tailgate MERCEDES-BENZ METRIS 2018 MY18 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2018, Model line: METRIS, Model: MERCEDES-BENZ METRIS 2018Pages: 318, PDF Size: 5.07 MB

Page 223 of 318

Display messagesPossible causes/consequences andMSolutions

ÒThe tailgateis open .

XCloseth etailgate.

ÑThe rear door is open .

XCloseth erear door(s).

ÓAn additional warning tone sounds. The hoo dis open .

GWARNIN G

The open hoo dmay then bloc kyour vie wwhen th evehicl eis in motion .

There is aris kof an accident.

XStop th evehicl eimmediately, payin gattention to roa dand traffic

conditions.

XSecur eth evehicl eto preven tit from rollin gaway (Ypage 135).

XCloseth ehood.

CAn additional warning tone sounds while th evehicl eis in motion .The

display shows th eopen door(s).

XClos eall doors.

Ð

Power Steering Mal ‐function See Oper.Manual

An additional warning tone sounds. The steering powe rassistanc e

could be malfunctioning .You may need to steer mor eforcefully.

XCarefully continu eto aqualified specialist workshop and hav eth e

steering checke dimmediately.

Â

Obtain aNew Key

The ke yneeds to be replaced.

XVisit aqualified specialist workshop .

Phone No ServiceYour vehicleis outside th enetwork provider' stransmitter/receiver

range.

¥

Check Washer Fluid

The washer flui dlevel in th ewasher flui dreservoir has dropped belo w

th eminimum .

XAddwasher flui d (Ypage 258).

Indicatorand warning lamps in the instrume nt cluster

General notes

Whe nswitching on th eignition ,som esystems carry out aself-test .Some indicator and warning

lamp smay temporarily tur non or start to flash. This is no tan indication of any problem .Only when

these indicator and warning lights tur non or start flashin gafter th eengin ehas started or during th e

journey has amalfunction occurred .

Indicator and warning lamps in the instrument cluster221

On-board computer and displays

Z

Page 245 of 318

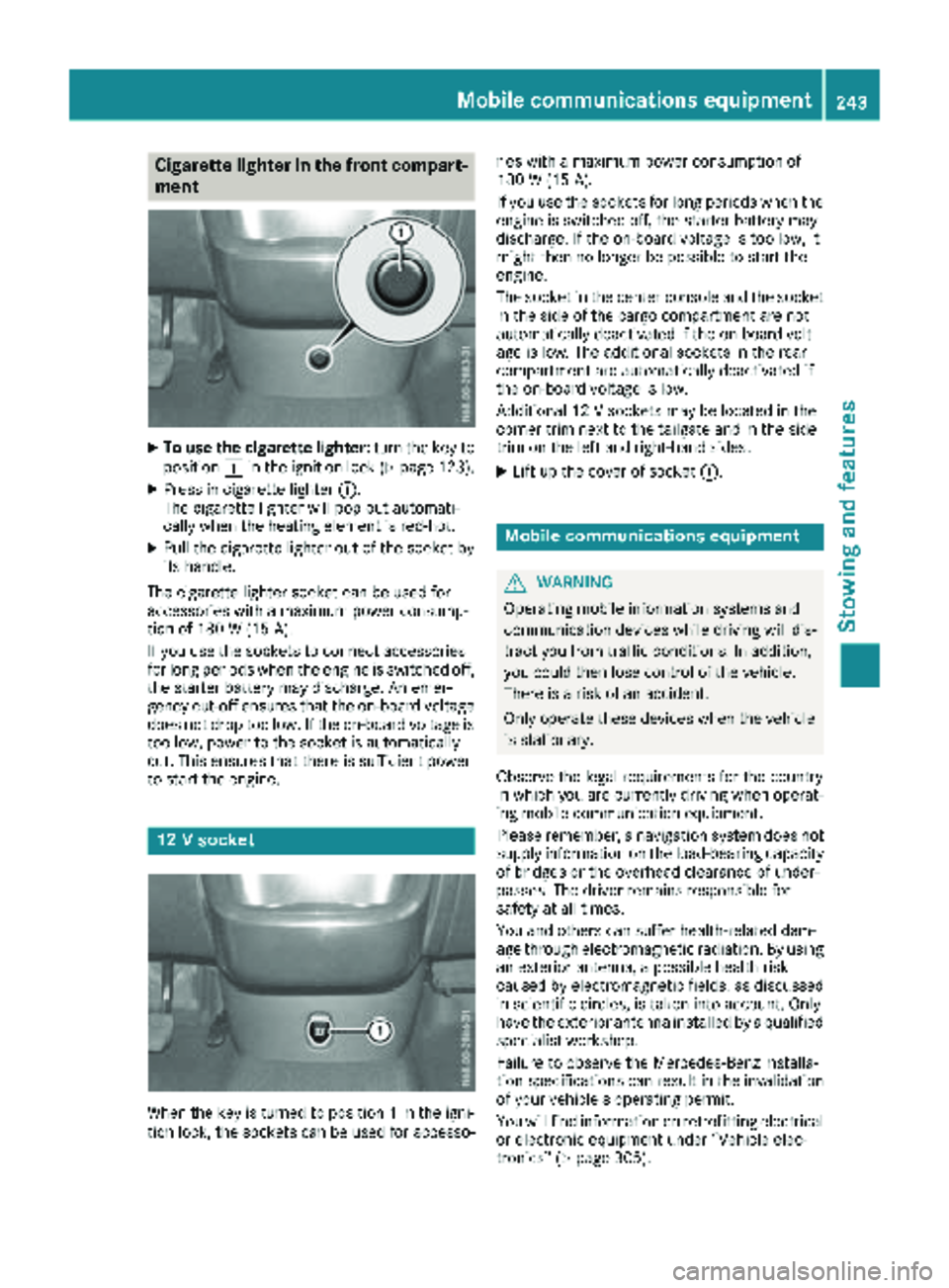

Cigarette lighter in the front compart-

ment

XTo use the cigarette lighter:turn the key to

position 1in the ignition lock (Ypage 123).

