Tail MERCEDES-BENZ M-Class 2015 W166 Service Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2015, Model line: M-Class, Model: MERCEDES-BENZ M-Class 2015 W166Pages: 466, PDF Size: 8.92 MB

Page 417 of 466

Step 3

Example 1 Example 2 Example 3

Permissible load

(maximum gross vehi-

cle weight rating from

the Tire and Loading

Information placard

minus the gross

weight of all occu-

pants) 1500 lbs (680 kg)

00F8750 lbs (340 kg) =

750 lbs (340 kg) 1500 lbs (680 kg)

00F8540 lbs (245 kg)

=960 lbs (435 kg) 1500 lbs (680 kg)

00F8150 lbs (68 kg) =

1350 lbs (612 kg)

Vehicle identification plate

Even if you have calculated the total cargo

carefully, you should still make sure that the

gross vehicle weight rating and the gross axle weight rating are not exceeded. Details can

be found on the vehicle identification plate on the B-pillar on the driver's side of the vehicle

(Y page 412).

Permissible gross vehicle weight: the

gross weight of the vehicle, all passengers,

load and trailer load/noseweight (if applica-

ble) must not exceed the permissible gross

vehicle weight.

Gross axle weight rating: the maximum per-

missible weight that can be carried by one

axle (front or rear axle).

To ensure that your vehicle does not exceed

the maximum permissible values (gross vehi-

cle weight and maximum gross axle weight

rating), have your loaded vehicle (including

driver, occupants, cargo, and full trailer load if applicable) weighed on a suitable vehicle

