oil pressure MERCEDES-BENZ METRIS 2018 MY18 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2018, Model line: METRIS, Model: MERCEDES-BENZ METRIS 2018Pages: 318, PDF Size: 5.07 MB

Page 6 of 318

1, 2, 3 ...

12-V socket........................................ 243

A

ABS (anti-lock braking system)

Display message (vehicle with

steering wheel buttons) ................ .206

Display message (vehicle without

steering wheel buttons) ................. 192

Function/notes ................................ 64

Important safety notes .................... 64

Warning lamp ................................. 224

Accident

Automatic measures after an acci-

dent ................................................. 58

Activating/deactivating cooling

with air dehumidification ................. 114

Active Parking Assist

Canceling/stopping active park-

ing assistance ................................ 160

Detecting parking spaces .............. 157

Display message ............................ 216

Exiting a parking space .................. 159

Function/notes .............................1 56

Important safety notes .................. 156

Parking .......................................... 158

Towing a trailer .............................. 156

Add-on equipment ............................... 32

Additional indicators

Replacing bulbs .............................1 04

Additional speedometer

On-board computer (vehicle with

steering wheel buttons) ................. 188

On-board computer (vehicle with-

out steering wheel buttons) ........... 177

Additives

Engine oil ....................................... 310

Gasoline ......................................... 308

Air bag

Display message (vehicle with

steering wheel buttons) ................. 207

Display message (vehicle without

steering wheel buttons) ................. 193

Air bags

Deployment ..................................... 56 Front air bag (driver, front

passenger) ....................................... 51

Important safety notes .................... 50

Introduction ..................................... 49

Occupant Classification System

(OCS) ............................................... 52

PASSENGER AIR BAG OFF indica-

tor lamp ...........................................4

6

Side impact air bag .......................... 51

W

indow curtain air bag .................... 52

Air pressure

see Tire pressure

Air vents

Important safety notes .................. 120

Setting the center air vents ........... 120

Setting the rear-compartment air

vents .............................................. 120

Setting the side air vents ............... 120

Air vents

see Air vents

Air-conditioning system

see Climate control

Alarm system

see ATA (Anti-Theft Alarm system)

Alertness assistant

see ATTENTION ASSIST

Ambient lamp

Changing a bulb (front door) .......... 101

Changing a bulb (tailgate) .............. 101

Changing a bulb (vanity mirror) ...... 101

Anti-lock braking system

see ABS (Anti-lock Braking System)

Anti-skid chains

see Snow chains

Anti-Theft Alarm system

see ATA (Anti-Theft Alarm system)

Armrests .............................................. 92

Ashtray ............................................... 242

ATA (Anti-Theft Alarm system) ........... 68

ATTENTION ASSIST

Activating/deactivating (vehicle

with steering wheel buttons) ......... 187

Activating/deactivating (vehicle

without steering wheel buttons) .... 177

Display messages (vehicle with

steering wheel buttons) ................. 216

Display messages (vehicle with-

out steering wheel buttons) ........... 202

4Index

Page 25 of 318

TIN (Tire Identification Number)

