instrument cluster MERCEDES-BENZ M430 2000 W163 Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2000, Model line: M430, Model: MERCEDES-BENZ M430 2000 W163Pages: 317, PDF Size: 10.4 MB

Page 269 of 317

266 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

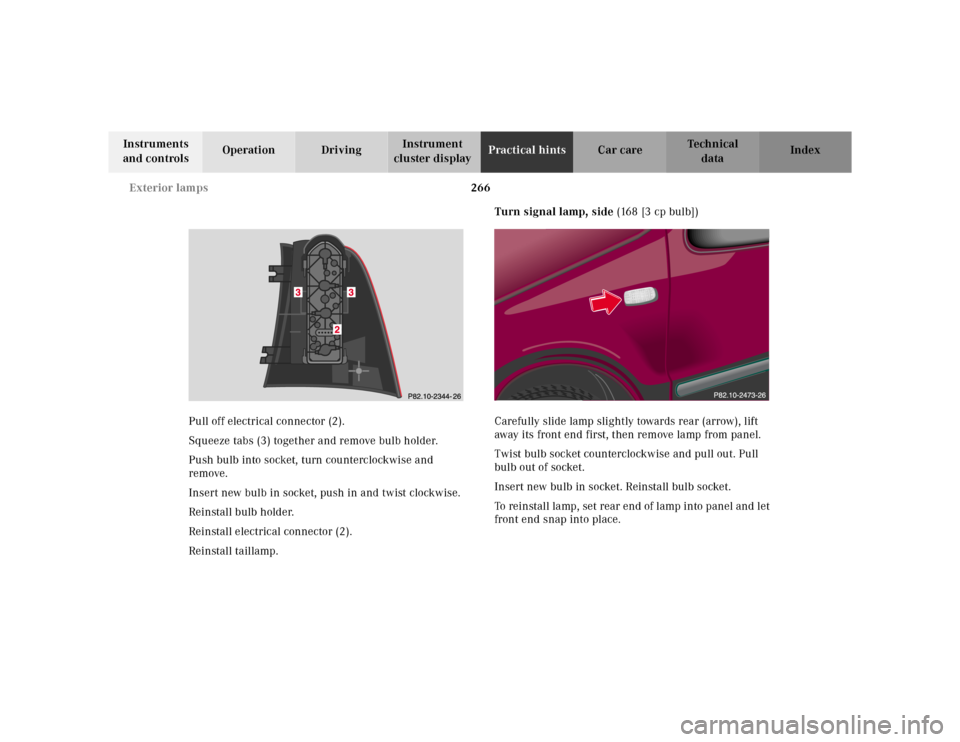

Pull off electrical connector (2).

Squeeze tabs (3) together and remove bulb holder.

Push bulb into socket, turn counterclockwise and

remove.

Insert new bulb in socket, push in and twist clockwise.

Reinstall bulb holder.

Reinstall electrical connector (2).

Reinstall taillamp.Turn signal lamp, side (168 [3 cp bulb])

Carefully slide lamp slightly towards rear (arrow), lift

away its front end first, then remove lamp from panel.

Twist bulb socket counterclockwise and pull out. Pull

bulb out of socket.

Insert new bulb in socket. Reinstall bulb socket.

To reinstall lamp, set rear end of lamp into panel and let

front end snap into place.

Page 270 of 317

![MERCEDES-BENZ M430 2000 W163 Owners Manual 267 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index License plate lamps (C 5 W [tubular] bulb)

Remove both securing MERCEDES-BENZ M430 2000 W163 Owners Manual 267 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index License plate lamps (C 5 W [tubular] bulb)

Remove both securing](/img/4/3342/w960_3342-269.png)

267 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index License plate lamps (C 5 W [tubular] bulb)

Remove both securing screws, remove lamp and take

out bulb.High mounted stop lamp (1073 [32 cp bulb])

To replace bulb, squeeze both sides (1, arrows) of cover,

fold forward and remove.

Press tab (2, arrow) on reflector and remove reflector.

Press bulb down, turn counterclockwise and remove.

Insert new bulb in socket, push in and twist clockwise.

Reinstall reflector.

Position tabs of cover in slots (3, arrows) and reinstall

cover until properly seated.