weighbridge. Trailer load/noseweight

The trailer load/noseweight affects the gross

weight of the vehicle. If a trailer is attached,

the trailer load/noseweight is included in the

load along with occupants and luggage. The

trailer load/noseweight is usually approx-

imately 8% of the gross weight of the trailer

and its cargo. All about wheels and tires

Uniform Tire Quality Grading Stand-

ards

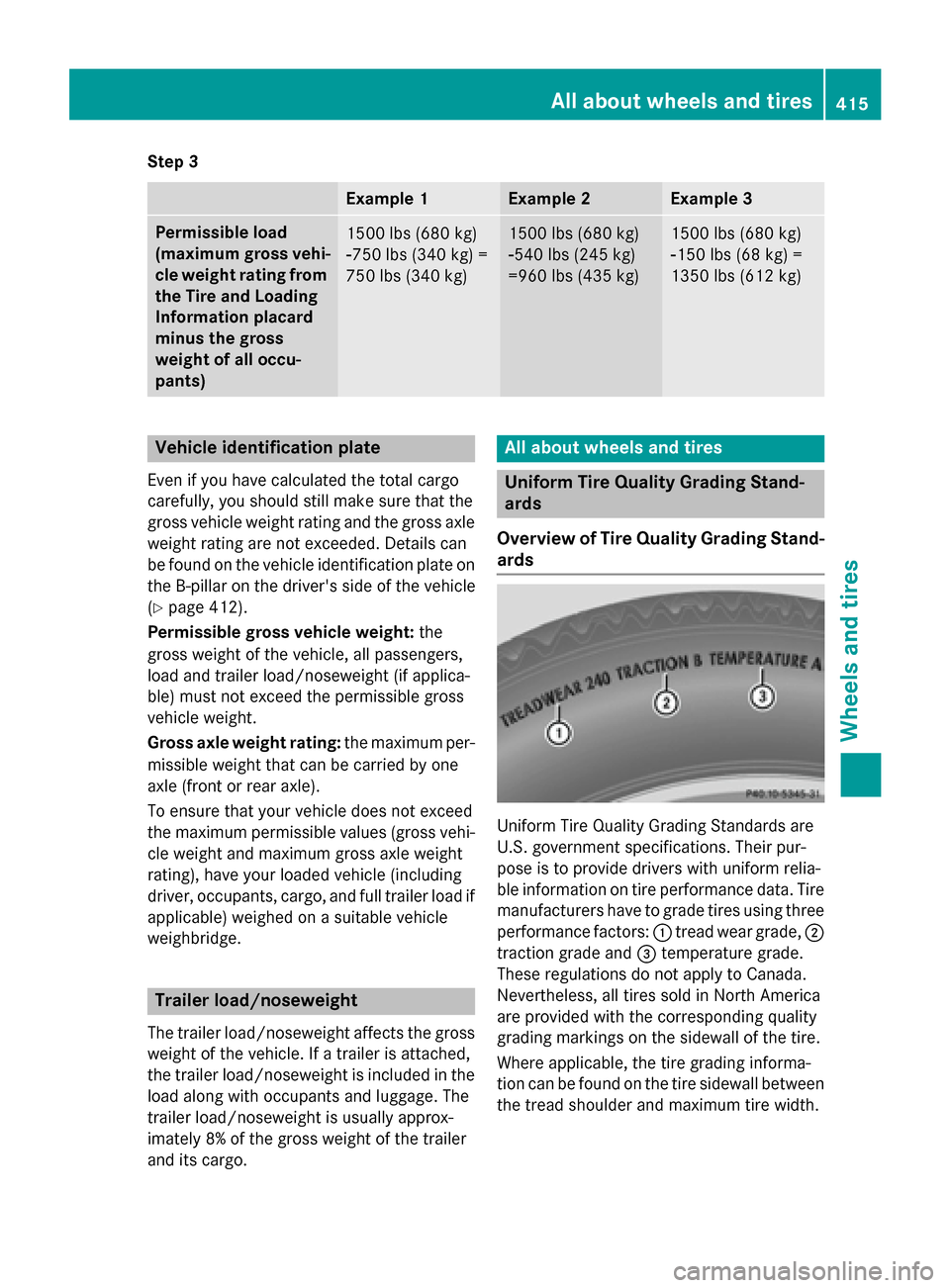

Overview of Tire Quality Grading Stand- ards Uniform Tire Quality Grading Standards are

U.S. government specifications. Their pur-

pose is to provide drivers with uniform relia-

ble information on tire performance data. Tire

manufacturers have to grade tires using three

performance factors: 0043tread wear grade, 0044

traction grade and 0087temperature grade.

These regulations do not apply to Canada.

Nevertheless, all tires sold in North America

are provided with the corresponding quality

grading markings on the sidewall of the tire.

Where applicable, the tire grading informa-

tion can be found on the tire sidewall between

the tread shoulder and maximum tire width. All about wheels and tires

415Wheels and tires Z

Page 422 of 466

ble load can be found on the vehicle's Tire and

Loading Information placard on the B-pillar on

the driver's side (Y page 412).

i The actual values for tires are vehicle-

specific and may deviate from the values in

the illustration.

