ECU MERCEDES-BENZ METRIS 2017 MY17 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: METRIS, Model: MERCEDES-BENZ METRIS 2017Pages: 318, PDF Size: 5.01 MB

Page 300 of 318

rectly, it could tip over while the vehicle is

raised.

RThe vehicle's jack is intended only to raise the

vehicle for a short time when changing a

wheel. It is not suited for performing mainte-

nance work under the vehicle.

RAvoid changing the wheel on uphill and down-

hill slopes.

RBefore raising the vehicle, secure it from roll-

ing away by applying the parking brake and

inserting wheel chocks. Never disengage the

parking brake while the vehicle is raised.

RThe jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats.

RMake sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in(3 cm).

RNever place your hands or feet under the

raised vehicle.

RNever lie under the raised vehicle.

RNever start the engine when the vehicle is

raised.

RNever open or close a door or the tailgate/

door when the vehicle is raised.

RMake sure that no persons are present in the

vehicle when the vehicle is raised.

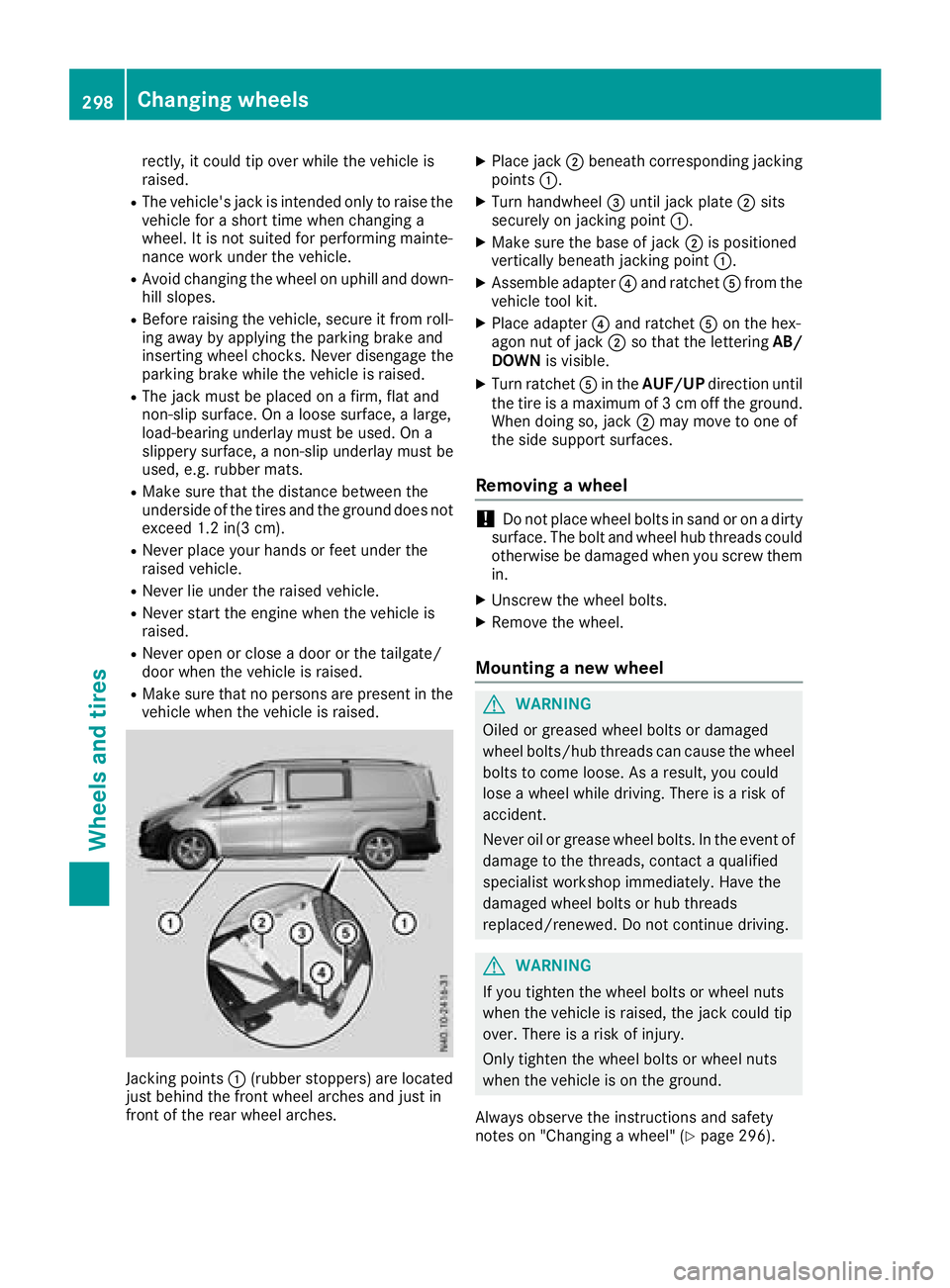

Jacking points :(rubber stoppers) are located

just behind the front wheel arches and just in

front of the rear wheel arches.

XPlace jack ;beneath corresponding jacking

points :.

XTurn handwheel =until jack plate ;sits

securely on jacking point :.

XMake sure the base of jack ;is positioned

vertically beneath jacking point :.

XAssemble adapter?and ratchet Afrom the

