load capacity MERCEDES-BENZ METRIS 2021 MY21 Operator's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 2021, Model line: METRIS, Model: MERCEDES-BENZ METRIS 2021Pages: 290, PDF Size: 4.68 MB

Page 133 of 290

R

yous teer actively ,e.g. swer vetoavoid an

obs tacle or chang elane quickl y.

R youc utthec orner on ashar pcurve. Tr

aile roperation Note

sont railer operation &

WARNING Risk of accident and inju ryif

th et ongue weight is exceeded

The car rier sy stem ma ydetac hf romt hevehi‐

cle, thereb yendangering other road users. #

Alwaysc ompl ywitht he permissible

to ngu eweight when using acarrier. &

WARNING Risk of accident du eto

unsuitable ball neck

If yo ui nstall an unsuitable ball nec k,the

traile rhitch and ther ear axle ma ybeoverloa‐

ded.

This can significantl yimp air thed riving char‐

acteristic sand thet railer ma ybecome loose.

Ther eisar isk offata linjur y. #

Only ins tallab all nec kthat complies

wit hthe permissible dimensions and is

designed fort he requ irements of trailer

operation. #

Do no tmodif ythe ball nec korthe

trailer hitch. Yo

uc an find specifications rega rding theb all

nec kont he trailer's identification plate. Youc an

fi nd specifications rega rding thet railer on the

to wing vehicle's identification plat eand in the

te ch nica ldata( /pag e233). &

WARNING Risk of accident and inju ry

due toan incor rectly ins talled ball cou‐

pling

If th eb all coupling is no tins talled and

engaged cor rectl y,it ma ybecom edetached

during tra vela nd endan gero ther road users.

Ther eisar isk offata linjur y. #

Install and secur ethe ball coupling as

described in theb all coupling manufac‐

turer's ins tallation instructions. #

When theb all coupling has been ins tal‐

led, ensur ethat it is cor rectly secu red

befor eevery trip. &

WARNING Risk of accident du etoan

incor rectl yins tal led and secured ball

coupling

If th eb all coupling has no tbeen cor rectly

ins talled and secured, thet railer can become

de tach ed. #

Install and secur ethe ball coupling as

described in theb all coupling manufac‐

turer's ins tallation instructions. #

When theb all coupling has been ins tal‐

led, ensur ethat it is cor rectly secu red

befor eevery trip. Yo

uc an attac hcarrier sy stems suc hasabicycle

ra ck or load-bearing implement totheb all nec k.

When using car rier sy stems on theb all nec k,the

maximu mloadc apacity is 165lb( 75kg).

Be sur etocomply wi th theoperating instructions

of them anufacturer of thet railer coupling and

th eb all nec k.

Place your vehicle/trailer combination on sur fa‐

ces that ar ease vena spossible and secu reit

agains trolling away ( /pag e108). Coupl eand

uncoupl ethe trailer carefully.

No tethef ollowing rega rding thet ongue weight:

R Mak efull use of them aximum tongu eweight,

wher epossible.

R Neverfall belo walegally prescribed minimum

to ngu eweight ;the tongu eweight must

alw aysbep ositive.

R Do no texceed or fall belo wthe permissible

to ngu eweights –this mus tbeobservedd ur‐

ing loading and unloading of thet railer.

Do no texceed thef ollowing values:

R Perm itted braked or unbraked towing capa‐

city

The maximum permissible towing capacity for

unbraked trailer sis1,653 lbs (750 kg).

R Perm issible rear axle load of thet ow ing vehi‐

cle

R Perm issible gross weight of thet ow ing vehi‐

cle

R Perm issible grossweight of thet railer

R Perm issible grosscombination weight

R Maximum permissible speed of thet railer Driving and parking

131

Page 168 of 290

Note

sonl oading guidelines &

DANG ER Risk of poisonin gfrome xhau st

ga ses

Combustion engines emit poisonous exhaust

ga ses, suc hascarbon monoxide. Exhaust

ga ses can enter thev ehicle interior if thet ail‐

gate orther ear-end door is open when the

engine is running ,especial lyifth ev ehicle is

in motion. #

Alwayss witc hoffthee ngine before

opening thet ailgat eortherear-end

door. #

Neverd rive thev ehicle when thet ail‐

ga te or rear-en ddoor is open. &

WARNING Risk of inju ryfrom unsecu red

object sinthevehicle

When objects ar eunsecured or inadequately

secured, they can slip, tip overorbet hrown

about, striking vehicle occupants.

This also appliest o:

R Luggag eorl oads

R Seats whic hhave been remo veda nd are

being transpor tedint hevehicle in an

ex ceptiona lcase

The reisar isk of injur y,particular lyin the

eve nt of braking maneuver sorabrupt

ch anges in direction. #

Alwayss towo bjectsins uchaw aythat

th ey canno tbetossed about. #

Befor etrave ling, secur eobjects, lug‐

ga ge or load topreve ntthem slipping or

tipping over. #

When aseat is remo ved, keep it prefera‐

bly outside thev ehicle. &

WARNING Risk of accident du etoincor‐

re ctly positioned load

The center of gr avity of thel oad can be too

high and/or toof ar towa rdst he rear.

This can significantl yimp air handlin gaswell

as steering and braking characteristics. #

Alwaysm akes uret hat thec enter of

gr av ity of thel oad is between thea xles

and as lo waspossible near ther ear

axle. &

WARNING Risk of accident du eto

exc eeding thep ermissible wheel/axle

loads or theg ross vehicle weight

The driving characteristics, as well as steering

and braking, ma ybegreatl yimp aired. Over‐

loaded tires ma yoverheat and bur stas ac on‐

sequence. #

When transpo rting aload, alw ays

obser vethep ermissible wheel loads,

axle loads and them aximum permissi‐

ble gross mass fort he vehicle (including

occupants). &

WARNING Risk of inju ryif unsuitable

climbin gaids ar eused

If yo uu se opening sinthevehicle's body work

or de tach able parts as steps, youc ould:

R Slip and/or fall.

R Damag ethe vehicle and thus slip and fall. #

Alwaysu se anti-slip, stable climbing

aids, e.g .asuitable ladder. *

NO

TEDama gecaused bytheu se of

openings in theb odywor kordetachable

par tasa step Using

thel owe rguide of thes liding door (car‐

ri age) as astepc an damag ethe trim and/or

mechanism of thes liding door. #

Do no tuse theg uide of thes liding door

(car riage) as astep. If

yo ua reusin gar oof luggag erack, please no te

th em aximum roof load and them aximum load

capacity of ther oof luggag erack( / pag e234).

