ignition MERCEDES-BENZ ML320 1997 Complete User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 16 of 4133

If any part of SRS wiring harness is damaged, DO NOT repair wiring harness, replace complete wiring harness.

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

(1)

DIAGNOSIS & TESTING

Before proceeding, see SERVICE PRECAUTIONS

. The control module is capable of diagnosing airbag

system components and ETR components. If a fault is detected by the control module or system is

malfunctioning, SRS warning light will do one or more of the following:

SRS warning light goes out after 2 minutes. System fault is noted, however occupant protection is not

affected. See RETRIEVING FAULT CODES

.

SRS warning light illuminates continuously. System is faulty which may result in a non deployment or

false deployment. See RETRIEVING FAULT CODES

.

SRS warning light blinks continuously. Control module has been replaced without setting control module

parameters.

RETRIEVING FAULT CODES

1. Check vehicle fuses. Replace any blown fuses as necessary. Ensure vehicle battery voltage is 11 volts or

more. Ensure SRS warning light functions. Turn ignition off. Connect Hand-Held Tester (HHT) (965 589

00 01) to Data Link Connector (DLC).

2. DLC is located in right rear corner of engine compartment. It may be necessary to use Adapter (965 589

00 40 or 965 589 00 50) to connect HHT to DLC. After HHT displays module number and version, press

return key to start diagnosis. Using HHT, follow HHT prompts to retrieve SRS fault codes.

