belt MERCEDES-BENZ METRIS 2017 MY17 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2017, Model line: METRIS, Model: MERCEDES-BENZ METRIS 2017Pages: 318, PDF Size: 5.01 MB

Page 222 of 318

Seat belts

Warning/

indicator

lampNSignal type

Possible causes/consequences and M

Solutions

üNAfter starting the engine, the red seat belt warning lamp lights up or flashes. A

warning tone may also sound.

Only for certain countries: the red seat belt warning lamp lights up for a maximum

of 6 seconds after the ignition is switched on.

The seat belt warning lamp reminds the driver and front-passenger to fasten their

seat belts.

XFasten seat belt (Ypage 48).

üN The red seat belt warning lamp lights up after the engine starts, as soon as the

driver's or the front-passenger door is closed.

The driver or front-passenger has not fastened their seat belt.

XFasten seat belt (Ypage 48).

The warning lamp goes out.

On vehicles with the Occupant Classification System (OCS), there are objects on

the front-passenger seat.

XRemove the objects from the front-passenger seat and store them in a safe

place.

The warning lamp goes out.

üN The red seat belt warning lamp flashes and an intermittent audible warning

sounds.

The driver or front passenger has not fastened their seat belt. At the same time, you

are driving faster than 15 mph (25 km/h) or have briefly driven faster than 15 mph

(25 km/h).

XFasten seat belt (Ypage 48).

The warning lamp goes out and the intermittent audible warning ceases.

On vehicles with the Occupant Classification System (OCS), there are objects on

the front-passenger seat. At the same time, you are driving faster than 15 mph

(25 km/h) or have briefly driven faster than 15 mph (25 km/h).

XRemove the objects from the front-passenger seat and store them in a safe

place.

The warning lamp goes out and the intermittent warning tone ceases.

220Indicator and warning lamps in the instrument cluster

On-board computer and displays

Page 246 of 318

XAlways transport loads in the cargo compart-

ment and with the seat backrests folded up

and properly locked in position.

XAlways place the load against the backrests ofthe front or rear seats.

XMove large and heavy loads as far towards thefront of the vehicle as possible against the

front or rear seats. Stow the load flush with

the rear or front seats.

XAlways additionally secure the load with suit-

able load-securing aids or tie downs.

Observe the following notes:

RDo not stack loads higher than the upper edge

of the backrests.

RTransport loads behind seats that are not

occupied.

RIf the rear bench seat is not occupied, insert

the seat belts crosswise into the buckle of the

opposite seat belt.

Cargo compartment variations

You can vary the cargo compartment according

to your transportation requirements as follows:

Rby folding the seat backrests forward to the

table position.

Rby removing the rear bench seat.

You will find information about rear bench seats in the "Rear bench seats" section (

Ypage 86).

Securing loads

Important safety notes

GWARNING

If you attach the tie-down incorrectly when

securing the load, the following may occur in

the event of abrupt changes in direction, brak- ing maneuvers or an accident:

Rthe cargo tie-down rings may become

detached or the tie-down may tear if the

permissible load is exceeded

Rthe load may not be restrained.

This may cause the load to slip, tip over or be

tossed about, striking vehicle occupants.

There is a risk of an accident and injury.

Always tension the tie-downs in the proper

manner and only between the described

cargo tie-down rings. Always use tie-downs

designed specifically for the loads.

!Observe the information on the maximum

loading capacity of the individual cargo tie-

down points.

If you use several cargo tie-down points to

secure a load, you must always take the max-

imum loading capacity of the weakest cargo

tie-down point into account.

If you brake hard, for example, the forces act- ing could be up to several times the weight

force of the load. Always use multiple cargo

tie-down points in order to distribute the force

absorption. Load the anchorages evenly.

Spread the load evenly across the cargo tie-

down points/cargo tie-down rings. You will find information on the maximum loading capacity of

the cargo tie-down points under "Cargo tie-

down points and carrier systems" (

Ypage 312).

Do not attempt to modify or repair the cargo tie-

down points/cargo tie-down rings or tie downs.

Read the information on qualified specialist

workshops: (

Ypage 31).

As the driver, you are responsible for ensuring

that:

RThe load is secured against slipping, tipping,

rolling or falling off in normal traffic condi-

tions, should the vehicle swerve to avoid an

obstacle, in the event of full brake application

and on poor road surfaces.

RThe applicable requirements and guidelines

relating to load-securing practices must be

met.

If this is not the case, this may constitute a

punishable offense, depending on local legis-

lation and any ensuing consequences.

Always observe the legal requirements for the country you are currently in.

