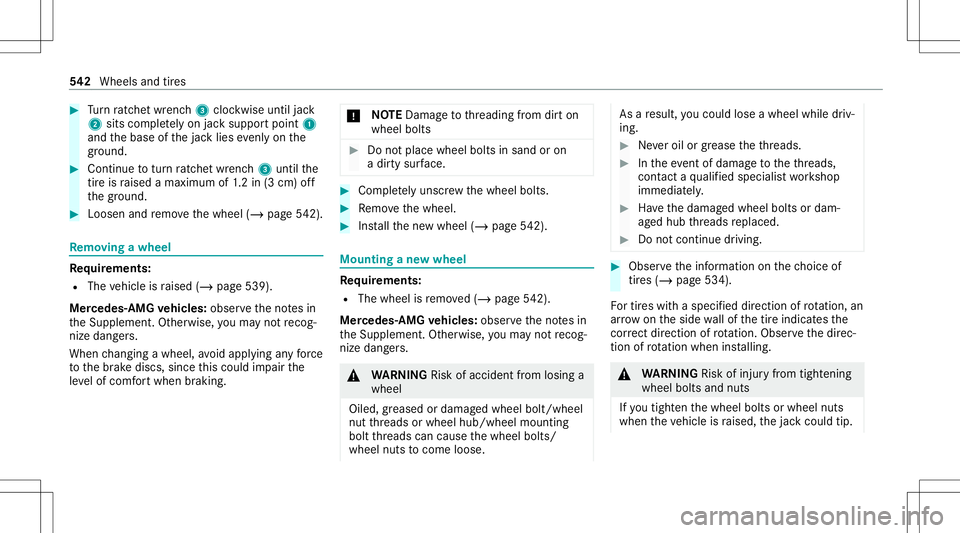

mo ving awh eel Re

quirement s:

R The vehicle israised (/page539).

Mer cedes- AMGvehicl es:obse rveth eno tesin

th eSupplement .Ot her wise, youma yno tre cog‐

nize dangers.

Whe nch ang ingawheel, avoid applying anyfo rc e

to thebr ak ediscs, sincethis could impair the

le ve lof com fort when brakin g. *

NO

TEDama getothre adin gfrom dirton

wheel bolts #

Donotplace wheel boltsin san dor on

a dir tysur face. #

Comp lete ly uns crew thewheel bolts. #

Remo vethewheel. #

Installth ene wwheel (/page54 2). Mo

untin gane wwh eel Re

quirement s:

R The wheel isremo ved(/ page54 2).

Me rcedes- AMGvehicl es:obse rveth eno tesin

th eSupplement .Ot her wise, youma yno tre cog‐

nize dangers. &

WARNIN GRisk ofacci dent from losing a

whe el

Oil ed, grea sed ordamag edwhe elbol t/whe el

nut thre ads orwheel hub/wheel mounting

bolt thre ads can caus eth ewheel bolts/

wheel nutstocome loose. As

are sult, youco uld lose awheel whiledriv‐

ing . #

Neveroil orgrease theth re ads. #

Intheeve ntofdama getotheth re ads,

con tact aqu alif ied spec ialistwo rkshop

immediat ely. #

Have thedamag edwheel boltsordam‐

ag ed hub thre ads replaced. #

Donotcon tinue driving. #

Obser vetheinf ormation onthech oice of

tir es (/ page534).

Fo rtir es wit haspecif ieddirection ofrotatio n,an

ar ro w on theside wallof thetir eindicat esthe

cor rect dire ction ofrotatio n.Ob serveth edir ec‐

tion ofrotatio nwh en installing. &

WARNIN GRisk ofinju ryfrom tight ening

whee lbol tsand nuts

If yo utig hten thewheel boltsorwheel nuts

when theve hicle israised, thejac kcould tip. 54

2

Wheels andtires

Page 545 of 682

#

Onlytight enwheel boltsorwheel nuts

when theve hicle ison thegr ound. #

Besureto obser vetheins truction sand

saf etyno teson "Cha nging awheel"

(/ page534). #

Forsaf etyre ason s,on lyuse wheel bolts

whic hha ve been approvedby Mer cedes-

Benz andforth ewheel inqu estion .

