ad blue MERCEDES-BENZ ML320 1997 Complete User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 1911 of 4133

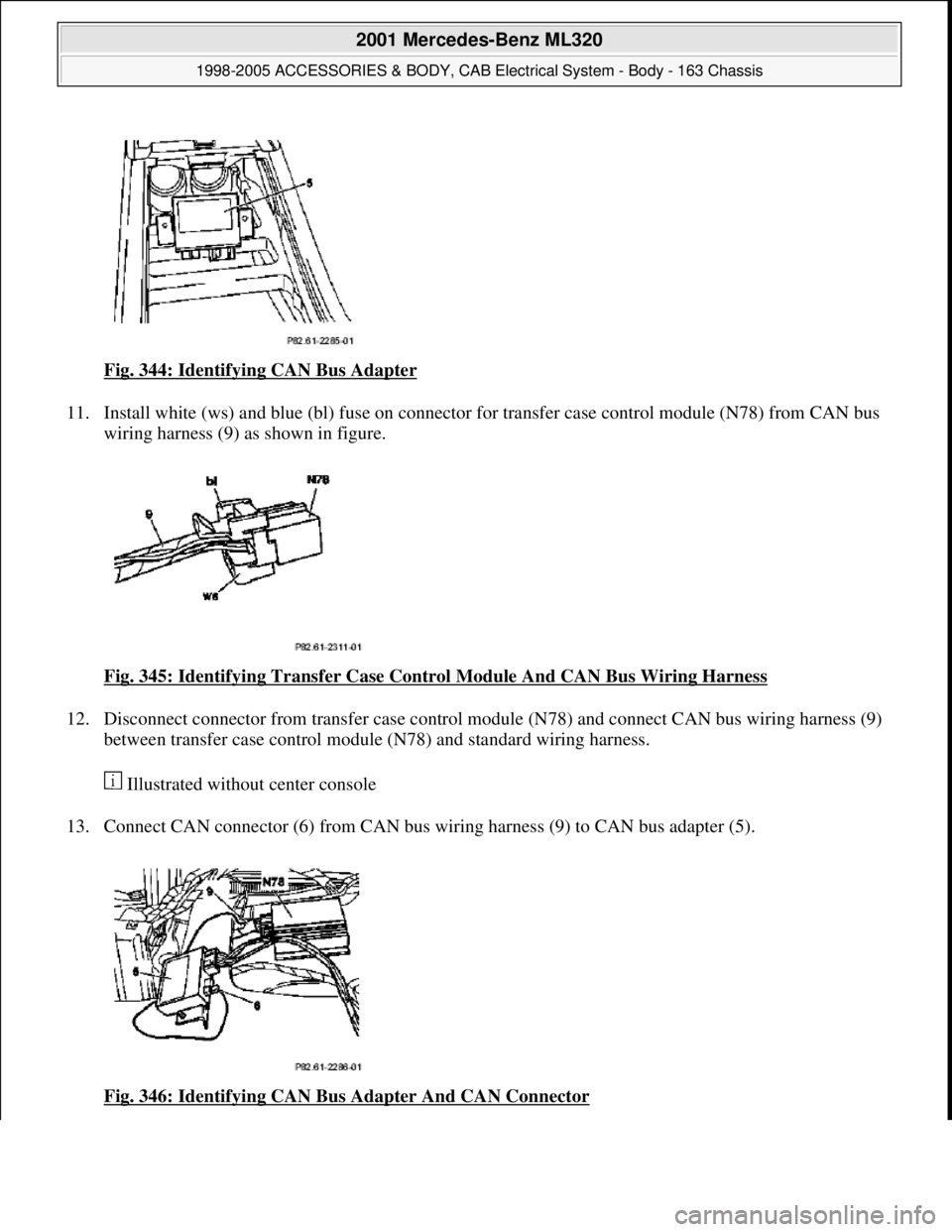

Fig. 344: Identifying CAN Bus Adapter

11. Install white (ws) and blue (bl) fuse on connector for transfer case control module (N78) from CAN bus

wiring harness (9) as shown in figure.

Fig. 345: Identifying Transfer Case Cont rol Module And CAN Bus Wiring Harness

12. Disconnect connector from transfer case control module (N78) and connect CAN bus wiring harness (9)

between transfer case control module (N78) and standard wiring harness.

Illustrated without center console

13. Connect CAN connector (6) from CAN bus wiring harnes s (9) to CAN bus adapter (5).

Fig. 346: Identifying CAN Bu s Adapter And CAN Connector

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electr ical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:13 PMPage 416 © 2006 Mitchell Repair Information Company, LLC.