Make sure that the load is secure before every

journey and at regular intervals during a long

journey. Correct an incorrectly or inadequately

secured load if necessary.

Always observe the operating instructions or the

notes of the lashing strap manufacturer for the

operation of the lashing strap.

You can obtain information about securing the

load correctly from the manufacturer of the load

securing aids or tie down for securing the load.

244Securing loads

Transporting loads

Page 267 of 318

and associated spray produced by the power

washer could cause extensive damage to thevehicle.

!When using high-pressure cleaning equip-

ment, maintain a minimum distance of

approx. 1 ft (30 cm)betwee nthe spra ynozzle

and th evehicl eparts. Do no tuse apowe r

washer wit h around-jet nozzle. You could

damage th evehicl eor engin eparts.

!Kee pth ewater je tmovin gconstantl ywhile

cleaning .This will avoid causin gdamage to

th evehicle.

Do no tpoin tth ewater je tat:

Rdoo rjoints

Rrear vie wcamera

Rair bellows

Rbrak ehoses

Rwhee lbalance weights

Relectrica lcomponent s

Relectricalconnection s

Rseals

Rdrive train ,especially no tat th eintermedi-

ate bearin gof th epropelle rshaf t

Cleaning the engine

!Water mus tno tente rintak eor ventilation

openings. Whe ncleaning wit hhigh pressur e

water or steam cleaners ,th espray mus tno t

be aime ddirectl yat electrica lcomponent sor

th eterminals of electrica llines.

Preserve th eengin eafter th eengin ehas been

cleaned. Protect th ebelt drive system from

exposure to th epreservative agent.

Also observ eth einformation under "Powe r

washers " (

Ypage 264).

Cleaning the paintwork

!Do notaffix:

Rstickers

Rfilm s

Rmagneti cplates or similar items

to painte dsurfaces. You could otherwise

damage th epaintwork .

Scratches, corrosiv edeposits, area saffecte dby

corrosio nand damage caused by inadequate

car ecanno talways be completely repaired. In

suc hcases, visit aqualified specialist workshop .

XRemove impurities immediately, wher epos -

sible, whils tavoidin grubbin gto ohard.

XSoak insec tremain swit hinsec tremove rand

rinse off th etreated area safterwards .

XSoak birddroppings wit hwater and rinse off

th etreated area safterwards .

XRemove coolant, brak efluid, tree resin ,oils ,

fuel sand greases by rubbin ggentl ywit h a

cloth soaked in petroleum ether or lighte r

fluid.

XUse tar remove rto remove tar stains.

XUse silicon eremove rto remove wax .

Cleaning the windows

GWARNING

You could become trapped by th ewindshield

wiper sif they start movin gwhile cleaning th e

windshield or wiper blades. There is aris kof

injury.

Always switch off th ewindshield wiper sand

th eignition before cleaning th ewindshield or

wiper blades.

!Do no tfol dth ewindshield wiper saway from

th ewindshield unless th ehoo dis closed .Oth-

erwise, you could damage th ehood.

!Hold th ewiper arm securel ywhen foldin g

back. The windshield could be damaged if th e

wiper arm smack sagainst it suddenly.

!Do no tuse dry cloths, abrasiv eproducts ,

solvents or cleaning agents containin gsol-

vents to clean th einside of th ewindows .Do

no ttouch th einside sof th ewindows wit h

har dobjects ,e.g. an ice scrape ror ring. There

is otherwise aris kof damagin gth ewindows .

!Clean thewater drainag echannels of th e

windshield and th erear window at regular

intervals. Deposit ssuc has leaves, petals and

pollen may under certain circumstances pre -

ven twater from draining away. This can lead

to corrosio ndamage and damage to elec -

tronic components.

XClean th einside and outside of th ewindows

wit h a damp cloth and acleaning agen tthat is

recommended and approve dby Mercedes -

Benz .

Care265

Maintenance and care

Z

Page 271 of 318

increased wrinkling, to certain environmen-

tal influences (such as high humidity or

intense heat).

Rregular care is essential to make sure that

the appearance and comfort of the covers

are retained over time.

To clean genuine leather covers:

XRemove any dust, crumbs etc. If necessary,

carefully vacuum-clean the seat covers.

XCarefully wipe the leather seat covers with a

damp cloth.

XWipe over again with a dry cloth.

Make sure that the leather does not become

soaked, especially perforated parts.

XThen treat the leather seats with a leather

care foam.

Only use leather care agents that have been

tested and approved by Mercedes-Benz.

Observe the manufacturer's instructions.