P82.10-2347-26

P82.10-2346-26

Page 271 of 317

268 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

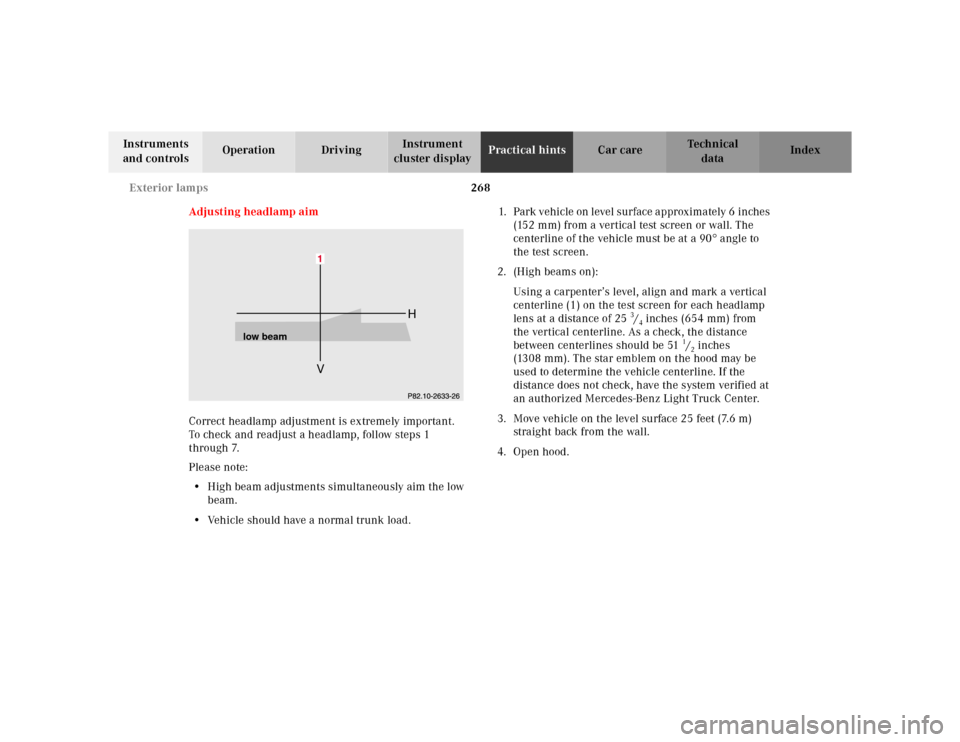

Adjusting headlamp aim

Correct headlamp adjustment is extremely important.

To check and readjust a headlamp, follow steps 1

through 7.

Please note:

•High beam adjustments simultaneously aim the low

beam.

•Vehicle should have a normal trunk load.1. Park vehicle on level surface approximately 6 inches

(152 mm) from a vertical test screen or wall. The

centerline of the vehicle must be at a 90° angle to

the test screen.

2. (High beams on):

Using a carpenter’s level, align and mark a vertical

centerline (1) on the test screen for each headlamp

lens at a distance of 25

3/4inches (654 mm) from

the vertical centerline. As a check, the distance

between centerlines should be 51

1/2inches

(1308 mm). The star emblem on the hood may be

used to determine the vehicle centerline. If the

distance does not check, have the system verified at

an authorized Mercedes-Benz Light Truck Center.

3. Move vehicle on the level surface 25 feet (7.6 m)

straight back from the wall.

4. Open hood.

VH

low beam

Page 272 of 317

269 Exterior lamps

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index 5. (High beams on):

Simultaneously turn adjusting screws (1 and 2 on

page 261 or 262) counterclockwise to adjust

headlamp downward, clockwise upward) equally

until bubble in the level (7 on page 261) is centered

on the “0” mark.

Graduations:

screw 1: 0.50° pitch,

screw 2: 0.67° pitch.

6. Horizontal headlamp aim (High beams on):

Turn adjusting screw (2) (left headlamp:

counterclockwise to adjust to the left, clockwise to

the right [right headlamp in opposite direction])

until the headlamp (high beam pattern) is centered

about the vertical centerline (1) as shown.