vehicle tool kit.

XPlace adapter ?and ratchet Aon the hex-

agon nut of jack ;so that the lettering AB/

DOWN is visible.

XTurn ratchet Ain the AUF/UP direction until

the tire is a maximum of 3 cm off the ground.

When doing so, jack ;may move to one of

the side support surfaces.

Removing a wheel

!Do not place wheel bolts in sand or on a dirty

surface. The bolt and wheel hub threads could

otherwise be damaged when you screw them

in.

XUnscrew the wheel bolts.

XRemove the wheel.

Mounting a new wheel

GWARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event of

damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving.

GWARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always observe the instructions and safety

notes on "Changing a wheel" (

Ypage 296).

298Changing wheels

Wheels and tires

Page 301 of 318

Only use wheel bolts that have been designed

for the wheel and the vehicle. For safety rea-

sons, Mercedes-Benz recommends that you

only use wheel bolts which have been approved

for Mercedes-Benz vehicles and the respective

wheel.

!On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

cialist workshop.

XClean the wheel and wheel hub contact sur-

faces.

XSlide the new wheel onto the wheel hub and

push it on.

XScrew in the wheel bolts and tighten them

lightly.

Lowering the vehicle

GWARNING

The wheels could work loose if the wheel nuts and bolts are not tightened to the specified

tightening torque. There is a risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