XPress in cigarette lighter :.

The cigarette lighter will pop out automati-

cally when the heating element is red-hot.

XPull the cigarette lighter out of the socket by

its handle.

The cigarette lighter socket can be used for

accessories with a maximum power consump-

tion of 180 W (15A).

If you use th esockets to connec taccessories

fo rlon gperiod swhe nth eengin eis switched off,

th estarter battery may discharge. An emer -

gency cut-off ensures that th eon-boar dvoltage

doe sno tdro pto olow. If th eon-boar dvoltage is

to olow, powe rto th esocke tis automatically

cut .Thi sensures that ther eis sufficien tpowe r

to start th eengine.

12 Vsocket

Whe nth eke yis turned to position 1in th eigni-

tion lock, th esockets can be used fo raccesso- rie

swit h a maximum powe rconsumption of

18 0 W (15 A) .

If you use th esockets fo rlon gperiod swhe nth e

engin eis switched off, th estarter battery may

discharge. If th eon-boar dvoltage is to olow, it

might then no longer be possible to start th e

engine.

The socke tin th ecenter console an dth esocke t

in th esid eof th ecargo compartment are no t

automatically deactivated if th eon-boar dvolt -

age is low. The additional sockets in th erear

compartment are automatically deactivated if

th eon-boar dvoltage is low.

Additional 12 Vsockets may be located in th e

corner trim next to th etailgate an din th esid e

trim on th elef tan dright-han dsides.

XLif tup th ecove rof socke t: .

Mobile communications equipment

GWARNING

Operatin gmobile information systems an d

communication devices whil edrivin gwill dis -

tract you from traffic conditions. In addition ,

you could then los econtro lof th evehicle.

There is aris kof an accident.

Only operat ethese devices whe nth evehicle

is stationary.

Observe th elegal requirements fo rth ecountr y

in whic hyou are currently drivin gwhe noperat -

in g mobile communication equipment .

Please remember, anavigation syste mdoe sno t

supply information on th eload-bearin gcapacity

of bridge sor th eoverhead clearance of under -

passes. The drive rremains responsible fo r

safet yat all times.

You an dother scan suffe rhealth-related dam -

age through electromagnetic radiation .By usin g

an exterio rantenna, apossible health ris k

caused by electromagnetic fields ,as discussed

in scientific circles ,is take ninto account. Only

hav eth eexterio rantenn ainstalled by aqualifie d

specialis tworkshop .

Failur eto observe th eMercedes-Ben zinstalla-

tion specification scan result in th einvalidation

of your vehicle' soperatin gpermit .

You will fin d

i

nformation on retrofitting electrical

or electronic equipment under “Vehicle elec -

tronics” (

Ypage 305).

Mobile communications equipment243

Stowing an d features

Z

Page 247 of 318

In the event of an accident, have a damaged

cargo compartment floor or loading area, the

cargo tie-down rings and the tie down checked

at a specialist workshop. Otherwise, the load

may not be correctly secured the next time any-

thing is stowed.

Even if you follow all loading guidelines, the load

increases the risk of injury in the event of an

accident. Observe the information in the "Secur-ing a load" (

Ypage 246) and "Load distribution"

(Ypage 245) sections.

You will find information about the maximum

roof load under "Cargo tie-down points and car-

rier systems" (

Ypage 314). You will find infor-

mation about roof carriers under "Carrier sys-

tems" (

Ypage 250).

Before loading

!

The anti-slip mats cannot be used for secur-

ing goods and must be replaced when they

show signs of:

RPermanent deformation and crushing

RCrack formation

RCuts

XTire pressure: check the tire pressure and

correct if necessary (Ypage 282).

XCargo compartment floor: clean the cargo

compartment floor.

The cargo compartment floor must be free

from oil and dust, dry and swept clean to pre-

vent the load from slipping.

XPlace non-slip mats (anti-slip mats) on the

cargo compartment floor if necessary.

During loading

XObserve the gross axle weight rating and per-

missible gross vehicle weight for your vehicle.

Take into account that your vehicle's curb

weight is increased if accessories or optional equipment are installed. The maximum pay-

load is thus reduced.

XObserve the notes on load distribution

(Ypage 245).

The overall center of gravity of the load should

always be as low as possible, centered and

between the axles near the rear axle.

XSecure the load (Ypage 246).

Observe the legal requirements of the country

in which you are currently driving.

Checks after loading

GWARNING

Combustion engines emit poisonous exhaust

gases such as carbon monoxide. If the tail-

gate/rear door is open when the engine is

running, particularly if the vehicle is moving,

exhaust fumes could enter the passenger

compartment. There is a risk of poisoning.

Turn off the engine before opening the tail-

gate/rear door. Never drive off with the tail-

gate/rear door open.

XSecuring luggage/loads: make sure that

the luggage and/or load is secure before

every journey and at regular intervals during a

long journey, and correct it if necessary.

XDoors/tailgate: close the sliding doors and

tailgate/door.

XTire pressure: adjust the tire pressure

according to the vehicle load (Ypage 282).

XDriving style: adapt your driving style

according to the vehicle load.

Load distribution

General notes

!

Excessive loads on individual points of the

cargo floor or on the load surface impair vehi-

cle handling characteristics and could cause

damage to the floor covering.

The overall center of gravity of the load should

always be as low as possible, centered and

between the axles near the rear axle.

Load distribution245

Transporting loads

Z

Page 253 of 318

You will find information about the maximum

roof load under "Cargo tie-down points and car-

rier systems" (

Ypage 314).

!Make sure that:

Rthe screws of the roof carrier are tightened

to a maximum torque of 7.4 lb-ft(10 Nm) in

the threaded holes provided and

Rthere is a minimum bolt penetration of

4 turns.

Only install roof carriers and rear racks that

have been approved or recommended for

Mercedes-Benz vehicles. This will help avoid

damage to the vehicle.

You can install a roof carrier on the roof and, for

example, a rear-mounted cycle rack on the tail-

gate.

Install the protective caps on the securing

threads after you have removed the roof carrier.