Page 1922 of 4133

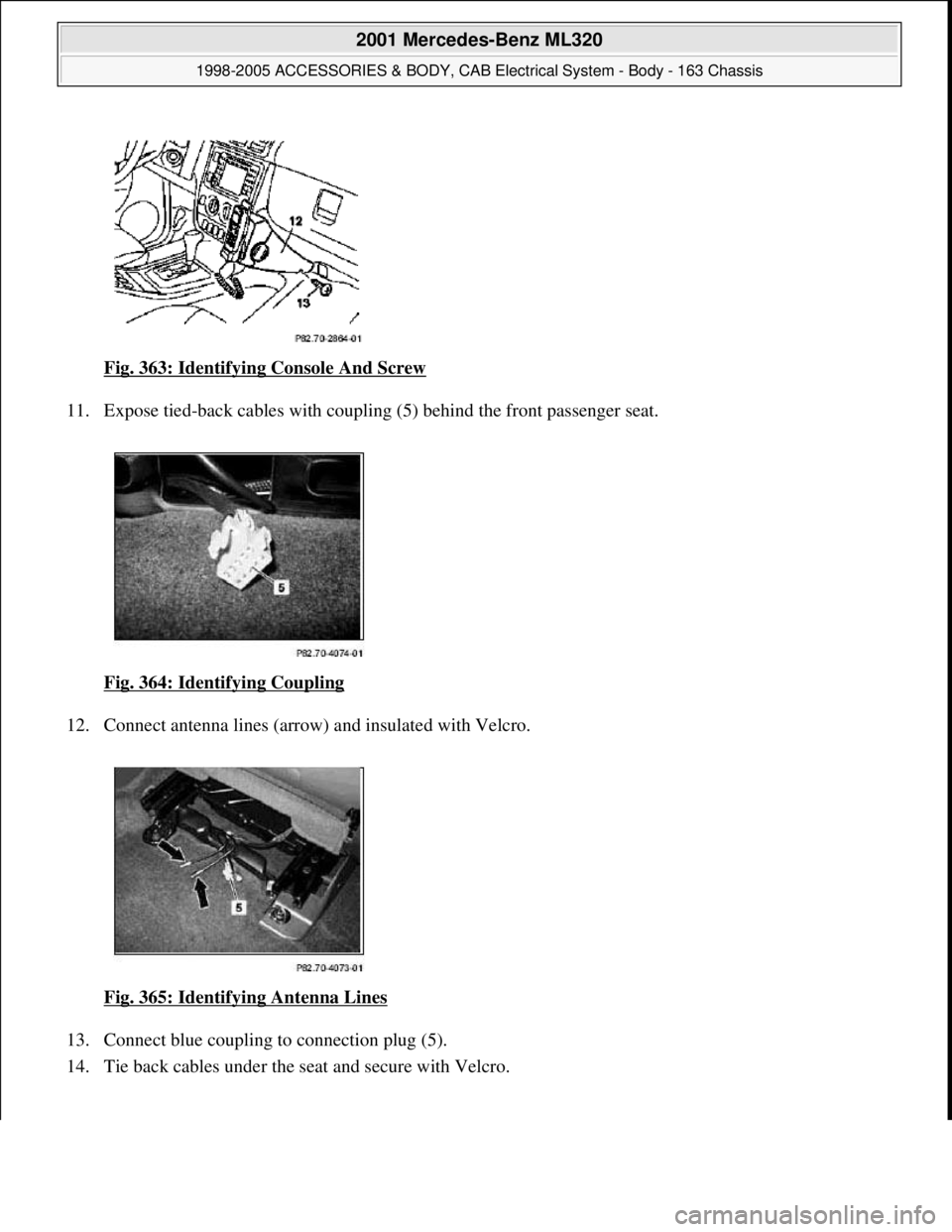

Fig. 363: Identifying Console And Screw

11. Expose tied-back cables with coupli ng (5) behind the front passenger seat.

Fig. 364: Identifying Coupling

12. Connect antenna lines (arrow ) and insulated with Velcro.

Fig. 365: Identifying Antenna Lines

13. Connect blue coupling to connection plug (5).

14. Tie back cables under the se at and secure with Velcro.

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electr ical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:13 PMPage 427 © 2006 Mitchell Repair Information Company, LLC.