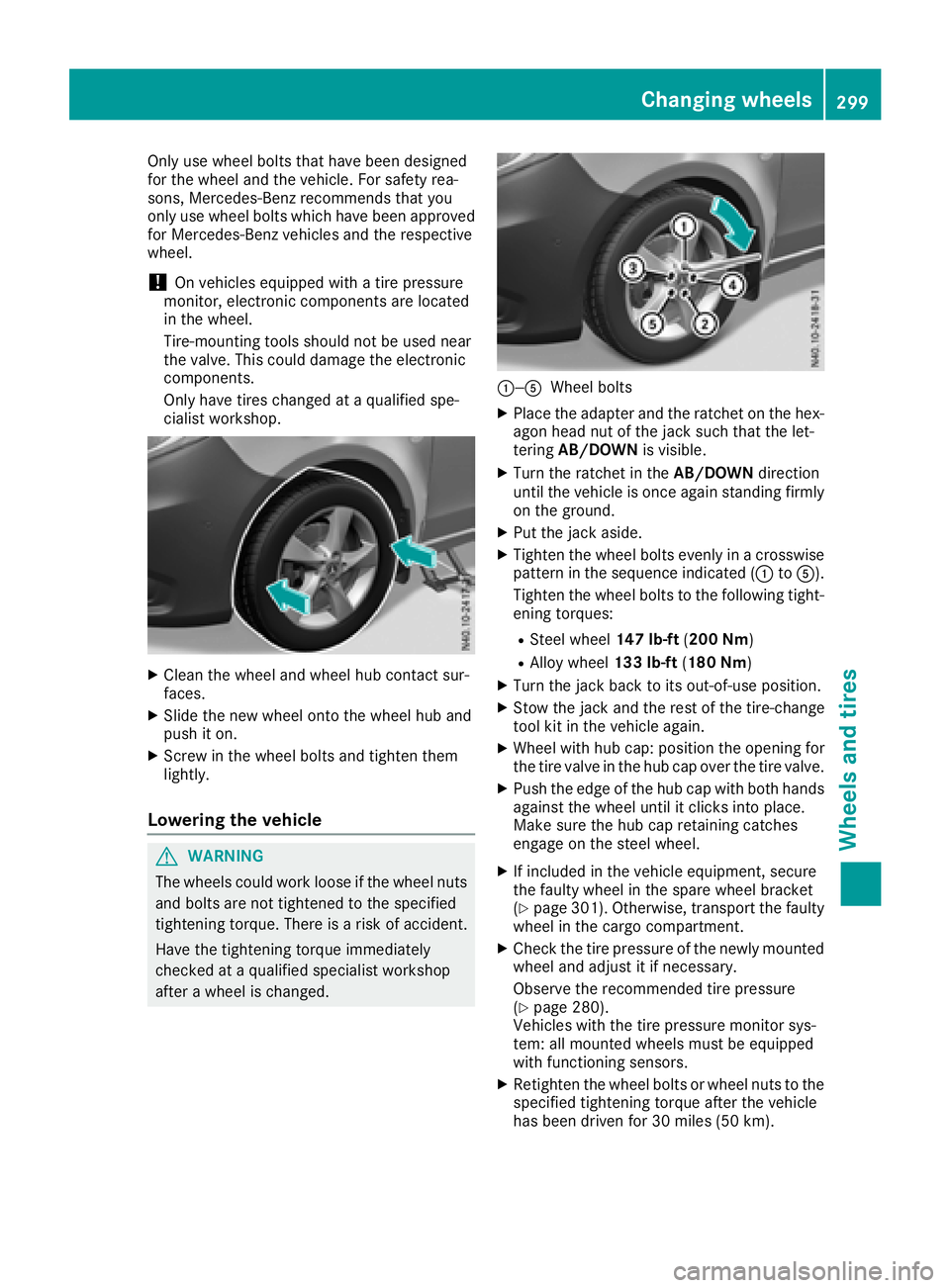

:—AWheel bolts

XPlace the adapter and the ratchet on the hex-

agon head nut of the jack such that the let-

tering AB/DOWN is visible.

XTurn the ratchet in the AB/DOWNdirection

until the vehicle is once again standing firmly

on the ground.

XPut the jack aside.

XTighten the wheel bolts evenly in a crosswise

pattern in the sequence indicated (: toA).

Tighten the wheel bolts to the following tight-

ening torques:

RSteel wheel 147 lb-ft(200 Nm)

RAlloy wheel 133 lb-ft(180 Nm)

XTurn the jack back to its out-of-use position.

XStow the jack and the rest of the tire-change

tool kit in the vehicle again.

XWheel with hub cap: position the opening for

the tire valve in the hub cap over the tire valve.

XPush the edge of the hub cap with both hands

against the wheel until it clicks into place.

Make sure the hub cap retaining catches

engage on the steel wheel.

XIf included in the vehicle equipment, secure

the faulty wheel in the spare wheel bracket

(

Ypage 301). Otherwise, transport the faulty

wheel in the cargo compartment.