* NO

TEDama getopaintw orkof thewheel

ri m when screwing onthefirs twh eelbo lt If

th ewheel hastoomuc hpla ywhen screw‐

ing inthefirs twh eelbo lt, thewheel rim pai nt

can bedama ged. #

Press thewheel firm lyag ains tth e

wheel hubwhen screwing onthefirs t

wheel bolt. #

Tight enthewheel boltsevenlyin adi ag ona l

pa tter nin theor der indicat eduntil they are

fi ng er-tig ht. #

Ifth ecollapsible sparewheel hasbeen

ins talled, inflateth ecollapsible sparewheel

(/ page54 8). #

Lowe rth eve hicle (/page54 3). Lo

we ring theve hicl eaf te ra wh eelch ang e Re

quirement s:

R The newwheel hasbeen installed

(/ page54 2).

Obse rveth einf ormation ontirepr essur e

(/ page51 5). #

Plac eth era tche twr enc hont oth ehe xagon

nut ofthejac kso that theletter ing "AB" is

visible. #

Tolowe rthe vehicl e:tur nth era tche t

wr enc hof thejac kcount er-cloc kwise. #

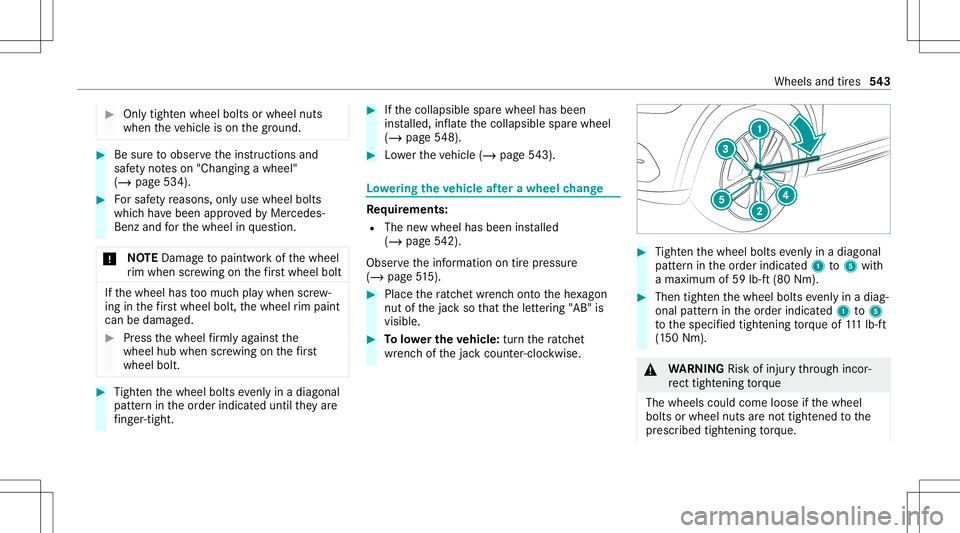

Tight enthewheel boltsevenlyin adi ag ona l

pa tter nin theor der indicat ed1 to5 with

a max imum of59 lb-ft(80 Nm). #

Then tighten thewheel boltsevenlyin adi ag ‐

ona lpa tter nin theor der indicat ed1 to5

to thespecif iedtight ening torq ue of111 lb-ft

(1 50 Nm). &

WARNIN GRisk ofinju rythro ugh incor‐

re ct tigh tening torq ue

Th ewh eelscou ldcome looseifth ewheel

bolts orwheel nutsareno ttight ened tothe

pr escr ibed tighteningto rq ue. Wh

eelsan dtir es 54

3

Page 546 of 682

#

Mak esur eth ewheel boltsorwheel

nuts aretight ened tothepr escr ibed

tight ening torq ue. #

Ifyo uar eno tsur e,do notmo vethe

ve hicle. Consult aqu alif ied spec ialist

wo rkshop andhave thetight ening tor‐

qu ech eckedimmediat ely. #

Chec kth etir epr essur eof thene wlymoun‐

te dwheel andadjus taccor dingly. #

Vehicl eswith tirepr ess urelos swa rning

sy stem: Restar tth etir epr essur eloss warn‐

ing system (/ page52 1). #

Vehicl eswith atir epr ess uremonit oring

sy stem: Restar tth etir epr essur emonit oring

sy stem (/ page520).