The handling characteristic sofyourvehicle are

dependent on thel oad distribution.

Therefore, please obser vethef ollowing no tes

when loading:

R The load mus tnotprotru de abo vetheu pper

edg eoft he seat backrests.

R If possible, alw ayst ranspor tthe load in the

cargo compa rtment.

R fastenthel oad tothet ie-down eyes and dis‐

tribut ethe load evenl yamong them. 16 6

Transporting

Page 170 of 290

R

Movelarge and heavy loads as farasp ossible

to wa rdst he front of thev ehicle in thed irec‐

tion of tra vel, agains tthe front or rear seats.

St orel oads flush wit hthe rear or front seats.

R Additionall ysecur ethe load wit hsuitable load

securing aids or tie downs.

R The load mus tnotprotru de abo vetheu pper

edg eoft he seat backrests.

R Transpor tloads behin dseat sthat ar enot

occupied.

R Ifth er ear benc hseat is no toccupied, insert

th es eat belts crosswise int othe seat belt

buckle of theo pposit eseat belt.

Cargo compartment variants

Yo uc an vary thec argo compartmen taccording

to your transpor tatio nr equirements as follo ws:

R Byfolding thes eat backrests forw ardtot he

ta ble position

R Byremoving ther ear benc hseat

Yo uw illfind information abou trear benc hseats

in the" Seats" section (/ page66). Securing loads

Note

sonl oad securing &

WARNING Risk of accident and inju ry

due toincor rect use of thel ashing stra ps

The following can occur:

R The tie-down eyes ma ydetac hort he lash‐

ing stra pm aytear if thep ermissible load

is exc eeded

R The load cann otbe restra ined

The load can slip, tip over or be flung about,

st riking vehicle occupants. #

Alwayst ension thel ashing stra ps in the

proper manner and onl ybetwe en the

described tie-down eyes. #

Alwaysu se lashing stra ps designed spe‐

cificall yfor thel oads. *

NO

TEDama getothev ehicle if them axi‐

mum loading capacity of thec argo tie-

down point is exceeded If

yo uc ombin evarious cargo tie-down points

to secur eaload, alw ayst aket he maximum loading capacity of

thew eakes tcargo tie-

down poin tint oa ccount.

During maximum full- stop braking, forc es may

act whic hcan multipl ythe weight of thel oad. #

Alwaysu se se veralc argo tie-down

point stod istribut ethe load. #

Distribut ethe load on thec argo tie-

down points evenly. Obser

vetheO perating Instruction sorthe lashing

st ra pm anufacturer's instruction sfor theo pera‐

tion of thel ashing stra p.

Obser vethei nformation relatin gtot he maximum

loading capacity of thec argo tie-down points

(/ page234).

As thed rive r,yo ua re re sponsible fore nsuring the

fo llowing:

R The load is secured agains tslipping, tipping,

ro lling or falling off.

Ta ke usual traf ficc onditions as well as swerv‐

ing or full brak eapplication and bad roads

int oa ccount.

R The applicable requ irements and guidelines

re latin gtol oad-securing practices ar emet.

If th is is no tthe case, this ma yconstitut ea

punishable of fense, depending on local legis‐

lation and an yensuing conse quences.

Obser vecountr y-specific la ws.

Mak esuret hat thel oad is secur ebefor eevery

jou rney and at regular inter vals during along

journe y.Ad jus tthe load securing as necessar y.

Information on ho wtosecureloads cor rectly can

be obtained from them anufacturer softhe load

securing aids or tie downs forl oa ds ecuring, for

ex ample.

Als oo bse rvet he no tesonl oading guidelines

(/ page166).

Whe nsecuring loads, obser vethef ollowing:

R Fill spaces between thel oad and thec argo

compartmen twalls or wheel wells. Forthis

purpose, use rigid load securing aids, suc has

ch oc ks,w ooden fixing sorp adding.

R Attach secured and stabilized loads in all

directions.

Use thec argo tie-down points or thet ie-down

ey es and guide rails in ther ear compartment.

Only use tie downs, suc haslashin gnetsa nd

lashin gstraps, whic hhave been tested in

accordance wit hcurrent standards. Alw ays 16 8

Transporting

Page 172 of 290

th

el oad. The lashing rods directly absorb the

po tentia lshifting forc es.

Securing loads on thec argo compartmen tfloor

by lashing them down is onl yrecommended for

light weight loads. La yanti-slip mats under the

load toassis tinsecuring it.

Do no tattem pttomodify or repair thec argo tie-

down points ,tie-down eyesort ie downs. Read

th ei nformation on qualified specialis tworks hops

(/ page18). Using lashin

gstraps Obser

vetheo perating instruction sorthe lashing

st ra pm anufacturer's instruction sfor theo pera‐

tion of thel ashing stra p.

Securing loads on thec argo compartmen tfloor

by lashing them down is onl yrecommended for

light weight loads. La yanti-slip mats under the

load toassis tinsecuring it. #

Obse rvet he no tesons ecuring loads

(/ page168). #

Obser vethem aximum loading capacity of the

cargo tie-d ownp oints and tie-down eyes

(/ page234).

No tesa nd information on them aximum loading

capacity of thel ashing stra pc an be found on the

lashing stra pl abel. If thel abel is missing or illegi‐

ble, thel ashing stra pisr eady tobe discarded and

mus tber eplaced. Suc halashing stra pm ustn ot

be used.

