air filter MERCEDES-BENZ ML320 1997 Complete Repair Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 3775 of 4133

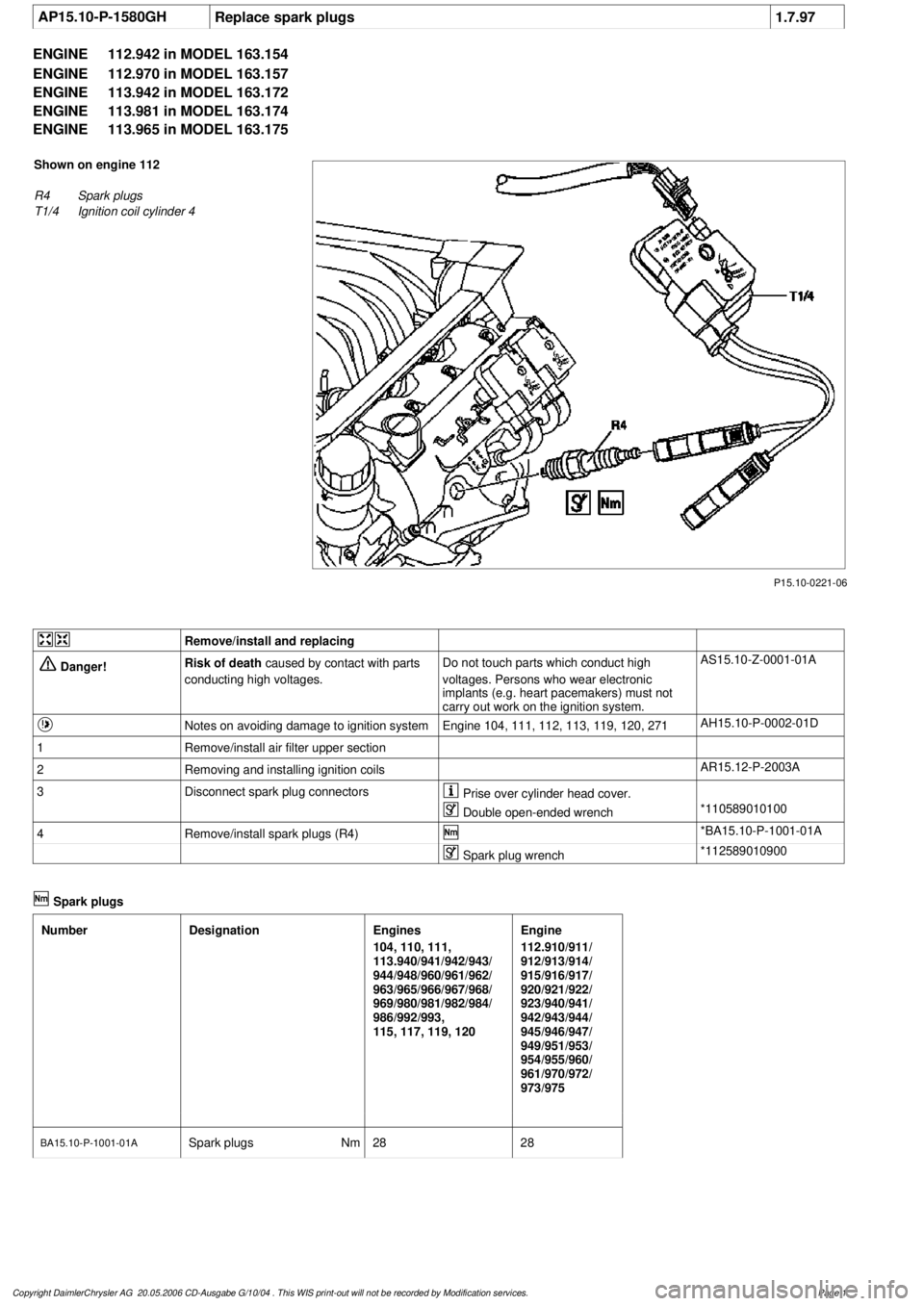

AP15.10-P-1580GHReplace spark plugs

1.7.97

ENGINE

112.942 in MODEL 163.154

ENGINE

112.970 in MODEL 163.157

ENGINE

113.942 in MODEL 163.172

ENGINE

113.981 in MODEL 163.174

ENGINE

113.965 in MODEL 163.175

P15.10-0221-06

Shown on engine 112

R4

Spark plugs

T1/4

Ignition coil cylinder 4

Remove/install and replacing

Danger!