The left and right headlamps must be adjusted

individually.7. For proper aim, the indicator (8 on page 261) should

align with the “0” mark after horizontal adjustment.

Graduations: 0.33° pitch.

Note:

If it is not possible to obtain a proper headlamp

adjustment, have the system checked at your authorized

Mercedes-Benz Light Truck Center.

Page 273 of 317

270 Remote control

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

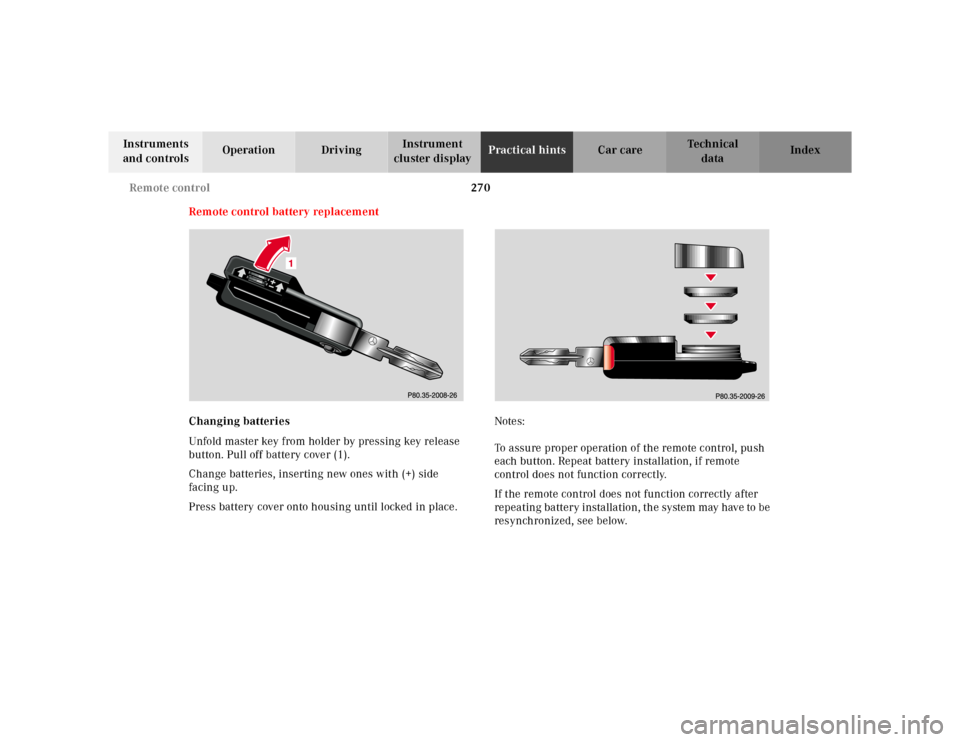

Remote control battery replacement

Changing batteries

Unfold master key from holder by pressing key release

button. Pull off battery cover (1).

Change batteries, inserting new ones with (+) side

facing up.

Press battery cover onto housing until locked in place.Notes:

To assure proper operation of the remote control, push

each button. Repeat battery installation, if remote

control does not function correctly.

If the remote control does not function correctly after

repeating battery installation, the system may have to be

resynchronized, see below.

Page 274 of 317

271 Remote control

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Synchronizing remote control

If the remote control does not function correctly and the

batteries are in order, the system may have to be

resynchronized.

Turn key in steering lock to position 2, then to

position 0 and remove.

Within 10 seconds, push and hold button‹ while

pushing buttonΠfive times.

Release the button, and press‹, Œ orŠ once.

Check all functions. The remote control should once

again be operational.

Note:

If it is not possible to resynchronize the remote control,

have the system checked at your authorized Mercedes-

Benz Light Truck Center.Important!

Batteries contain materials that can harm the

environment if disposed of improperly. Recycling of

batteries is the preferred method of disposal. For

disposal, please follow manufacturer’s recommendation

on battery package.

Replacement Battery:

Lithium, type CR 2025 or equivalent.