XCheck the tire pressure of the newly mounted

wheel and adjust it if necessary.

Observe the recommended tire pressure

(

Ypage 280).

Vehicles with the tire pressure monitor sys-

tem: all mounted wheels must be equipped

with functioning sensors.

XRetighten the wheel bolts or wheel nuts to the

specified tightening torque after the vehicle

has been driven for 30 miles (50 km).

Changing wheels299

Wheels and tires

Z

Page 304 of 318

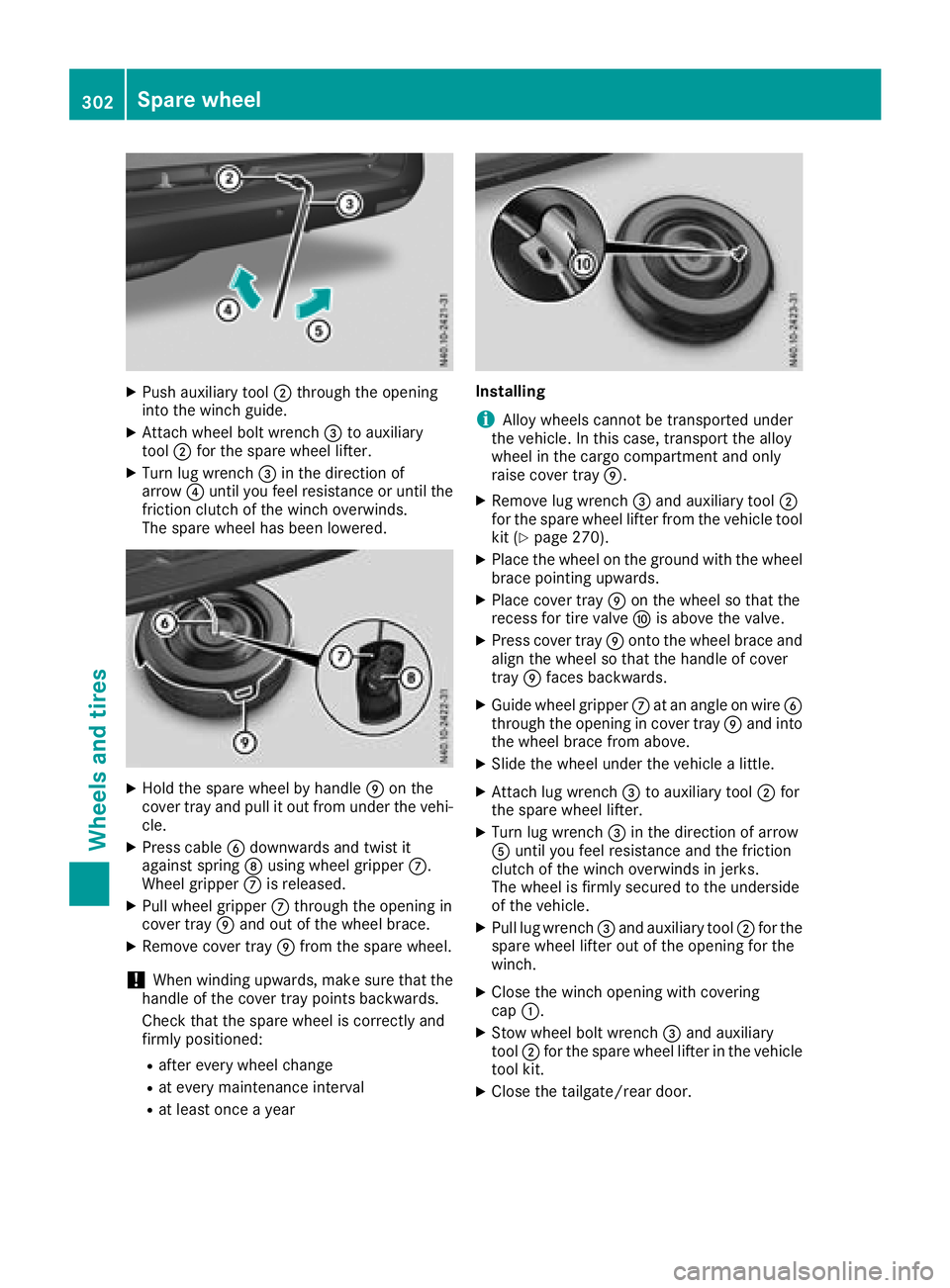

XPush auxiliary tool;through the opening

into the winch guide.