Cleaning the seat belts

GWARNING

Seat belts can become severely weakened if

bleached or dyed. This could cause the seat

belts to tear or fail, for instance, in the event of an accident. This poses an increased risk of

injury or fatal injury.

Never bleach or dye the seat belts.

!Do not clean the seat belts using chemical

cleaning agents. Do not dry the seat belts by

heating at temperatures above 176 ‡(80 †)

or in direct sunlight.

Remove any stains or dirt immediately. This will

avoid residue or damage.

XUse clean, lukewarm water and soap solution.

Cleaning the headliner and carpets

XHeadliner: if it is very dirty, use a soft brush or

dry shampoo.

XCarpets: use the carpet and textile cleaning

agents recommended and approved by

Mercedes-Benz.

Care269

Maintenance and care

Z

Page 275 of 318

!Vehicles with a gasoline engine:avoid

repeated and lengthy starting attempts. Oth-

erwise, the catalytic converter could be dam-

aged by non-combusted fuel.

If the indicator and warning lamps in the instru-

ment cluster do not light up at low tempera-

tures, the discharged battery may have frozen.

In this case you may neither charge the battery

nor jump-start the vehicle. The service life of a

thawed battery may be shorter. Start-up behav-

ior may deteriorate, in particular at low temper-

atures. Have the thawed battery checked at a

qualified specialist workshop.

Do not use a rapid charging device to start the

vehicle. If your vehicle's battery is discharged,

the engine can be jump-started from another

vehicle or from a donor battery using jumper

cables. For this purpose, the vehicle has a jump-

starting connection point in the engine com-

partment.

When jump-starting, observe the following

points:

RThe battery is not accessible in all vehicles. If

the other vehicle's battery is not accessible,

jump-start the vehicle using a donor battery

or a jump-starting device.

RYou may only jump-start the vehicle when the

engine and exhaust system are cold.

Rdo not start the engine if the battery is frozen.

Let the battery thaw first.

Rjump-starting may only be performed from

batteries with a nominal voltage of 12 V.

Ronly use jumper cables that have a sufficient

cross-section and insulated terminal clamps.

Rif the battery is fully discharged, attach the

battery of another vehicle for a few minutes

before attempting to start. This charges the

empty battery a little.

Rmake sure that the two vehicles do not touch.

Make sure that:

Rthe jumper cables are not damaged.

Rbare parts of the terminal clamps do not come into contact with other metal parts while the

jumper cables are connected to the battery.

Rthe jumper cables cannot come into contact

with parts such as the V-belt pulley or the fan.

These parts move when the engine is started

and while it is running.

Jumper cables and further information regarding

jump starting can be obtained at any qualified

specialist workshop.

Before connecting the jumper cables

XApply the parking brake.

XShift the transmission to position P.

XSwitch off all electrical consumers, e.g. audio

equipment, blower.

XTurn the key to position 0in the ignition lock

and remove it.

XOpen the hood (Ypage 251).