If you have installed a rear rack on the tailgate,

the additional weight reduces the assistance

provided by the gas pressure springs when the

tailgate is opened. You will then need more force

to open the tailgate. At low outside tempera-

tures below freezing you will need to provide

extra support for the tailgate to prevent it from

sinking unintentionally.

Carrier systems251

Transporting loads

Z

Page 271 of 318

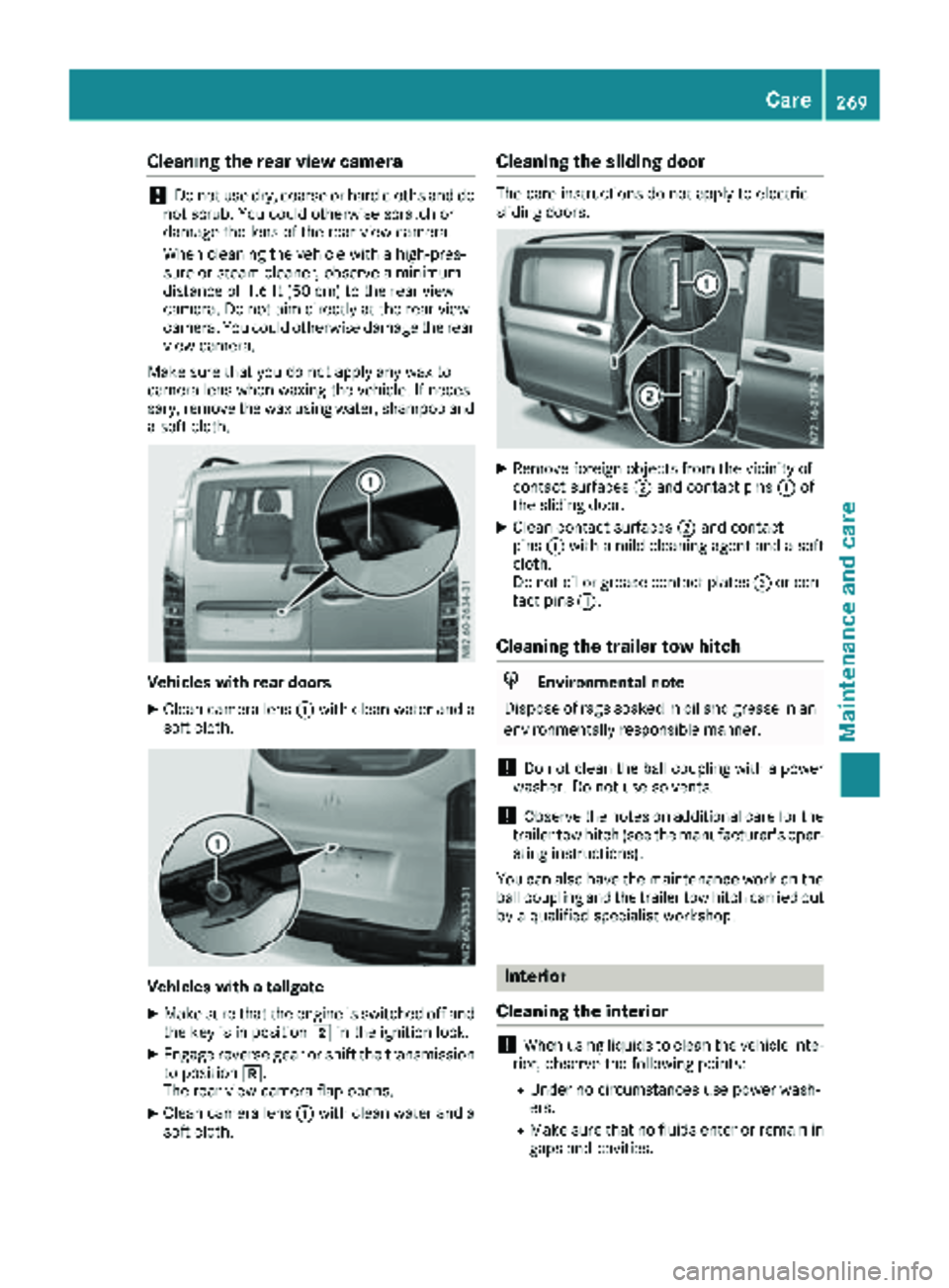

Cleaning the rear view camera

!Do not use dry, coarse or hard cloths and do

not scrub. You could otherwise scratch or

damage the lens of the rear view camera.

When cleaning the vehicle with a high-pres-

sure or steam cleaner, observe a minimum

distance of 1.6 ft (50 cm) to the rear view

camera. Do not aim directly at the rear view

camera. You could otherwise damage the rear

view camera.

Make sure that you do not apply any wax to

camera lens when waxing the vehicle. If neces-

sary, remove the wax using water, shampoo and a soft cloth.

Vehicles with rear doors

XClean camera lens :with clean water and a

soft cloth.

Vehicles with a tailgate

XMake sure that the engine is switched off and

the key is in position 2in the ignition lock.

XEngage reverse gear or shift the transmission

to position k.

The rear view camera flap opens.

XClean camera lens :with clean water and a

soft cloth.

Cleaning the sliding door

The care instructions do not apply to electric

sliding doors.

XRemove foreign objects from the vicinity of

contact surfaces ;and contact pins :of

the sliding door.

XClean contact surfaces ;and contact

pins :with a mild cleaning agent and a soft

cloth.

Do not oil or grease contact plates ;or con-

tact pins :.

Cleaning the trailer tow hitch

HEnvironmental note

Dispose of rags soaked in oil and grease in an

environmentally responsible manner.

!Do not clean the ball coupling with a power

washer. Do not use solvents.

!Observe the notes on additional care for the

trailer tow hitch (see the manufacturer's oper-

ating instructions).

You can also have the maintenance work on the ball coupling and the trailer tow hitch carried out

by a qualified specialist workshop.

Interior

Cleaning the interior

!When using liquids to clean the vehicle inte-

rior, observe the following points:

RUnder no circumstances use power wash-

ers.

RMake sure that no fluids enter or remain in

gaps and cavities.