Risk of death

caused by contact with parts

conducting high voltages.

Do not touch parts which conduct high

voltages. Persons who wear electronic

implants (e.g. heart pacemakers) must not

carry out work on the ignition system.

AS15.10-Z-0001-01A

Notes on avoiding damage to ignition system

Engine 104, 111, 112, 113, 119, 120, 271

AH15.10-P-0002-01D

1

Remove/install air filter upper section

2

Removing and installing ignition coils

AR15.12-P-2003A

3

Disconnect spark plug connectors

Prise over cylinder head cover.

Double open-ended wrench

*110589010100

4

Remove/install spark plugs (R4)

*BA15.10-P-1001-01A

Spark plug wrench

*112589010900

Spark plugs

Number

Designation

Engines

104, 110, 111,

113.940/941/942/943/

944/948/960/961/962/

963/965/966/967/968/

969/980/981/982/984/

986/992/993,

115, 117, 119, 120

Engine

112.910/911/

912/913/914/

915/916/917/

920/921/922/

923/940/941/

942/943/944/

945/946/947/

949/951/953/

954/955/960/

961/970/972/

973/975

BA15.10-P-1001-01A

Spark plugs

Nm

2828

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1

Page 3836 of 4133

Measures for slightly sludged engine:

Oil and filter change. Purge engine, i.e. normal engine operation

in neutral, or while driving, using oil from Sheet 229.3, 228.3, or

228.5. Drain off scavenging oil after purging process (approx. 1

hour). Repeat purging process if necessary. Refill using engine oil

from Sheet 229.3, or 229.1. The first oil change after clearing the

sludge should be performed after approx. 10,000 km or beforehand;

when doing so use engine oil from Sheet 229.3.

Measures for severely sludged engine:

Engines with severe oil sludging and caking onto engine parts

and into bores have to be dismantled and mechanically cleaned.

Tough sludge residue must not enter the clean side of the oil circuit,

as otherwise, e.g. the piston oil spray and the hydraulic

compensation elements may have their functionality impaired. Refill

using engine oil from Sheet 229.3, or 229.1.

The first oil change after sludging should be performed after approx.

10,000 km; when doing so use engine oil from

Sheet 229.3.

Warranty/goodwill regulations

If in combination with engine oil sludging a warranty/goodwill claim is

submitted, then a regular documentation of maintenance must be

presented. The ASSYST printout is to be filed carefully for further

reference.

Oil sludging in combination with an exceeded oil change interval, or

because of special additives in the fuel/engine oil are costs to be

borne by the customer.