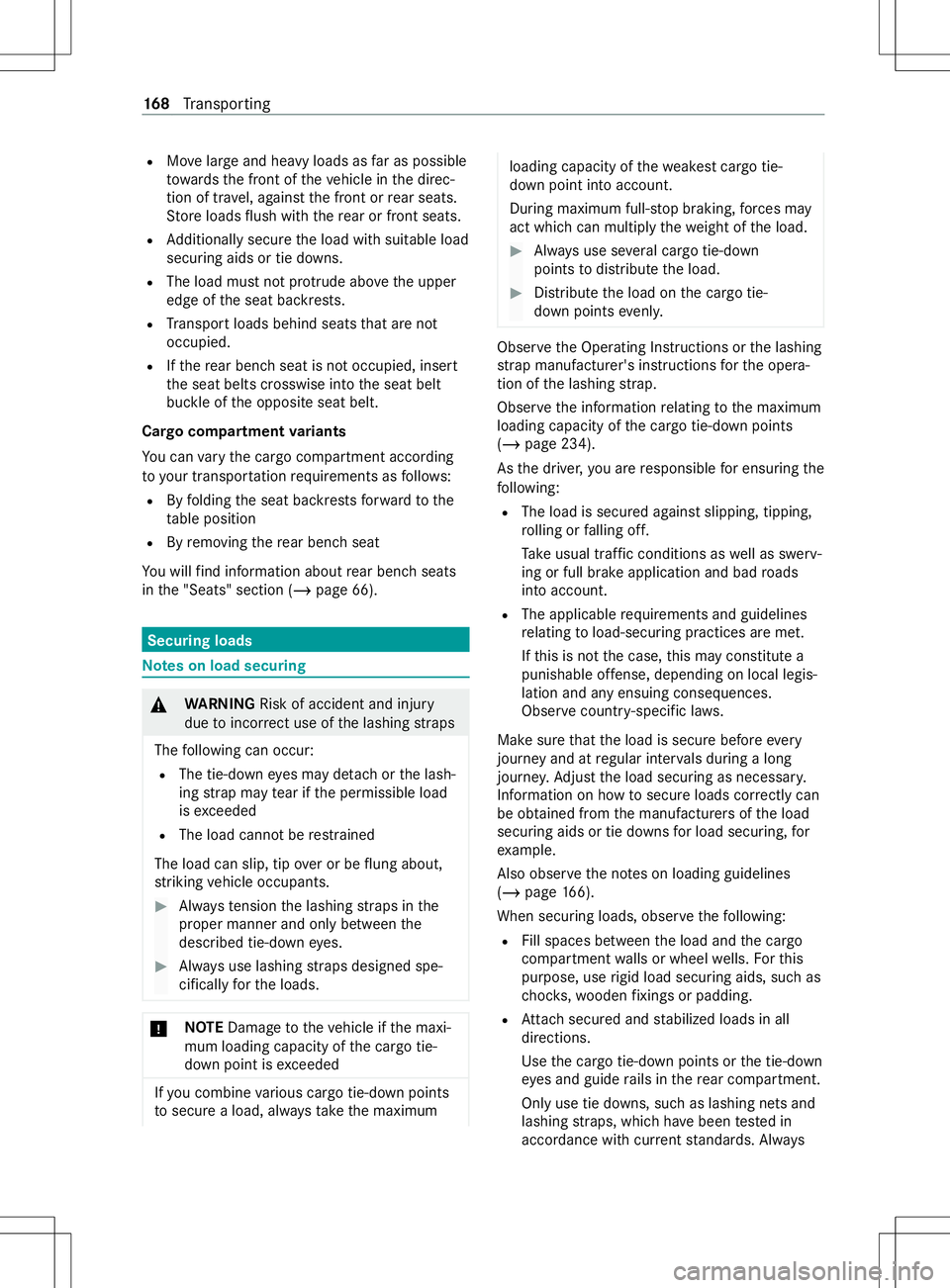

If re fere nce sticke rs we reincluded on deliver y,

af fixt hem tothev ehicle as follo ws: #

Clean thes urface befor esticker 1is af fixe d.

The sticke rs mus tbea ffixed toaflat, me tallic

sur face free from grease and du st. #

Affixs tickers 1 oneverys ide of thev ehicle

in close pr oximit ytot he loading rails in a

clearly visible location.