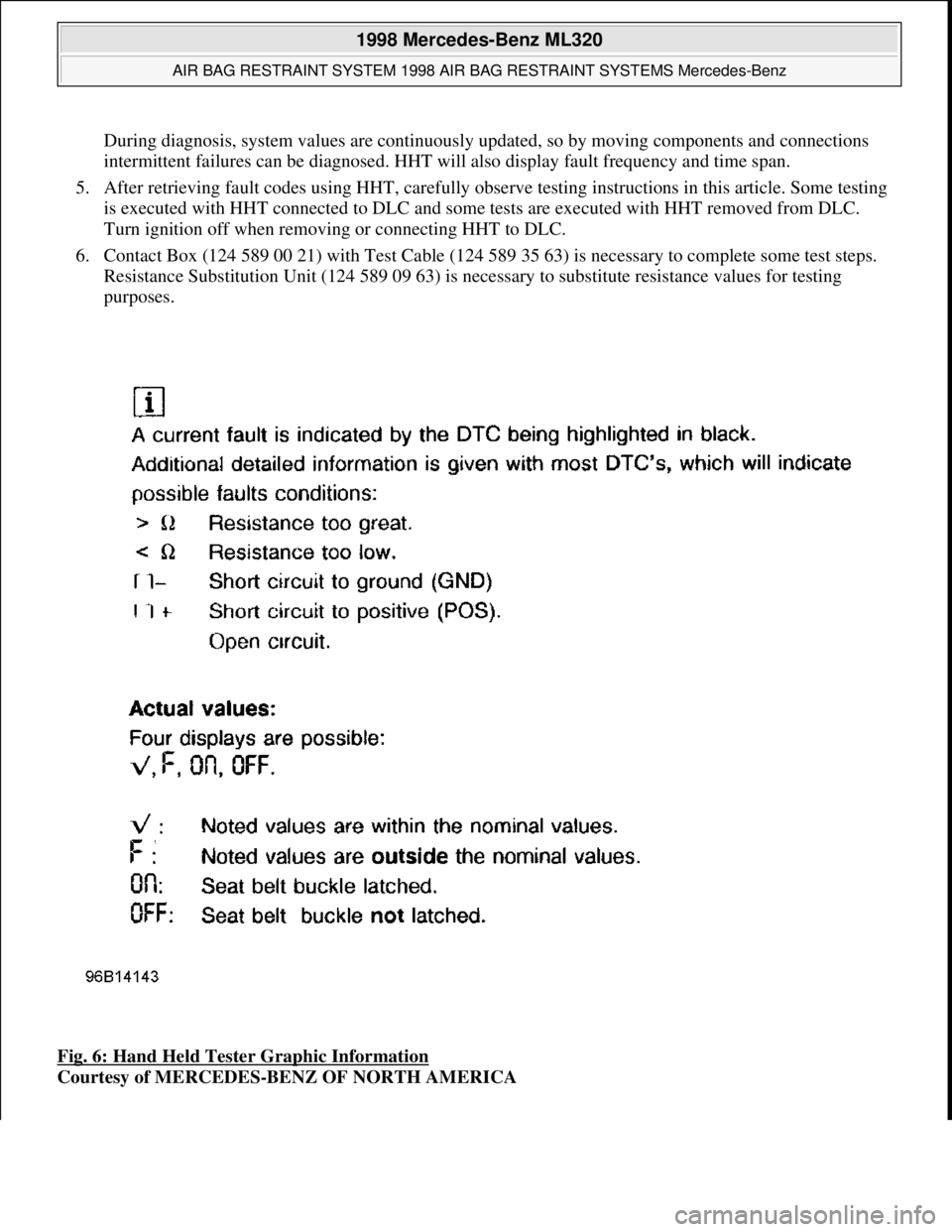

3. HHT will display a 3 digit fault code, and may display additional graphic information. This additional

graphic information will help in diagnosis of fault code. See Fig. 6

. During diagnosis HHT will display 4

different graphic displays informing technician if a test passes or fails, or if seat belt buckle is latched or

not latched. See Fig. 6

.

4. These

graphic displays are displayed as applicable by HHT during testing. See FAULT CODES table.

ApplicationFt. Lbs. (N.m)

Steering Wheel Hub Bolt52-66 (70-90)

INCH Lbs. (N.m)

Driver Air Bag Module Bolts (Torx)44-62 (5-7)

(1)Torque specifications are not available for clockspring assembly, control module or passenger-side

air bag module.

NOTE: After component replacement, perform a system operation check to ensure

proper system operation. See SYSTEM OPERATION CHECK

.

NOTE: Fault codes may only be retrieved using Hand-Held Tester (965 589 00 01) and

Adapter (965 589 00 40 or 965 589 00 50).

1998 Mercedes-Benz ML320

AIR BAG RESTRAINT SYSTEM 1998 AIR BAG RESTRAINT SYSTEMS Mercedes-Benz

me

Saturday, October 02, 2010 3:33:14 PMPage 16 © 2006 Mitchell Repair Information Company, LLC.

Page 17 of 4133

During diagnosis, system values are continuously updated, so by moving components and connections

intermittent failures can be diagnosed. HHT will also display fault frequency and time span.

5. After retrieving fault codes using HHT, carefully observe testing instructions in this article. Some testing

is executed with HHT connected to DLC and some tests are executed with HHT removed from DLC.

Turn ignition off when removing or connecting HHT to DLC.

6. Contact Box (124 589 00 21) with Test Cable (124 589 35 63) is necessary to complete some test steps.

Resistance Substitution Unit (124 589 09 63) is necessary to substitute resistance values for testing

purposes.

Fig. 6: Hand Held Tester Graphic Information

Courtesy of MERCEDES-BENZ OF NORTH AMERICA

1998 Mercedes-Benz ML320

AIR BAG RESTRAINT SYSTEM 1998 AIR BAG RESTRAINT SYSTEMS Mercedes-Benz

me

Saturday, October 02, 2010 3:33:14 PMPage 17 © 2006 Mitchell Repair Information Company, LLC.

Page 19 of 4133

CLEARING FAULT CODES

Connect Hand-Held Tester (965 589 00 01) to Data Link Connector (DLC). DLC is located in right rear corner

of engine compartment. It may be necessary to use Adapter (965 589 00 40 or 965 589 00 50) to connect HHT

to DLC. After HHT displays module number and version, press return key to start sequence. Using HHT,

follow HHT prompts to clear SRS fault codes. SRS codes are clear when ignition is turned on and SRS warning

light functions normally. See SYSTEM OPERATION CHECK

.