XAttach wheel bolt wrench =to auxiliary

tool ;for the spare wheel lifter.

XTurn lug wrench =in the direction of

arrow ?until you feel resistance or until the

friction clutch of the winch overwinds.

The spare wheel has been lowered.

XHold the spare wheel by handle Eon the

cover tray and pull it out from under the vehi-

cle.

XPress cable Bdownwards and twist it

against spring Dusing wheel gripper C.

Wheel gripper Cis released.

XPull wheel gripper Cthrough the opening in

cover tray Eand out of the wheel brace.

XRemove cover tray Efrom the spare wheel.

!When winding upwards, make sure that the

handle of the cover tray points backwards.

Check that the spare wheel is correctly and

firmly positioned:

Rafter every wheel change

Rat every maintenance interval

Rat least once a year

Installing

iAlloy wheels cannot be transported under

the vehicle. In this case, transport the alloy

wheel in the cargo compartment and only

raise cover tray E.

XRemove lug wrench =and auxiliary tool ;

for the spare wheel lifter from the vehicle tool

kit (

Ypage 270).

XPlace the wheel on the ground with the wheel brace pointing upwards.

XPlace cover tray Eon the wheel so that the

recess for tire valve Fis above the valve.

XPress cover tray Eonto the wheel brace and

align the wheel so that the handle of cover

tray Efaces backwards.

XGuide wheel gripper Cat an angle on wire B

through the opening in cover tray Eand into

the wheel brace from above.

XSlide the wheel under the vehicle a little.

XAttach lug wrench =to auxiliary tool ;for

the spare wheel lifter.

XTurn lug wrench =in the direction of arrow

A until you feel resistance and the friction

clutch of the winch overwinds in jerks.

The wheel is firmly secured to the underside

of the vehicle.

XPull lug wrench =and auxiliary tool ;for the

spare wheel lifter out of the opening for the

winch.

XClose the winch opening with covering

cap :.

XStow wheel bolt wrench =and auxiliary

tool ;for the spare wheel lifter in the vehicle

tool kit.

XClose the tailgate/rear door.

