clock MERCEDES-BENZ METRIS 2019 MY19 Operator’s Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2019, Model line: METRIS, Model: MERCEDES-BENZ METRIS 2019Pages: 318, PDF Size: 5.07 MB

Page 259 of 318

Adding coolant

XIfthe coolant drops under marker bar=in

the filler neck, add coolant.

Observe the information on the correct cool-

ant mixture rat ioand the required water qual-

ity under "Service products and capacities"

(

Ypage 311). To prevent damage to the

engine co oling system, use only appr oved

corrosion inh ibitor/antifreeze that co mplies

wit h the Mercedes-Benz Specifications for

Service Products.

XReplac e cap:and tighten ina clock wise

dire ction.

XStart the engine.

XSet the temperature inthe veh icleinterior to

the maximum output on the air-conditioning

system control panel.

XAfter approximate lyfive minutes, switch off

the engine again and allow itto cool down.

XCheck the coolant level again and add coolant

ifnecessary.

XClose the hood.

Brake fluid

GWAR NING

Service products may be poisonous and haz-

ardous to health. There isa risk of injury.

Comp ly with instructions on the use, storage

and dispo sal of service products on the labels

of the respective original containers. Always

store service products sealed intheir original

containers. Always keep service products out

of the reach of ch ildren.

GWAR NING

Opening the hood when the engine isover-

heated or when there isa fire inthe engine

compartment could expose you to hot gases

or other service products. There isa risk of

injury.

Let an overheated engine cool downbefore

opening the hood. Ifthere isa fire inthe

engine compartment, keep the hood closed

and contact the fire department.

GWARNING

Certain components in the engine compart-

ment, such as the engine, radiator and parts

of the exhaust system, can become very hot.

Working in the engine compartment poses a

risk of injury.

Where possible, let the engine cool downand

touch only the components describe d in the

foll owin g.

Brake fluid is hazardous to health. Also observe the safety notes under "Service products and

capacities" (

Ypage 306).

GWARNING

The brake fluid constantly absorbs moisture

from the air. This lowers the boiling point of

the brake fluid. Ifthe boilin g point of the brake

fluid is too low,vapor pockets may form in the

brake system when the brakes are applied

hard. This would impair braking efficiency.

There is a risk of an accident.

You should have the brake fluid renewed at

the specified intervals.

!If the brake fluid level in the brake fluid res-

ervoir has fallen to the MIN mark or below,

check the brake system immediately for

leaks. Also check the thickness of the brake

linings. Visit a qualified specialist workshop

immediately.

Do not add brake fluid. This does not correct

the malfunction.

!Brake fluid corrodes paint, plastic and rub-

ber. Ifpaint, plastic or rubber has come into

contact with brake fluid, rinse with water

immediately.

Have the brake fluid renewed every two years at a qualified specialist workshop. Observe the

information regarding brake fluid in the "Service

products and capacities" section (

Ypage 311).

Engine compartment257

Maintenance and care

Z

Page 275 of 318

XTo open:turn top rotary catch :clockwise

and bottom rotary catch :counter-clock-

wise.

XRemove cover ;.

XTo close:insert cover ;.

XTurn top rotary catch :counter-clockwise

and bottom rotary catch :clockwise.

XFold down the rear seat.