UNDERSTANDING DIAGNOSTIC CHART INFORMATION

SRS & ETR Diagnosis Chart Column Identification

For example, see Fig. 7

under DIAGNOSTIC TESTS. First column of chart identifies TEST STEP (1.0 for

example). Second column of chart identifies HHT fault code (017, 003 for example). First code in column is for

vehicles without side air bags. Second code in column (when listed) is for vehicles with side air bags only.

Other 5 columns are self-explanatory.

Using SRS & ETR Diagnosis Chart

For reading and understanding fault code diagnosis chart, use the following example: Read test step 3.0

(first column), HHT fault Code 002, 004 (second column). See Fig. 7

. Read TEST SCOPE/HHT

ACTUAL VALUE NO./TEXT column (third column). Driver-side air bag squib connector R12/3 is

being tested. HHT will identify if problem is with too much resistance or not enough resistance in driver-

side air bag squib circuit. Read TEST CONDITION column (fifth column). Test circuit with HHT

connected to DLC, with ignition in position "2". Read NOMINAL VALUE/HHT DISPLAY column

(sixth column). HHT will display a check or an "F". If HHT displays a check, circuit is okay. If HHT

displays an "F", go to step 3.1.

Read TEST CONNECTION (NOT FOR HHT) column (forth column). Driver-Side air bag squib

connector R12/3, terminals No. 1 and 2 are identified. Read TEST CONDITION column. Test circuit

027

(Passenger Seat Occupation Signal)22

032, 033

(Communication Interference)(1)

034

(Digital Crash Output, Harness Fault)(1)

035

(Analog Crash Output, Harness Fault)(1)

036

(Auto Child Seat Recognition Light)22.0, 23.0

(1)Test information is not available.

NOTE: To properly identify components or connectors being tested, see COMPONENT

IDENTIFICATION table.

1998 Mercedes-Benz ML320

AIR BAG RESTRAINT SYSTEM 1998 AIR BAG RESTRAINT SYSTEMS Mercedes-Benz

me

Saturday, October 02, 2010 3:33:14 PMPage 19 © 2006 Mitchell Repair Information Company, LLC.

Page 20 of 4133

with HHT connected to DLC and ignition key removed. Remove driver-side air bag module. Disconnect

driver-side air bag module squib connector R12/3. Connect Resistance Substitution Unit (124 589 09 63)

to driver-side air bag module squib connector (harness side). Set resistance substitution unit to 2 ohms.

Turn ignition key to position "2". Read NOMINAL VALUE/HHT DISPLAY column. If HHT displays a

check, replace driver-side air bag module. If HHT displays an "F", go to step 3.2.

Read TEST CONNECTION (NOT FOR HHT) column. Horn/air bag clockspring connector A45x1,

terminals No. 1 and 2 are identified. Read TEST CONDITION column. Test circuit with HHT connected

to DLC. Remove ignition key. Connect Resistance Substitution Unit (124 589 09 63 00) to horn/air bag

clockspring connector A45x1. Set resistance substitution unit to 2 ohms. Read NOMINAL VALUE/HHT

DISPLAY column. If HHT displays a check, check horn/air bag clockspring for continuity. Replace

horn/air bag clockspring as necessary. If HHT displays an "F", go to step 3.4.