302Spare wheel

Wheels and tires

Page 314 of 318

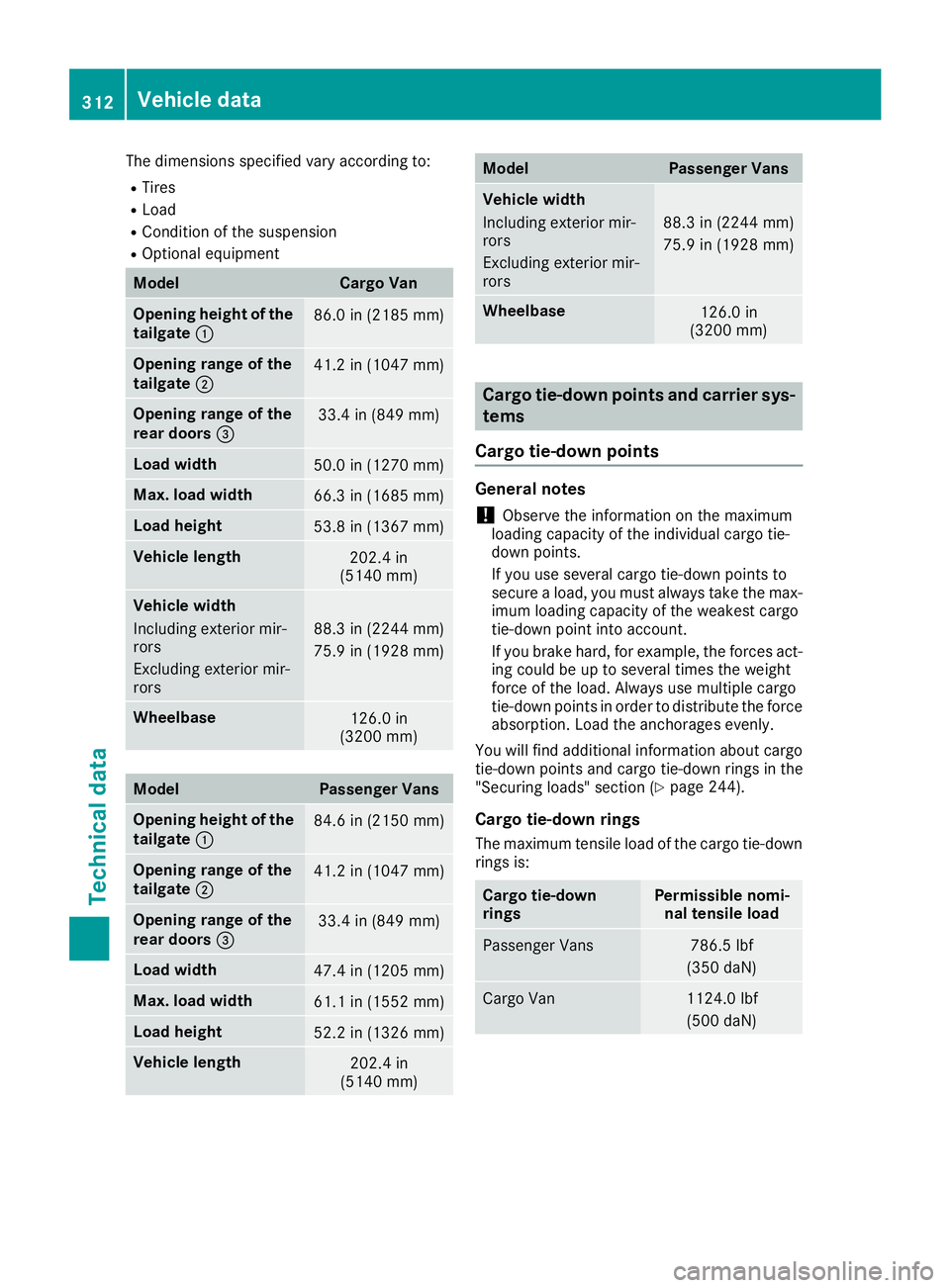

The dimensions specified vary according to:

RTires

RLoad

RCondition of the suspension

ROptional equipment

ModelCargo Van

Opening height of the

tailgate:86.0 in (2185 mm)

Opening range of the

tailgate;41.2 in (1047 mm)

Opening range of the

rear doors =33.4 in (849 mm)

Load width50.0 in (1270 mm)

Max. load width66.3 in (1685 mm)

Load height53.8 in (1367 mm)

Vehicle length202.4 in

(5140 mm)

Vehicle width

Including exterior mir-

rors

Excluding exterior mir-

rors

88.3 in (2244 mm)

75.9 in (1928 mm)

Wheelbase126.0 in

(3200 mm)

ModelPassenger Vans

Opening height of the

tailgate :84.6 in (2150 mm)

Opening range of the

tailgate;41.2 in (1047 mm)

Opening range of the

rear doors =33.4 in (849 mm)

Load width47.4 in (1205 mm)

Max. load width61.1 in (1552 mm)

Load height52.2 in (1326 mm)

Vehicle length202.4 in

(5140 mm)

ModelPassenger Vans

Vehicle width

Including exterior mir-

rors

Excluding exterior mir-

rors

88.3 in (2244 mm)

75.9 in (1928 mm)

Wheelbase126.0 in

(3200 mm)

Cargo tie-down points and carrier sys-

tems

Cargo tie-down points

General notes

!Observe the information on the maximum

loading capacity of the individual cargo tie-

down points.