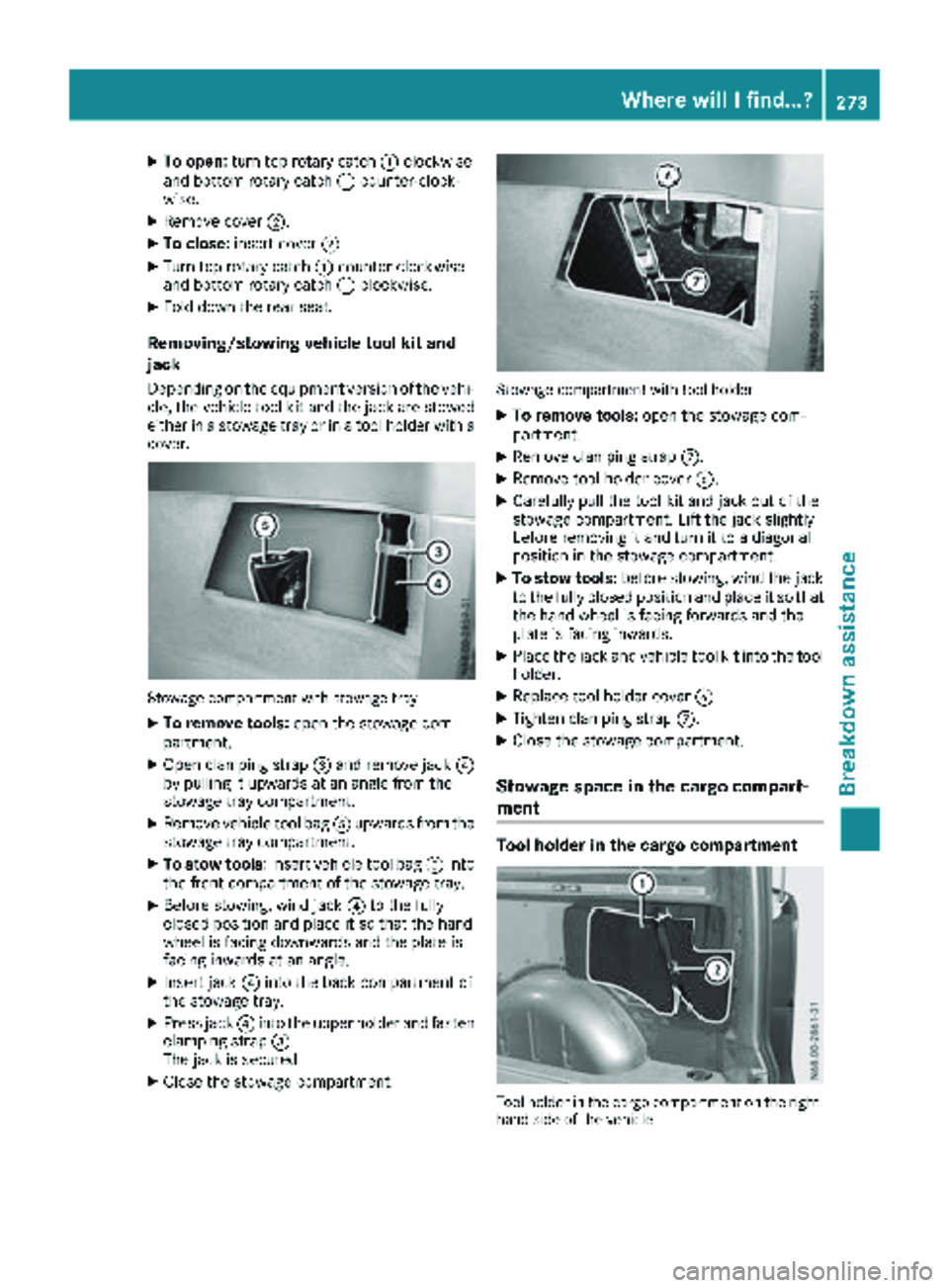

Removing/stowing vehicle tool kit and

jack

Depending on the equipment version of the vehi-

cle, the vehicle tool kit and the jack are stowed

either in a stowage tray or in a tool holder with a

cover.

Stowage compartment with stowage tray

XTo remove tools: open the stowage com-

partment.

XOpen clamping strap =and remove jack ?

by pulling it upwards at an angle from the

stowage tray compartment.

XRemove vehicle tool bag Aupwards from the

stowage tray compartment.

XTo stow tools: insert vehicle tool bag Ainto

the front compartment of the stowage tray.

XBefore stowing, wind jack ?to the fully

closed position and place it so that the hand

wheel is facing downwards and the plate is

facing inwards at an angle.

XInsert jack ?into the back compartment of

the stowage tray.

XPress jack ?into the upper holder and fasten

clamping strap =.

The jack is secured.

XClose the stowage compartment.

Stowage compartment with tool holder

XTo remove tools: open the stowage com-

partment.

XRemove clamping strap C.

XRemove tool holder cover B.

XCarefully pull the tool kit and jack out of the

stowage compartment. Lift the jack slightly

before removing it and turn it to a diagonal

position in the stowage compartment.

XTo stow tools:before stowing, wind the jack

to the fully closed position and place it so that

the hand wheel is facing forwards and the

plate is facing inwards.

XPlace the jack and vehicle tool kit into the tool holder.

XReplace tool holder cover B.

XTighten clamping strapC.

XClose the stowage compartment.