Ex cep tion: thene wwheel isan emer gency

spa rewheel. Emer

gency spar ewheel No

teson theemer gency spar ewheel &

WARNIN GRisk ofacci dent caused by

inc orrect whe eland tiredimensi ons

The wheelor tiresize andthetir etype ofthe

emer gency sparewheel orspar ewheel and

th ewheel tobe replaced maydif fer. Mount‐

ing anemer gency sparewheel/ sparewheel

ma yse verely im pa irth edr iving charact eris‐

tic s.

To preve nthazardous situa tions: #

Adaptyo ur drivin gst yle accor dinglyand

dr ive car efull y. #

Nevermount moreth an oneemer gency

spa rewheel orspar ewheel that dif fers

in size . #

Onlyuse anemer gency sparewheel or

spar ewheel ofadif fere nt size briefly. #

Donotsw itchof fESP ®

. #

>Ha vetheemer gency sparewheel or

spar ewheel ofadif fere nt size replaced

at thenear estqu alif ied spec ialistwo rk‐ shop.

Thenewwheel mustha ve the

cor rect dimensi ons. Ch

eckth etir epr essur eof theemer gency spare

wheel installed. Correct thepr essur eas neces ‐

sar y.

The maximum permissible speedwithan emer‐

ge ncy sparewheel installed is50 mph

(80 km/ h).

Do notins tallth eemer gency sparewheel with

sn ow chains .

Re place theemer gency sparewheel afte rsix

ye arsat thelat est,re ga rdless ofwe ar.

% Ve

hicl eswith atir epr ess uremonit oring

sy stem: Ifan emer gency sparewheel is

ins talled thetir epr essur emonit oring system

cann otfunction reliabl y.Fo ra fe w min utes

af te ran emer gency sparewheel isins talled,

th esy stem mayst ill displa yth etir epr essur e

of there mo vedwheel. Onlyre star tth esy s‐

te m again when theemer gency sparewheel

has been replaced withane wwheel. 54

4

Wheels andtires

Page 547 of 682

Be

sureto also obse rveth efo llo wing further

re lat ed subje cts:

R Noteson tirepr essur e(/ page51 5)

R Tire and Loadi ngInfo rm atio nplacar d

(/ page52 2)

R Tire pressur eta ble (/ page51 6) Re

mo ving the eme rgency sparewheel The

eme rgency sparewheel islocat edunder the

cargo compartment floor .

% Notfo rMer cedes-Ma ybachvehicles. #

Obser vetheinf ormation onmount ingtires

(/ page534). #

Open theta ilg ate. #

Open thecar gocom partmen tfloor

(/ page14 1). #

Remo vetheemer gency sparewheel bagwith

th eemer gency sparewheel. #

Open theemer gency sparewheel bagand

re mo vetheemer gency sparewheel. Inflati

ngtheemer gency spar ewheel *

NO

TEOverhea ting dueto thetir einf la‐

tion compressor running toolong #

Donotru nth etir einf lation compressor

fo rlong erthan tenminu teswit hout

int erru ption. Re

quirement s:

R Com plywithth emanuf acturer'ssafetyno tes

on thest icke rof theemer gency sparewheel

and onthetir einf lation compressor .