Page 1923 of 4133

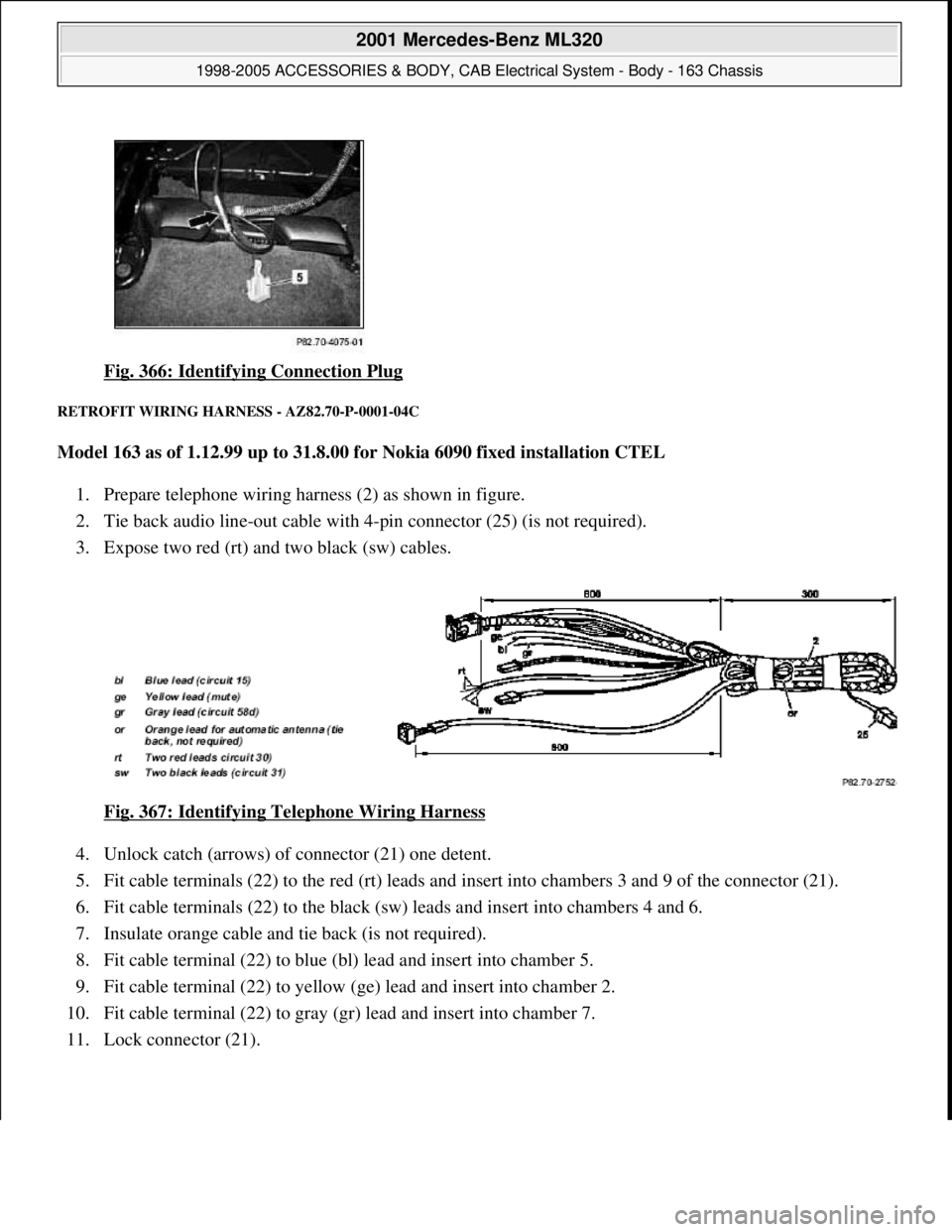

Fig. 366: Identifying Connection Plug

RETROFIT WIRING HARNESS - AZ82.70-P-0001-04C

Model 163 as of 1.12.99 up to 31.8.00 for Nokia 6090 fixed installation CTEL

1. Prepare telephone wiring harness (2) as shown in figure.

2. Tie back audio line-out cable with 4-pin connector (25) (is not required).

3. Expose two red (rt) and two black (sw) cables.

Fig. 367: Identifying Telephone Wiring Harness

4. Unlock catch (arrows) of connector (21) one detent.

5. Fit cable terminals (22) to the red (rt) leads and insert into chambers 3 and 9 of the connector (21).

6. Fit cable terminals (22) to the black (sw) leads and insert into chambers 4 and 6.

7. Insulate orange cable and tie back (is not required).

8. Fit cable terminal (22) to blue (bl) lead and insert into chamber 5.

9. Fit cable terminal (22) to yellow (ge) lead and insert into chamber 2.

10. Fit cable terminal (22) to gray (gr) lead and insert into chamber 7.

11. Lock connector (21).

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:13 PMPage 428 © 2006 Mitchell Repair Information Company, LLC.

Page 1926 of 4133

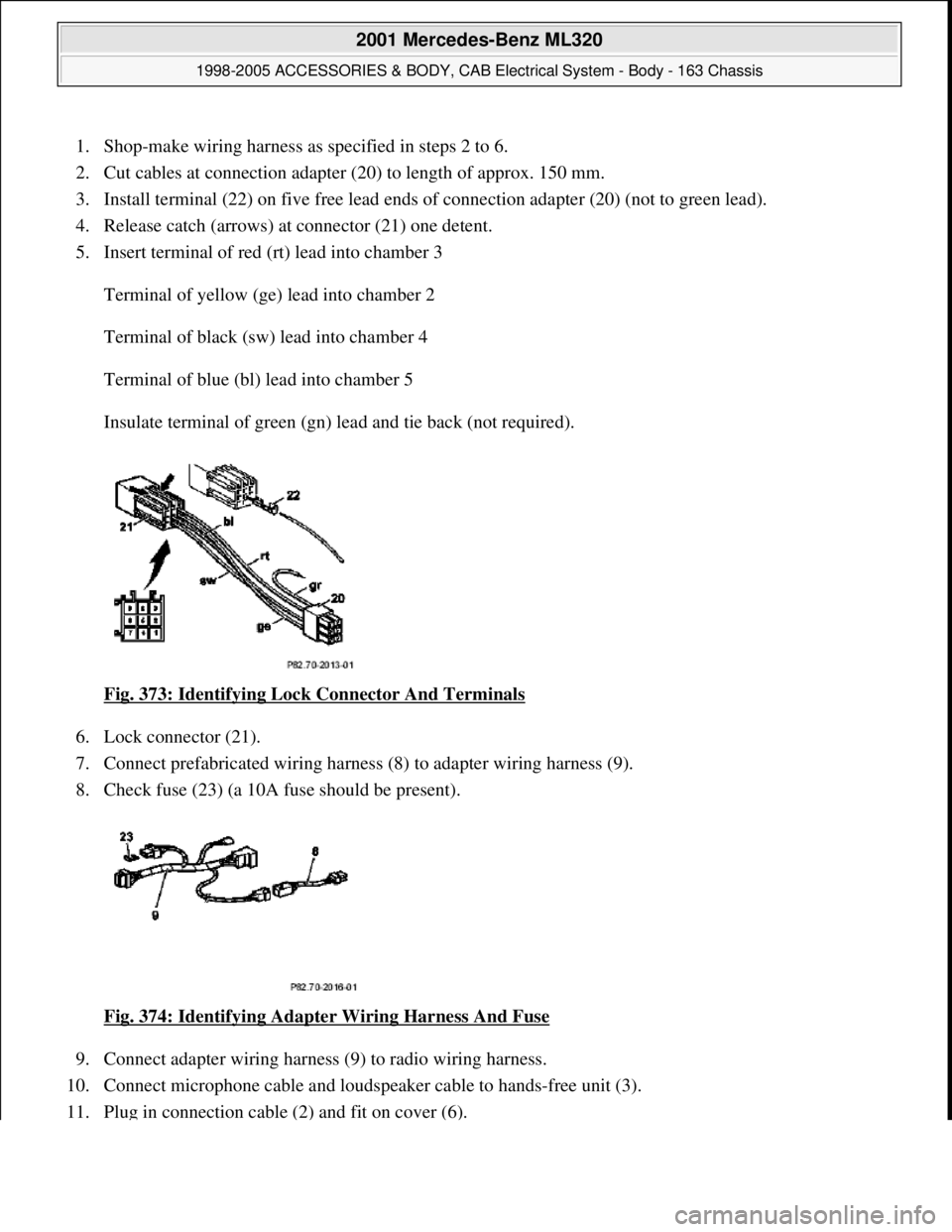

1. Shop-make wiring harness as specified in steps 2 to 6.

2. Cut cables at connection adapter (20) to length of approx. 150 mm.

3. Install terminal (22) on five fr ee lead ends of connection adapter (20) (not to green lead).

4. Release catch (arrows) at connector (21) one detent.

5. Insert terminal of red (rt) lead into chamber 3

Terminal of yellow (ge) lead into chamber 2

Terminal of black (sw) lead into chamber 4

Terminal of blue (bl) lead into chamber 5

Insulate terminal of green (gn) lead and tie back (not required).

