lock MERCEDES-BENZ M320 2000 W163 Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2000, Model line: M320, Model: MERCEDES-BENZ M320 2000 W163Pages: 317, PDF Size: 10.4 MB

Page 258 of 317

255 Towing

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Tow in g t h e ve hic l e

Important!

When towing the vehicle, please, note the following:

With the automatic central locking activated and the

engine running, the vehicle doors lock if the left front

wheel is turning at vehicle speeds of approximately

9 mph (15 km / h) or more.

To prevent the vehicle door locks from locking,

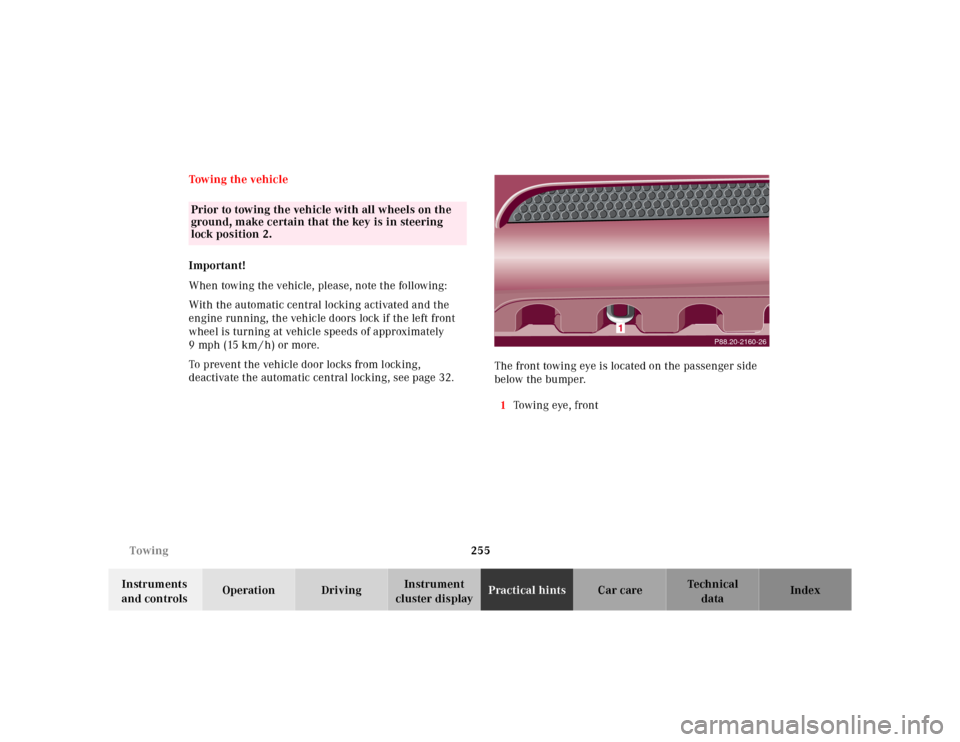

deactivate the automatic central locking, see page 32.The front towing eye is located on the passenger side

below the bumper.

1To w i n g eye , f r o n t

Prior to towing the vehicle with all wheels on the

ground, make certain that the key is in steering

lock position 2.

P88.20-2160-26

Page 261 of 317

258 Towing

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

To be certain to avoid additional damage to the vehicle

powertrain, however you should d o the following:

•With damage to front axle, raise front axle. Remove

flexible drive shaft between rear axle and transfer

case

•With damage to rear axle, raise rear axle and tow

vehicle with wheel lift or dolly placed under front

wheels.

•With damage to transfer case, remove flexible drive

shafts to the drive axles.

Note:

Always install new self-locking nuts when reinstalling

the flexible drive shaft.Caution!

If the vehicle is towed with the front axle raised, the

engine must be shut off (key in steering lock position 1).

Otherwise, the 4-ETS+ may become engaged which may

cause loss of towing control. Switch off the tow-away

alarm (see page 36) as well as the ESP (see page 207).

Note:

To signal turns while being towed with hazard warning

flasher in use, turn key in steering lock to position 2

and activate combination switch for left or right turn

signal in usual manner. Now deactivate the hazard

warning flasher, only the selected turn signal will

operate. Upon canceling the turn signal, the hazard

warning flasher must be activated again.

Wa r n i n g !

With the engine not running, there is no power

assistance for the braking and steering systems. In

this case, it is important to keep in mind that a

considerably higher degree of effort is necessary to

brake and steer the vehicle.

