Torque specification MERCEDES-BENZ ML320 1997 Complete User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 1179 of 4133

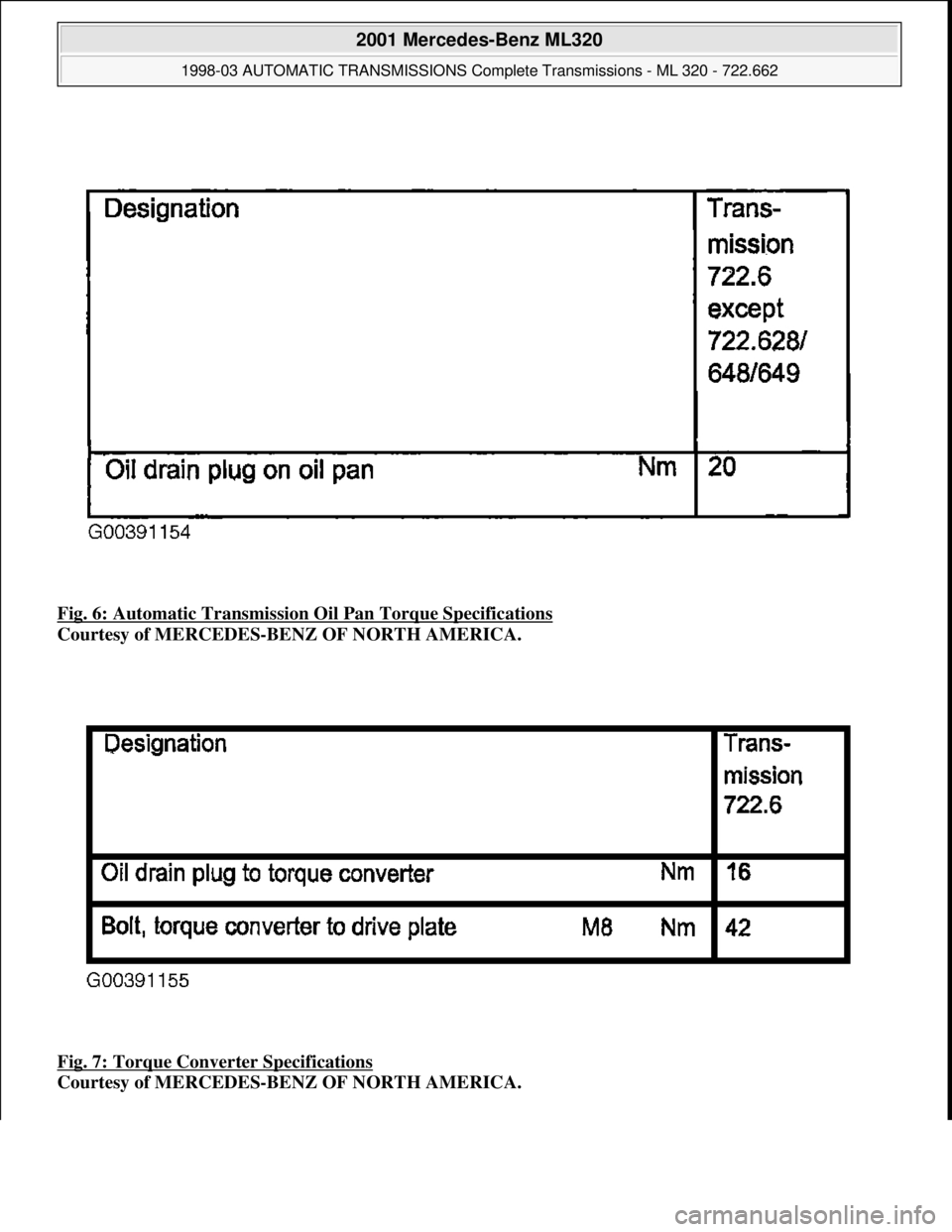

Fig. 6: Automatic Transmission Oil Pan Torque Specifications

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

Fig. 7: Torque Converter Specifications

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMI SSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:25 PMPage 10 © 2006 Mitchell Repair Information Company, LLC.