Fig. 373: Identifying Lock Connector And Terminals

6. Lock connector (21).

7. Connect prefabricated wiring harness (8) to adapter wiring harness (9).

8. Check fuse (23) (a 10A fuse should be present).

Fig. 374: Identifying Adapter Wiring Harness And Fuse

9. Connect adapter wiring harness (9) to radio wiring harness.

10. Connect microphone cable and loudspeaker cable to hands-free unit (3).

11. Plu

g in connection cable (2) and fit on cover (6).

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electr ical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:13 PMPage 431 © 2006 Mitchell Repair Information Company, LLC.

Page 1934 of 4133

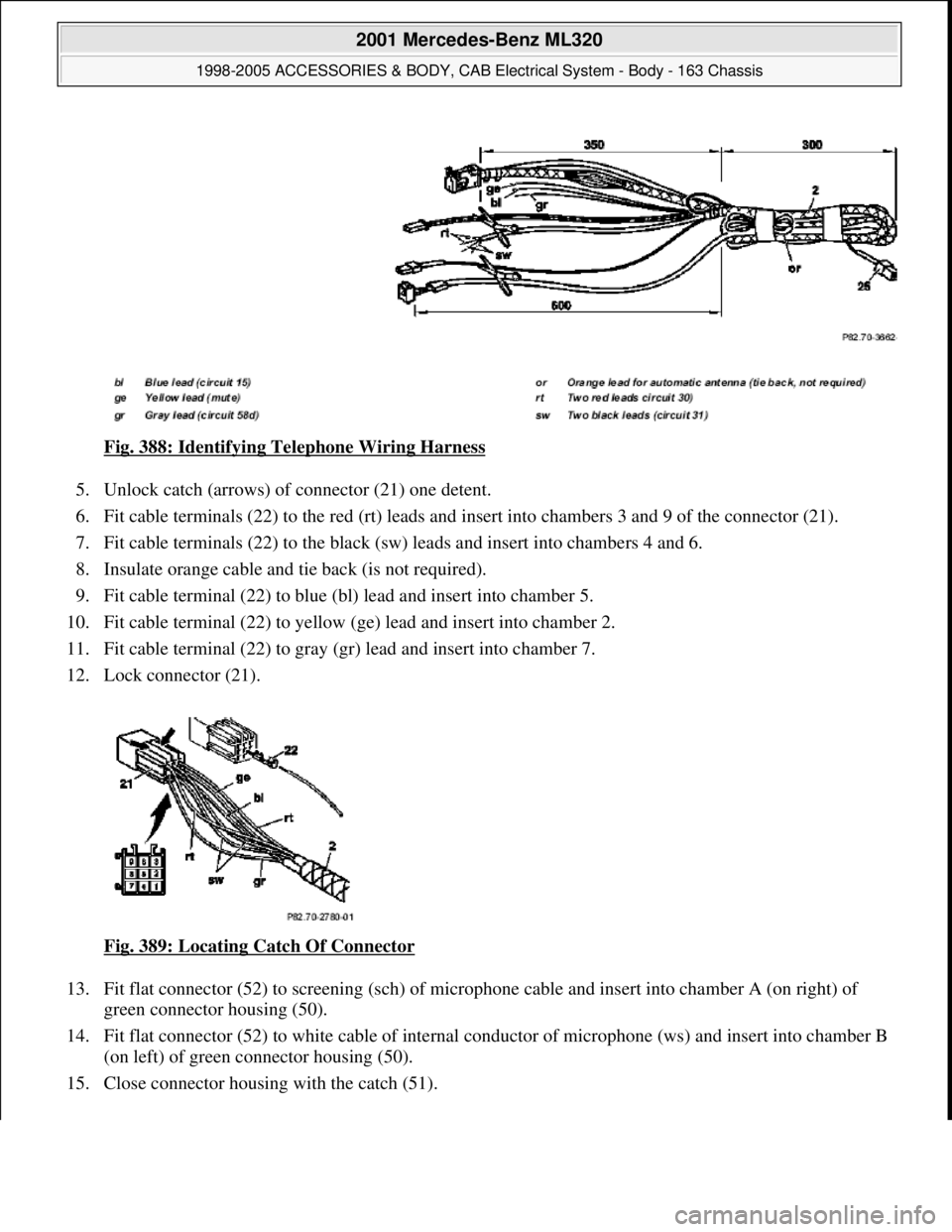

Fig. 388: Identifying Telephone Wiring Harness

5. Unlock catch (arrows) of connector (21) one detent.

6. Fit cable terminals (22) to the red (rt) leads and insert into chambers 3 and 9 of the connector (21).

7. Fit cable terminals (22) to the black (sw) leads and insert into chambers 4 and 6.

8. Insulate orange cable and tie back (is not required).

9. Fit cable terminal (22) to blue (bl) lead and insert into chamber 5.

10. Fit cable terminal (22) to yellow (ge) lead and insert into chamber 2.

11. Fit cable terminal (22) to gray (gr) lead and insert into chamber 7.

12. Lock connector (21).

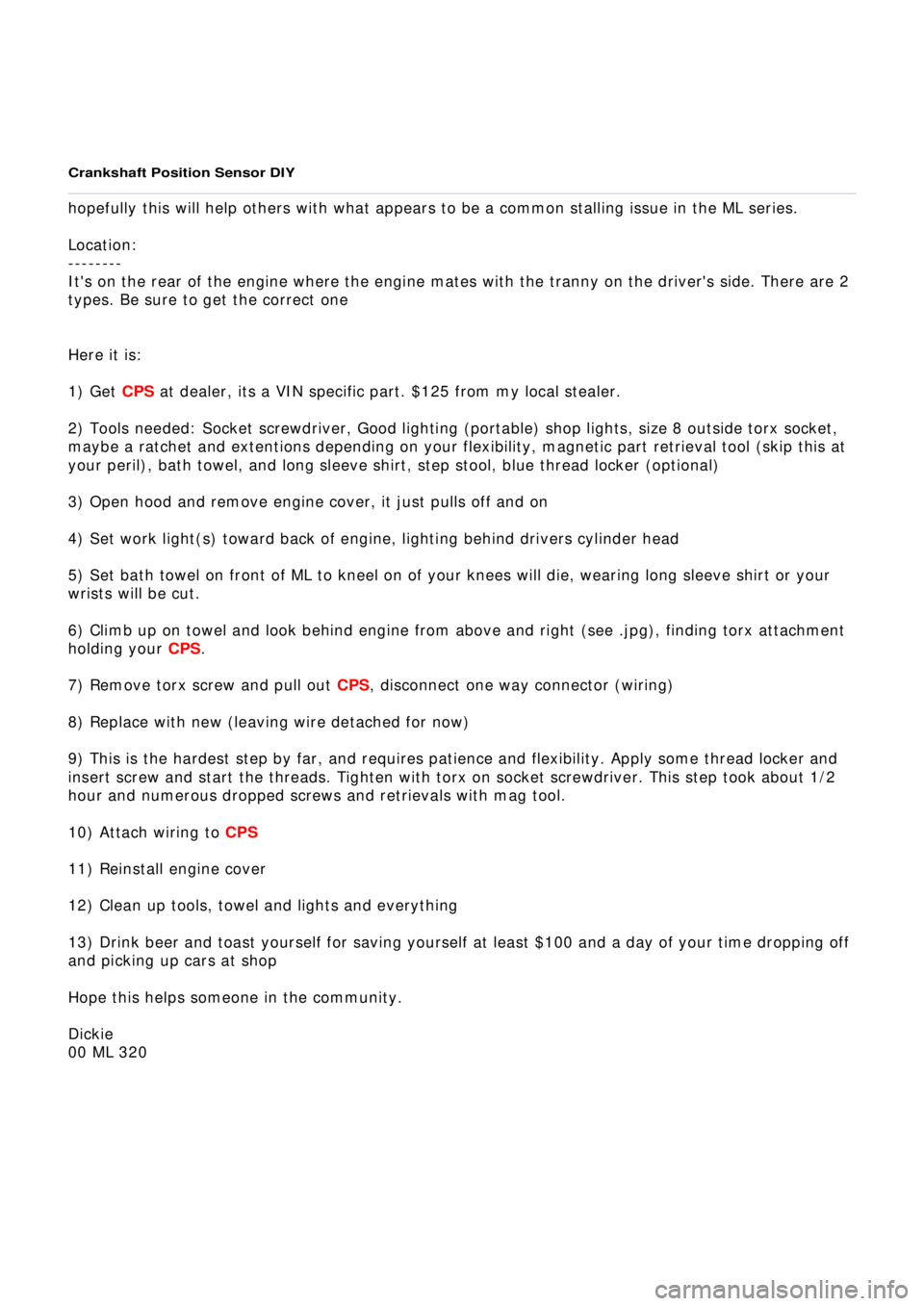

Fig. 389: Locating Catch Of Connector

13. Fit flat connector (52) to screening (sch) of microphone cable and insert into chamber A (on right) of

green connector housing (50).

14. Fit flat connector (52) to white cable of internal conductor of microphone (ws) and insert into chamber B

(on left) of green connector housing (50).

15. Close connector housin

g with the catch (51).

2001 Mercedes-Benz ML320

1998-2005 ACCESSORIES & BODY, CAB Electrical System - Body - 163 Chassis

me

Saturday, October 02, 2010 3:30:13 PMPage 439 © 2006 Mitchell Repair Information Company, LLC.

Page 2080 of 4133