Page 262 of 317

259 Towing

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

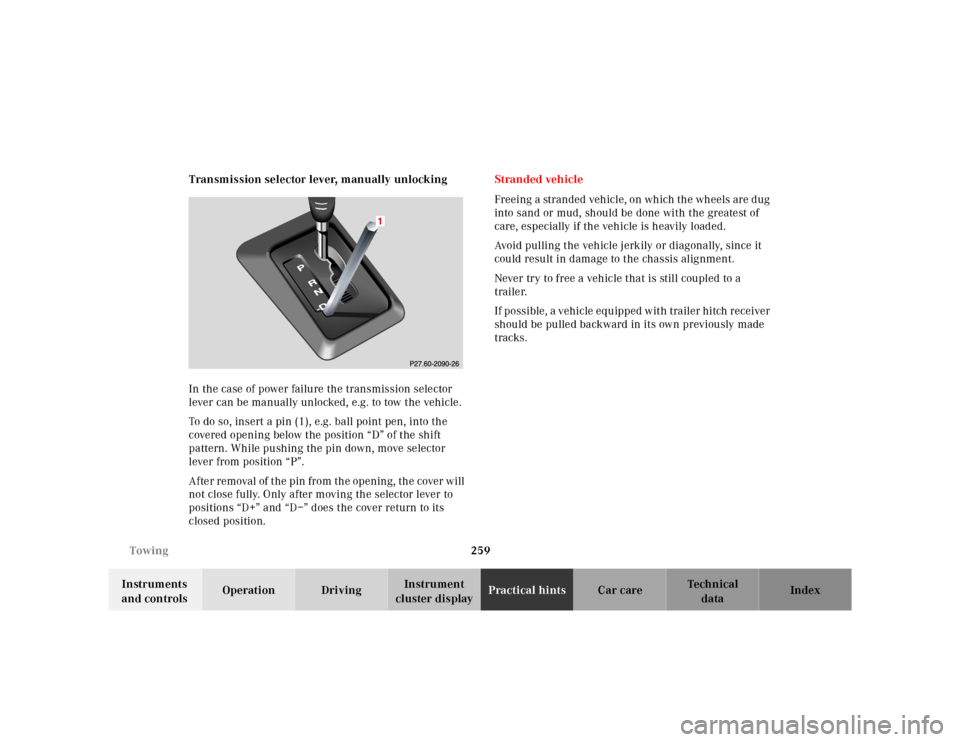

cluster displayPractical hintsCar care Index Transmission selector lever, manually unlocking

In the case of power failure the transmission selector

lever can be manually unlocked, e.g. to tow the vehicle.

To do so, insert a pin (1), e.g. ball point pen, into the

covered opening below the position “D” of the shift

pattern. While pushing the pin down, move selector

lever from position “P”.

After removal of the pin from the opening, the cover will

not close fully. Only after moving the selector lever to

positions “D+” and “D–” does the cover return to its

closed position.Stranded vehicle

Freeing a stranded vehicle, on which the wheels are dug

into sand or mud, should be done with the greatest of

care, especially if the vehicle is heavily loaded.

Avoid pulling the vehicle jerkily or diagonally, since it

could result in damage to the chassis alignment.

Never try to free a vehicle that is still coupled to a

trailer.

If possible, a vehicle equipped with trailer hitch receiver

should be pulled backward in its own previously made

tracks.