Page 1180 of 4133

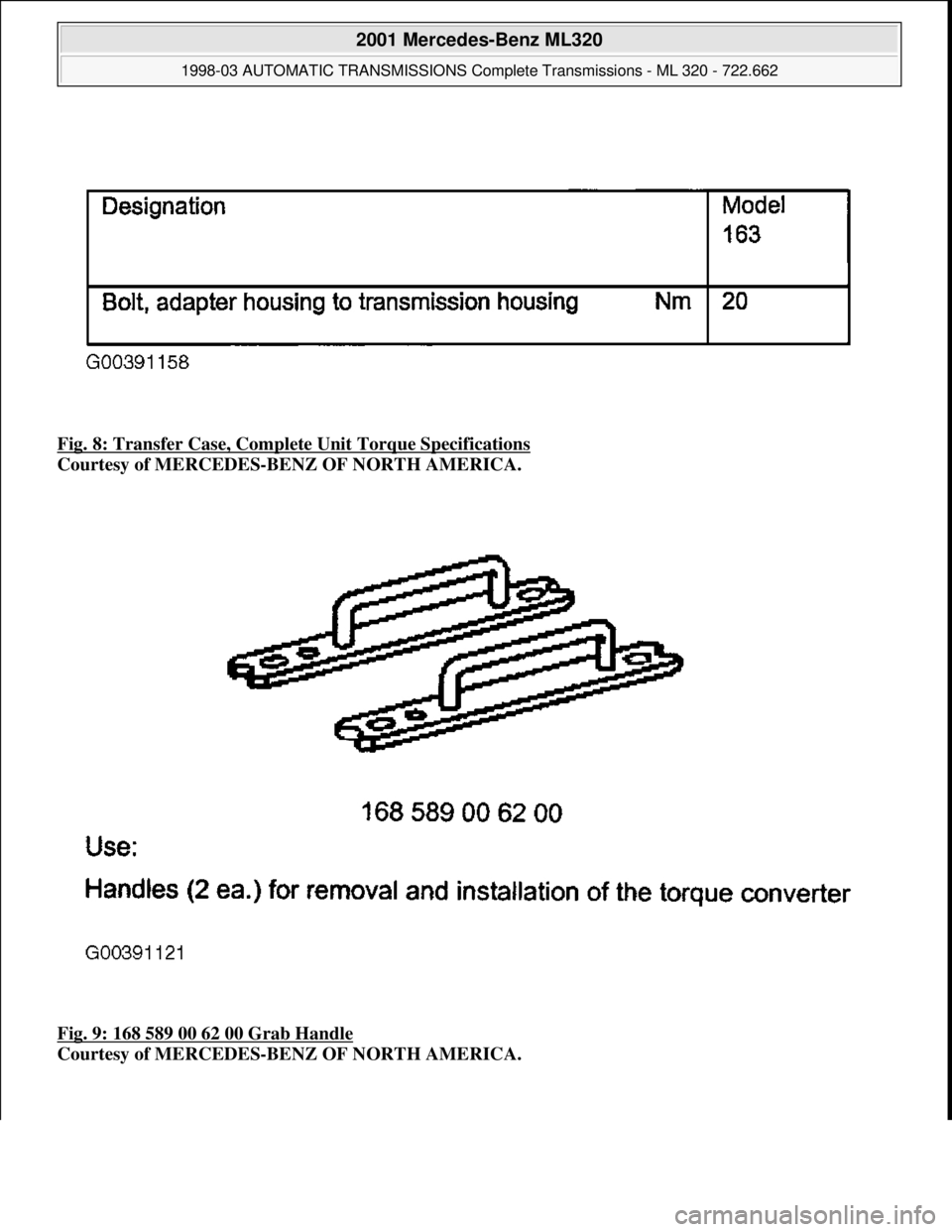

Fig. 8: Transfer Case, Complete Unit Torque Specifications

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

Fig. 9: 168 589 00 62 00 Grab Handle

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:25 PMPage 11 © 2006 Mitchell Repair Information Company, LLC.

Page 1184 of 4133

Connect ground cable.

4 - Code radio.

5 - Set time at instrument cluster

6.1 - Activate steering angle sensor.

7.1 - Synchronize tilt/slide sunroof.

8.1 - Synchronize lamella (thin plate) sliding roof.

9.1 - Synchronize power windows.

Torque Specification; Nut Of Ground Cable To Body NOTE: After opening the vehicle wait for at least 4 minutes before disconnecting

the battery otherwise the alarm will be triggered.

NOTE: Model 163: Tighten the nut (5) of the ground line (1) to the specified

torque. Perform work described below only when quiescent current

retention unit was not connected. Model Series 163 see Torque

Specification; Nut Of Ground Cable To Body.