Stowage space in the cargo compart-

ment

Tool holder in the cargo compartment

Tool holder in the cargo compartment on the right-

hand side of the vehicle

Where will I find...?273

Breakdown assis tance

Page 279 of 318

Have the vehicle transported on a transporter or

trailer if it has transmission damage.

The automatic transmission must be in position

iwhen the vehicle is being towed away. If the

automatic transmission cannot be shifted to

position i, have the vehicle transported on a

transporter or trailer.

The battery must be connected and charged.

Otherwise, you:

Rcannot turn the key to position 2in the igni-

tion lock.

Rcannot shift the transmission to position i.

Before the vehicle is towed, switch off the auto-

matic locking feature (

Ypage 74). You could

otherwise lock yourself out of the vehicle when

pushing or towing away the vehicle.

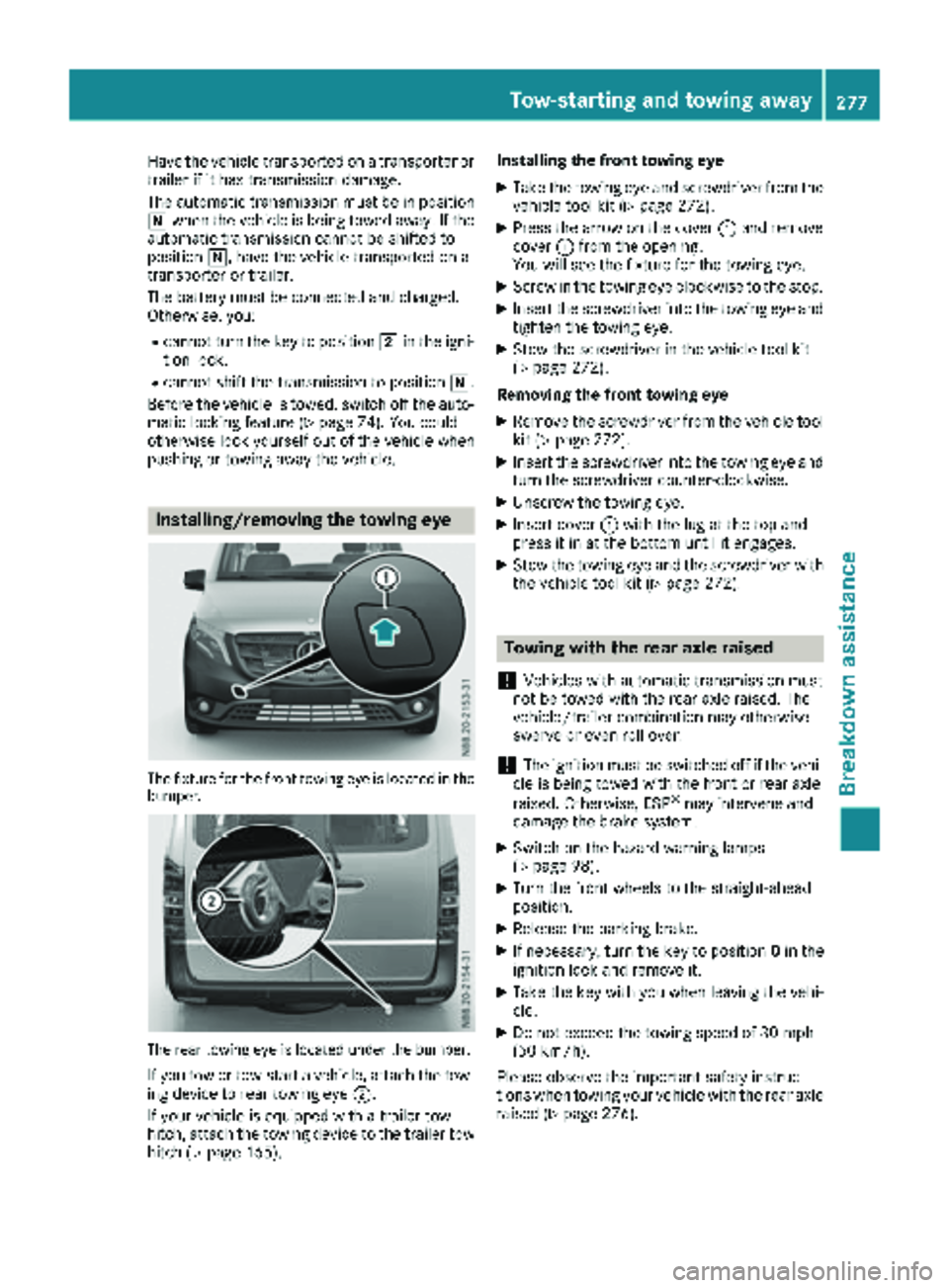

Installing/removing the towing eye

The fixture for the front towing eye is located in the

bumper.