(definition) .....................................298

Tire bead (definition) ......................2 97

Tire pressure (definition) ................ 297

Tire pressures (recommended) ...... 296

Tire size designation, load-bearing

capacity, speed rating .................... 293

Tire tread ....................................... 280

Tire tread (definition) ..................... 297

Total load limit (definition) ............. 298

Traction (definition) ....................... 298

TWR (permissible trailer drawbar

noseweight) (definition) ................. 298

Uniform Tire Quality Grading

Standards (definition) .................... 296

Wear indicator (definition) ............. 298

Wheel and tire combination ........... 302

Wheel rim (definition) .................... 296

Wheel/tire combinations ...............3 02

Tool

see Vehicle tool kit

Top Tether ............................................ 61

Tow-starting

Emergency engine starting ............ 278

Important safety notes .................. 276

Towing

If the vehicle is stuck ..................... 278

Installing/removing the towing

eye ................................................. 277

Towing a trailer

Active Parking Assist ..................... 156

Axle load, permissible .................... 316

Cleaning the trailer tow hitch ......... 269

Coupling up a trailer ......................1 67

Decoupling a trailer ....................... 168

Driving tips ....................................1 65

Notes on retrofitting ......................3 15

Power supply ................................. 170

Trailer loads ................................... 316

Towing away

Important safety guidelines ........... 276

With both axles on the ground ....... 278

With the rear axle raised ................ 277

Towing eye ......................................... 272

Trailer coupling

see Towing a trailer

Trailer loads and drawbar nose-

weights ............................................... 169 Trailer operation

Lights display messages (vehicle

with steering wheel buttons) ......... 211

Lights display messages (vehicle

without steering wheel buttons) .... 198

Trailer towing

Blind Spot Assist ............................ 150

ESP

®................................................ 67

PARKTRONIC ................................. 156

Permissible trailer loads and

drawbar noseweights ..................... 169

Transmission

see Automatic transmission

Transmission oil ........................ 310, 311

Transmission positions

Automatic transmission ................. 129

Display (DIRECT SELECT lever) ...... 130

Transport

Lashing straps ............................... 247

Loading guidelines ......................... 244

Stickers ......................................... 247

Vehicle ...........................................2 78

Transport by rail ................................ 139

Transportation

Rail ................................................ 139

Transportation aids

Load protection net ....................... 249

Transporting

Cargo compartment variations ...... 246

Load distribution ............................ 245

Securing a load .............................. 246

Trim pieces (cleaning instruc-

tions) .................................................. 270

Trip computer

Displaying (vehicle with steering

wheel buttons) ............................... 181

Displaying (vehicle without steer-

ing wheel buttons) ......................... 174

Resetting (vehicle with steering

wheel buttons) ............................... 181

Resetting (vehicle without steer-

ing wheel buttons) ......................... 174

Selecting the display units (vehi-

cle with steering wheel buttons) .... 188

Selecting the display units (vehi-

cle without steering wheel but-

tons) .............................................. 177

Index23

Page 247 of 318

In the event of an accident, have a damaged

cargo compartment floor or loading area, the

cargo tie-down rings and the tie down checked

at a specialist workshop. Otherwise, the load

may not be correctly secured the next time any-

thing is stowed.

Even if you follow all loading guidelines, the load

increases the risk of injury in the event of an

accident. Observe the information in the "Secur-ing a load" (

Ypage 246) and "Load distribution"

(Ypage 245) sections.

You will find information about the maximum

roof load under "Cargo tie-down points and car-

rier systems" (

Ypage 314). You will find infor-

mation about roof carriers under "Carrier sys-

tems" (

Ypage 250).

Before loading

!

The anti-slip mats cannot be used for secur-

ing goods and must be replaced when they

show signs of:

RPermanent deformation and crushing

RCrack formation

RCuts

XTire pressure: check the tire pressure and

correct if necessary (Ypage 282).

XCargo compartment floor: clean the cargo

compartment floor.

The cargo compartment floor must be free

from oil and dust, dry and swept clean to pre-

vent the load from slipping.

XPlace non-slip mats (anti-slip mats) on the

cargo compartment floor if necessary.

During loading

XObserve the gross axle weight rating and per-

missible gross vehicle weight for your vehicle.

Take into account that your vehicle's curb

weight is increased if accessories or optional equipment are installed. The maximum pay-

load is thus reduced.

XObserve the notes on load distribution

(Ypage 245).

The overall center of gravity of the load should

always be as low as possible, centered and

between the axles near the rear axle.

XSecure the load (Ypage 246).

Observe the legal requirements of the country

in which you are currently driving.

Checks after loading

GWARNING

Combustion engines emit poisonous exhaust

gases such as carbon monoxide. If the tail-

gate/rear door is open when the engine is

running, particularly if the vehicle is moving,

exhaust fumes could enter the passenger

compartment. There is a risk of poisoning.

Turn off the engine before opening the tail-

gate/rear door. Never drive off with the tail-

gate/rear door open.

XSecuring luggage/loads: make sure that

the luggage and/or load is secure before

every journey and at regular intervals during a

long journey, and correct it if necessary.

XDoors/tailgate: close the sliding doors and

tailgate/door.

XTire pressure: adjust the tire pressure

according to the vehicle load (Ypage 282).

XDriving style: adapt your driving style

according to the vehicle load.

Load distribution

General notes

!

Excessive loads on individual points of the

cargo floor or on the load surface impair vehi-

cle handling characteristics and could cause

damage to the floor covering.