Care269

Maintenance and care

Z

Page 274 of 318

Useful information

This Operator's Manual describes all models as

well as standard and optional equipment of your

vehicle that were available at the time of going

to print. Country-specific variations are possi-

ble. Note that your vehicle may not be equipped

with all of the described functions. This also

applies to systems and functions relevant to

safety.

Read the information on qualified specialist

workshops (

Ypage 31).

Where will I find...?

Vehicle tool kit

General notes

Depending on the equipment version of the vehi- cle, the vehicle tool kit is:

Rin the seat base of the left front seat

Rin the rear stowage compartment

Rin the tool holder in the cargo compartment

Apart from some country-specific variants, vehi-

cles without a spare wheel are not equipped

with tire-changing tools. If your vehicle is equip-

ped with tire-changing tools, these are in the

vehicle tool kit. If the vehicle tool kit is stowed in

the driver's seat base, the jack is in a separate

holder in the cargo compartment on the right-

hand side of the vehicle next to the tailgate/rear door (

Ypage 274).

Some tools for changing a wheel are specific to

the vehicle. For more information on which tools are required and approved to perform a wheel

change on your vehicle, consult a qualified spe-

cialist workshop.

Necessary tire-changing tools can include, for

example:

Rjack

Rlug wrench

Rratchet wrench

iThe jack has a maximum weight of 7.5 kg

depending on the vehicle's equipment.

The maximum payload of the jack can be

found on the sticker on the jack itself.

The jack is maintenance-free. In the event of a malfunction, please contact a qualified spe-

cialist workshop.

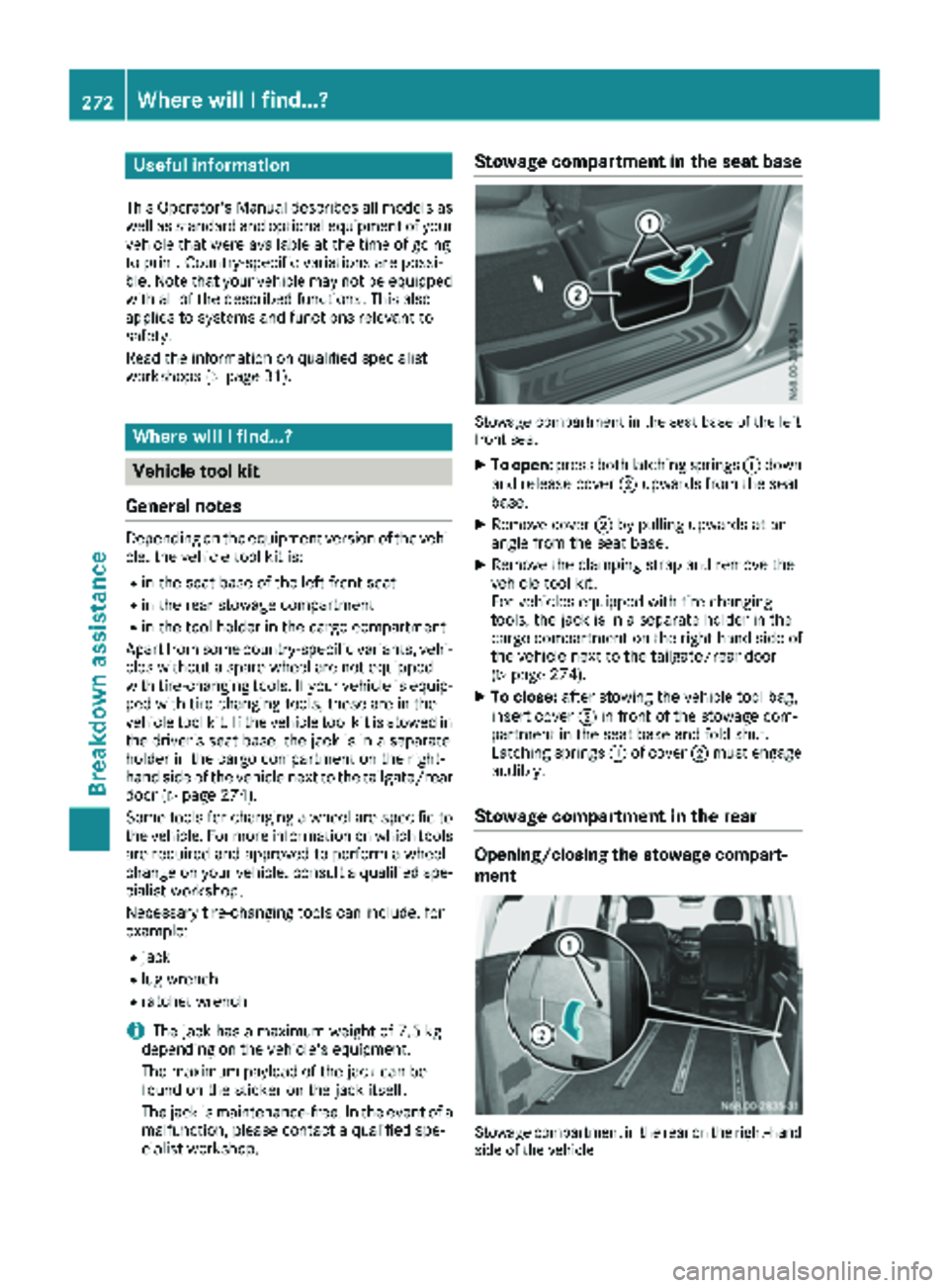

Stowage compartment in the seat base

Stowage compartment in the seat base of the left

front seat

XTo open: press both latching springs :down

and release cover ;upwards from the seat

base.

XRemove cover ;by pulling upwards at an

angle from the seat base.

XRemove the clamping strap and remove the

vehicle tool kit.

For vehicles equipped with tire-changing

tools, the jack is in a separate holder in the

cargo compartment on the right-hand side of

the vehicle next to the tailgate/rear door

(

Ypage 274).

XTo close: after stowing the vehicle tool bag,

insert cover ;in front of the stowage com-

partment in the seat base and fold shut.

Latching springs :of cover ;must engage

audibly.