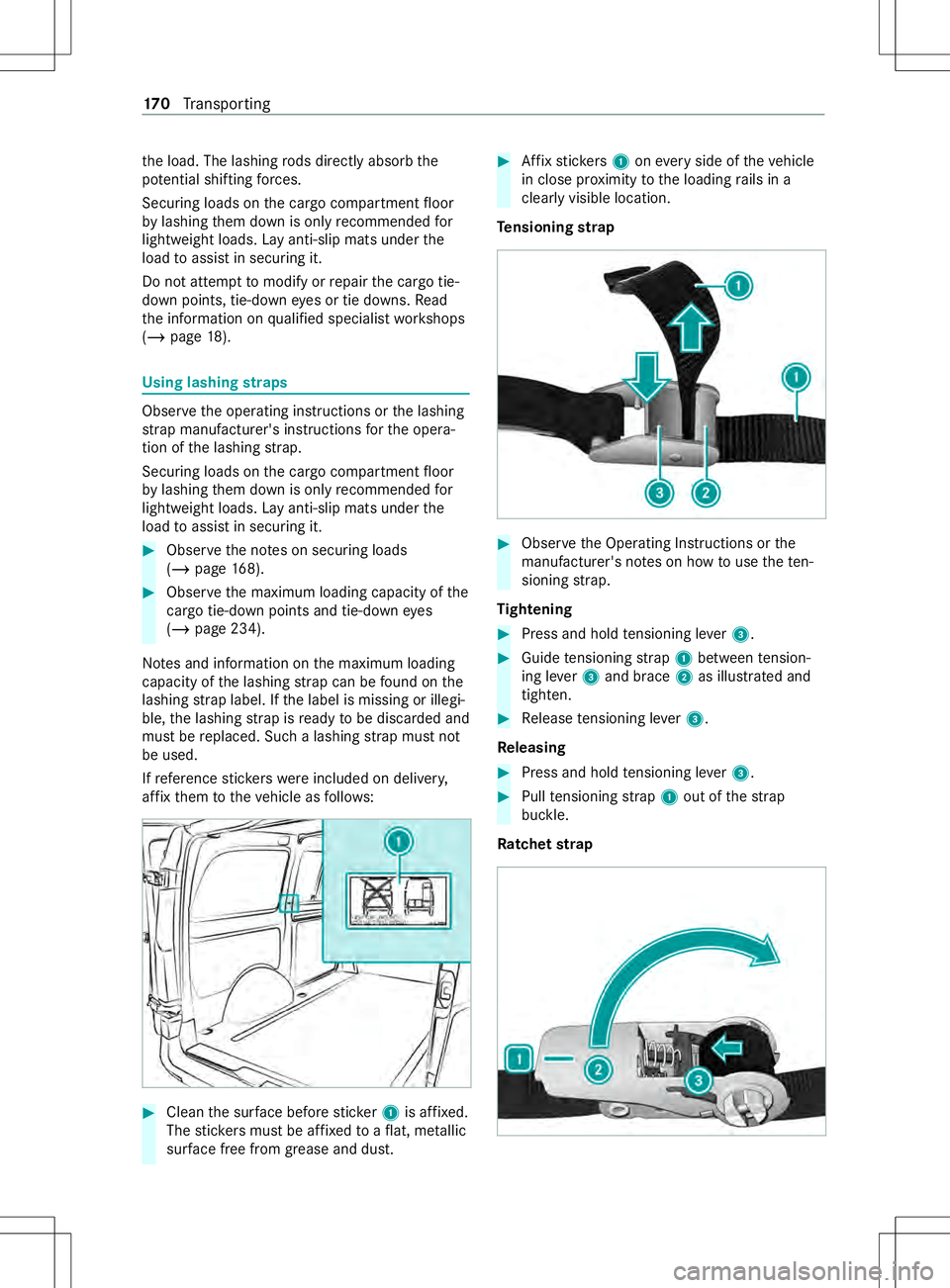

Te nsioning strap #

Obser vetheO perating Instruction sorthe

manufacturer's no tesonh owtouse thet en‐

sioning stra p.

Ti ghtening #

Press and hold tensioning le ver3. #

Guide tensioning strap 1between tension‐

ing le ver3and brace 2as illustrated and

tighten. #

Release tensioning le ver3.

Re leasing #

Press and hold tensioning le ver3. #

Pullt ensioning strap 1out of thes trap

bu ckle.

Ra tche tstrap 17 0

Transporting

Page 177 of 290

Note

sonm aintenance

+ ENVIRONMEN

TALN OTE Environmental

pollution du etodisposal in anon-envi‐

ro nmentally-friendly manner If circums

tances demand that youh ave todo

some maintenanc eworky ourself, environ‐

mental pr otection requirements mus tbe

obser ved. When disposing of service prod‐

ucts, e.g. engin eoil,youm ustc ompl ywith

th el egal requ irements. This also includes all

components, e.g. filters, whic hhave come

int oc ontact wi thoperating fluids. #

Dispose of em ptyc ontainers, cleaning

clo thsa nd car eproducts in an environ‐

mentally responsible manner. #

Obser vethei nstruction sfor car eprod‐

ucts. #

Do no trun thee ngine forl onger than

necessar ywhen thev ehicle is station‐

ar y. When

working on thev ehicle, comply wit hall

saf etyr egulations, suc hasthe operating instruc‐

tions, regulations concerning hazardous materi‐

als, environmental pr otection measures, work

saf etya nd acciden tpreve ntion regulations.

Yo um usts ecur ethe vehicle on jac kstands of

suf ficient load-bearing capacity if workis being

car ried out underneat hthe vehicle.

Please also refertot he no tesa bout qualified spe‐

cialis tworks hops (/ page18).

The scope and regularity of thei nspection and

maintenanc eworkp rimaril ydepend on theo ften

diverse operating conditions .Inspection and

maintenanc eworkr equires special skills that

canno tbeacquired byreading these Operating

Instructions. This workshould onl ybecarried out

by trained pe rsonnel.

The vehicle Maintenance Bookle tdescribes the

scope and frequency of maintenance workand

contains additional no tesont he Limited War‐

ra nty .You will find information abou toperating

fl uids appr ovedfor Mercedes-Benz and capacities

under "Operatin gFluid sand Capacities"

(/ page 227).

Maintenance services mus tbecarried out in

accordance wit hthe instructions in theM ainte‐

nanc eBooklet. No tdoing so could void an ywar‐

ra nty claims and lead torefusa lofg oodwil lges‐

tures af tert he manufacturer has submitted a

damag ereport. Obser

vethei nformation under "Mercedes-Benz

GenuineParts" (/ page13). Se

rvice inter vald isplay Service inter

vald ispla yfunction The AS

SYST PLUS service inter vald ispla yont he

instrument clus terd ispla yprovide sinformation

on ther emaining time or dis tance be fore then ext

service due date.

Under arduous operating conditions or if thev ehi‐

cle is subjected toinc reased loads, theA SSYST

PLUS service inter vald ispla ymayshor tent he

service inter val.

Yo uc an obtain fur ther information concerning

th es ervicing of your vehicle from aqualified spe‐

cialis tworks hop. Displaying

thes ervice du edate( vehicles

without steering wheel but tons) Requ

irements:

R The vehicle is stationar y.

R The ignition is switched on.

Use theb uttons on thei nstrument clus ter. #

Press theÈbutton toselect thes ervice dis‐

pla y.

The displa ywill sho wapossible service mes‐

sage. #

Toexitth ed ispla y:press the0078button on

th ei nstrument clus ter. Displaying

thes ervice du edate( vehicles with

st eering wheel but tons) Re

quirements:

R The ignition is switched on.

On-boar dcomputer:

4 Service 5

ASSYS TPLUS

The next service due dat eisdisplayed. #

Toexitth ed ispla y:press the0076 or0038

st eering-wheel button. Maintenanc

eand care 175

Page 203 of 290

Electrical fuses

Note

sone lectrical fuses *

NO

TEElectrica lfuses #

Obser vethei nformation in thes upple‐

ment .You ma yotherwise failto recog‐

nize dangers. The fus

eallocation charta nd thei nformation on

th ef uses can be found in the" Fuse allocation

ch art" Supplement. Ve

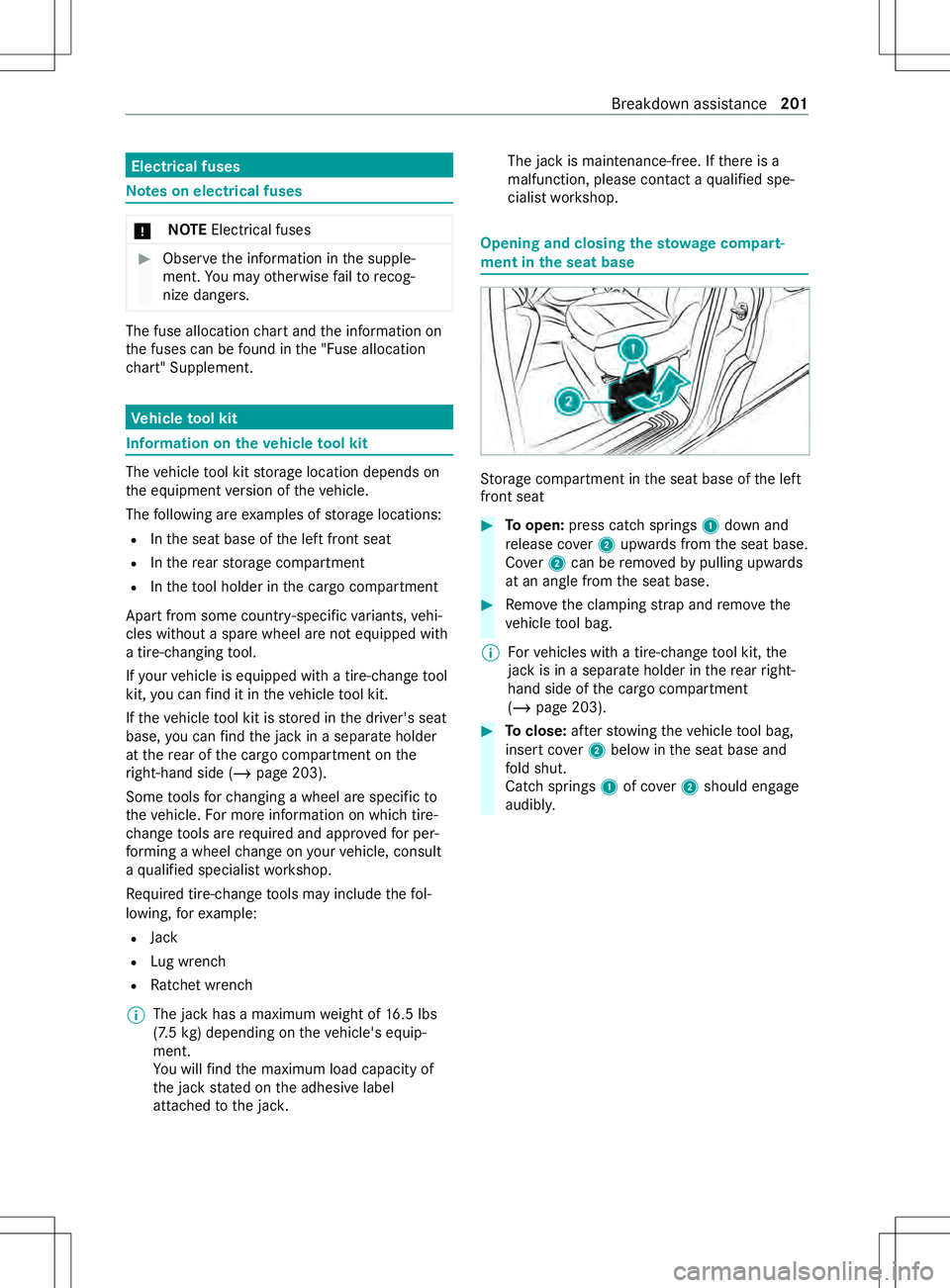

hicl etool kit Information on

thev ehicle tool kit The

vehicle tool kit storag elocation depends on

th ee quipment version of thev ehicle.

The following ar eexamp les of storag elocations:

R Inthes eat base of thel eftf ront seat

R Inther ear storag ecompartment

R Inthet ool holder in thec argo compartment

Apar tfroms ome count ry-specific variants, vehi‐

cles without aspar ew heel ar enotequipped with

at ire-changing tool.

If yo ur vehicle is equipped wit hatire-chang etool

kit, youc an find it in thev ehicle tool kit.

If th ev ehicle tool kit is stored in thed rive r's seat

base, youc an find thej ackinas eparateholder

at ther ear of thec argo compartmen tonthe

ri ght-han dside (/ page203).

Some tools forc hanging awheel ar especific to

th ev ehicle. Form orei nformation on whic htire-

ch ang etools ar erequired and appr oved forp er‐

fo rm ing awheel chang eony ourvehicle, consult

aq ualified specialis tworks hop.

Re quired tire-chang etools ma yinclude thef ol‐

lowing, fore xamp le:

R Jack

R Lugw rench

R Ratche twrench

% The jac

khasam aximum weight of 16.5 lbs

(7.5 kg)d epending on thev ehicle's equip‐

ment.

Yo uw illfind them aximum load capacity of

th ej acks tatedont he adhesiv elabel

attached tothej ack. The jac

kismaintenance-free. If ther eisa

malfunction, please contact aqualified spe‐

cialis tworks hop. Opening and closing

thes towa ge compa rt‐

men tint he seat base St

orag ecompartmentint he seat base ofthel eft

front seat #

Toopen: press cat chsprings 1down and

re lease co ver2upwards from thes eat base.

Co ver 2can be remo vedbyp ulling upwards

at an angle from thes eat base. #

Remo vethec lamping stra pa nd remo vethe

ve hicle tool bag.

% Fo

rv ehicles wit hatire-chang etool kit, the

jac kisinas eparateholde rint herear right-

hand side of thec argo compartment

(/ page203). #

Toclose: afte rs towing thev ehicle tool bag,

inser tcover 2 belo wint he seat base and

fo ld shut.

Catc hsprings 1of co ver2should engage

audibly. Breakdown assi

stance 201

Page 213 of 290

Count

ry Radio equipment appr oval

number

Philip‐

pines NTC

Ty

pe Appr oved.