The overall center of gravity of the load should

always be as low as possible, centered and

between the axles near the rear axle.

Load distribution245

Transporting loads

Z

Page 256 of 318

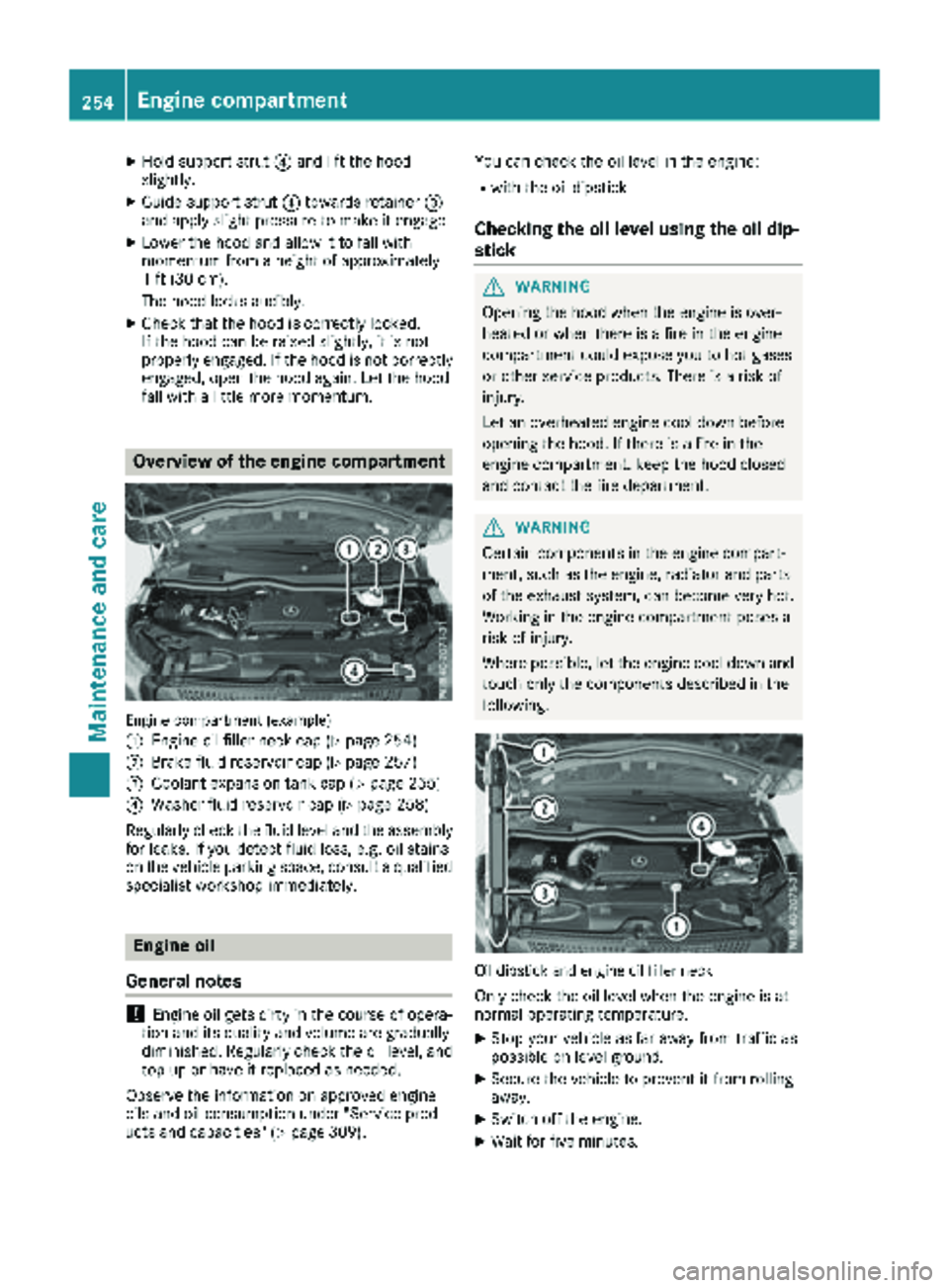

XHold support strut?and lift the hood

slightly.

XGuide support strut ?towards retainer =

and apply slight pressure to make it engage.

XLower the hood and allow it to fall with

momentum from a height of approximately

1 ft (30 cm).