The rear towing eye is located under the bumper.

If you tow or tow-start a vehicle, attach the tow-

ing device to rear towing eye ;.

If your vehicle is equipped with a trailer tow

hitch, attach the towing device to the trailer tow

hitch (

Ypage 165). Installing the front towing eye

XTake the towing eye and screwdriver from the

vehicle tool kit (Ypage 272).

XPress the arrow on the cover

:and remove

cover :from the opening.

You will see the fixture for the towing eye.

XScrew in the towing eye clockwise to the stop.

XInsert the screwdriver into the towing eye and

tighten the towing eye.

XStow the screwdriver in the vehicle tool kit

(Ypage 272).

Removing the front towing eye

XRemove the screwdriver from the vehicle tool

kit (Ypage 272).

XInsert the screwdriver into the towing eye and

turn the screwdriver counter-clockwise.

XUnscrew the towing eye.

XInsert cover :with the lug at the top and

press it in at the bottom until it engages.

XStow the towing eye and the screwdriver with

the vehicle tool kit (Ypage 272).

Towing with the rear axle raised

!

Vehicles with automatic transmission must

not be towed with the rear axle raised. The

vehicle/trailer combination may otherwise

swerve or even roll over.

!The ignition must be switched off if the vehi-

cle is being towed with the front or rear axle

raised. Otherwise, ESP

®may intervene and

damage the brake system.

XSwitch on the hazard warning lamps

(Ypage 98).

XTurn the front wheels to the straight-ahead

position.

XRelease the parking brake.

XIf necessary, turn the key to position 0in the

ignition lock and remove it.

XTake the key with you when leaving the vehi-

cle.

XDo not exceed the towing speed of 30 mph

(50 km/h).

Please observe the important safety instruc-

tions when towing your vehicle with the rear axle

raised (

Ypage 276).