No: ESD-13 06995C

Singapo reComplies wit hIDA Standards

DA -103365

Sou th

Africa TA

-20 13/461

United

Arab Emi‐

ra tes

Abu Dhabi

and Dubai TRA

Re

gis tere dN o: ER0 104996/13

Dealer No: DA00470 74/10 Tir

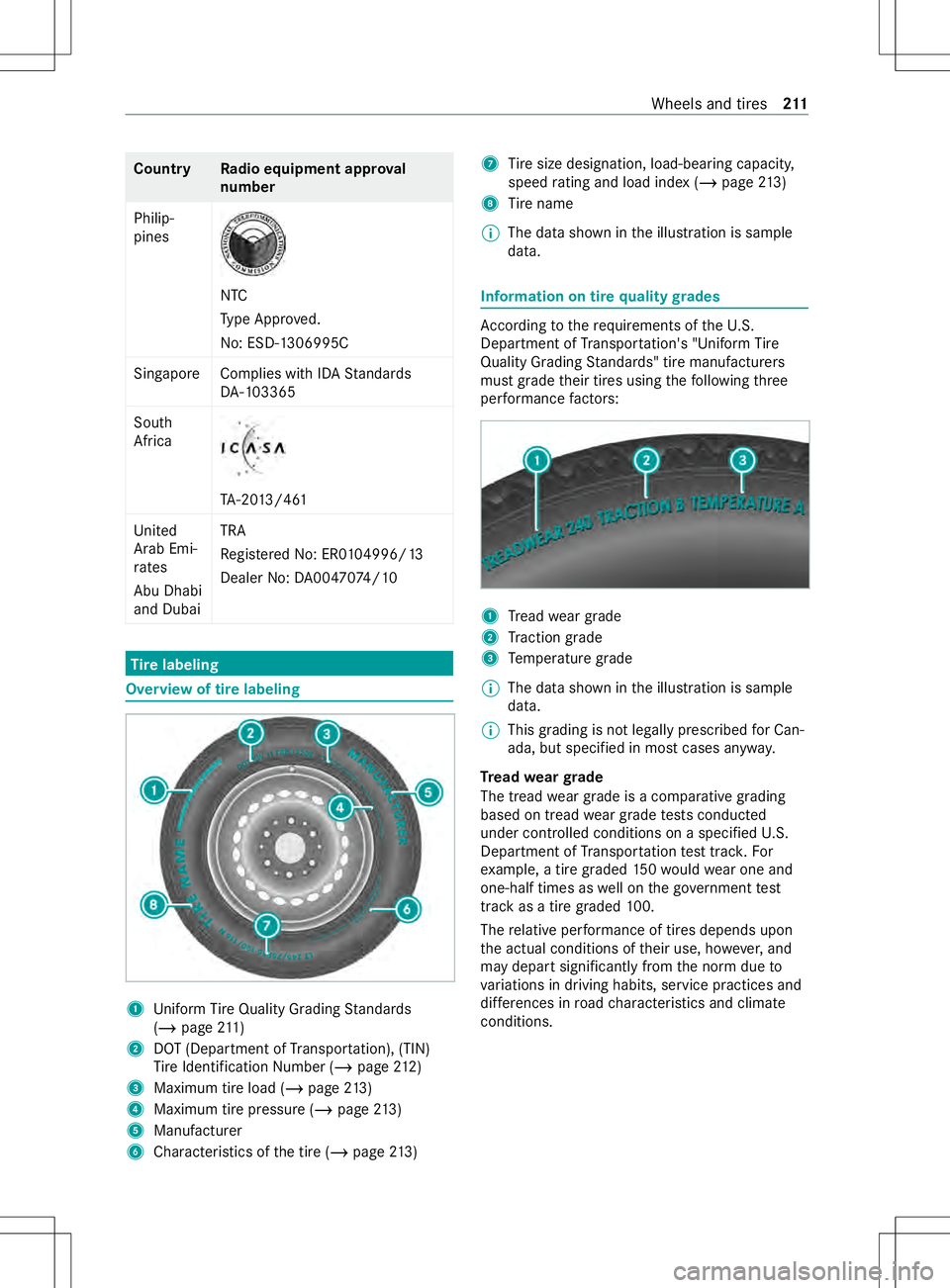

elabeling Overvie

woftirel abeling 1

Unifor mTireQ uality Grading Standards

(/ page211 )

2 DOT(Depa rtment of Transpor tation), (TIN)

Ti re Identification Number (/ page212 )

3 Maximum tir eloa d( /pag e213 )

4 Maximum tirep ressur e(/ page 213)

5 Manu facturer

6 Characteristics of thet ire( /pag e213 ) 7

Tire size designation, load-beari ng capacity,

speed rating and load ind ex (/pag e213 )

8 Tire name

% The da

tashown in thei llustration is sample

data. Information on tir

equality grades Ac

cording tother equirements of theU .S.

Depa rtment of Transpor tation's "Uni form Tire

Quality Grading Standards" tir emanufacturers

mus tgrade their tires using thef ollowing three

per form anc efactors: 1

Tread weargrade

2 Traction grade

3 Temp eratur egrade

% The dat

ashown in thei llustration is sample

data.

% This grading is no

tlegall yprescribed forC an‐

ada,b ut specified in mos tcases anyw ay.

Tr ead weargrade

The tread wear grade is acomparativ egrading

based on tread wear grade testsc onducted

under controlled conditions on aspecified U.S.

Depa rtment of Transpor tatio nt esttrack .F or

ex ample, atireg raded 150w ould wear one and

one-half times as well on theg ove rnment test

trac kasat ireg rade d1 00.

The relativ eperform anc eoft ires depends upon

th ea ctual conditions of their use, ho wever,and

ma ydepar tsignificantl yfromt he nor mdueto

va riations in drivin ghabits, servic epractices and

dif fere nces in road characteristic sand climate

conditions. Wheel

sand tires 211

Page 215 of 290

Information on maximum tir

eload %

The dat

ashown in thei llustration is sample

data.

Maximum tir eload 1isthem aximum permissi‐

ble weight forw hichthe tir eisa pprove d.

Do no toverload thet ires by ex ceeding them axi‐

mum permissible load. The maximum permissible

load can be found on thev ehicle's Tire and Load‐

ing In form atio nplacar dont he B-pillar on thed riv‐

er's side . Information on maximum tir

epressure %

The dat

ashown in thei llustration is sample

data.

Maximum permitted tir epressure 1mus tnever

be exc eeded. Alw ayso bser vether ecommended

tir ep ressur efor your vehicle when adjusting the

tir ep ressur e(/pag e207). Information on tir

echaracteristics %

The dat

ashown in thei llustration is sample

data.

This information describes thet ype of tir ecord

and then umber of la yers in side wall1 and

under tir etread 2. Ti

re size designation, load-bearing capacity,

speed ratin ga nd load index &

WARNING Risk of inju rythro ugh exceed‐

ing thes pecified tir eload-bearing capa‐

city or thep ermissible speed rating

Exceeding thes pecified tir eload rating or the

permissible speed rating ma ylea dtot ire

dama geand tothet ires bur sting. #

Therefore, onl yuse tir etypes and sizes

appr ovedfor your vehicle model. #

Obser vethet irel oad rating and speed

ra ting requ ired fory our vehicle. 1

Firstletter(s)

2 Nominal tir ewidthinm illimeters

3 Aspect ratio (i npercent)

4 Tire code

5 Rimd iame ter

6 Load-bearing index

7 Load index

8 Speed rating

% The da

tashown in thei llustration is sample

data.