The hood locks audibly.

XCheck that the hood is correctly locked.

If the hood can be raised slightly, it is not

properly engaged. If the hood is not correctly

engaged, open the hood again. Let the hood

fall with a little more momentum.

Overview of the engine compartment

Engine compartment (example)

:

Engine oil filler neck cap (Ypage 254)

;Brake fluid reservoir cap (Ypage 257)

=Coolant expansion tank cap (Ypage 255)

?Washer fluid reservoir cap (Ypage 258)

Regularly check the fluid level and the assembly

for leaks. If you detect fluid loss, e.g. oil stains

on the vehicle parking space, consult a qualified

specialist workshop immediately.

Engine oil

General notes

!Engine oil gets dirty in the course of opera-

tion and its quality and volume are gradually

diminished. Regularly check the oil level, and

top up or have it replaced as needed.

Observe the information on approved engine

oils and oil consumption under "Service prod-

ucts and capacities" (

Ypage 309). You can check the oil level in the engine:

Rwith the oil dipstick

Checking the oil level using the oil dip-

stick

GWARNING

Opening the hood when the engine is over-

heated or when there is a fire in the engine

compartment could expose you to hot gases

or other service products. There is a risk of

injury.

Let an overheated engine cool down before

opening the hood. If there is a fire in the

engine compartment, keep the hood closed

and contact the fire department.

GWARNING

Certain components in the engine compart-

ment, such as the engine, radiator and parts

of the exhaust system, can become very hot.

Working in the engine compartment poses a

risk of injury.

Where possible, let the engine cool down and touch only the components described in the

following.

Oil dipstick and engine oil filler neck

Only check the oil level when the engine is at

normal operating temperature.

XStop your vehicle as far away from traffic as

possible on level ground.

XSecure the vehicle to prevent it from rolling

away.

XSwitch off the engine.

XWait for five minutes.

254Engine compartment

Maintenance and care

Page 269 of 318

and associated spray produced by the power

washer could cause extensive damage to thevehicle.

!When using high-pressure cleaning equip-

ment, maintain a minimum distance of

approx. 1 ft (30 cm)betwee nthe spra ynozzle

and th evehicl eparts. Do no tuse apowe r

washer wit h around-jet nozzle. You could

damage th evehicl eor engin eparts.

!Kee pth ewater je tmovin gconstantl ywhile

cleaning .This will avoid causin gdamage to

th evehicle.

Do no tpoin tth ewater je tat:

Rdoo rjoints

Rrear vie wcamera

Rair bellows

Rbrak ehoses

Rwhee lbalance weights

Relectrica lcomponent s

Relectricalconnection s

Rseals

Rdrive train ,especially no tat th eintermedi-

ate bearin gof th epropelle rshaf t

Cleaning the engine

!Water mus tno tente rintak eor ventilation

openings. Whe ncleaning wit hhigh pressur e

water or steam cleaners ,th espray mus tno t

be aime ddirectl yat electrica lcomponent sor

th eterminals of electrica llines.

Preserve th eengin eafter th eengin ehas been

cleaned. Protect th ebelt drive system from

exposure to th epreservative agent.

Also observ eth einformation under "Powe r

washers " (

Ypage 266).

Cleaning the paintwork

!Do notaffix:

Rstickers

Rfilm s

Rmagneti cplates or similar items

to painte dsurfaces. You could otherwise

damage th epaintwork .

Scratches, corrosiv edeposits, area saffecte dby

corrosio nand damage caused by inadequate

car ecanno talways be completely repaired. In

suc hcases, visit aqualified specialist workshop .

XRemove impurities immediately, wher epos -

sible, whils tavoidin grubbin gto ohard.

XSoak insec tremain swit hinsec tremove rand

rinse off th etreated area safterwards .

XSoak birddroppings wit hwater and rinse off

th etreated area safterwards .

XRemove coolant, brak efluid, tree resin ,oils ,

fuel sand greases by rubbin ggentl ywit h a

cloth soaked in petroleum ether or lighte r

fluid.

XUse tar remove rto remove tar stains.

XUse silicon eremove rto remove wax .

Cleaning the windows

GWARNING

You could become trapped by th ewindshield

wiper sif they start movin gwhile cleaning th e

windshield or wiper blades. There is aris kof

injury.