Tow-starting and towing away277

Breakdown assistance

Z

Page 301 of 318

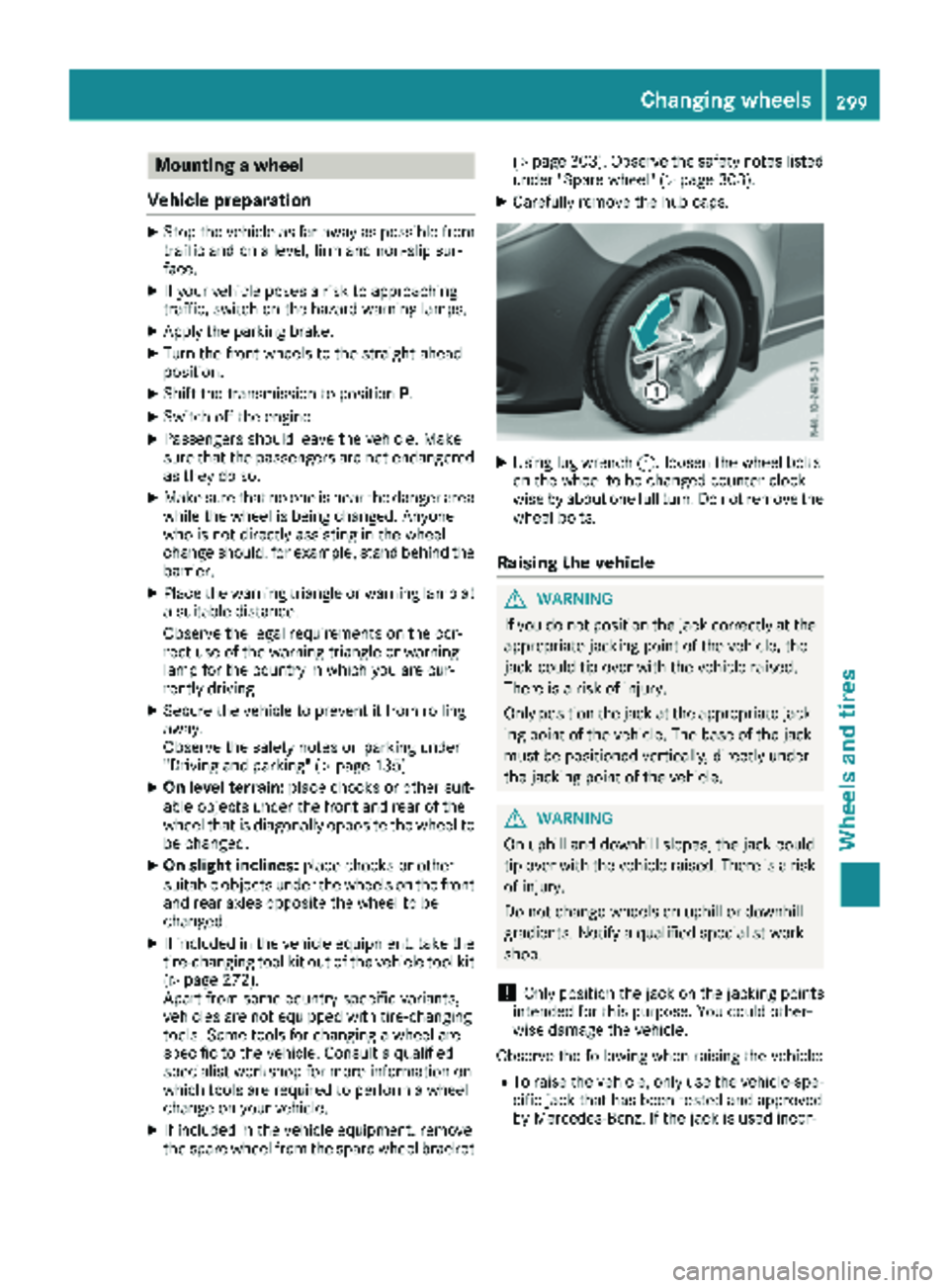

Mounting a wheel

Vehicle preparation

XStop the vehicle as far away as possible from

traffic and on a level, firm and non-slip sur-

face.

XIf your vehicle poses a risk to approaching

traffic, switch on the hazard warning lamps.

XApply the parking brake.

XTurn the front wheels to the straight-ahead

position.

XShift the transmission to position P.

XSwitch off the engine.

XPassengers should leave the vehicle. Make

sure that the passengers are not endangered

as they do so.

XMake sure that no one is near the danger area

while the wheel is being changed. Anyone

who is not directly assisting in the wheel

change should, for example, stand behind the

barrier.

XPlace the warning triangle or warning lamp at

a suitable distance.

Observe the legal requirements on the cor-

rect use of the warning triangle or warning

lamp for the country in which you are cur-

rently driving

XSecure the vehicle to prevent it from rolling

away.

Observe the safety notes on parking under

"Driving and parking" (

Ypage 135)

XOn level terrain: place chocks or other suit-

able objects under the front and rear of the

wheel that is diagonally opposite the wheel to

be changed.

XOn slight inclines: place chocks or other

suitable objects under the wheels on the front and rear axles opposite the wheel to be

changed.

XIf included in the vehicle equipment, take the

tire-changing tool kit out of the vehicle tool kit

(

Ypage 272).

Apart from some country-specific variants,

vehicles are not equipped with tire-changing

tools. Some tools for changing a wheel are

specific to the vehicle. Consult a qualified

specialist workshop for more information on

which tools are required to perform a wheel

change on your vehicle.

XIf included in the vehicle equipment, remove

the spare wheel from the spare wheel bracket (

Ypage 303). Observe the safety notes listed

under "Spare wheel" (Ypage 303).

XCarefully remove the hub caps.

XUsing lug wrench :, loosen the wheel bolts

on the wheel to be changed counter-clock-

wise by about one full turn. Do not remove the

wheel bolts.

Raising the vehicle

GWARNING

If you do not position the jack correctly at the

appropriate jacking point of the vehicle, the

jack could tip over with the vehicle raised.

There is a risk of injury.

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

GWARNING

On uphill and downhill slopes, the jack could

tip over with the vehicle raised. There is a risk

of injury.

Do not change wheels on uphill or downhill

gradients. Notify a qualified specialist work-

shop.

!Only position the jack on the jacking points

intended for this purpose. You could other-

wise damage the vehicle.

Observe the following when raising the vehicle:

RTo raise the vehicle, only use the vehicle-spe-

cific jack that has been tested and approved

by Mercedes-Benz. If the jack is used incor-

Changing wheels299

Wheels and tires

Z