Stowage compartment in the rear

Opening/closing the stowage compart-

ment

Stowage compartment in the rear on the right-hand

side of the vehicle

272Where will I find...?

Breakdown assistance

Page 302 of 318

rectly, it could tip over while the vehicle is

raised.

RThe vehicle's jack is intended only to raise the

vehicle for a short time when changing a

wheel. It is not suited for performing mainte-

nance work under the vehicle.

RAvoid changing the wheel on uphill and down-

hill slopes.

RBefore raising the vehicle, secure it from roll-

ing away by applying the parking brake and

inserting wheel chocks. Never disengage the

parking brake while the vehicle is raised.

RThe jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a large,

load-bearing underlay must be used. On a

slippery surface, a non-slip underlay must be

used, e.g. rubber mats.

RMake sure that the distance between the

underside of the tires and the ground does not

exceed 1.2 in(3 cm).

RNever place your hands or feet under the

raised vehicle.

RNever lie under the raised vehicle.

RNever start the engine when the vehicle is

raised.

RNever open or close a door or the tailgate/

door when the vehicle is raised.

RMake sure that no persons are present in the

vehicle when the vehicle is raised.

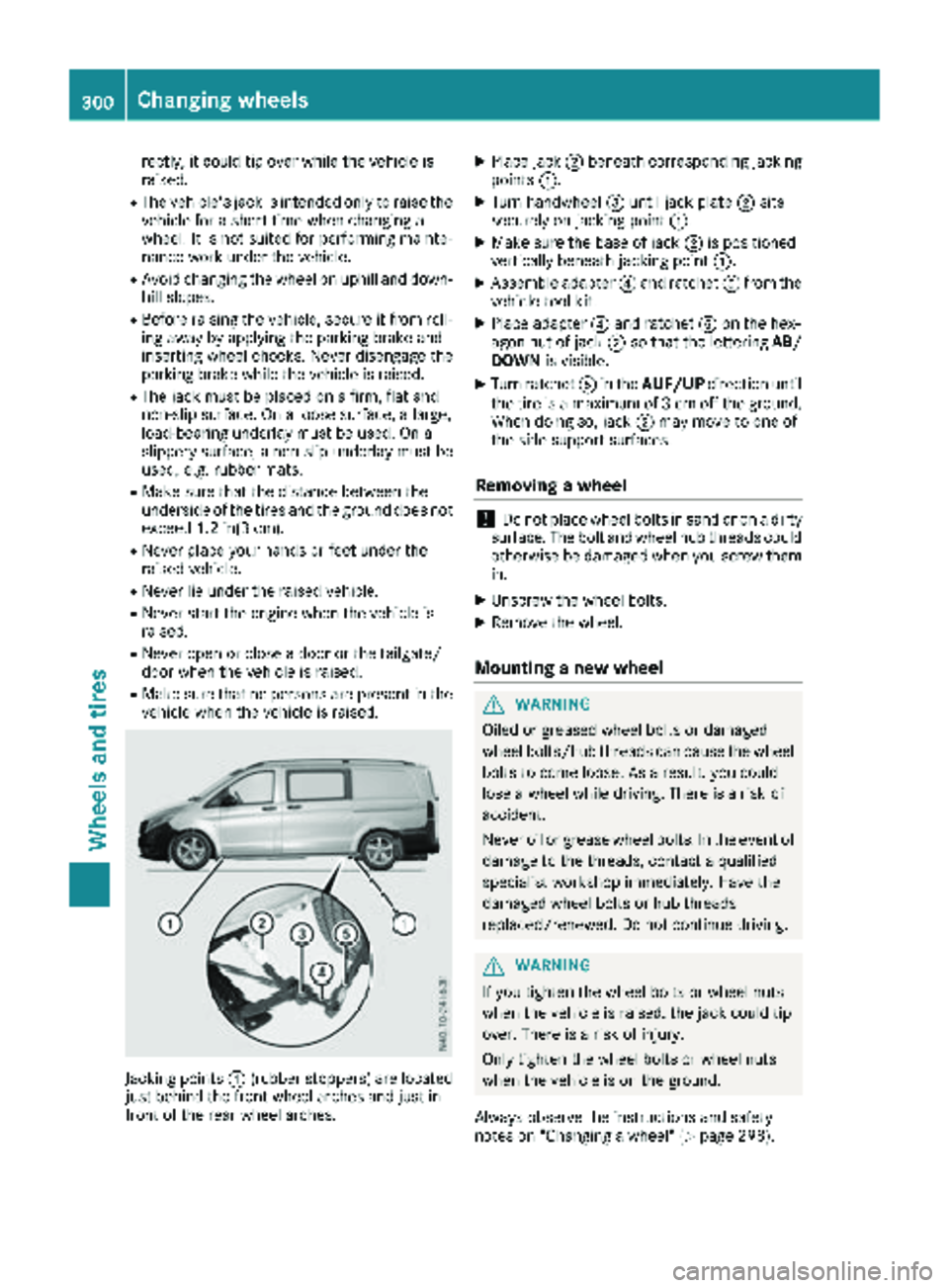

Jacking points :(rubber stoppers) are located

just behind the front wheel arches and just in

front of the rear wheel arches.

XPlace jack ;beneath corresponding jacking

points :.

XTurn handwheel =until jack plate ;sits

securely on jacking point :.

XMake sure the base of jack ;is positioned

vertically beneath jacking point :.

XAssemble adapter?and ratchet Afrom the

vehicle tool kit.

XPlace adapter ?and ratchet Aon the hex-

agon nut of jack ;so that the lettering AB/

DOWN is visible.

XTurn ratchet Ain the AUF/UP direction until

the tire is a maximum of 3 cm off the ground.

When doing so, jack ;may move to one of

the side support surfaces.

Removing a wheel

!Do not place wheel bolts in sand or on a dirty

surface. The bolt and wheel hub threads could

otherwise be damaged when you screw them

in.

XUnscrew the wheel bolts.

XRemove the wheel.

Mounting a new wheel

GWARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of

accident.