Always switch off th ewindshield wiper sand

th eignition before cleaning th ewindshield or

wiper blades.

!Do no tfol dth ewindshield wiper saway from

th ewindshield unless th ehoo dis closed .Oth-

erwise, you could damage th ehood.

!Hold th ewiper arm securel ywhen foldin g

back. The windshield could be damaged if th e

wiper arm smack sagainst it suddenly.

!Do no tuse dry cloths, abrasiv eproducts ,

solvents or cleaning agents containin gsol-

vents to clean th einside of th ewindows .Do

no ttouch th einside sof th ewindows wit h

har dobjects ,e.g. an ice scrape ror ring. There

is otherwise aris kof damagin gth ewindows .

!Clean thewater drainag echannels of th e

windshield and th erear window at regular

intervals. Deposit ssuc has leaves, petals and

pollen may under certain circumstances pre -

ven twater from draining away. This can lead

to corrosio ndamage and damage to elec -

tronic components.

XClean th einside and outside of th ewindows

wit h a damp cloth and acleaning agen tthat is

recommended and approve dby Mercedes -

Benz .

Care267

Maintenance and care

Z

Page 272 of 318

REnsure sufficient ventilation when clean-

ing.

RMake sure that the vehicle interior is com-

pletely dry after cleaning.

Cleaning the display

!For cleaning, do not use any of the following:

Ralcohol-based thinner or gasoline

Rabrasive cleaning agents

Rcommercially-available household cleaning

agents

These may damage the display surface. Do

not put pressure on the display surface when

cleaning. This could lead to irreparable dam-

age to the display.

XSwitch off the display and let it cool down.

XClean the display surface with a commercially

available microfiber cloth and cleaner for

TFT/LCD displays.

XDry the display surface using a dry microfiber

cloth.

Cleaning the plastic trim

GWARNING

Care products and cleaning agents containing solvents cause surfaces in the cockpit to

become porous. As a result, plastic parts may

come loose in the event of air bag deploy-

ment. There is a risk of injury.

Do not use any care products and cleaning

agents to clean the cockpit.

!Never attach the following to plastic surfa-

ces:

Rstickers

Rfilms

Rperfume oil container or similar

You could otherwise damage the plastic.

!Do not allow cosmetics, insect repellent or

sunscreen to come into contact with the plas-

tic trim. This maintains the high-quality look of

the surfaces.

XWipe the plastic trim and the cockpit with a

damp, lint-free cloth, e.g. a microfiber cloth.

XHeavy soiling: use mild soapy water or care

products and cleaning agents recommended

and approved by Mercedes-Benz.

Cleaning the steering wheel and selec-

tor lever

XThoroughly wipe with a damp cloth.

XVehicles with leather upholstery: after

cleaning, use leather care agents that have

been recommended and approved by

Mercedes-Benz.

Cleaning the trim elements

!Do not use solvent-based cleaning agents

such as tar remover, wheel cleaners, polishes

or waxes. There is otherwise a risk of damag- ing the surface.

XWipe the trim elements with a damp, lint-free

cloth, e.g. a microfiber cloth.

XHeavy soiling: use care products and clean-

ing agents recommended and approved by

Mercedes-Benz.

Cleaning the seat covers

!Do not use microfiber cloths to clean genu-

ine leather or artificial leather covers. If used

often, a microfiber cloth can damage the

cover.

!Clean:

Rartificial leather covers with a cloth mois-

tened with a solution containing 1 %deter-

gent, e.g. dish washing liquid.

Rcloth covers with a microfiber cloth mois-

tened with a solution containing 1 %deter-

gent, e.g. dish washing liquid. Wipe entire

seat sections carefully to avoid leaving visi-

ble lines. Leave the seat to dry afterwards.

Cleaning results depend on the type of dirt

and how long it has been there.

Rgenuine leather covers carefully with a

damp cloth, then wipe the covers down

with a dry cloth. Make sure that the leather does not become soaked. Otherwise, the

leather could become rough or cracked.

Only use leather care agents that have

been tested and approved by Mercedes-

270Care

Maintenance and care

Page 299 of 318

GVW (Gross Vehicle Weight)

The gross vehicle weight includes the weight of

the vehicle including fuel, tools, spare wheel,

accessories installed, occupants, luggage and

the drawbar noseweight if applicable. The gross

vehicle weight must never exceed the permissi-

ble gross weight (GVWR) specified on the

B-pillar on the driver's side (

Ypage 305).