NOTE: MB (models 163).

Hi-Line, premium with Bose (model 163).

NOTE: If necessary set time at stationary heater timer.

NOTE: Model 163 with Code 414.

Open tilt/slide sunroof and hold down switch. Sliding/pop-up roof

mechanism moves to end position, pulls back 1/4 turn and stops.

NOTE: Open tilt/slide sunroof and hold down switch. Sliding/pop-up roof

mechanism moves to end position, pulls back 1/4 turn and stops.

NOTE: Model 163 as of VIN A289565, X754620.

Press power windows switch up to the 1st pressure point and, after

reaching the upper end position of the window, keep pressed for further 5

seconds.

NumberDesignationModel Series 163

BA54.10--P-1001--01ANut of ground cable to bodyNM18

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:25 PMPage 15 © 2006 Mitchell Repair Information Company, LLC.

Page 1466 of 4133

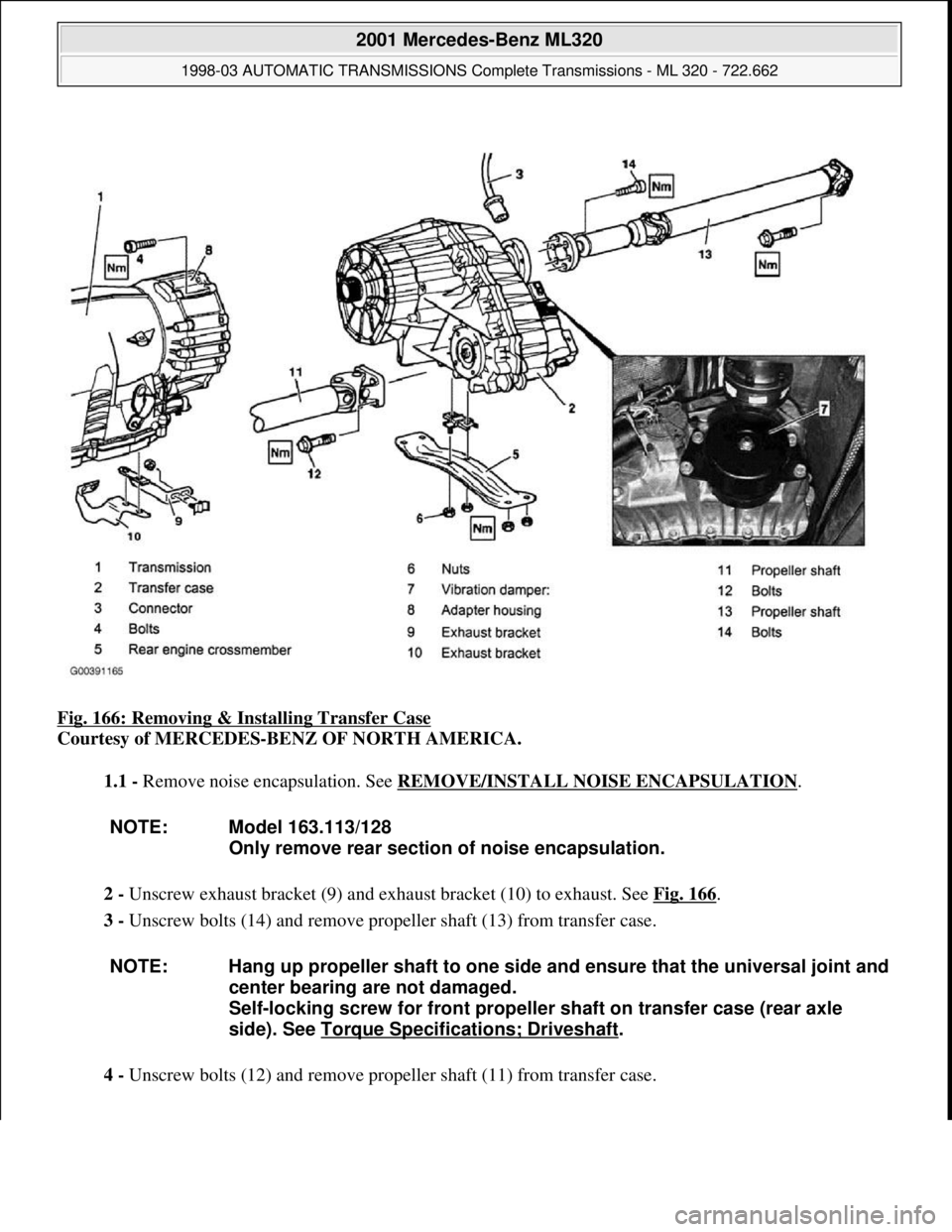

Fig. 166: Removing & Installing Transfer Case

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

1.1 - Remove noise encapsulation. See REMOVE/INSTALL NOISE ENCAPSULATION

.