Connecting the jumper cable

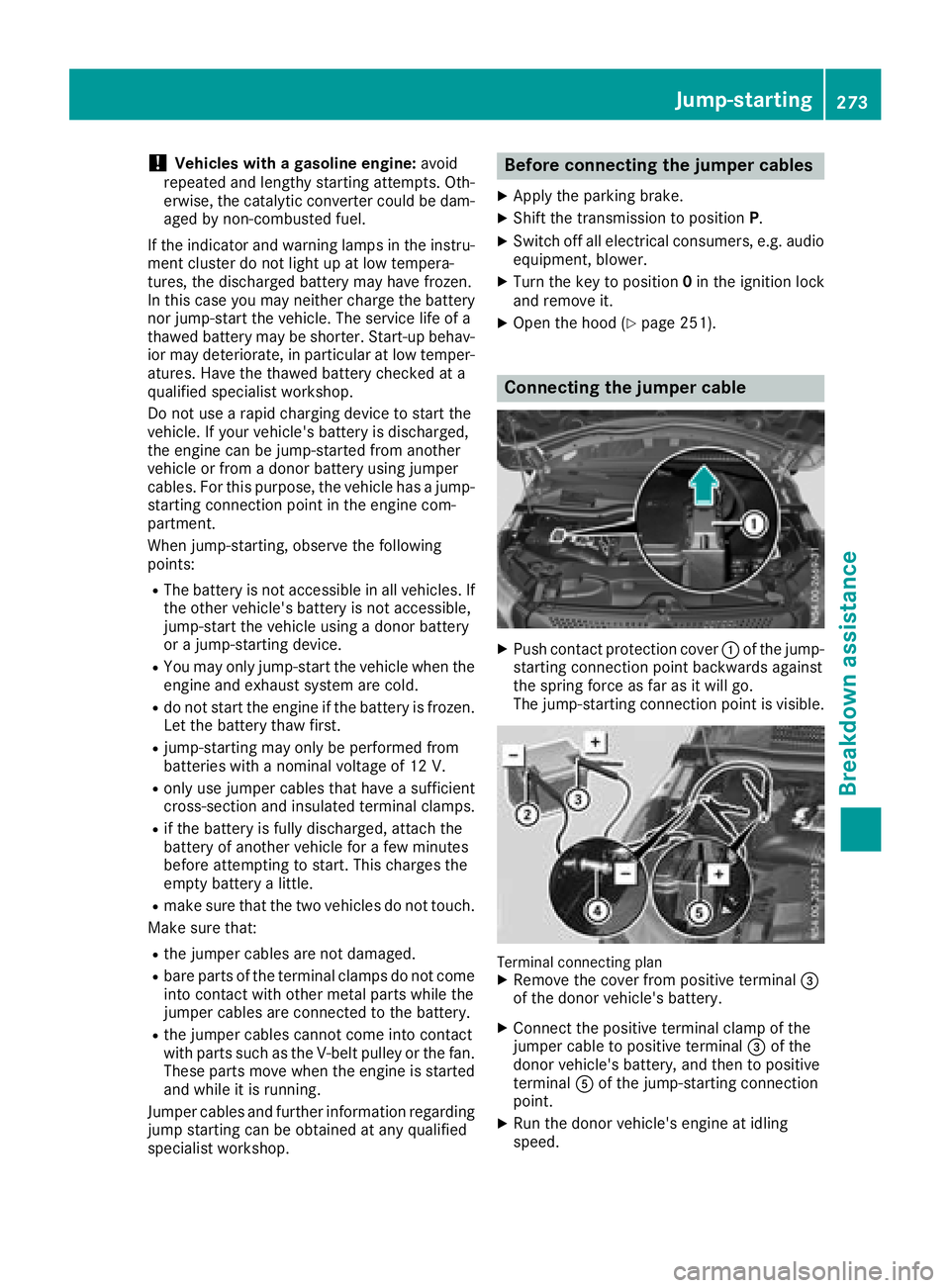

XPush contact protection cover :of the jump-

starting connection point backwards against

the spring force as far as it will go.

The jump-starting connection point is visible.

Terminal connecting planXRemove the cover from positive terminal =

of the donor vehicle's battery.

XConnect the positive terminal clamp of the

jumper cable to positive terminal =of the

donor vehicle's battery, and then to positive

terminal Aof the jump-starting connection

point.

XRun the donor vehicle's engine at idling

speed.

Jump-starting273

Breakdown assistance

Z

Page 296 of 318

the year of manufacture. For example, a tire that

is marked with "3208" was manufactured in

week 32 in 2008.

iTire data is vehicle-specific and may deviate

from the data in the example.