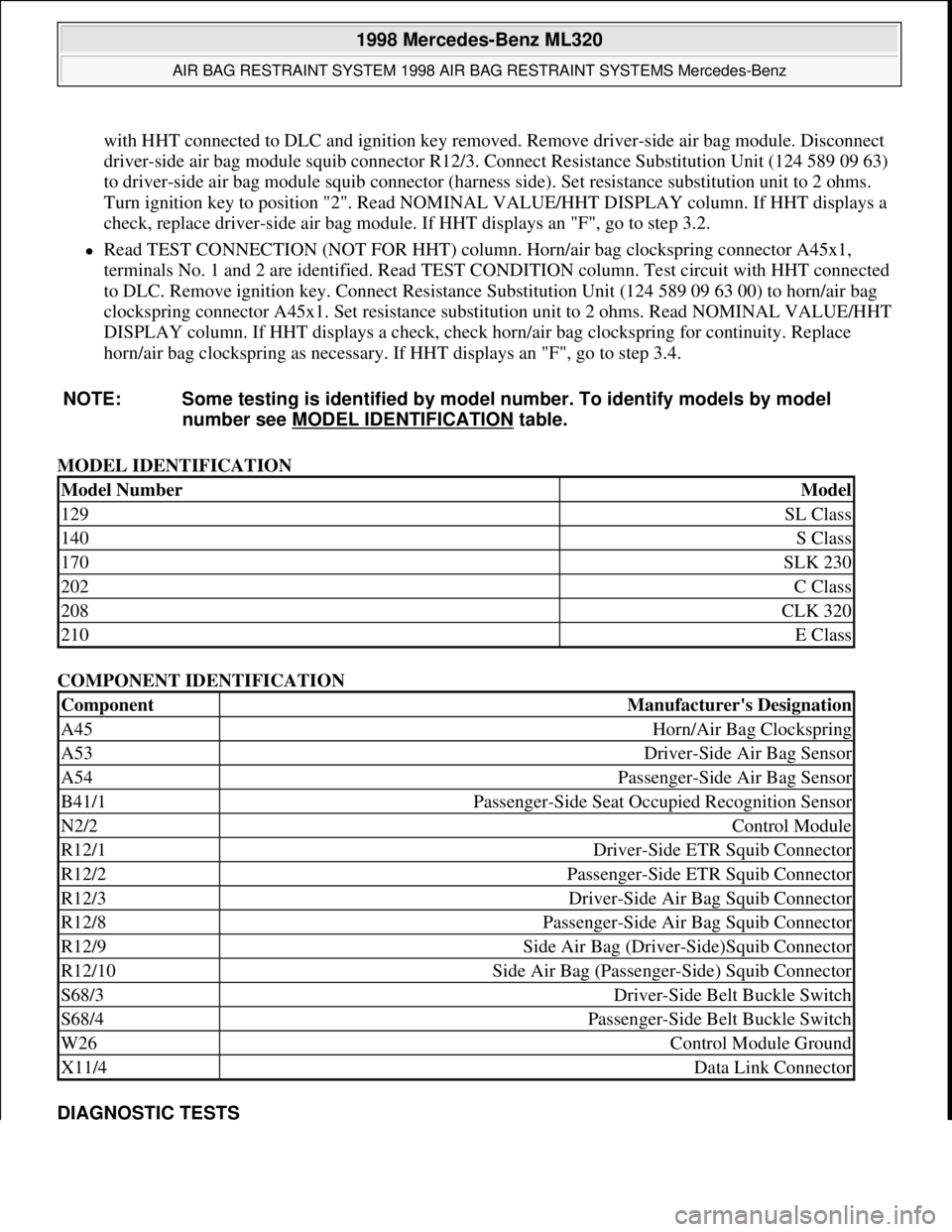

MODEL IDENTIFICATION

COMPONENT IDENTIFICATION

DIAGNOSTIC TESTS NOTE: Some testing is identified by model number. To identify models by model

number see MODEL IDENTIFICATION

table.

Model NumberModel

129SL Class

140S Class

170SLK 230

202C Class

208CLK 320

210E Class

ComponentManufacturer's Designation

A45Horn/Air Bag Clockspring

A53Driver-Side Air Bag Sensor

A54Passenger-Side Air Bag Sensor

B41/1Passenger-Side Seat Occupied Recognition Sensor

N2/2Control Module

R12/1Driver-Side ETR Squib Connector

R12/2Passenger-Side ETR Squib Connector

R12/3Driver-Side Air Bag Squib Connector

R12/8Passenger-Side Air Bag Squib Connector

R12/9Side Air Bag (Driver-Side)Squib Connector

R12/10Side Air Bag (Passenger-Side) Squib Connector

S68/3Driver-Side Belt Buckle Switch

S68/4Passenger-Side Belt Buckle Switch

W26Control Module Ground

X11/4Data Link Connector

1998 Mercedes-Benz ML320

AIR BAG RESTRAINT SYSTEM 1998 AIR BAG RESTRAINT SYSTEMS Mercedes-Benz

me

Saturday, October 02, 2010 3:33:14 PMPage 20 © 2006 Mitchell Repair Information Company, LLC.