Page 275 of 317

272 Emergency operation of sliding/pop-up roof

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

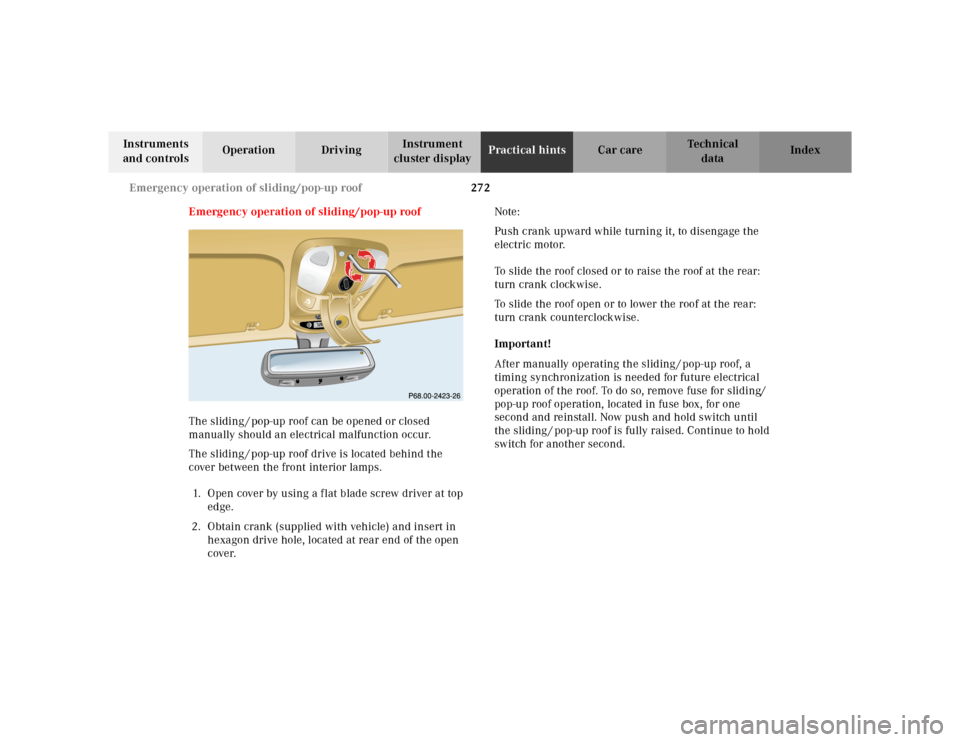

Emergency operation of sliding/pop-up roof

The sliding / pop-up roof can be opened or closed

manually should an electrical malfunction occur.

The sliding / pop-up roof drive is located behind the

cover between the front interior lamps.

1. Open cover by using a f lat blade screw driver at top

edge.

2. Obtain crank (supplied with vehicle) and insert in

hexagon drive hole, located at rear end of the open

cover.Note:

Push crank upward while turning it, to disengage the

electric motor.

To slide the roof closed or to raise the roof at the rear:

turn crank clockwise.

To slide the roof open or to lower the roof at the rear:

turn crank counterclockwise.

Important!

After manually operating the sliding / pop-up roof, a

timing synchronization is needed for future electrical

operation of the roof. To do so, remove fuse for sliding/

pop-up roof operation, located in fuse box, for one

second and reinstall. Now push and hold switch until

the sliding / pop-up roof is fully raised. Continue to hold

switch for another second.

RESETMODEMODE

Page 276 of 317

273 Emergency operation of Skyview Top

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Emergency operation of Skyview Top