2 - Unscrew exhaust bracket (9) and exhaust bracket (10) to exhaust. See Fig. 166

.

3 - Unscrew bolts (14) and remove propeller shaft (13) from transfer case.

4 - Unscrew bolts (12) and remove propeller shaft (11) from transfer case.

NOTE: Model 163.113/128

Only remove rear section of noise encapsulation.

NOTE: Hang up propeller shaft to one side and ensure that the universal joint and

center bearing are not damaged.

Self-locking screw for front propeller shaft on transfer case (rear axle

side). See Torque Specifications; Driveshaft

.

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:30 PMPage 297 © 2006 Mitchell Repair Information Company, LLC.

Page 1467 of 4133

5 - Detach plug (3) from actuator motor.

6 - Support transmission and remove rear engine crossmember (5) with engine mount.

7 - Slightly lower engine transmission unit.

8 - Support transfer case (2) with lifting device. See SUPPORTING TRANSMISSION WITH

INSPECTION PIT LIFT.

9 - Unscrew bolts (4) and take out transfer case to the back.

10 - Install in the reverse order.

11 - Check filling capacity of transfer case.

Check transfer case (2) for leaks.

Torque Specifications; Driveshaft NOTE: Hang up propeller shaft to one side and ensure that the universal joint is

not damaged.

Self-locking bolt, propeller shaft to transfer case (to front axle). See

Torque Specifications; Driveshaft

.

NOTE:

Engine 112:

Bolt of rear engine crossmember to body.

Engine 112:

Bolt or nut, rear engine mount to transmission.

NOTE: Ensure that no lines are damaged.

NOTE: Transmission plate.

NOTE: Bolt, transfer case to automatic transmission.

Bolt, transfer case to manual transmission.

NOTE: Correct oil level: Bottom edge of filler hole.

Screw plug to transfer case.

DesignationModel 163

Self-locking bolt, front propeller shaft to transfer case (to rear axle)Nm40

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:30 PMPage 298 © 2006 Mitchell Repair Information Company, LLC.

Page 1468 of 4133

Torque Specifications; Engine Mounts, Engine Supports

Torque Specifications; Engine Suspension, Engine Mounts, Engine Supports

Torque Specifications; Engine Suspension, Engine Mounts, Engine Supports

Torque Specifications; Transfer Case, Complete Unit

Fig. 167: Commercially Available Tools (See Workshop Equipment Manual)

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

Remove/Install Noise Encapsulation

Self-locking screw, propeller shaft to transfer case (to front axle)Nm50

DesignationEngine 112.942/970 113.942/965/ in model 163.154/157/

172/174/175

Bolt of rear engine crossmember to bodyNm40

Bolt or nut, rear engine mount to

transmissionM8Nm-

M10Nm40

DesignationEngine 612.963 in model

163.113Engine 628.963 in model

163

Bolt/nut, rear engine crossmember to

bodyNm4040

Bolt or nut, rear engine mount to

transmissionNm4040

DesignationEngine 111 in model 163

Bolt of rear engine crossmember to bodyNm40

Bolt or nut, rear engine mount to transmissionNm35

DesignationModel 163

Threaded plug in transfer caseNm30

Bolt, transfer case to automatic transmissionNm20

Bolt, transfer case to manual transmissionNm20

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:30 PMPage 299 © 2006 Mitchell Repair Information Company, LLC.

Page 2060 of 4133

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

WIRING DIAGRAMS

See CHARGING SYSTEM in appropriate SYSTEM WIRING DIAGRAMS article in ELECTRICAL.

ApplicationFt. Lbs. (N.m)

Generator Mounting Bolts30 (42)

Generator Pulley Nut52 (70)

2001 Mercedes-Benz ML320

2001-04 STARTING & CHARGING SYSTEMS Generators & Regulators - 163 Chassis

me

Saturday, October 02, 2010 3:20:32 PMPage 26 © 2006 Mitchell Repair Information Company, LLC.