Fu rther information about reading tir edatac an

be obtaine dfroma nyqualified specialis twork‐

shop.

First letter(s) 1 1:

R "LT": light truc ktires in acco rdanc ewithUS

manufacturer standards.

R "C": tires forc ommercial usage in accordance

wit hE uropean manufacturer standards. Wheel

sand tires 213

Page 216 of 290

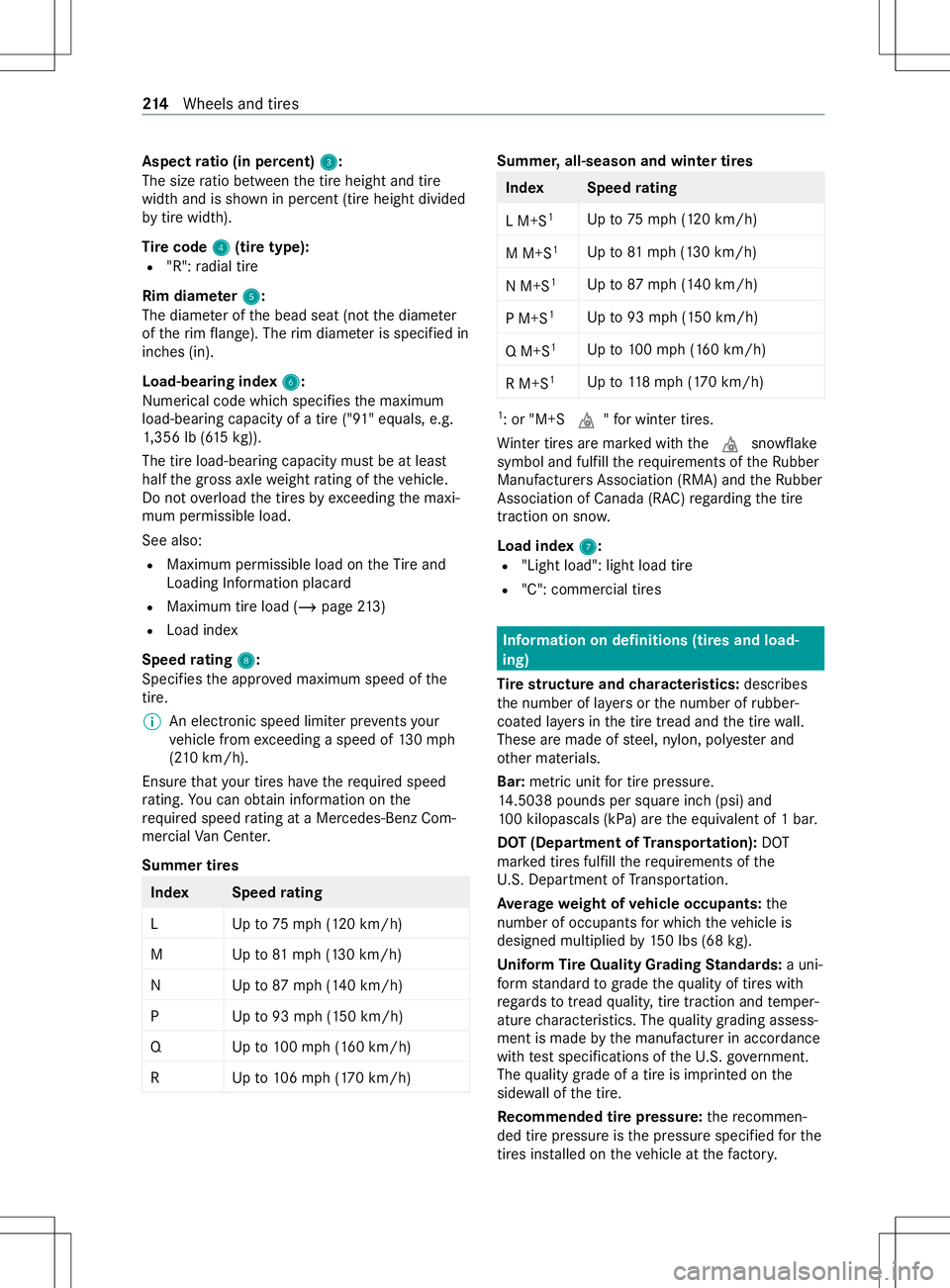

Aspec

tratio (in percent) 3 3:

The size ratio betwee nthe tir eheight and tire

widt hand is shown in percent (tir eheight divided

by tirew idth ).

Tir ec ode 4

4 (tire type):

R "R": radial tire

Rim diam eter 5 5:

The diame teroft he bead seat (no tthe diame ter

of ther im flange). The rimd iame teriss pecified in

inches (in).

Load-bearing index 6 6:

Nu merical code whic hspecifies them aximum

load-bearing capacity of atire( "91" equals, e.g.

1, 356 lb (6 15kg)).

Th et irel oad-bea ring capacity mu stbe at least

half theg ross axle weight rating of thev ehicle.

Do no toverload thet ires by ex ceeding them axi‐

mum permissible load.

See also:

R Maximum permissible load on theT irea nd

Loading In form atio nplacard

R Maximum tir eload (/ page213 )

R Load index

Spee drating 8 8:

Specifies thea ppr ove dm aximum speed of the

tire.

% An electroni

cspeed limiter pr events your

ve hicle from exceeding aspeed of 130m ph

(2 10 km/h).

Ensu rethat your tires ha vether equired speed

ra ting .You can obtain information on the

re qu ired speed rating at aMercedes-Benz Com‐

mercial VanC enter.

Summe rtires Inde

xS peedrating

LU pto75mph (120 km/h)

MU pto81mph (130 km/h)

NU pto87mph (140 km/h)

PU pto93mph (150 km/h)

QU pto100mph(160k m/h)

RU pto106mph(170k m/h) Summer

,all-season and winter tires Inde

xS peedrating

LM +S1

Upto75 mph(120k m/h)

MM +S1

Upto81 mp h(130k m/h)

NM +S1

Upto87 mph(140k m/h)

PM +S1

Upto93 mph(150k m/h)

QM +S1

Upto100m ph (160 km/h)

RM +S1

Upto118m ph (170 km/h) 1

:or" M+S 004D"f or winter tires.

Wi nter tires ar emarke dw itht he 004D snowflake

symbol and fulfill ther equirements of theR ubber

Manufacturer sAssociation (RMA) and theR ubber

Associatio nofCanada (RAC) rega rding thet ire

traction on sno w.