If you use several cargo tie-down points to

secure a load, you must always take the max-

imum loading capacity of the weakest cargo

tie-down point into account.

If you brake hard, for example, the forces act-

ing could be up to several times the weight

force of the load. Always use multiple cargo

tie-down points in order to distribute the force absorption. Load the anchorages evenly.

You will find additional information about cargo

tie-down points and cargo tie-down rings in the

"Securing loads" section (

Ypage 244).

Cargo tie-down rings

The maximum tensile load of the cargo tie-down

rings is:

Cargo tie-down

ringsPermissible nomi- nal tensile load

Passenger Vans786.5 lbf

(350 daN)

Cargo Van1124.0 lbf (500 daN)

312Vehicle data

Technical data

Page 315 of 318

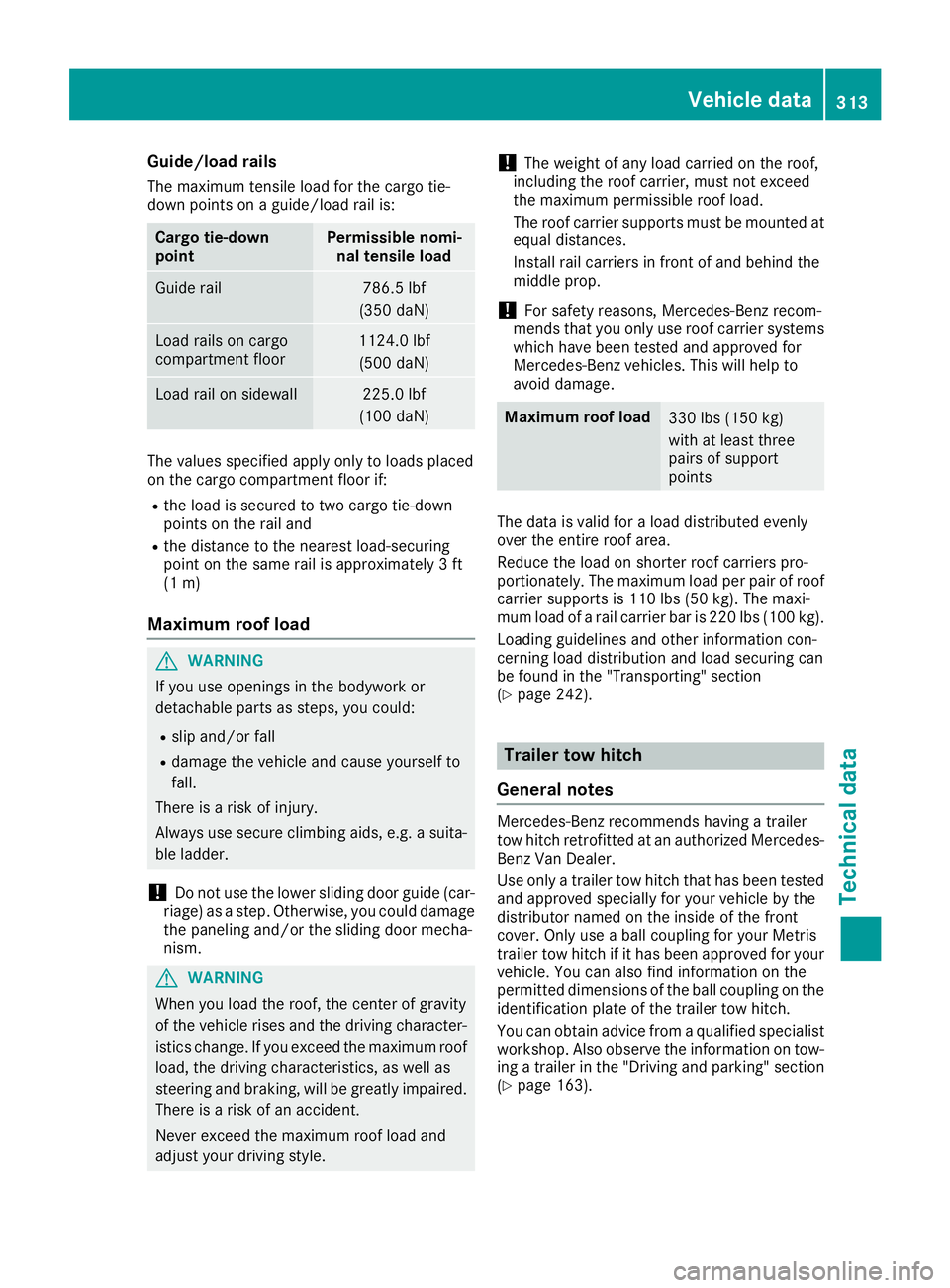

Guide/load rails

The maximum tensile load for the cargo tie-

down points on a guide/load rail is:

Cargo tie-down

pointPermissible nomi-nal tensile load

Guide rail786.5 lbf

(350 daN)

Load rails on cargo

compartment floor1124.0 lbf (500 daN)

Load rail on sidewall225.0 lbf

(100 daN)

The values specified apply only to loads placed

on the cargo compartment floor if:

Rthe load is secured to two cargo tie-down

points on the rail and

Rthe distance to the nearest load-securing

point on the same rail is approximately 3 ft

(1 m)

Maximum roof load

GWARNING

If you use openings in the bodywork or

detachable parts as steps, you could:

Rslip and/or fall

Rdamage the vehicle and cause yourself to

fall.

There is a risk of injury.

Always use secure climbing aids, e.g. a suita-

ble ladder.

!Do not use the lower sliding door guide (car-

riage) as a step. Otherwise, you could damage

the paneling and/or the sliding door mecha-

nism.

GWARNING

When you load the roof, the center of gravity

of the vehicle rises and the driving character-