Page 2559 of 4133

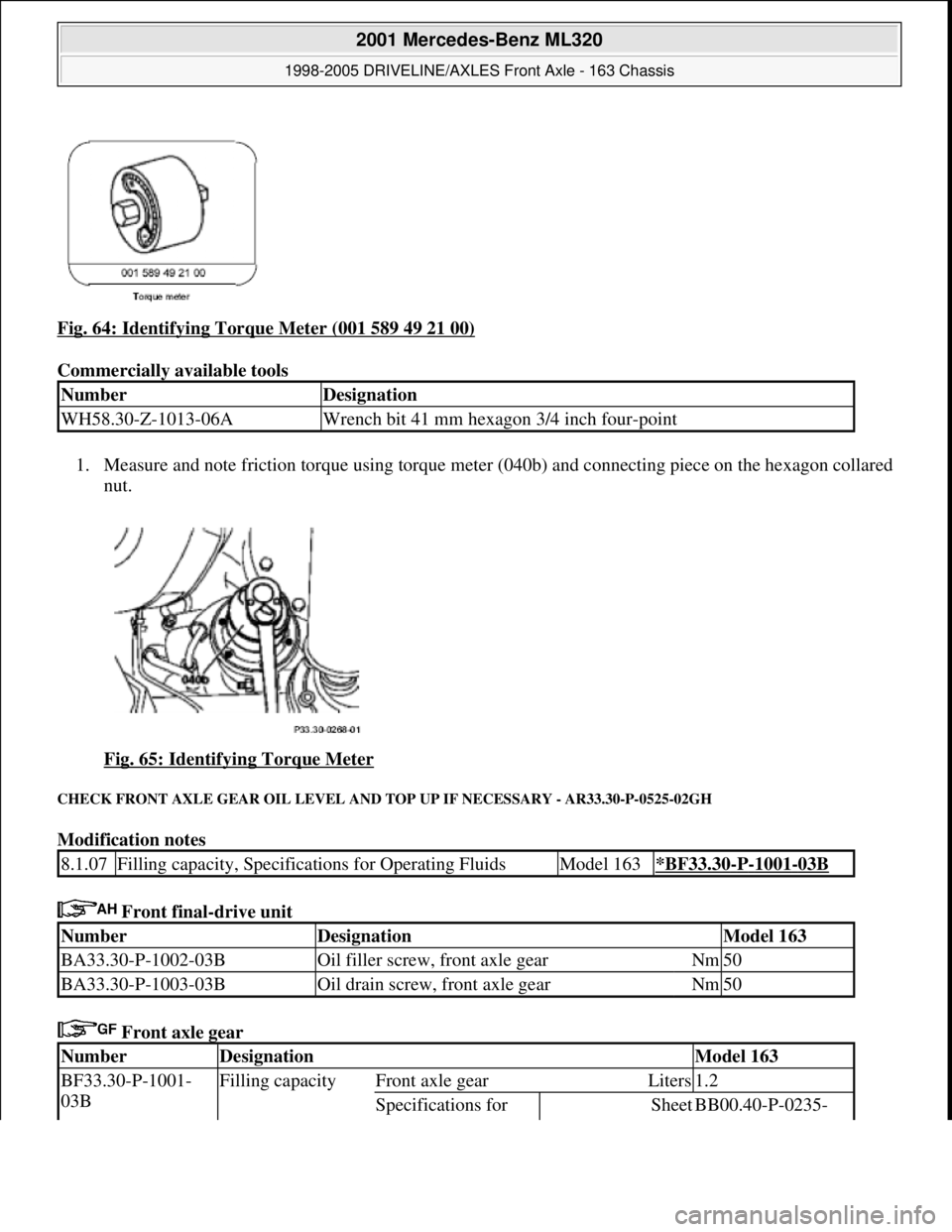

Fig. 64: Identifying Torque Meter (001 589 49 21 00)

Commercially available tools

1. Measure and note friction torque using torque meter (040b) and connecting piece on the hexagon collared

nut.