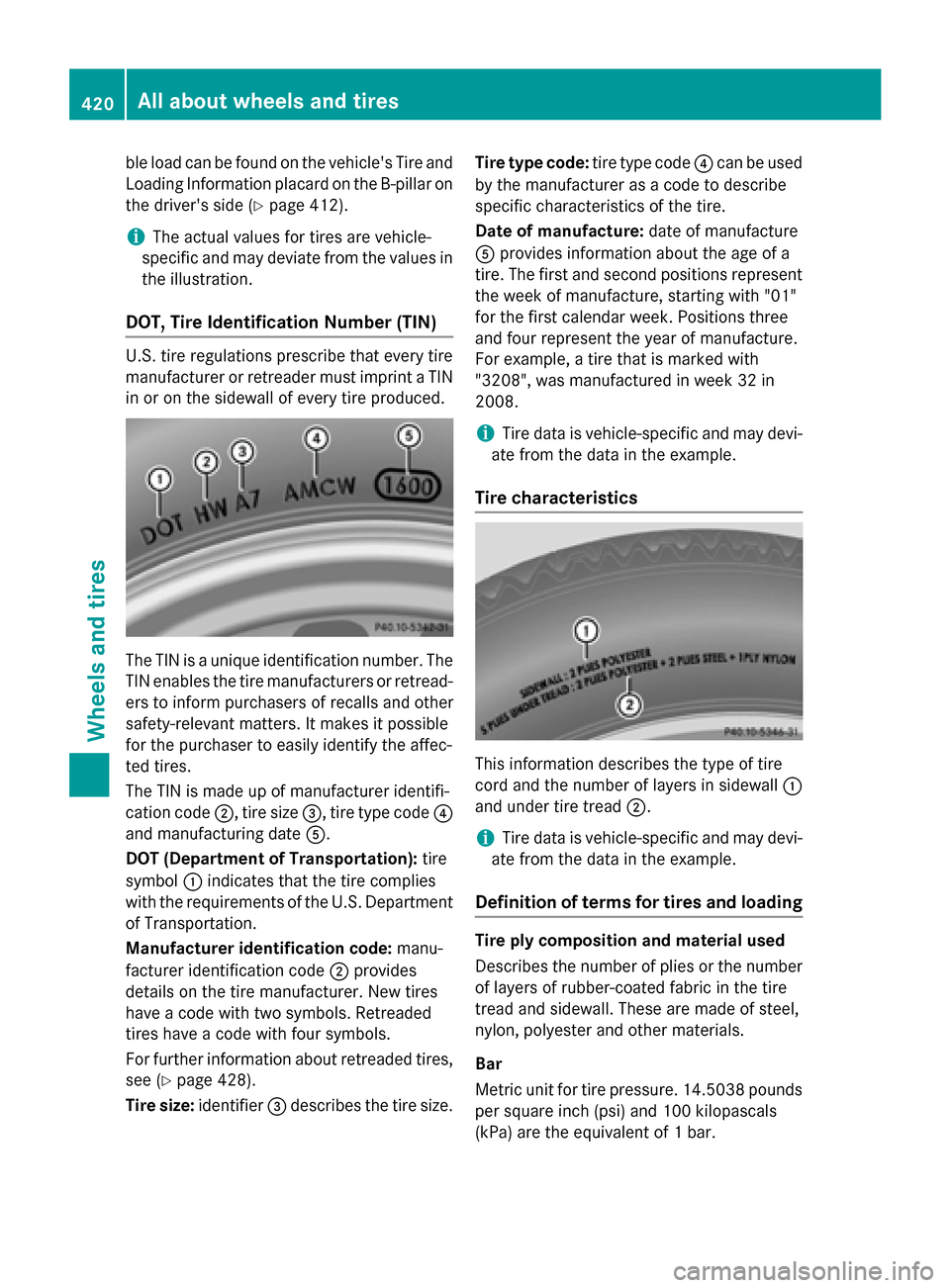

DOT, Tire Identification Number (TIN) U.S. tire regulations prescribe that every tire

manufacturer or retreader must imprint a TIN

in or on the sidewall of every tire produced. The TIN is a unique identification number. The

TIN enables the tire manufacturers or retread- ers to inform purchasers of recalls and other

safety-relevant matters. It makes it possible

for the purchaser to easily identify the affec-

ted tires.

The TIN is made up of manufacturer identifi-

cation code 0044, tire size0087, tire type code 0085

and manufacturing date 0083.

DOT (Department of Transportation): tire

symbol 0043indicates that the tire complies

with the requirements of the U.S. Department

of Transportation.

Manufacturer identification code: manu-

facturer identification code 0044provides

details on the tire manufacturer. New tires

have a code with two symbols. Retreaded

tires have a code with four symbols.

For further information about retreaded tires,

see (Y page 428).

Tire size: identifier0087describes the tire size. Tire type code:

tire type code0085can be used

by the manufacturer as a code to describe

specific characteristics of the tire.