Page 264 of 317

261 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

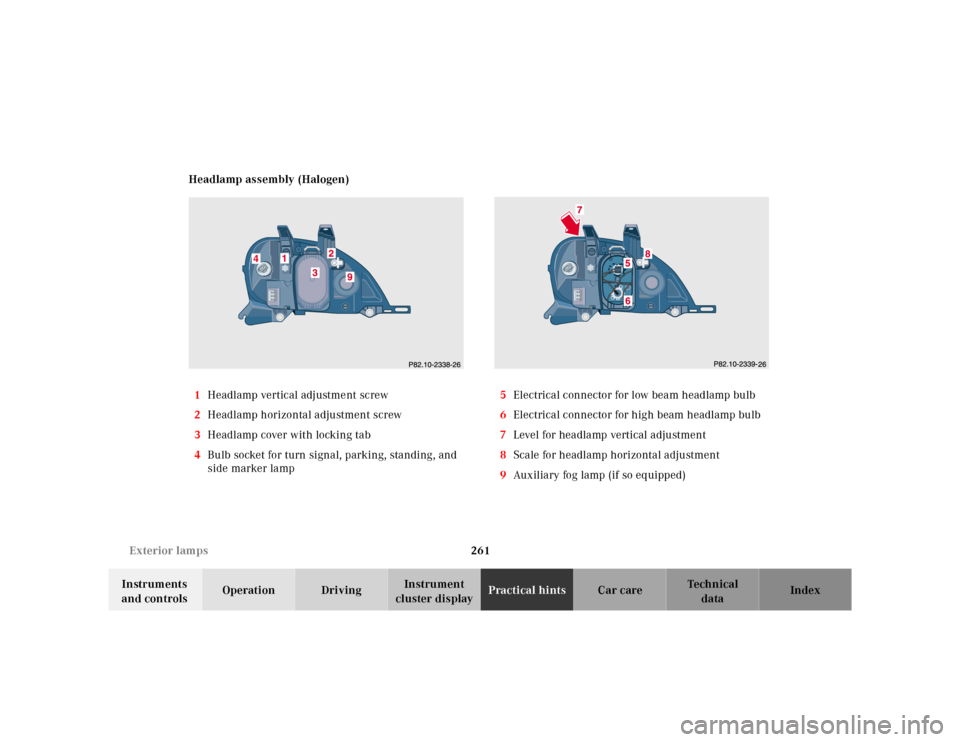

cluster displayPractical hintsCar care Index Headlamp assembly (Halogen)

1Headlamp vertical adjustment screw

2Headlamp horizontal adjustment screw

3Headlamp cover with locking tab

4Bulb socket for turn signal, parking, standing, and

side marker lamp5Electrical connector for low beam headlamp bulb

6Electrical connector for high beam headlamp bulb

7Level for headlamp vertical adjustment

8Scale for headlamp horizontal adjustment

9Auxiliary fog lamp (if so equipped)

Page 265 of 317

262 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

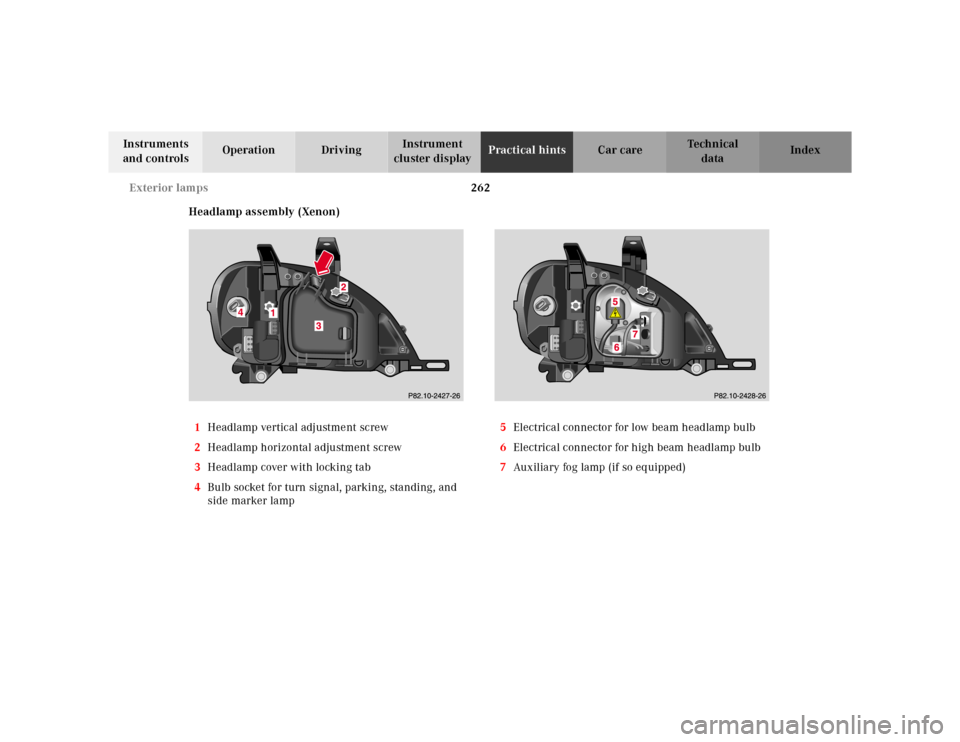

Headlamp assembly (Xenon)

1Headlamp vertical adjustment screw

2Headlamp horizontal adjustment screw

3Headlamp cover with locking tab

4Bulb socket for turn signal, parking, standing, and

side marker lamp5Electrical connector for low beam headlamp bulb

6Electrical connector for high beam headlamp bulb

7Auxiliary fog lamp (if so equipped)

Page 267 of 317

264 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Parking, standing, side marker and turn signal lamp

115 6 N A ( 3 2 / 4 c p b u l b )

Open hood.