Load index 7 7:

R "Light load": light load tire

R "C": commercial tires Information on definitions (tires and load‐

ing)

Ti re stru ctu reand characteristics: describes

th en umber of la yers or then umber of rubber-

coated la yers inthet iret read and thet irew all.

These ar emade of steel, nylon, pol yester and

ot her materials.

Bar: metric unit fort irep ressu re.

14 .5038 pounds per squar einc h( psi) and

10 0k ilopascals (kPa) ar ethe equivalent of 1bar.

DO T(Department of Transportation): DOT

mar kedt ires fulfill ther equirements of the

U. S. Depa rtment of Transpor tatio n.

Av erag eweight of vehicl eoccupants: the

number of occupants forw hichthe vehicle is

designed multiplied by150lbs (68 kg).

Un ifor mT ireQ uality Grading Standards: auni‐

fo rm standar dtog rade theq uality of tires with

re ga rdstot read quality ,tiret raction and temp er‐

atur echaracteristics. The quality grading assess‐

men tism adebythem anufacturer in accordance

wit htests pecifications of theU .S. go vernment.

The quality grade of atireisi mprinted on the

side wall of thet ire.

Re commended tir epressu re:ther ecommen‐

ded tir epressur eist he pressur especified fort he

tires ins talled on thev ehicle at thef actor y. 214

Wheels and tires

Page 217 of 290

The

Tire and Loadin gInforma tionp lacar dcon‐

ta ins ther ecommended tir epressures forc old

tires, them aximum permissible load and the

maximu mpermissible vehicle speed.

The tir epressur etable con tains ther ecommen‐

ded tir epressures forc old tires under various

operating conditions, i.e. load and/or speed of

th ev ehicle.

Increased vehicl eweight due tooptional

equipment: thec ombined weight of all standard

and optional equipmen tavailable fort he vehicle,

re ga rdless of whe ther it is actually ins talled on

th ev ehicle or not.

Rim: thep artoft he wheel on whic hthe tir eis

ins talled.

GA WR (Gross AxleW eightRating): GAWR is the

gross axle weight rating .The actual load on an

axl em ustn eve rexceed theG ross Axle Weight

Ra ting .You can find theG ross Axle Weight Rating

on theB -pillar on thed rive r's side.

Speed rating: thes peed rating is pa rtof thet ire

identification .Itspecifies thes peed rang ef or

whic hatireisa pprove d.

GV W( Gross Vehicl eW eight): theG ross Vehicle

We ight includes thew eight of thev ehicle includ‐

ing fuel, tools, thes par ew heel, accessories

ins talled, occupants, luggag eand thet railer

dr aw bar nose weight if applicable. The Gross Vehi‐

cle Weight mus tnever exceed theG ross Vehicle

We ight Rating (GVWR )specifie donthe B-pillar on

th ed rive r's side.

GV WR (Gross Vehicl eW eight Rating): the

GV WR is them aximum permitted gross weight of

th ef ully laden vehicle (weight of thev ehicle

including all accessories, occupants, fuel, lug‐

ga ge and thet railer dr awbar nose weight if appli‐

cable). The Gross Vehicle Weight Rating is speci‐

fi ed on thev ehicle identification plat eonthe B-

pillar on thed rive r's side.

Maximum weight of thel aden vehicle: the

maximu mweight is thes um of thev ehicle's curb

we ight ,weight of thea ccessories, maximum load

and thew eight of thef actor yins talled optional

equipment.

Kilopascal (kPa): metric unitfort irep ressu re.

6.9 kP aarethee quivalent of 1psi. Ano ther unit

fo rt irep ressu reis bar .100 kilopascals (kPa) are

th ee quivalent of 1bar.

Load index: in additiontothel oad-bearing index,

th el oad inde xmayalso be imprinted on thes ide‐

wa ll of thet ire. This specifies thel oad-bearing

capacity mor eprecisel y. Cur

bw eight: thew eight of avehicle wit hstand‐

ar de quipmen tincludin gthe maximum capacity

of fuel, oil and coolant. It also includes thea ir-

conditioning sy stem and optional equipment if

th ese ar einstalled on thev ehicle, but does not

include passenger sorluggage.

Maximum tir eload: them aximum tir eload is

th em aximum permissible weight in kilog rams or

lbs forw hichat ireisa pprove d.

Maximum permissible tir epressure: maximum

permissible tir epressur efor one tire.

Maximum load on one tire: maximum load on

one tire. This is calculated bydividing them axi‐

mum axle load foro ne axle bytwo.

PSI (pounds per squar einch): standar dunit of

measuremen tfor tir epressu re.

Aspec tratio: relationship between tir eheight

and tir ewidthinp ercent.

Ti re pressure: pressureinside thet irea pplying

an outwar dforce toeve rysquar einc hoft he

tire's sur face. The tir epressur eiss pecified in

pounds per squar einc h( psi), in kilopascal (kPa)

or in bar .The tir epressur eshould onl ybecorrec‐

te dw hen thet ires ar ecold.

Ti re pressur eoncoldt ires: thet ires ar ecold

when thev ehicle has been par kedw itht he tires

out of direct sunlight foratl east thre eh our sand

th ev ehicle has been driven less than 1m ile

(1.6 km).

Ti re contact sur face: thep artoft he tir ethat

comes int ocontact wi th theroad.

Ti re bead: thep urpose of thet ireb ead is to

ensur ethat thet ires its securely on thew heel

ri m. Ther eareseveralw irec ores in thet ireb ead

to preve ntthet iref romc hanging lengt honthe

whee lrim.

Sid ew all: thep artoft he tir ebetwe en thet read

and thet ireb ead.

Special equipment weight: thec ombined

we ight of those optional extras that we igh more

th an ther eplaced standar dparts and mor ethan

5l bs (2. 3kg). These optiona lextras ,suc has

high-pe rformance brakes, le velc ontrol sy stem, a

ro of luggag erackorah igh-perform anc ebatter y,

ar en otincluded in thec urb weight and the

we ight of thea ccessories.

TIN (Tir eIdentification Number): auniqu eiden‐

tification number whic hcan be used byatire

manufacturer toidentify tires, fore xamp lefora

product recall, and thus identif ythe pur chasers.

The TIN is made up of them anufacturer identifi‐ Wheels and tires

215