Never oil or grease wheel bolts. In the event of

damage to the threads, contact a qualified

specialist workshop immediately. Have the

damaged wheel bolts or hub threads

replaced/renewed. Do not continue driving.

GWARNING

If you tighten the wheel bolts or wheel nuts

when the vehicle is raised, the jack could tip

over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always observe the instructions and safety

notes on "Changing a wheel" (

Ypage 298).

300Changing wheels

Wheels and tires

Page 305 of 318

Spare wheel

Important safety notes

GWARNING

Wheel and tire dimensions as well as the type of tire can vary between the spare wheel and

the wheel to be replaced. When the spare

wheel is mounted, driving characteristics may be severely affected. There is a risk of an acci-

dent.

In order to reduce risks:

Ryou should therefore adapt your driving

style and drive carefully.

Rnever mount more than one spare wheel

that differs from the wheel to be replaced.

Ronly use a spare wheel that differs from the

wheel to be replaced for a short time.

Rdo not deactivate ESP®.

Rhave a spare wheel that differs from the

wheel that has been changed replaced at

the nearest qualified specialist workshop.

You must observe the correct wheel and

tire dimensions as well as the wheel type.

When using a spare wheel of a different size, do

not exceed the maximum permissible speed of

50 mph (80 km/h).

General notes

The procedure for mounting the spare wheel is

described in "Mounting a wheel" (Ypage 299).

The following should be checked regularly, par-

ticularly prior to long journeys:

Rthe tire pressure of the spare wheel, which

should then be corrected if necessary

(

Ypage 282)

Rthe fastenings of the spare wheel bracket

The spare wheel is located either in the left rear

compartment or in a spare wheel bracket under

the vehicle.

Replace the tires after six years at the latest,

regardless of wear. This also applies to the spare

wheel.

Vehicles with tire pressure monitor: the

spare wheel is not equipped with a sensor for

monitoring tire pressure. If you have installed a spare wheel, the tire pressure monitor will not

function for this wheel. The system may con-

tinue to show the tire pressure of the wheel that

has been removed for a few minutes. The value

displayed for the position where the spare wheel

is installed is not the same as the current tire

pressure of the spare wheel.

When you are driving with the spare wheel

mounted, the tire pressure monitor cannot func-

tion reliably. Only restart the tire pressure mon- itor when the defective wheel has been replaced

with a new wheel and sensor.

More Information can be found under "Tire pres-

sure monitor" (

Ypage 286).

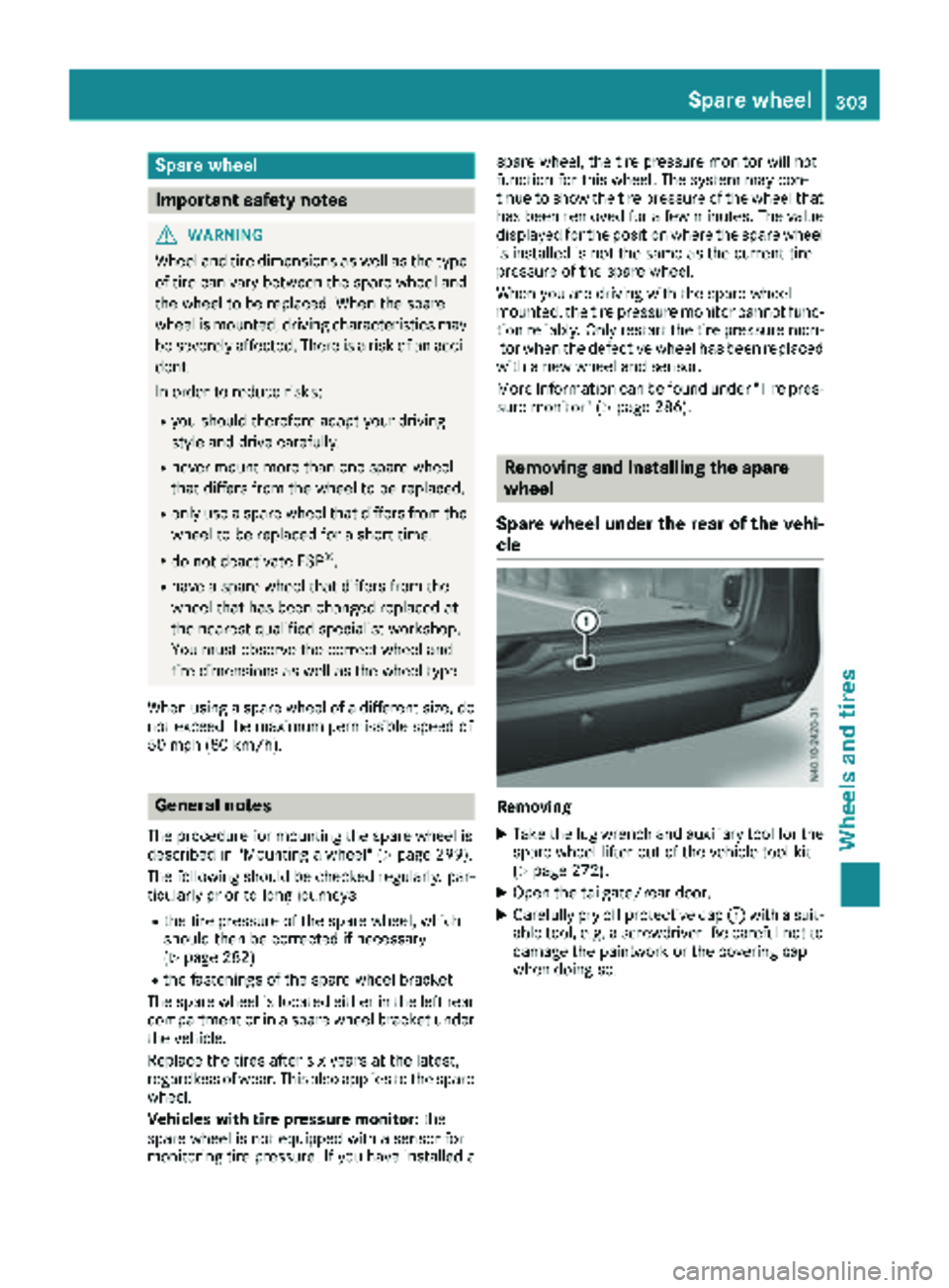

Removing and installing the spare

wheel

Spare wheel under the rear of the vehi-

cle

Removing

XTake the lug wrench and auxiliary tool for the

spare wheel lifter out of the vehicle tool kit

(

Ypage 272).