Date of manufacture: date of manufacture

0083 provides information about the age of a

tire. The first and second positions represent the week of manufacture, starting with "01"

for the first calendar week. Positions three

and four represent the year of manufacture.

For example, a tire that is marked with

"3208", was manufactured in week 32 in

2008.

i Tire data is vehicle-specific and may devi-

ate from the data in the example.

Tire characteristics This information describes the type of tire

cord and the number of layers in sidewall

0043

and under tire tread 0044.

i Tire data is vehicle-specific and may devi-

ate from the data in the example.

Definition of terms for tires and loading Tire ply composition and material used

Describes the number of plies or the number of layers of rubber-coated fabric in the tire

tread and sidewall. These are made of steel,

nylon, polyester and other materials.

Bar

Metric unit for tire pressure. 14.5038 pounds

per square inch (psi) and 100 kilopascals

(kPa) are the equivalent of 1 bar. 420

All about wheels and tiresWheels and tires

Page 428 of 466

R

Do not use wooden blocks or similar

objects as a jack underlay. Otherwise, the

jack will not be able to achieve its load-

bearing capacity due to the restricted

height.

R Make sure that the distance between the

underside of the tires and the ground does

not exceed 1.2 in (3 cm).

R Do not place your hands or feet under the

raised vehicle.

R Do not lie under the vehicle.

R Do not start the engine when the vehicle is

raised.

R Never open or close a door or the tailgate

when the vehicle is raised.