R Remo vethetir einf lation compressor from

th estow agespac eunde rth ecar gocom part‐

ment floor (/ page495). #

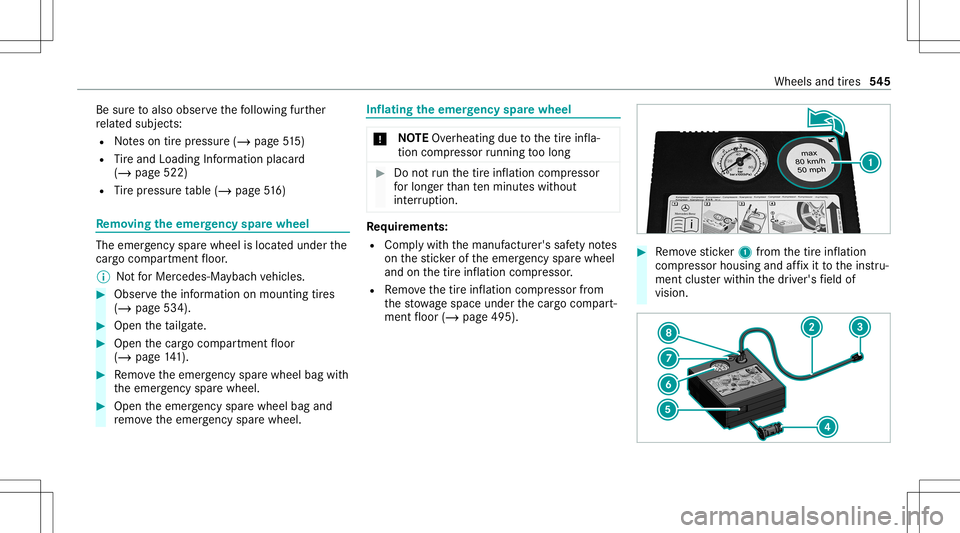

Remo vesticke r1 from thetir einf lation

com pressor housing andaffix it to theins tru‐

ment clusterwit hin thedr iver's field of

vision. Wheels

andtires 54

5

Page 548 of 682

#

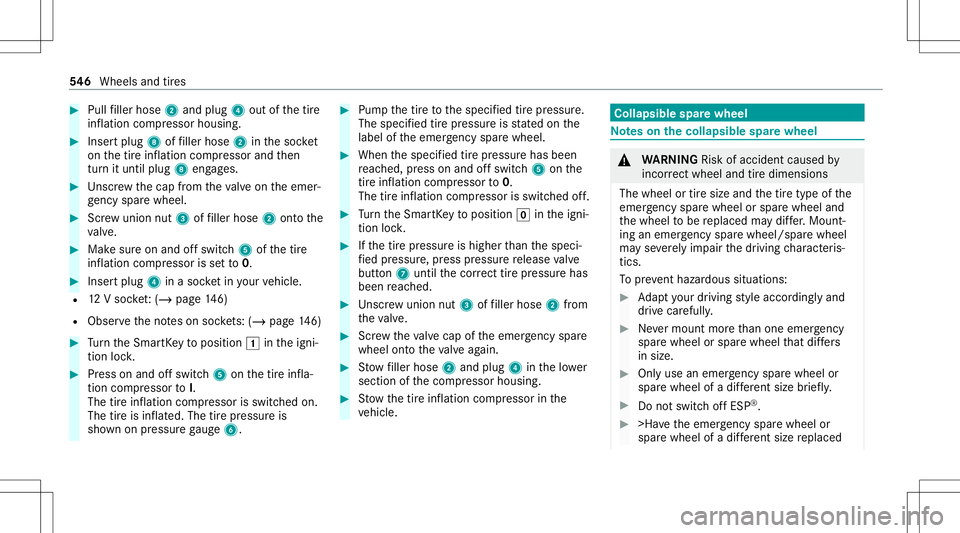

Pull filler hose 2and plug 4out ofthetir e

inf lation compressor housing. #

Inser tplug 8offiller hose 2inthesoc ket

on thetir einf lation compressor andthen

tur nit until plug8eng ages. #

Unscr ew thecap from theva lve on theemer‐

ge ncy sparewheel. #

Screw union nut3offiller hose 2ontoth e

va lve. #

Mak esur eon and offswitc h5 ofthetir e

inf lation compressor issetto 0. #

Inser tplu g4 inasoc ketin your vehicle.

R 12Vsoc ket:(/ pag e14 6)

R Obse rveth eno teson soc kets: (/ page 146) #

Turn theSmar tKey toposition 0047intheigni‐

tion lock. #

Press onand offswitc h5 onthetir einf la‐

tion compressor toI.

The tireinf lation compressor isswitc hedon.

The tireis inf lated. The tirepr essur eis

sho wnonpressur ega ug e6. #

Pum pth etir eto thespecif iedtirepr essur e.

The specif iedtirepr essur eis stat ed on the

label oftheemer gency sparewheel. #

When thespecif iedtirepr essur ehas been

re ac hed, press onand offswit ch5 onthe

tir einf latio ncom pres sor to0.