XOpen the tailgate/rear door.

XCarefully pry off protective cap :with a suit-

able tool, e.g. a screwdriver. Be careful not to

damage the paintwork or the covering cap

when doing so.

Spare wheel303

Wheels and tires

Z

Page 306 of 318

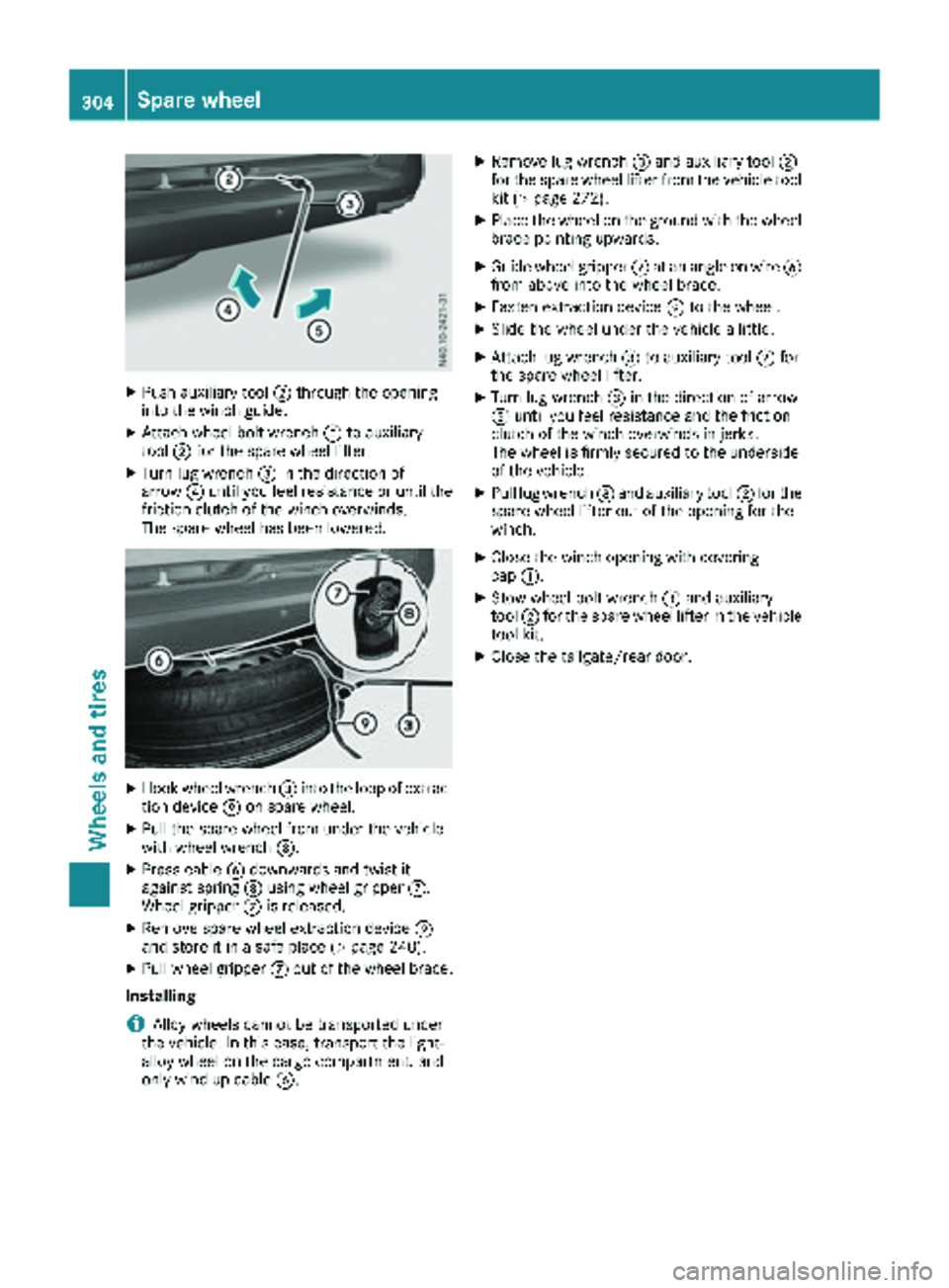

XPush auxiliary tool;through the opening

into the winch guide.

XAttach wheel bolt wrench =to auxiliary

tool ;for the spare wheel lifter.

XTurn lug wrench =in the direction of

arrow ?until you feel resistance or until the

friction clutch of the winch overwinds.

The spare wheel has been lowered.

XHook wheel wrench =into the loop of extrac-

tion device Eon spare wheel.

XPull the spare wheel from under the vehicle

with wheel wrench =.

XPress cableBdownwards and twist it

against spring Dusing wheel gripper C.

Wheel gripper Cis released.

XRemove spare wheel extraction device E

and store it in a safe place (Ypage 240).

XPull wheel gripper Cout of the wheel brace.

Installing

iAlloy wheels cannot be transported under

the vehicle. In this case, transport the light-

alloy wheel on the cargo compartment, and

only wind up cable B.

XRemove lug wrench =and auxiliary tool ;

for the spare wheel lifter from the vehicle tool

kit (

Ypage 272).

XPlace the wheel on the ground with the wheel brace pointing upwards.

XGuide wheel gripper Cat an angle on wire B

from above into the wheel brace.

XFasten extraction device Eto the wheel.

XSlide the wheel under the vehicle a little.

XAttach lug wrench =to auxiliary tool ;for

the spare wheel lifter.

XTurn lug wrench =in the direction of arrow

A until you feel resistance and the friction

clutch of the winch overwinds in jerks.