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

Page 3989 of 4133

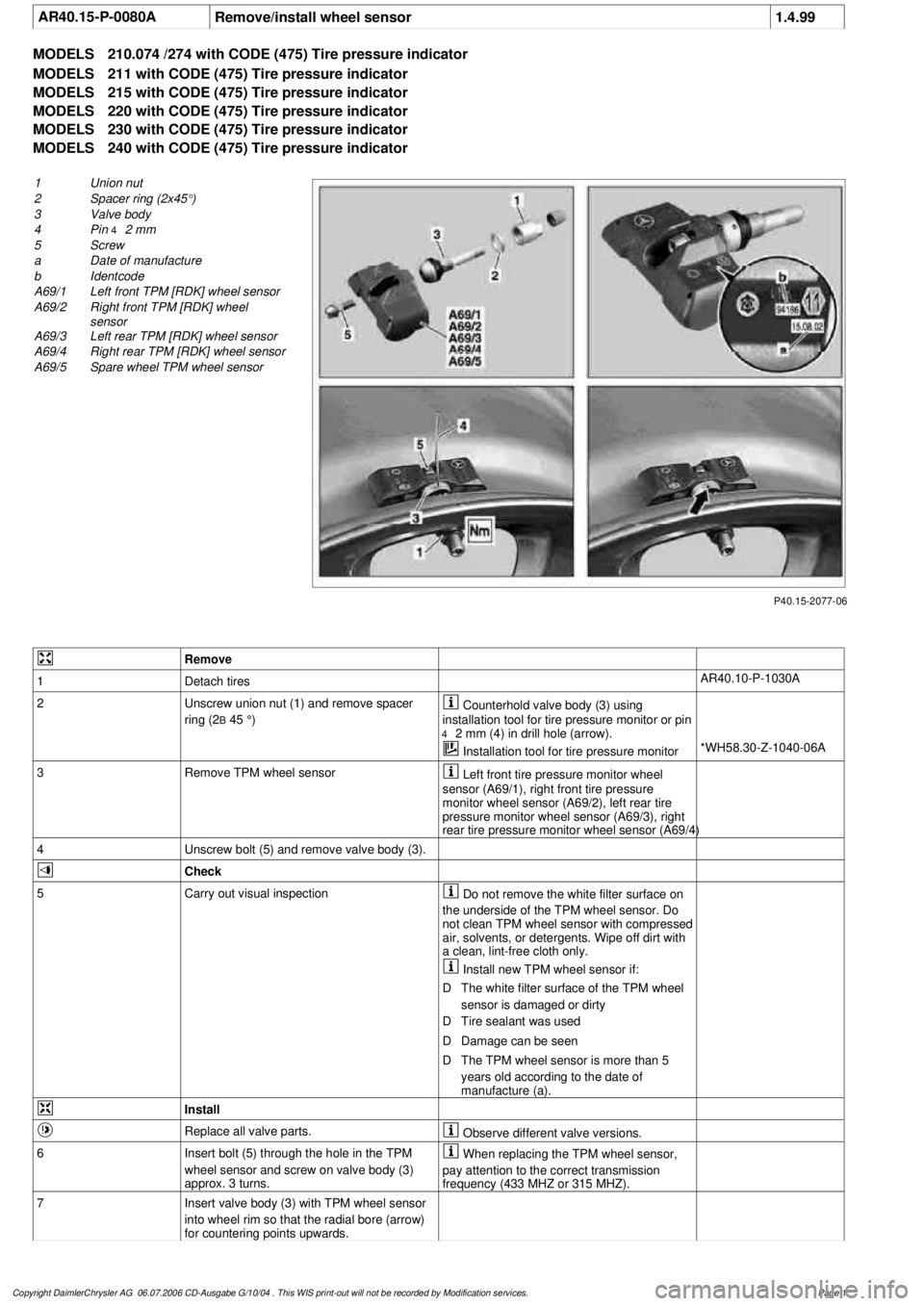

AR40.15-P-0080A

Remove/install wheel sensor

1.4.99

MODELS

210.074 /274 with CODE (475) Tire pressure indicator

MODELS

211 with CODE (475) Tire pressure indicator

MODELS

215 with CODE (475) Tire pressure indicator

MODELS

220 with CODE (475) Tire pressure indicator

MODELS

230 with CODE (475) Tire pressure indicator

MODELS

240 with CODE (475) Tire pressure indicator

P40.15-2077-06

1

Union nut

2

Spacer ring (2x45°)

3

Valve body

4

Pin

4

2 mm

5

Screw

a

Date of manufacture

b

Identcode

A69/1

Left front TPM [RDK] wheel sensor

A69/2

Right front TPM [RDK] wheel

sensor

A69/3

Left rear TPM [RDK] wheel sensor

A69/4

Right rear TPM [RDK] wheel sensor

A69/5

Spare wheel TPM wheel sensor

Remove

1

Detach tires

AR40.10-P-1030A

2

Unscrew union nut (1) and remove spacer

ring (2

B

45 °)

Counterhold valve body (3) using

installation tool for tire pressure monitor or pin

4

2 mm (4) in drill hole (arrow).

Installation tool for tire pressure monitor

*WH58.30-Z-1040-06A

3

Remove TPM wheel sensor

Left front tire pressure monitor wheel

sensor (A69/1), right front tire pressure

monitor wheel sensor (A69/2), left rear tire

pressure monitor wheel sensor (A69/3), right

rear tire pressure monitor wheel sensor (A69/4)

4

Unscrew bolt (5) and remove valve body (3).

Check

5

Carry out visual inspection

Do not remove the white filter surface on

the underside of the TPM wheel sensor. Do

not clean TPM wheel sensor with compressed

air, solvents, or detergents. Wipe off dirt with

a clean, lint-free cloth only.

Install new TPM wheel sensor if:

D

The white filter surface of the TPM wheel

sensor is damaged or dirty

D

Tire sealant was used

D

Damage can be seen

D

The TPM wheel sensor is more than 5

years old according to the date of

manufacture (a).

Install

Replace all valve parts.

Observe different valve versions.

6

Insert bolt (5) through the hole in the TPM

wheel sensor and screw on valve body (3)

approx. 3 turns.

When replacing the TPM wheel sensor,

pay attention to the correct transmission

frequency (433 MHZ or 315 MHZ).

7

Insert valve body (3) with TPM wheel sensor

into wheel rim so that the radial bore (arrow)

for countering points upwards.

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1