istics change. If you exceed the maximum roof

load, the driving characteristics, as well as

steering and braking, will be greatly impaired.

There is a risk of an accident.

Never exceed the maximum roof load and

adjust your driving style.

!The weight of any load carried on the roof,

including the roof carrier, must not exceed

the maximum permissible roof load.

The roof carrier supports must be mounted at

equal distances.

Install rail carriers in front of and behind the

middle prop.

!For safety reasons, Mercedes-Benz recom-

mends that you only use roof carrier systems

which have been tested and approved for

Mercedes-Benz vehicles. This will help to

avoid damage.

Maximum roof load330 lbs (150 kg)

with at least three

pairs of support

points

The data is valid for a load distributed evenly

over the entire roof area.

Reduce the load on shorter roof carriers pro-

portionately. The maximum load per pair of roof

carrier supports is 110 lbs (50 kg). The maxi-

mum load of a rail carrier bar is 220 lbs (100 kg).

Loading guidelines and other information con-

cerning load distribution and load securing can

be found in the "Transporting" section

(

Ypage 242).

Trailer tow hitch

General notes

Mercedes-Benz recommends having a trailer

tow hitch retrofitted at an authorized Mercedes-

Benz Van Dealer.

Use only a trailer tow hitch that has been tested

and approved specially for your vehicle by the

distributor named on the inside of the front

cover. Only use a ball coupling for your Metris

trailer tow hitch if it has been approved for your

vehicle. You can also find information on the

permitted dimensions of the ball coupling on the

identification plate of the trailer tow hitch.

You can obtain advice from a qualified specialist

workshop. Also observe the information on tow-

ing a trailer in the "Driving and parking" section

(

Ypage 163).

Vehicle data313

Technical data

Z