The tireinf lation compressor isswitc hedoff. #

Turn theSmar tKey toposition 005Aintheigni‐

tion lock. #

Ifth etir epr essur eis higher than thespeci‐

fi ed pressur e,press pressur ere lease valve

bu tton 7 unti lth ecor rect tirepr ess ureha s

bee nre ac hed. #

Unscr ew unio nnut 3offiller hose 2from

th eva lve. #

Screw theva lve cap oftheemer gency spare

wheel ontoth eva lve ag ain. #

Stow filler hose 2and plug 4inthelowe r

section ofthecom pressor housing. #

Stow thetir einf lation compressor inthe

ve hicle. Collapsible

sparewheel No

teson thecollap siblesparewheel &

WARNIN GRisk ofacci dent caused by

inc orrect whe eland tiredimensi ons

The wheelor tiresize andthetir etype ofthe

emer gency sparewheel orspar ewheel and

th ewheel tobe replaced maydif fer. Mount‐

ing anemer gency sparewheel/ sparewheel

ma yse verely im pa irth edr iving charact eris‐

tic s.

To preve nthazardous situa tions: #

Adaptyo ur drivin gst yle accor dinglyand

dr ive car efull y. #

Nevermount moreth an oneemer gency

spa rewheel orspar ewheel that dif fers

in size . #

Onlyuse anemer gency sparewheel or

spar ewheel ofadif fere nt size briefly. #

Donotsw itchof fESP ®

. #

>Ha vetheemer gency sparewheel or

spar ewheel ofadif fere nt size replaced 54

6

Wheels andtires

Page 549 of 682

at

thenear estqu alif ied spec ialistwo rk‐

shop. Thenewwheel mustha ve the

cor rect dimensi ons. The

collapsib lespa rewheel isan emer gency

spa rewheel whichis onl ysuit able foruse fora

limi tedper iod oftime andinare strict ed manne r

in theeve ntofaflat tire(e. g.unt ilth enear est

wo rkshop).

The tireside walls arefo lded when intranspo rt

mode. Beforeuse, thecollapsible sparewheel

has tobe inflated withth eaccom panying com‐

pr essor .

Chec kth etir epr essur eof thecollapsible spare

wheel onceins talled. Correct thepr essur eas

neces sary.

The maximum permissible speedwithacollapsi‐

ble spar ewheel installed is50 mph(8 0km/h).

Do notins tallsno wch ains onthecollapsible

spar ewheel.

Re place thecollapsible sparewheel afte rsix

ye arsat thelat est,re ga rdless ofwe ar.

% Ve

hicl eswith atir epr ess uremonit oring

sy stem: Ifacollap siblesparewheel isins tal‐ led

thetir epr essur emonit oring system can‐

no tfunc tion reliabl y.Fo ra fe w min utes afte r

an emer gency sparewheel isins talled, the

sy stem mayst ill displa yth etir epr essur eof

th ere mo vedwheel. Onlyre star tth esy stem

ag ain when thecollapsible sparewheel has

been replaced withane wwheel.

Be sureto also obse rveth efo llo wing further

re lat ed subje cts:

R Noteson tirepr essur e(/ page51 5)

R Tire pressur eta ble (/ page51 6) Re

mo ving the collapsi blespar ewh eel The

collaps ible sparewh eelis locat ed und erthe

cargo compartment floor . #

Obser vetheinf ormation onmount ingtires

(/ page534). #

Open theta ilg ate. #

Open thecar gocom partmen tfloor

(/ page14 1). #

Remo vethecollapsible sparewheel. Mer

cedes‑Ma ybachve hicl es

Wi thout refrig er ator box:The colla psiblespar e

whee lis locat edinthecollapsible sparewheel

bag onthecar gocom partmen tfloor . #

Obser vetheno teson mounting tires

(/ page534). #

Open thecar gocom partmen t. #

Detach thesecur ingstra ps. #

Unhook there tainin gspr ing hook sof the

secur ingstra ps from thebr ac kets. #

Remo vethecollapsible sparewheel bag

to ge ther wit hth ecollapsible sparewheel. #

Open thecollapsible sparewheel bagand

re mo vethecollapsible sparewheel.