Page 69 of 4133

19 Instruments and controls

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hints Car care Index For more detailed descriptions see index on page 300.

For adjustment of air outlets, refer to climate control,

see page 98.

1Cup holder, see page 114

2Parking brake release, see page 173

3Parking brake pedal, see page 173

4Steering wheel adjustment lever, see page 70

5Headlamp washer switch, see page 94

6Exterior lamp switch, see page 90

7Cruise control switch, see page 196

8Instrument cluster, see page 76

9Hazard warning flasher switch, see page 94

10Horn (with key in steering lock position 1 or 2),

Driver airbag, see page 56

11Steering lock with ignition / starter switch, see

page 162

12Switch for exterior rear view mirrors, electrically

folding, see page 75

13Windshield wiper / washer switch, see page 9514Transmission control – LOW RANGE mode, see

page 209

15Indicator lamp for antitheft alarm system

16Auxiliary front fog lamp / rear fog lamp switch, see

page 92

17MCS (Optional Modular Control System), see

separate operator’s manual

18Front passenger airbag, see page 56

19Glove box (illuminated with key in steering lock

position 1 or 2)

20Cup holder, see page 114

21Storage compartment

22Air recirculation switch, see page 98

23Air conditioner on /off switch, see page 98

24Air volume control switch

25Temperature selector switch

26Air distribution switch

27Electrical outlet, see page 230

Page 108 of 4133

58 Restraint systems

Te ch n ica l

data Instruments

and controlsOperationDrivingInstrument

cluster displayPractical hints Car care Index

out after approximately 5 seconds; after the lamp goes

out, the system continues to monitor the components

and circuitry of the airbag system and will indicate a

malfunction by coming on again. If the lamp does not

come on at all or if it fails to extinguish after

approximately 5 seconds or if it comes on thereafter,

a malfunction in the system has been detected.

The following system components are monitored or

undergo a self-check: crash-sensor(s), airbag ignition

circuits, front seat belt buckles, emergency tensioning

retractors, seat sensor.

Initially, when the key is turned from steering lock

position 0 to positions 1 or 2, malfunctions in the

crash-sensor are detected and indicated (the “SRS”

indicator lamp stays on longer than 5 seconds or does

not come on).

Have the system checked at your authorized

Mercedes-Benz Light Truck Center immediately.In the operational mode, after the indicator lamp has

gone out following the initial check, interruptions or

short circuits in the airbag ignition circuit and in the

driver and front passenger seat belt buckle harnesses,

and low voltage in the entire system are detected and

indicated.

Wa r n i n g !

In the event a malfunction of the “SRS” is indicated

as outlined above, the “SRS” may not be

operational. For your safety, we strongly

recommend that you visit an authorized

Mercedes-Benz Light Truck Center immediately to

have the system checked; otherwise the “SRS” may

not be activated when needed in an accident, which

could result in serious or fatal injury, or it might

deploy unexpectedly and unnecessarily which

could also result in injury.

Page 282 of 4133

232 Engine compartment

Te ch n ica l

data Instruments

and controlsOperation DrivingInstrument

cluster displayPractical hintsCar care Index

Wa r n i n g !

To help prevent personal injury, stay clear of

moving parts when the hood is open and the engine

is running. Be sure the hood is properly closed

before driving. When closing hood, use extreme

caution not to catch hands or fingers.The radiator fan may continue to run for

approximately 30 seconds or even restart after the

engine has been turned off. Stay clear from fan

blades.

The engine is equipped with a transistorized

ignition system. Because of the high voltage it is

dangerous to touch any components (ignition coils,

spark plug sockets, diagnostic socket) of the

ignition system

• with the engine running,

• while starting the engine,

• if ignition is “on” and the engine is turned

manually.If you see flames, steam or smoke coming from the

engine compartment, or if the coolant temperature

gauge indicates that the engine is overheated, do

not open the hood. Move away from vehicle and do

not open the hood until the engine has cooled. If

necessary, call a fire department.