R Make sure that no persons are present in

the vehicle when the vehicle is raised. X

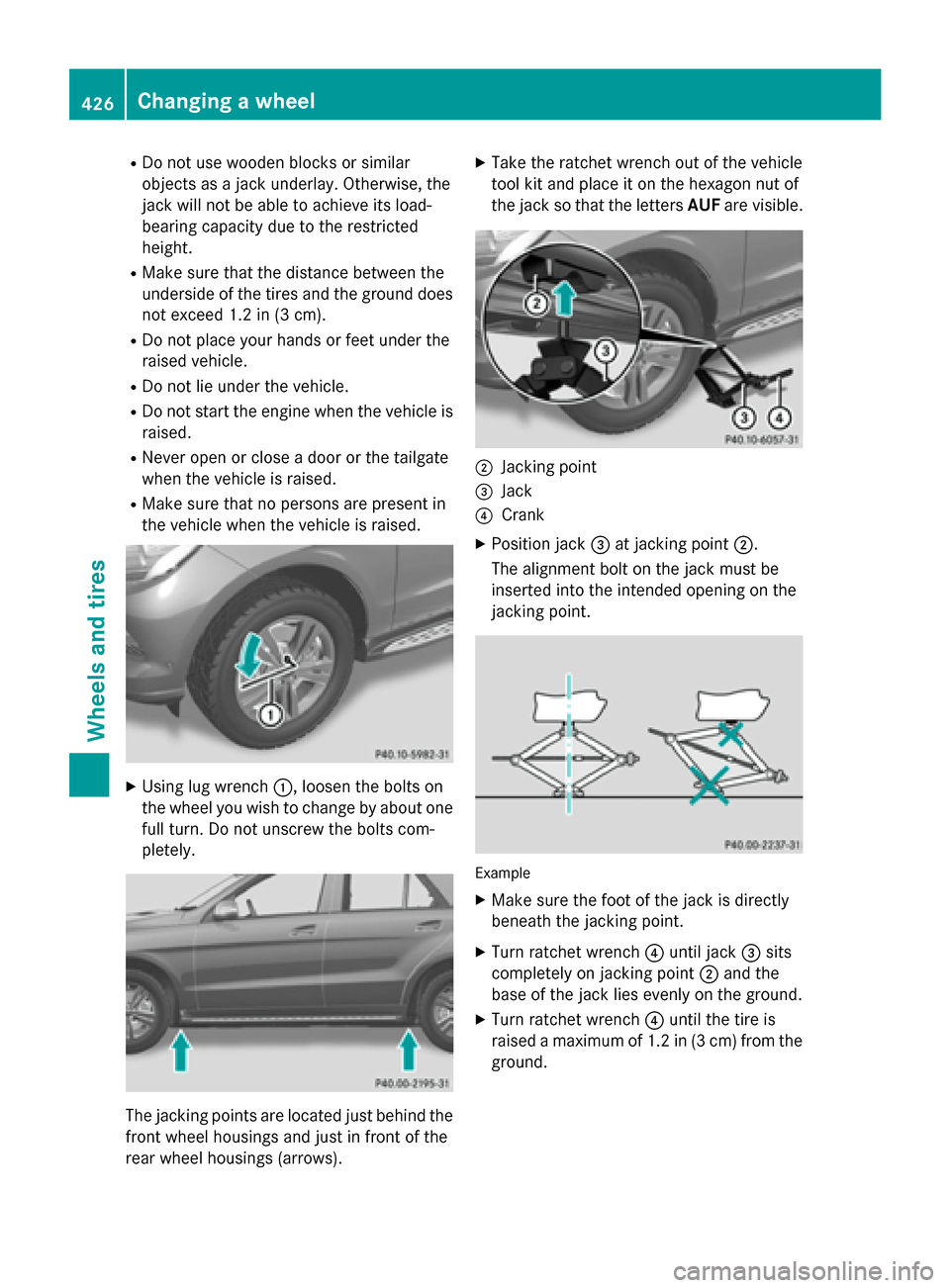

Using lug wrench 0043, loosen the bolts on

the wheel you wish to change by about one full turn. Do not unscrew the bolts com-

pletely. The jacking points are located just behind the

front wheel housings and just in front of the

rear wheel housings (arrows). X

Take the ratchet wrench out of the vehicle

tool kit and place it on the hexagon nut of

the jack so that the letters AUFare visible. 0044

Jacking point

0087 Jack

0085 Crank

X Position jack 0087at jacking point 0044.

The alignment bolt on the jack must be

inserted into the intended opening on the

jacking point. Example

X Make sure the foot of the jack is directly

beneath the jacking point.

X Turn ratchet wrench 0085until jack 0087sits

completely on jacking point 0044and the

base of the jack lies evenly on the ground.