Fig. 65: Identifying Torque Meter

CHECK FRONT AXLE GEAR OIL LEVEL AND TOP UP IF NECESSARY - AR33.30-P-0525-02GH

Modification notes

Front final-drive unit

Front axle gear

NumberDesignation

WH58.30-Z-1013-06AWrench bit 41 mm hexagon 3/4 inch four-point

8.1.07Filling capacity, Specifications for Operating FluidsModel 163*BF33.30-P-1001-03B

NumberDesignationModel 163

BA33.30-P-1002-03BOil filler screw, front axle gearNm50

BA33.30-P-1003-03BOil drain screw, front axle gearNm50

NumberDesignationModel 163

BF33.30-P-1001-

03BFilling capacityFront axle gearLiters1.2

Specifications for SheetBB00.40-P-0235-

2001 Mercedes-Benz ML320

1998-2005 DRIVELINE/AXLES Front Axle - 163 Chassis

me

Saturday, October 02, 2010 3:38:22 PMPage 40 © 2006 Mitchell Repair Information Company, LLC.

Page 2565 of 4133

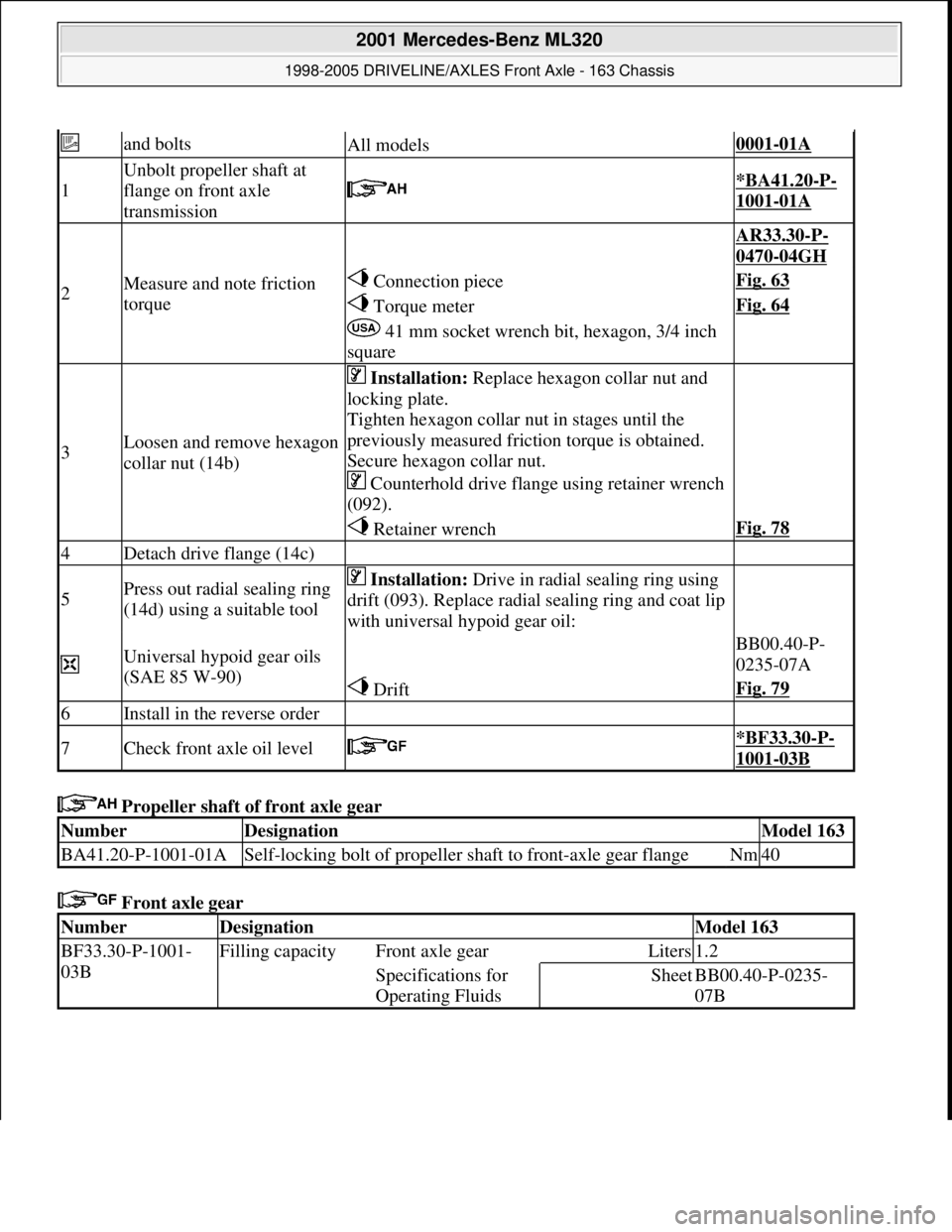

Propeller shaft of front axle gear

Front axle gear

and boltsAll models0001-01A

1

Unbolt propeller shaft at

flange on front axle

transmission

*BA41.20-P-

1001-01A

2Measure and note friction

torque

AR33.30-P-

0470-04GH

Connection pieceFig. 63

Torque meterFig. 64

41 mm socket wrench bit, hexagon, 3/4 inch

square

3Loosen and remove hexagon

collar nut (14b)

Installation: Replace hexagon collar nut and

locking plate.