Wi th refrig er ator box:The colla psiblespar e

whee lis locat edinthecollapsible sparewheel

bag inside theopen cargocom partmen tfloor . #

Obser vetheinf ormation onmount ingtires

(/ page534). #

Open thecar gocom partmen t. #

Detach thesecur ingstra ps. Wheels

andtires 54

7

Page 550 of 682

#

Unhook there tainin gspr ing hook sof the

secur ingstra ps from thebr ac kets. #

Remo vethecollapsible sparewheel bag

to ge ther wit hth ecollapsible sparewheel. #

Open thecollapsible sparewheel bagand

re mo vethecollapsible sparewheel. Inflating

thecollap siblesparewheel Re

quirement s:

R Mount thecollapsible sparewheel asdescr i‐

bed (/page54 2).

R Remo vethetir einf lation compressor from

th estow agespac eunde rth etrunk floor

(/ page495).

* NO

TEDama getothecollapsible spare

wheel whenlowe ring theve hicle Lo

we ring theve hicle without prev iousl y

inf latin gth ecollapsible sparewheel can

damag eits rim. #

Inflateth ecollapsible sparewheel using

th etir einf lation compressor before

lo we ring theve hicle. *

NO

TEOverhea ting dueto thetir einf la‐

tion compressor running toolong #

Donotru nth etir einf lation compressor

fo rlong erthan tenminu teswit hout

int erru ption. #

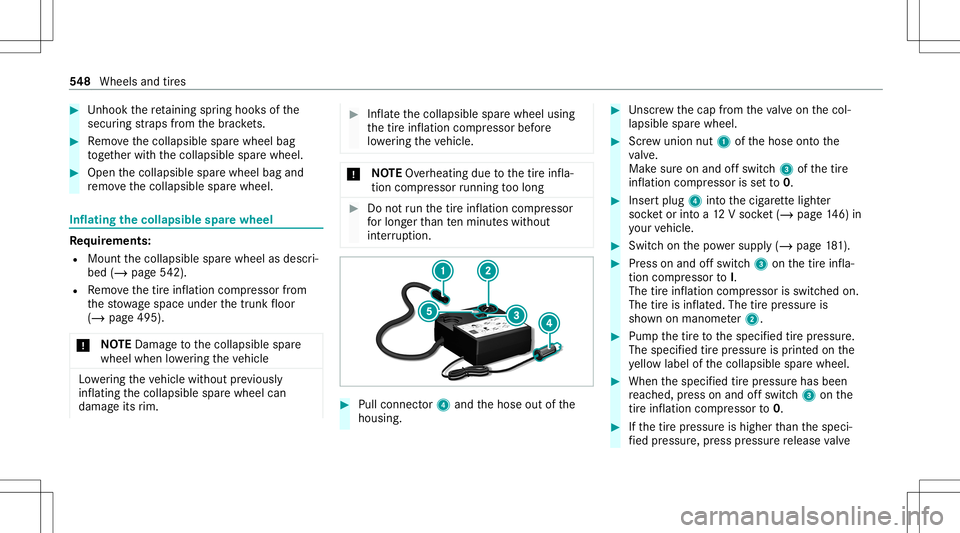

Pull connector4 and thehose outofthe

housing. #

Unscr ew thecap from theva lve on thecol‐

lapsible sparewheel. #

Screw unio nnut 1ofthehose ontoth e

va lve.

Mak esur eon and offswitc h3 ofthetir e

inf lation compressor issetto 0. #

Inser tplu g4 intoth ecig arette light er

soc ketor intoa12 Vsoc ket(/ page 146) in

yo ur vehicle. #

Switc hon thepo we rsupp ly(/ pag e18 1). #

Press onand offswi tch3 onthetir einf la‐

tion compressor toI.

The tireinf lation compressor isswitc hedon.

The tireis inf lated. The tirepr essur eis

sho wnonmanome ter2. #

Pum pth etir eto thespecif iedtirepr essur e.

The specif iedtirepr essur eis print ed on the

ye llo wlabel ofthecollapsible sparewheel. #

When thespecif iedtirepr essur ehas been

re ac hed, press onand offswit ch3 onthe

tir einf latio ncom pres sor to0. #

Ifth etir epr essur eis higher than thespeci‐

fi ed pressur e,press pressur ere lease valve 54

8

Wheels andtires