Crankshaft Position Sensor DIY

hopefully this will help others with what appears to be a common stalling issue in the ML series.

Location:

--------

It's on the rear of the engine where the engine mates with the tranny on the driver's side. There are 2

types. Be sure to get the correct one

Here it is:

1) Get

CPS

at dealer, its a VIN specific part. $125 from my local stealer.

2) Tools needed: Socket screwdriver, Good lighting (portable) shop lights, size 8 outside torx socket,

maybe a ratche

t and extentions depending on your flexibility, magnetic part retrieval tool (skip this at

your peril), bath towel, and long sleeve shirt, step stool, blue thread locker (optional)

3) Open hood and remove engine cover, it just pulls off and on

4) Set wor

k light(s) toward back of engine, lighting behind drivers cylinder head

5) Set bath towel on front of ML to kneel on of your knees will die, wearing long sleeve shirt or your

wrists will be cut.

6) Climb up on towel and look behind engine from above and

right (see .jpg), finding torx attachment

holding your

CPS

.

7) Remove torx screw and pull out

CPS

, disconnect one way connector (wiring)

8) Replace with new (leaving wire detached for now)

9) This is the hardest step by far, and requires patience and fl exibility. Apply some thread locker and

insert screw and start the threads. Tighten with torx on socket screwdriver. This step took about 1/2

hour and numerous dropped screws and retrievals with mag tool.

10) Attach wiring to

CPS

11) Reinstall engine cov

er

12) Clean up tools, towel and lights and everything

13) Drink beer and toast yourself for saving yourself at least $100 and a day of your time dropping off

and picking up cars at shop

Hope this helps someone in the community.

Dickie

00 ML 32

0

Page 2233 of 4133

11

Check oil level approx. 5 min. after switching

off warm engine

Insert oil dipstick up to the stop and keep

to a residence time of at least 3 seconds.