Twist bulb socket (4) counterclockwise and pull out.

Push bulb into socket, turn counterclockwise and

remove.

Insert new bulb in socket, push in and twist clockwise.

Reinstall bulb socket.Bulbs for auxiliary fog lamp (optional)

H3 U (55 W)

Open hood.

Remove cover (9). Unhook clamping ring and remove

bulb. Pull off electrical connector.

Insert new bulb in socket (seating properly in cutouts of

bulb socket), and mount clamping ring. Reinstall and

push electrical connector on securely.

Reinstall cover (9).

Page 269 of 317

266 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

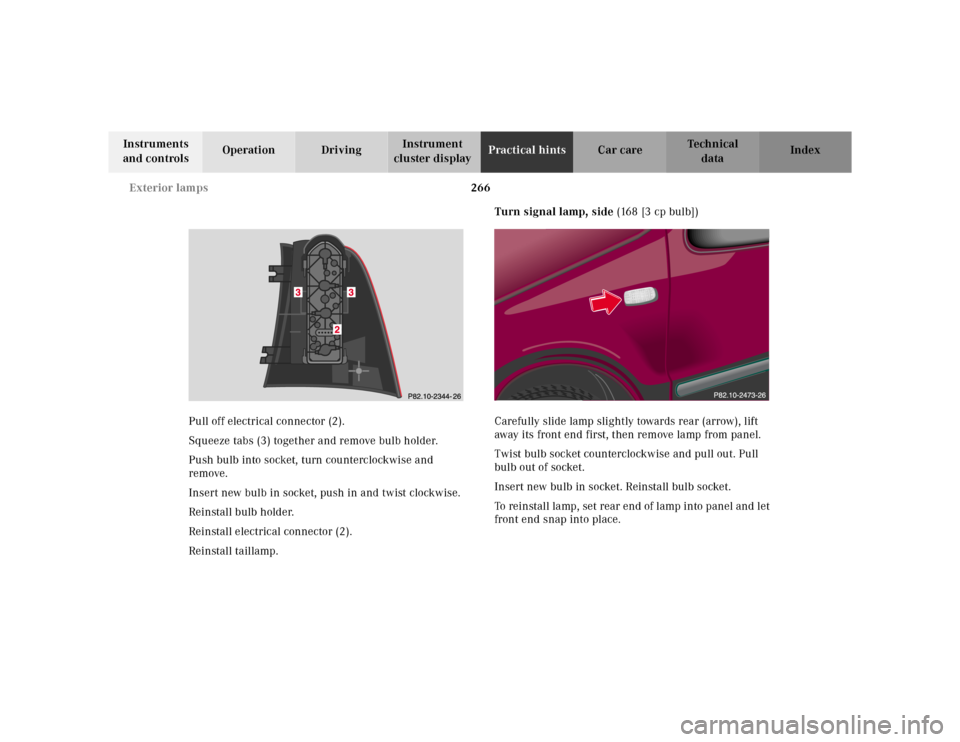

Pull off electrical connector (2).

Squeeze tabs (3) together and remove bulb holder.

Push bulb into socket, turn counterclockwise and

remove.

Insert new bulb in socket, push in and twist clockwise.

Reinstall bulb holder.

Reinstall electrical connector (2).

Reinstall taillamp.Turn signal lamp, side (168 [3 cp bulb])

Carefully slide lamp slightly towards rear (arrow), lift

away its front end first, then remove lamp from panel.

Twist bulb socket counterclockwise and pull out. Pull

bulb out of socket.

Insert new bulb in socket. Reinstall bulb socket.

To reinstall lamp, set rear end of lamp into panel and let

front end snap into place.

Page 270 of 317

![MERCEDES-BENZ M320 2000 W163 Owners Manual 267 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index License plate lamps (C 5 W [tubular] bulb)

Remove both securing MERCEDES-BENZ M320 2000 W163 Owners Manual 267 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index License plate lamps (C 5 W [tubular] bulb)

Remove both securing](/img/4/3342/w960_3342-269.png)

267 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index License plate lamps (C 5 W [tubular] bulb)

Remove both securing screws, remove lamp and take

out bulb.High mounted stop lamp (1073 [32 cp bulb])

To replace bulb, squeeze both sides (1, arrows) of cover,

fold forward and remove.