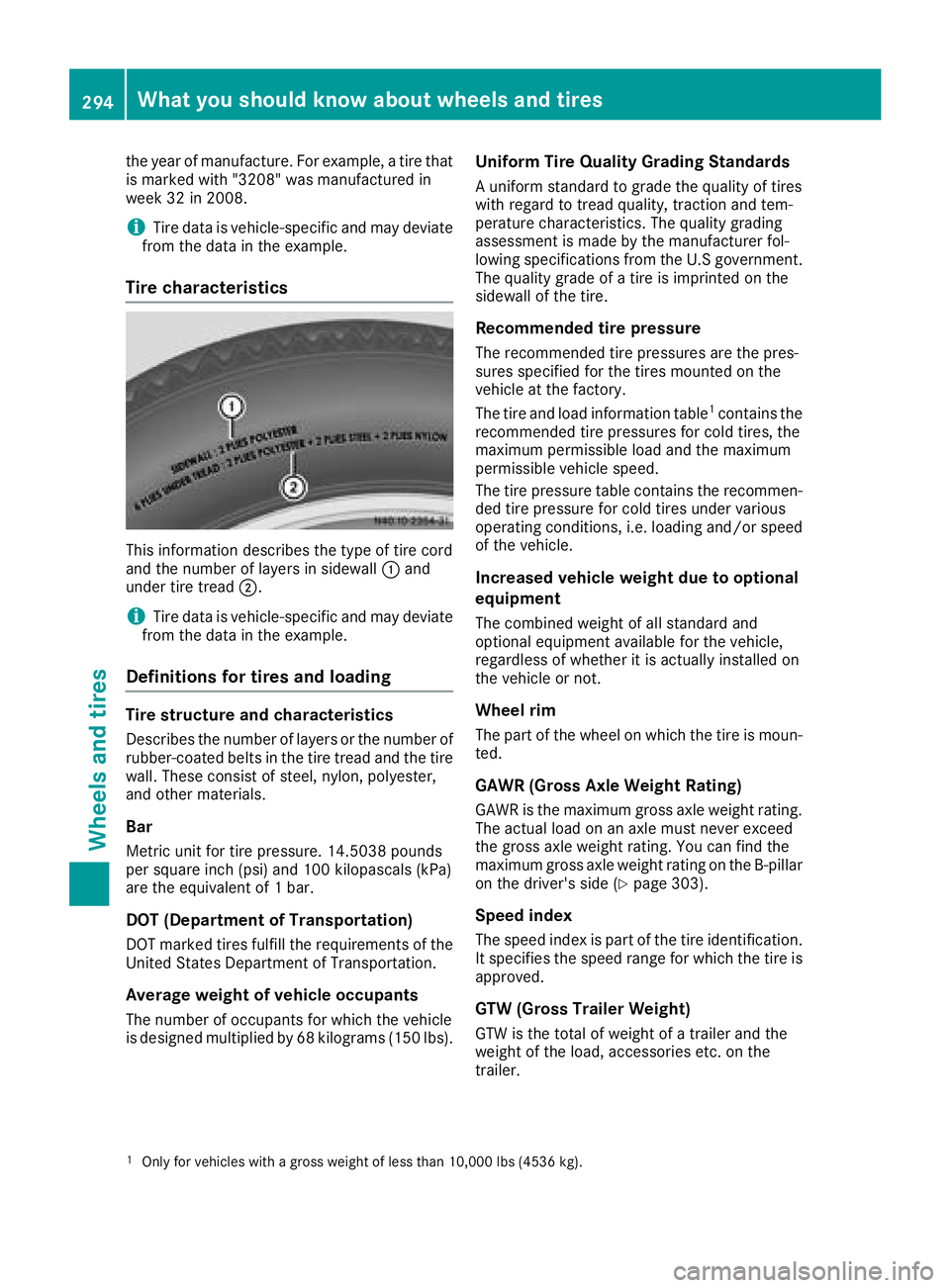

Tire characteristics

This information describes the type of tire cord

and the number of layers in sidewall :and

under tire tread ;.

iTire data is vehicle-specific and may deviate

from the data in the example.

Definitions for tires and loading

Tire structure and characteristics

Describes the number of layers or the number of

rubber-coated belts in the tire tread and the tire

wall. These consist of steel, nylon, polyester,

and other materials.

Bar

Metric unit for tire pressure. 14.5038 pounds

per square inch (psi) and 100 kilopascals (kPa)

are the equivalent of 1 bar.

DOT (Department of Transportation)

DOT marked tires fulfill the requirements of the

United States Department of Transportation.

Average weight of vehicle occupants

The number of occupants for which the vehicle

is designed multiplied by 68 kilograms (150 lbs).

Uniform Tire Quality Grading Standards

A uniform standard to grade the quality of tires

with regard to tread quality, traction and tem-

perature characteristics. The quality grading

assessment is made by the manufacturer fol-

lowing specifications from the U.S government.

The quality grade of a tire is imprinted on the

sidewall of the tire.

Recommended tire pressure

The recommended tire pressures are the pres-

sures specified for the tires mounted on the

vehicle at the factory.

The tire and load information table

1contains the

recommended tire pressures for cold tires, the

maximum permissible load and the maximu

m

permissible vehicle speed.

The tire pressure table contains the recommen-

ded tire pressure for cold tires under various

operating conditions, i.e. loading and/or speed

of the vehicle.

Increased vehicle weight due to optional

equipment

The combined weight of all standard and

optional equipment available for the vehicle,

regardless of whether it is actually installed on

the vehicle or not.

Wheel rim

The part of the wheel on which the tire is moun-

ted.

GAWR (Gross Axle Weight Rating)

GAWR is the maximum gross axle weight rating.

The actual load on an axle must never exceed

the gross axle weight rating. You can find the

maximum gross axle weight rating on the B-pillar

on the driver's side (

Ypage 303).

Speed index

The speed index is part of the tire identification. It specifies the speed range for which the tire is

approved.

GTW (Gross Trailer Weight)

GTW is the total of weight of a trailer and the

weight of the load, accessories etc. on the

trailer.

1Only for vehicles with a gross weight of less than 10,000 lbs (4536 kg).

294What you should know about wheels and tires

Wheels and tires