Model 163, 210 with Engine 612

*BE18.00-P-1001-02B

Model 203, Model 209 with Engine 612

On Model 203, Model 209 after oil level

check pay attention to correct seating of the

cap, otherwise it could result in engine

damage.

Only Model 203:

Up to engine end number: 134 163 oil level

MAX. 135

mm,

MIN 110

mm.

As of engine end number: 134 164 oil level

MAX. 124,5

mm,

MIN 99,5

mm.

Measuring rod

*120589072100

12

Install trim panel of cylinder head cover

AR01.20-P-5014-02B

*BA01.20-P-1002-01A

*BA01.20-P-1003-01A

Test values for engine lubrication - general

Number

Designation

Engine

612.961

Engine

612.963

BE18.00-P-1001-02B

Dipstick marking

Color red

t

1

Color black

t

2

Color green

t

3

Color gentian blue

t

4

Numbers on handle

Number

6020760206

Round handle

Color

--

Bottle opener-shaped

handle

Color

11

Designation

Engine

612.961/962/

963/965/966,

613.961

Engine

612.967

Engine

612.990

BA01.45-P-1003-01A

Oil drain plug at oil pan

M12

Nm

---

M14

Nm

303030

Engine lubrication, oil filter

Number

Designation

Engine

612.961/962/

963/967/990,

613.960/961

BA18.20-P-1002-01G

Screw cap at oil filter

Nm

25

Crankcase ventilation, cylinder head cover

Number

Designation

Engine

612.961/

962/967

Engine

612.963

Engine

612.990

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2

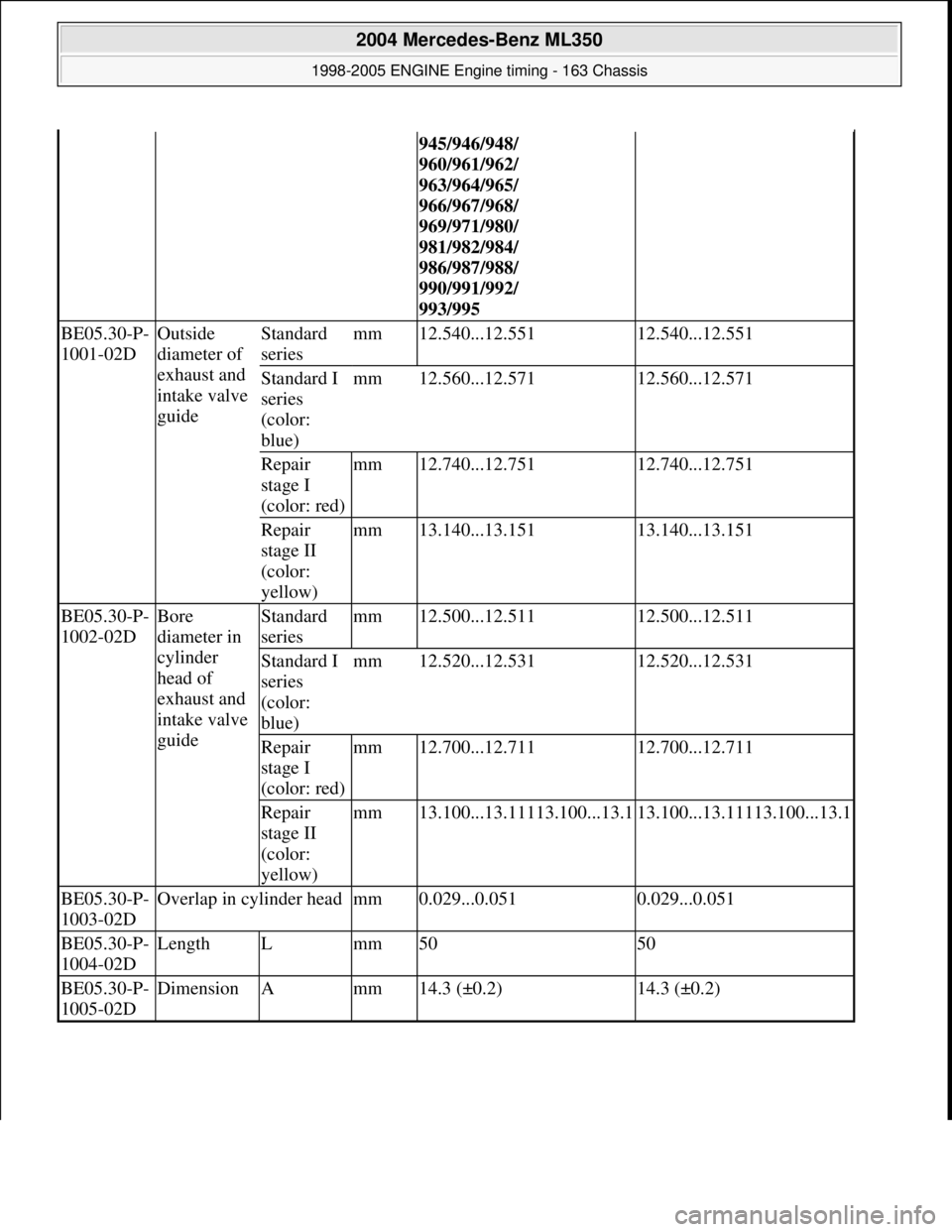

Page 2333 of 4133

945/946/948/

960/961/962/

963/964/965/

966/967/968/

969/971/980/

981/982/984/

986/987/988/

990/991/992/

993/995

BE05.30-P-

1001-02DOutside

diameter of

exhaust and

intake valve

guideStandard

seriesmm12.540...12.55112.540...12.551

Standard I

series

(color:

blue)mm12.560...12.57112.560...12.571

Repair

stage I

(color: red)mm12.740...12.75112.740...12.751

Repair

stage II

(color:

yellow)mm13.140...13.15113.140...13.151

BE05.30-P-

1002-02DBore

diameter in

cylinder

head of

exhaust and

intake valve

guideStandard

seriesmm12.500...12.51112.500...12.511

Standard I

series

(color:

blue)mm12.520...12.53112.520...12.531

Repair

stage I

(color: red)mm12.700...12.71112.700...12.711

Repair

stage II

(color:

yellow)mm13.100...13.11113.100...13.113.100...13.11113.100...13.1

BE05.30-P-

1003-02DOverlap in cylinder headmm0.029...0.0510.029...0.051

BE05.30-P-

1004-02DLengthLmm5050

BE05.30-P-

1005-02DDimensionAmm14.3 (±0.2)14.3 (±0.2)