X Turn ratchet wrench 0085until the tire is

raised a maximum of 1.2 in (3 cm) from the ground. 426

Changing a

wheelWheels and tires

Page 444 of 466

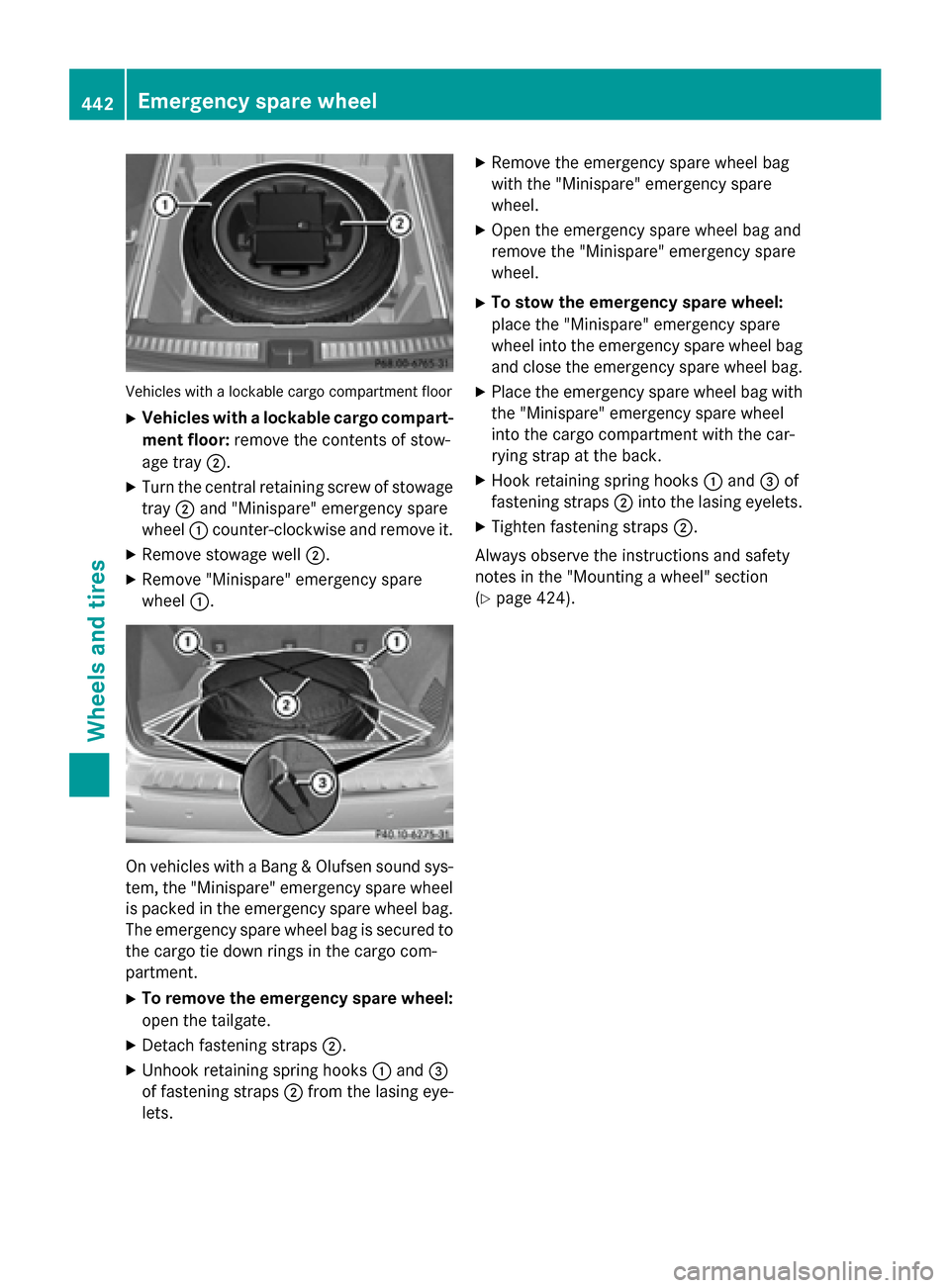

Vehicles with a lockable cargo compartment floor

X Vehicles with a lockable cargo compart-

ment floor: remove the contents of stow-

age tray 0044.

X Turn the central retaining screw of stowage

tray 0044and "Minispare" emergency spare

wheel 0043counter-clockwise and remove it.

X Remove stowage well 0044.

X Remove "Minispare" emergency spare

wheel 0043. On vehicles with a Bang & Olufsen sound sys-

tem, the "Minispare" emergency spare wheel

is packed in the emergency spare wheel bag. The emergency spare wheel bag is secured tothe cargo tie down rings in the cargo com-

partment.

X To remove the emergency spare wheel:

open the tailgate.

X Detach fastening straps 0044.

X Unhook retaining spring hooks 0043and 0087

of fastening straps 0044from the lasing eye-

lets. X

Remove the emergency spare wheel bag

with the "Minispare" emergency spare

wheel.

X Open the emergency spare wheel bag and

remove the "Minispare" emergency spare

wheel.

X To stow the emergency spare wheel:

place the "Minispare" emergency spare

wheel into the emergency spare wheel bag

and close the emergency spare wheel bag.

X Place the emergency spare wheel bag with

the "Minispare" emergency spare wheel

into the cargo compartment with the car-

rying strap at the back.

X Hook retaining spring hooks 0043and 0087of

fastening straps 0044into the lasing eyelets.

X Tighten fastening straps 0044.

Always observe the instructions and safety

notes in the "Mounting a wheel" section

(Y page 424). 442

Emergency spare wheelWheels and tires