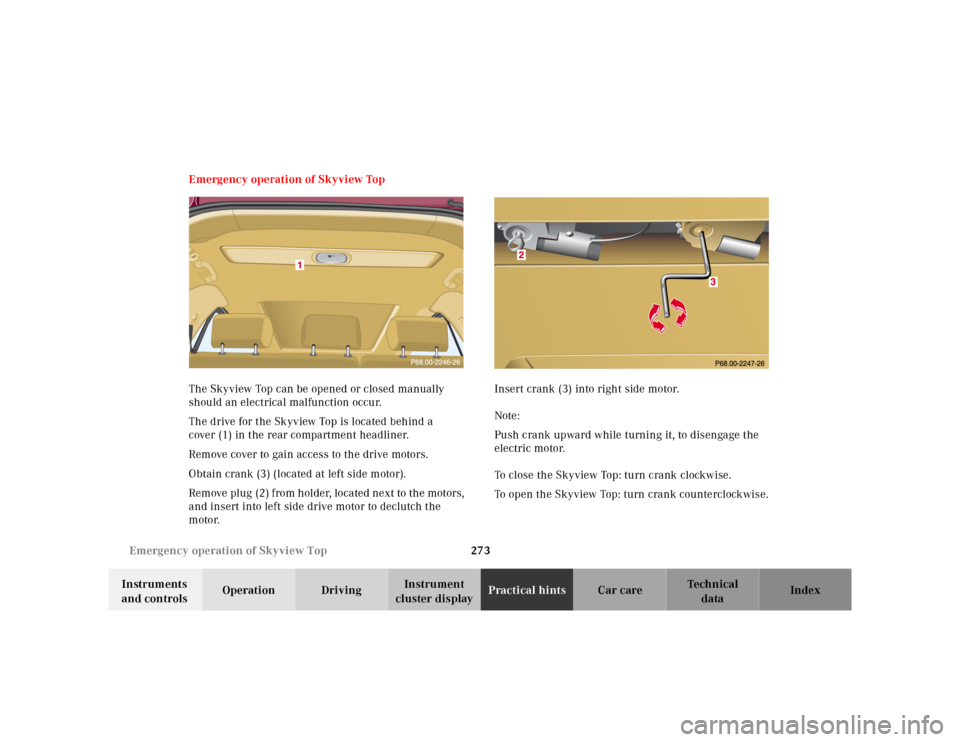

The Skyview Top can be opened or closed manually

should an electrical malfunction occur.

The drive for the Skyview Top is located behind a

cover (1) in the rear compartment headliner.

Remove cover to gain access to the drive motors.

Obtain crank (3) (located at left side motor).

Remove plug (2) from holder, located next to the motors,

and insert into left side drive motor to declutch the

motor.Insert crank (3) into right side motor.

Note:

Push crank upward while turning it, to disengage the

electric motor.

To close the Skyview Top: turn crank clockwise.

To open the Skyview Top: turn crank counterclockwise.

Page 277 of 317

274 Manual release for fuel filler flap

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Important!