2004 Mercedes-Benz ML350

1998-2005 ENGINE Engine timing - 163 Chassis

me

Saturday, October 02, 2010 3:39:38 PMPage 92 © 2006 Mitchell Repair Information Company, LLC.

Page 2336 of 4133

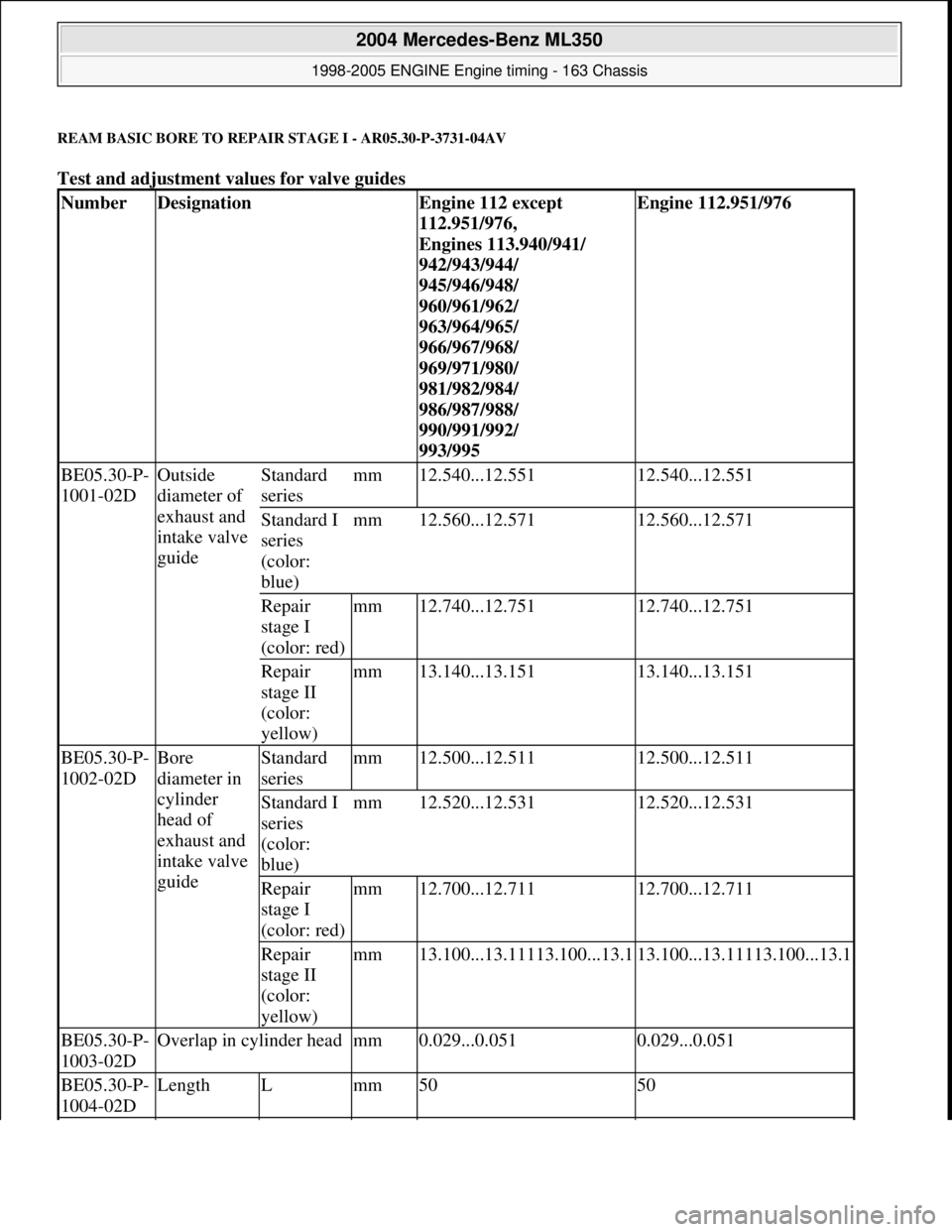

REAM BASIC BORE TO REPAIR STAGE I - AR05.30-P-3731-04AV

Test and adjustment values for valve guides

NumberDesignationEngine 112 except

112.951/976,

Engines 113.940/941/

942/943/944/

945/946/948/

960/961/962/

963/964/965/

966/967/968/

969/971/980/

981/982/984/

986/987/988/

990/991/992/

993/995Engine 112.951/976

BE05.30-P-

1001-02DOutside

diameter of

exhaust and

intake valve

guideStandard

seriesmm12.540...12.55112.540...12.551

Standard I

series

(color:

blue)mm12.560...12.57112.560...12.571

Repair

stage I

(color: red)mm12.740...12.75112.740...12.751

Repair

stage II

(color:

yellow)mm13.140...13.15113.140...13.151

BE05.30-P-

1002-02DBore

diameter in

cylinder

head of

exhaust and

intake valve

guideStandard

seriesmm12.500...12.51112.500...12.511

Standard I

series

(color:

blue)mm12.520...12.53112.520...12.531

Repair

stage I

(color: red)mm12.700...12.71112.700...12.711

Repair

stage II

(color:

yellow)mm13.100...13.11113.100...13.113.100...13.11113.100...13.1

BE05.30-P-

1003-02DOverlap in cylinder headmm0.029...0.0510.029...0.051

BE05.30-P-

1004-02DLengthLmm5050

2004 Mercedes-Benz ML350

1998-2005 ENGINE Engine timing - 163 Chassis

me

Saturday, October 02, 2010 3:39:38 PMPage 95 © 2006 Mitchell Repair Information Company, LLC.