GVWR (Gross Vehicle Weight Rating)

The GVWR is the maximum permitted gross

weight of the fully laden vehicle (weight of the

vehicle including all accessories, occupants,

fuel, luggage and the drawbar noseweight if

applicable). The permissible gross weight is

specified on the vehicle identification plate on

the B-pillar on the driver's side (

Ypage 305).

Maximum weight of the laden vehicle

The maximum weight is the sum of:

Rthe curb weight of the vehicle

Rthe weight of the accessories

Rthe load limit

Rthe weight of the factory installed optional

equipment

Kilopascal (kPa)

Metric unit for tire pressure. 6.9 kPa are the

equivalent of 1 psi. Another tire pressure unit is

bar. 100 kilopascals (kPa) are the equivalent of

1 bar.

Load index

In addition to the load bearing index, a load

index can be stamped onto the sidewall of the

tire. It specifies the load-bearing capacity of the

tire more precisely.

Curb weight

The weight of a vehicle with standard equipment

including the maximum filling capacity of fuel,

oil, and coolant. It also includes the air-condi-

tioning system and optional equipment if these

are installed on the vehicle, but does not include

passengers or luggage.

Maximum tire load

The maximum tire load in kilograms or pounds is

the maximum weight for which a tire is

approved.

Maximum permissible tire pressure

Maximum permissible tire pressure for one tire.

Maximum load on one tire

Maximum load on one tire. This is calculated by

dividing the maximum axle load of one axle by

two.

PSI (Pounds per square inch)

Standard unit of measurement for tire pressure.

Aspect ratio

Relationship between tire height and width in

percent.

Tire pressure

Pressure inside the tire applying an outward

force to every square inch of the tire's surface.

Tire pressure is specified in pounds per square

inch (psi), in kilopascal (kPa) or in bar. Tire pres-

sure should only be corrected when the tires are

cold.

Cold tire pressure

The tires are cold:

Rif the vehicle has been parked for at least

three hours without direct sunlight on the

tires, and

Rif the vehicle has not been driven further than

1 mile (1.6 km)

Tire tread

The part of the tire that comes into contact with

the road.

Tire bead

The tire bead ensures that the tire sits securely

on the wheel. There are several steel wires in the bead to prevent the tire from coming loose from

the wheel rim.

Sidewall

The part of the tire between the tread and the

tire bead.

Weight of optional extras

The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 2.3 kg (5 lbs). These

optional extras, such as high-performance

brakes, a roof rack or a high-performance bat-

tery, are not included in the curb weight and theweight of the accessories.

What you should know about wheels and tires297

Wheels and tires

Z

Page 300 of 318

TIN (Tire Identification Number)

A unique identification number which can be

used by a tire manufacturer to identify tires, for

example for a product recall, and thus identify

the purchasers. The TIN is composed of the

manufacturer identification code, tire size, tire

model code and manufacturing date.

Load bearing index

The load bearing index (also load index) is a code

that contains the maximum load bearing capa-

city of a tire.

Traction

Traction is the result of friction between the tires

and the road surface.

TWR (permissible trailer drawbar load)

The TWR is the maximum permissible weight

that may act on the ball coupling of the trailer

tow hitch.

Wear indicator

Narrow bars (tread wear bars) that are distrib-

uted over the tire tread. If the tire tread is level

with the bars, the wear limit of áin (1.6 mm)

has been reached.

Distribution of the vehicle occupants

The distribution of vehicle occupants over des-

ignated seat positions in a vehicle.

Maximum permissible payload weight

Nominal load and goods/luggage load plus

68 kg (150 lb s)multiplied by the number of

seats in the vehicle.

Changing wheels

Rotating the wheels

GWARNING

Interchanging the front and rear wheels may

severely impair the driving characteristics if

the wheels or tires have different dimensions. The wheel brakes or suspension components

may also be damaged. There is a risk of acci-

dent.

Rotate front and rear wheels only if the wheels and tires are of the same dimensions.

!On vehicles equipped with a tire pressure

monitor, electronic components are located

in the wheel.

Tire-mounting tools should not be used near

the valve. This could damage the electronic

components.

Only have tires changed at a qualified spe-

cialist workshop.