Press tab (2, arrow) on reflector and remove reflector.

Press bulb down, turn counterclockwise and remove.

Insert new bulb in socket, push in and twist clockwise.

Reinstall reflector.

Position tabs of cover in slots (3, arrows) and reinstall

cover until properly seated.

P82.10-2347-26

P82.10-2346-26

Page 272 of 317

269 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index 5. (High beams on):

Simultaneously turn adjusting screws (1 and 2 on

page 261 or 262) counterclockwise to adjust

headlamp downward, clockwise upward) equally

until bubble in the level (7 on page 261) is centered

on the “0” mark.

Graduations:

screw 1: 0.50° pitch,

screw 2: 0.67° pitch.

6. Horizontal headlamp aim (High beams on):

Turn adjusting screw (2) (left headlamp:

counterclockwise to adjust to the left, clockwise to

the right [right headlamp in opposite direction])

until the headlamp (high beam pattern) is centered

about the vertical centerline (1) as shown.

The left and right headlamps must be adjusted

individually.7. For proper aim, the indicator (8 on page 261) should

align with the “0” mark after horizontal adjustment.

Graduations: 0.33° pitch.

Note:

If it is not possible to obtain a proper headlamp

adjustment, have the system checked at your authorized

Mercedes-Benz Light Truck Center.

Page 273 of 317

270 Remote control

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

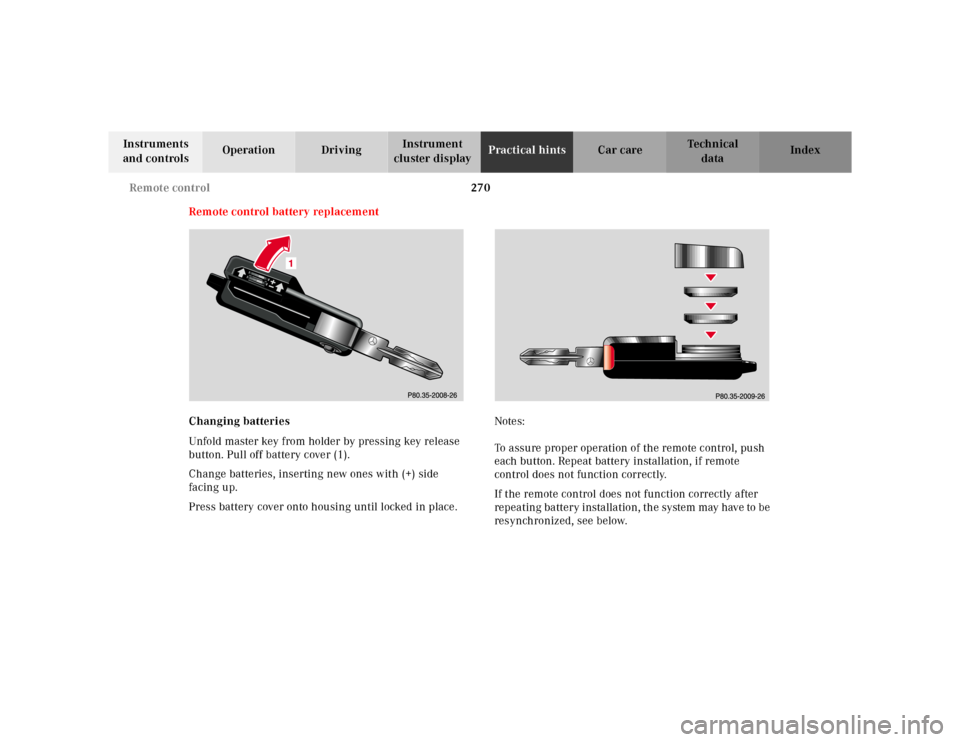

Remote control battery replacement

Changing batteries

Unfold master key from holder by pressing key release

button. Pull off battery cover (1).

Change batteries, inserting new ones with (+) side

facing up.

Press battery cover onto housing until locked in place.Notes:

To assure proper operation of the remote control, push

each button. Repeat battery installation, if remote

control does not function correctly.

If the remote control does not function correctly after

repeating battery installation, the system may have to be

resynchronized, see below.