Tighten hexagon collar nut in stages until the

previously measured friction torque is obtained.

Secure hexagon collar nut.

Counterhold drive flange using retainer wrench

(092).

Retainer wrenchFig. 78

4Detach drive flange (14c)

5Press out radial sealing ring

(14d) using a suitable tool Installation: Drive in radial sealing ring using

drift (093). Replace radial sealing ring and coat lip

with universal hypoid gear oil:

Universal hypoid gear oils

(SAE 85 W-90) BB00.40-P-

0235-07A

DriftFig. 79

6Install in the reverse order

7Check front axle oil level *BF33.30-P-

1001-03B

NumberDesignationModel 163

BA41.20-P-1001-01ASelf-locking bolt of propeller shaft to front-axle gear flangeNm40

NumberDesignationModel 163

BF33.30-P-1001-

03BFilling capacity Front axle gearLiters1.2

Specifications for

Operating FluidsSheetBB00.40-P-0235-

07B

2001 Mercedes-Benz ML320

1998-2005 DRIVELINE/AXLES Front Axle - 163 Chassis

me

Saturday, October 02, 2010 3:38:22 PMPage 46 © 2006 Mitchell Repair Information Company, LLC.

Page 3148 of 4133

of repairs or for service fills.

2.6 Transmission oils, sheet 235.11

The fully synthetic gear oils are approved for all MB commercial vehicle manual transmissions installed

in MB vehicles with steel/molybdenum synchronization with and without oil coolers, in MB transfer

cases with and without oil coolers as well as in ZF manual transmissions with steel/molybdenum

synchronization.

Due to the favorable viscosity/temperature characteristics, a good cold-shifting response and, due to the

composition of the transmission oil, a good thermal/oxidative stability of the oil at high transmission oil

temperatures as well as a fuel savings potential depending on the operating conditions can be expected.

2.7 Engine oils, sheet 235.12

The engine oils must be used with a common oil system for transmissions used in tropical countries, and

for manual transmissions with a torque converter and clutch unit. These engine oils display the very high

seizure resistance required for use in transmissions. The oils need not comply with the engine oil pour

point specifications in these Specifications for Operating Fluids.

2.8 Engine oils, sheet 235.27

Commercial vehicle retarder oils: the products listed in the tables apply to commercial vehicle

transmissions: see MB Specifications for Operating Fluids 231.2. The engine oils are suitable for retarder

use. The oils need not comply with the engine Specifications for Operating Fluids 231.2. The engine oils

are suitable for retarder use. The oils need not comply with the engine oil pour point specifications in

these Specifications for Operating Fluids.

3. Automatic transmission fluids (ATF), sheet 236.1/.2/.3/.5/.6/.7/.8/.81/.9/.10/.11/.12/.13/.20

ATFs are comparatively low-viscosity gear oils which, due to their universal use potential as a gear oil or

a hydraulic fluid, can cover a wide spectrum of applications. The ATFs in the individual their universal

use potential as a gear oil or a hydraulic fluid, can cover a wide spectrum of applications. The ATFs in the

individual sheets differ essentially due to their inherent friction coefficients in tribological contact. This

property predestines these oils as function fluids for automatic transmissions whose ease of shifting,

among other things, is considerably affected by the friction coefficient of the ATF. Therefore, to achieve

optimum performance of the vehicles, only the ATF quality (sheet no.) assigned to the major assembly is

to be used. The individual ATF qualities will be described in greater detail below.

3.1 Automatic transmission fluids (ATF), sheet 236.1

The approved ATF correspond to the currently no longer valid GM specification Dexron II-D or the

currently valid GM specification Dexron III.

The field of application of these ATF includes MB automatic transmissions without controlled torque

converter lockup clutch in passenger cars, ZF Ecomat transmissions, Allison automatic transmissions,

Voith-Diwa transmissions and MB automatic transmissions in commercial vehicles and busses except

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:56 PMPage 503 © 2006 Mitchell Repair Information Company, LLC.