After manually operating the Skyview Top, a timing

synchronization is needed for future electrical operation

o f the Sk yv iew To p. To do s o, tur n key i n stee ri n g lock to

position 2. Now push and hold switch until the Skyview

Top is fully closed. Continue to hold switch for

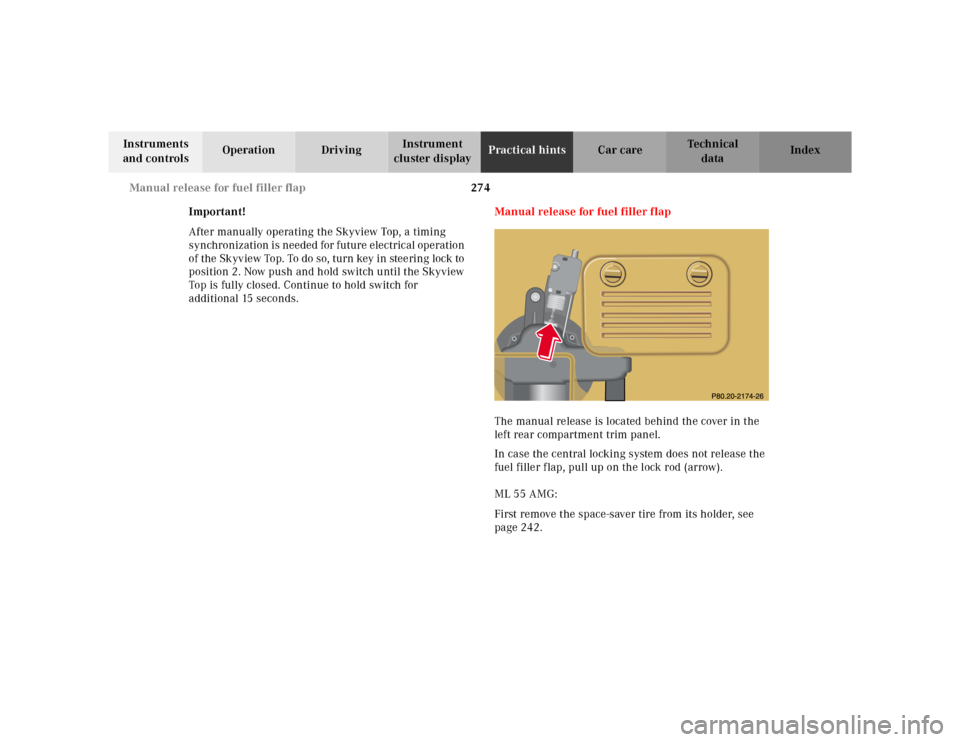

additional 15 seconds.Manual release for fuel filler flap

The manual release is located behind the cover in the

left rear compartment trim panel.

In case the central locking system does not release the

fuel filler flap, pull up on the lock rod (arrow).

ML 55 AMG:

First remove the space-saver tire from its holder, see

page 242.

Page 278 of 317

275 Replacing wiper blades

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index Replacing wiper blades

For safety reasons, remove key from steering lock before

replacing the wiper blade, otherwise the motor can

suddenly turn on and cause injury.

Notes:

Do not open engine hood with wiper arm folded forward.

Do not allow the wiper arm to contact the windshield

glass without a wiper blade inserted. The glass may be

scratched or broken.

Make certain that the wiper blade is properly installed.

An improperly installed wiper blade may cause

windshield damage.

The wiper with air spoiler should be mounted on the

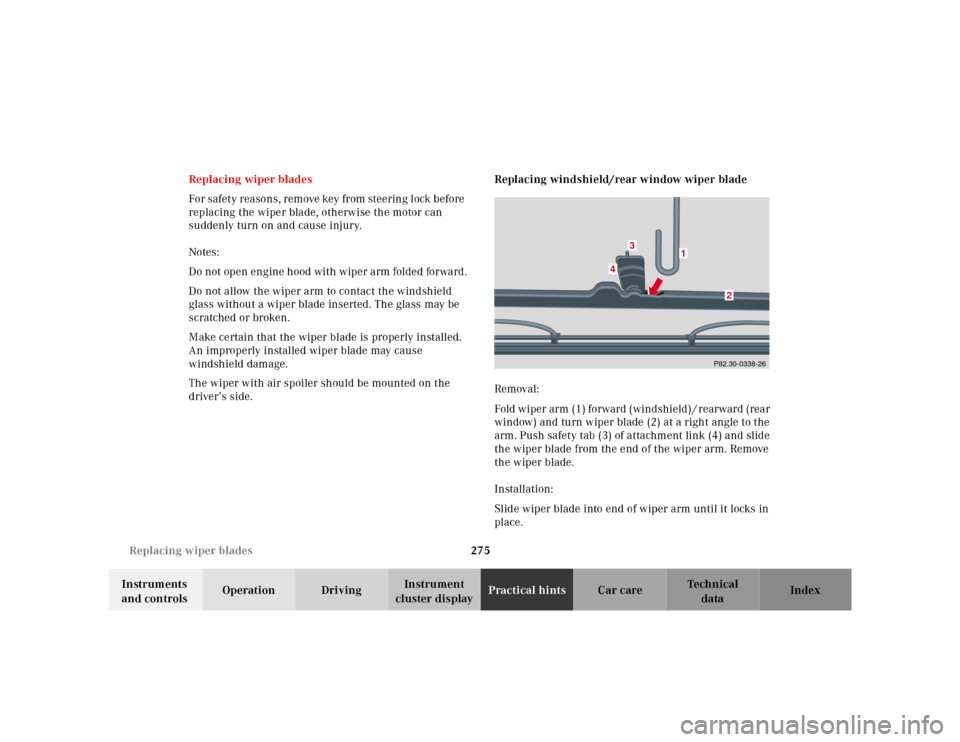

driver’s side.Replacing windshield/rear window wiper blade

Removal:

Fold wiper arm (1) forward (windshield) / rearward (rear

window) and turn wiper blade (2) at a right angle to the

arm. Push safety tab (3) of attachment link (4) and slide

the wiper blade from the end of the wiper arm. Remove

the wiper blade.

Installation:

Slide wiper blade into end of wiper arm until it locks in

place.

P82.30-0338-26

1

2

3

4