Page 2339 of 4133

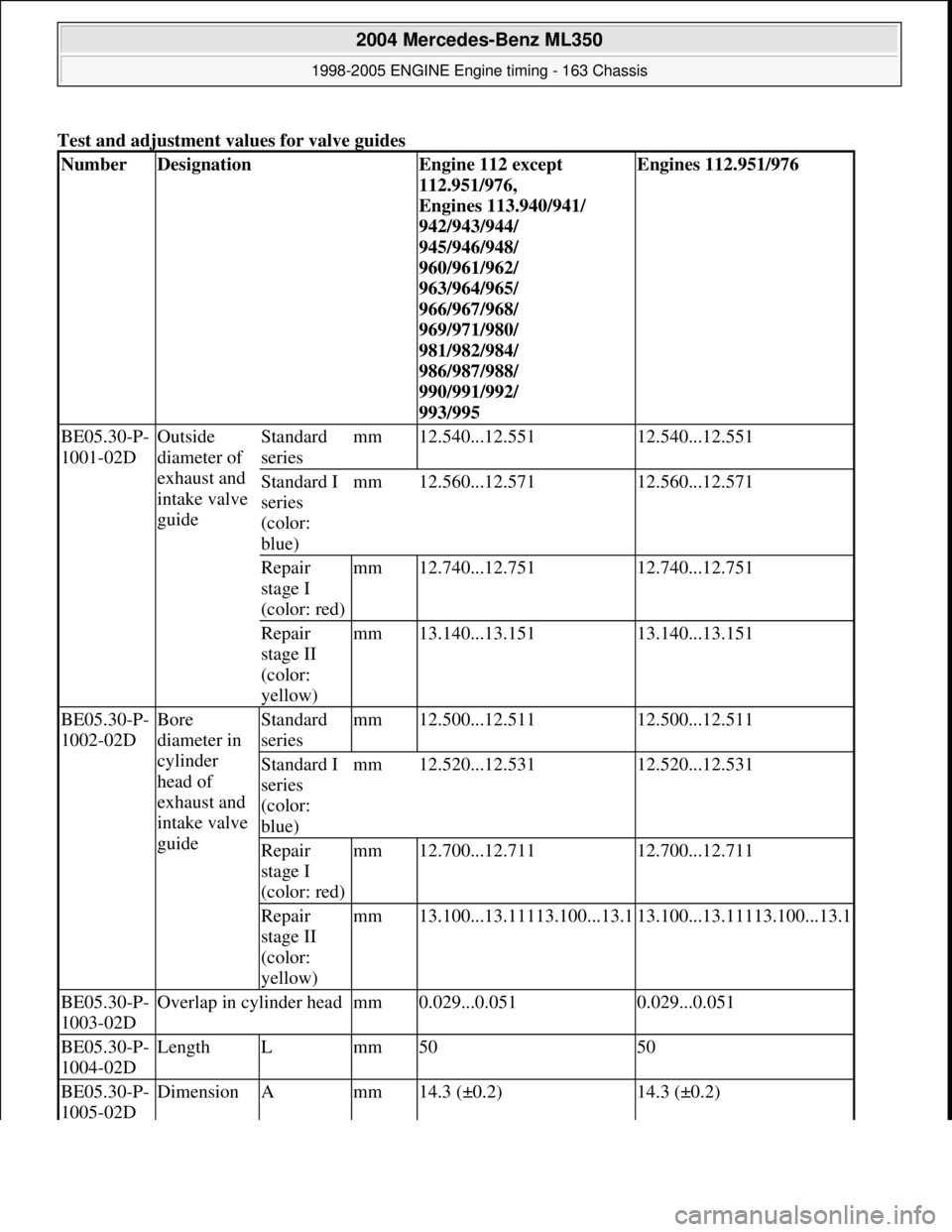

Test and adjustment values for valve guides

NumberDesignationEngine 112 except

112.951/976,

Engines 113.940/941/

942/943/944/

945/946/948/

960/961/962/

963/964/965/

966/967/968/

969/971/980/

981/982/984/

986/987/988/

990/991/992/

993/995Engines 112.951/976

BE05.30-P-

1001-02DOutside

diameter of

exhaust and

intake valve

guideStandard

seriesmm12.540...12.55112.540...12.551

Standard I

series

(color:

blue)mm12.560...12.57112.560...12.571

Repair

stage I

(color: red)mm12.740...12.75112.740...12.751

Repair

stage II

(color:

yellow)mm13.140...13.15113.140...13.151

BE05.30-P-

1002-02DBore

diameter in

cylinder

head of

exhaust and

intake valve

guideStandard

seriesmm12.500...12.51112.500...12.511

Standard I

series

(color:

blue)mm12.520...12.53112.520...12.531

Repair

stage I

(color: red)mm12.700...12.71112.700...12.711

Repair

stage II

(color:

yellow)mm13.100...13.11113.100...13.113.100...13.11113.100...13.1

BE05.30-P-

1003-02DOverlap in cylinder headmm0.029...0.0510.029...0.051

BE05.30-P-

1004-02DLengthLmm5050

BE05.30-P-

1005-02DDimensionAmm14.3 (±0.2)14.3 (±0.2)

2004 Mercedes-Benz ML350

1998-2005 ENGINE Engine timing - 163 Chassis

me

Saturday, October 02, 2010 3:39:38 PMPage 98 © 2006 Mitchell Repair Information Company, LLC.