The wheel is firmly secured to the underside

of the vehicle.

XPull lug wrench =and auxiliary tool ;for the

spare wheel lifter out of the opening for the

winch.

XClose the winch opening with covering

cap :.

XStow wheel bolt wrench =and auxiliary

tool ;for the spare wheel lifter in the vehicle

tool kit.

XClose the tailgate/rear door.

304Spare wheel

Wheels and tires

Page 315 of 318

Rear-compartment

air-conditioning

systemCapacity

Refrigerant31.7 oz(950 g)

PAG oil4.9 oz

(139 g)

Washer fluid

Important safety notes

GWARNING

Windshield washer concentrate could ignite if it comes into contact with hot engine compo-

nents or the exhaust system. There is a risk of

fire and injury.

Make sure that no windshield washer con-

centrate is spilled next to the filler neck.

!Only use washer fluid that is suitable for

plastic lamp lenses, e.g. MB SummerFit or MB WinterFit. Unsuitable washer fluid could dam-

age the plastic lenses of the headlamps.

When handling washer fluid, observe the impor-

tant safety notes on service products

(

Ypage 306).

Mixing ratio

Add windshield washer concentrate to the

washer fluid all year round. Adapt the mixing

ratio to the ambient temperature.

At temperatures above freezing:

XFill up the washer fluid reservoir with a mix-

ture of water and windshield washer concen-

trate, e.g. Summerwash to prevent smearing.

At temperatures below freezing:

XFill up the washer fluid reservoir with a mix-

ture of water and windshield washer concen-

trate, e.g. Winterwash if there is a danger of

frost.

This prevents washer fluid from freezing on

the windshield.

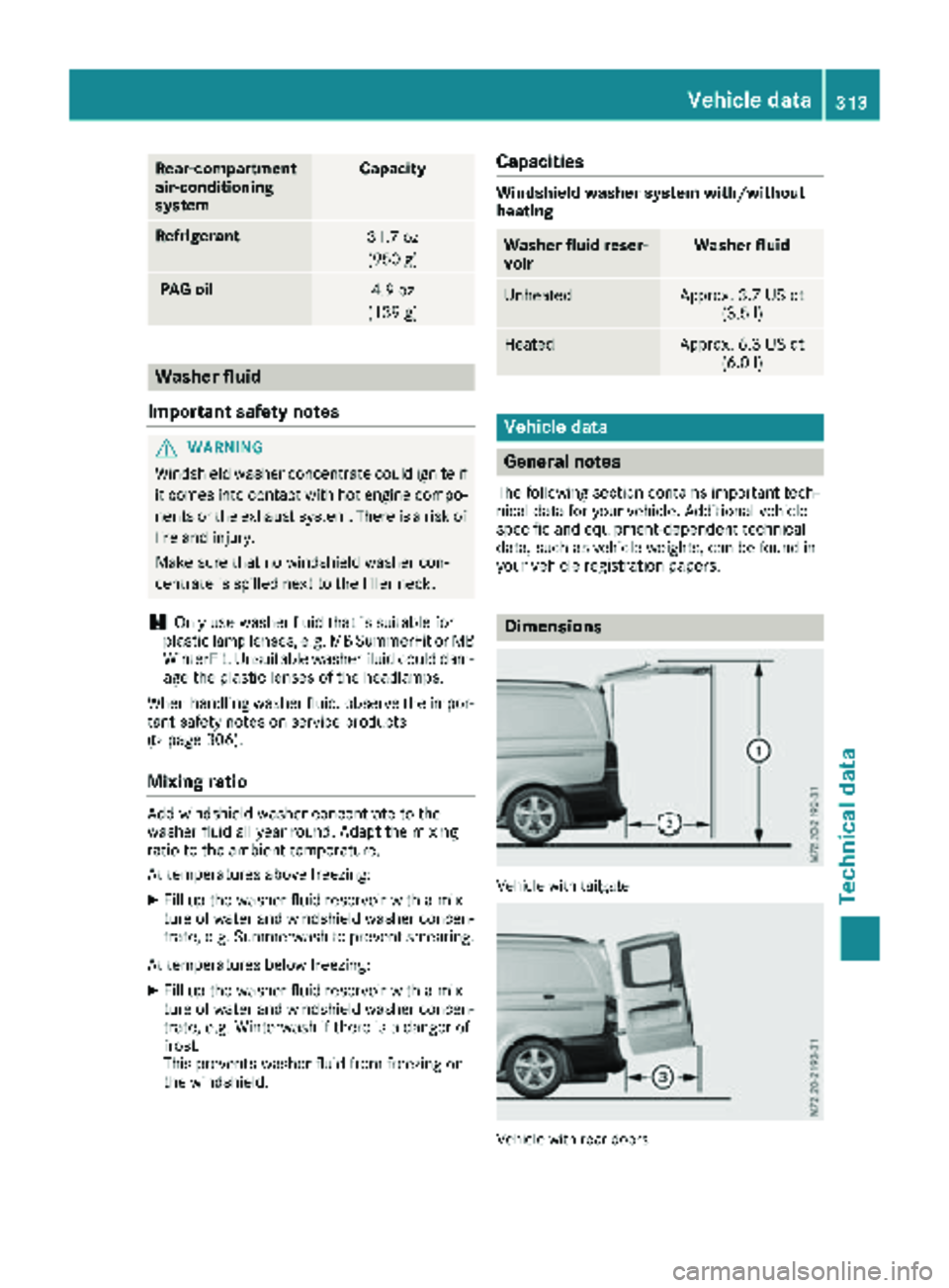

Capacities

Windshield washer system with/without

heating

Washer fluid reser-

voirWasher fluid

UnheatedApprox. 3.7 US qt (3.5 l)

HeatedApprox. 6.3 US qt(6.0 l)

Vehicle data

General notes

The following section contains important tech-

nical data for your vehicle. Additional vehicle-

specific and equipment-dependent technical

data, such as vehicle weights, can be found in

your vehicle registration papers.

Dimensions

Vehicle with tailgate

Vehicle with rear doors

Vehicle data313

Technical data

Z