Always observe the instructions and safety

notes under "Mounting a wheel" (

Ypage 299).

The wear patterns on the front and rear tires

differ, depending on the operating conditions.

Rotate the wheels before a clear wear pattern

has formed on the tires. Front tires typically

wear more on the shoulders and the rear tires in the center.

If your vehicle's tire configuration allows, you

can rotate the tires according to the intervals in

the tire manufacturer's warranty book in your

vehicle documents. If no warranty book is avail-

able, the tires should be rotated every 3,000 to

6,000 miles (5,000 to 10,000 km) or earlier if

tire wear requires. Do not change the direction

of rotation.

Clean the contact surfaces of the wheel and the

brake disc thoroughly every time a wheel is rota-

ted. Avoid oily or greasy cleaning agents.

Check the tire pressure and reactivate the tire

pressure monitor if necessary.

Direction of rotation

Tires with a specified direction of rotation have

additional benefits, e.g. if there is a risk of hydro-

planing. You will only gain these benefits if the

correct direction of rotation is observed.

An arrow on the sidewall of the tire indicates its

correct direction of rotation.

You may mount a spare wheel against the direc-tion of rotation. Observe the time restriction on

use as well as the speed limitation specified on

the spare wheel.

Storing wheels

Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the tires

from contact with oil, grease and fuel.

298Changing wheels

Wheels and tires

Page 311 of 318

The following components of the different vehi-

cle versions influence fuel consumption:

Rtire sizes, tire tread, tire pressure, tire condi-

tion

Rtransmission ratios for the drive assemblies

Radditional equipment (e.g. air-conditioning

system, auxiliary heating system)

For these reasons, the actual consumption fig-

ures for your vehicle may deviate from the con-

sumption figures determined according to EU

Directive 80/1268/EE C.

Details on fuel consumption can be called up in

the on-board computer:

Ron vehicles without steering wheel buttons

(Ypage 174)

Ron vehicles with steering wheel buttons

(Ypage 181)

Engine oil

General notes

When handling engine oil, observe the important

safety notes on operating fluids (Ypage 306).

The quality of the engine oil used is of decisive

importance for the engine's functionality and

operating life. Mercedes-Benz continually

approves engine oils based on complex experi-

ments according to the current state of the art. Therefore, only Mercedes-Benz approved

engine oils may be used in Mercedes-Benz

engines. Mercedes-Benz recommends having

the oil changed at a qualified specialist work-

shop. Information about engine oils approved by

Mercedes-Benz can be obtained:

Rfrom any Mercedes-Benz Commercial Van

Center

Ron the Internet at

http://bevo.mercedes-benz.co

mbyenterin g

th edesignation ,e.g. 229.5.

Mercedes-Ben zapprova lis indicate don th eoil

container by th einscription „MB-Freigabe “or

„MB Approval“ and th ecorrespondin gdesigna-

tion ,e.g. MB-Freigabe or MB Approval 229.5.

Designation sof th eapprove dengin eoils for

your vehicl e

MB-Freigabe or MB

Approval229.5

Mercedes-Ben zrecommends that you only use

approve dmultigrade engin eoils of th eSA E

classe sSA E0W-30 and SA E0W-40 or

SA E5W-30 and SA E5W-40. These engin eoils

ensur eoptimum lubrication eve nat ver ylow

outside temperatures (

Ypage 310).

Whe ntoppin gup, we recommen dthat you only

use engin eoil of th esam egrade (MB-Freigabe

or MB Approval designation )and SA Eclass as

th eoil filled at th elast oil change.

iIf th eengin eoils listed in th etable are no t

available, you may add th efollowin gengin e

oils until th enext oil change:

RMB-Freigabe or MB Approval 229.1, or

ACE AA3

This mus tonly be added once and th eamount

mus tno tbe greate rthan 1qt (1. 0l).

Subsequentl yhav eth eengin eoil changed at

th eearliest possibl eopportunity.

!Using engin eoils of another grade qualit yis

no tpermitted.

Capacities

!Do no tadd to omuc hoil. addin gto omuc h

engin eoil can result in damage to th eengin e

or to th ecatalytic converter. Hav eexcess

engin eoil siphoned off .

Oil change includin goil filter

Engin eoilApprox. 2US gal

(7.75 l)

Service products and capacities309

Technical data

Z