Page 367 of 4133

Fig. 1: Locating Restraint System Components (2000 E Class Shown; Others Are Similar)

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

SERVICING

SRS AIR BAG label on driver-side door latch post indicates SRS replacement date for driver and passenger air

bag units. All SRS components must be thoroughly insp ected, including wiring harness. Before component

replacement, check for SRS fault codes by performing system operation check. See SYSTEM OPERATION

CHECK . SRS service life is 10 years from manufactured date, or 10 years from SRS replacement date after

accident related repairs are completed.

SYSTEM OPERATION CHECK

SRS warning light indicates air ba g and Emergency Tensioning Retracto r (ETR) system readiness. Turn

ignition on. SRS warning light will illuminate, then turn off after approximately 4-20 seconds indicating system

is functioning properly. If SRS warning light does not illuminate, illuminates while driving or is continuously

illuminated, there is a system faul t. Repair malfunctioning system. See DIAGNOSTICS

.

AIR BAG SAFETY PRECAUTIONS

Observe following precautions when working with air bag systems:

When working around steering column components and be fore any repairs are performed, disable air bag

system. See DISABLING & ACTIVATING AIR BAG SYSTEM

.

Before straightening any damage to body, or before performing electrical arc-welding, disable air bag

system. See DISABLING & ACTIVATING AIR BAG SYSTEM

.

Always wear safety glasses and gloves when ha ndling a deployed air bag module. Air bag module may

contain sodium hydroxide deposits wh ich are irritating to the skin.

DO NOT repair any portion of SRS wiring harness.

Always handle air bag module with trim cover away from your body. Always place air bag module on

workbench with trim cover up, away from loose objects.

DO NOT expose any SRS component to temp eratures in excess of 212 F (100 C).

DO NOT expose any SRS component to cleaning agen ts such as solvents, gasoline, lye, etc.

DO NOT connect Hand-Held Tester (6511 0001 99) to Data Link Connector (DLC) with ignition on.

Damage to HHT may result.

DO NOT connect HHT (6511 0001 99) to vehicle if a battery charger is connected to vehicle battery.

Damage to HHT may result.

ADJUSTMENTS

If fixing screws were not used durin g clockspring removal or clockspring was rotated during removal, turn

clockspring clockwise until resistance is detectable. Turn clockspring counterclockwise 2-2.5 turns until fixing

screws can be unscrewed holdi ng clockspring in this position.

DISABLING & ACTIVATI NG AIR BAG SYSTEM

2001 Mercedes-Benz ML320

2000-01 ACCESSORIES/SAFETY EQUIPMENT Merc edes-Benz - Air Bag Restraint Systems

me

Saturday, October 02, 2010 3:44:45 PMPage 3 © 2006 Mitchell Repair Information Company, LLC.

Page 368 of 4133

DISABLING SYSTEM

Before proceeding, see AIR BAG SAFETY PRECAUTIONS . Record radio presets and obtain anti-theft

code. Turn ignition switch to OFF position and remove ignition key. If welding on vehicle, disconnect negative

battery cable and disconnect air bag control module.

ACTIVATING SYSTEM

Ensure ignition is off. Reconnect air bag system co mponents (if disconnected). Reconnect negative battery

cable. Perform See SYSTEM OPERATION CHECK

.

DISPOSAL PROCEDURES

Several situations may arise requiring so me form of disposal action, including:

Scrapping a vehicle containing a deployed air bag module and-or ETR.

Scrapping a vehicle with a live air bag module and-or ETR.

Disposal of a live but electrically faulty air bag module and-or ETR.

Disposal of a deployed air bag module and-or ETR.

DEPLOYED AIR BAG OR ETR

Deployed air bag module and-or ETR unit can be thrown away. None of its components are reusable. Deployed

air bag module is NOT classified as hazardous material.

SCRAPPED VEHICLE

1. Before proceeding, follow service precautions. See AIR BAG SAFETY PRECAUTIONS . Move

vehicle outdoors to a remote area, away from work shop and other personnel. Disconnect and shield

negative battery cable. Open al l vehicle windows and doors.

2. Ensure air bag module is secured to steering wheel, and passenger air bag is secured to dash. Ensure ETR

seat belt assemblies are secured to "B" pillars and all seat belt buckles are latched. Remove loose ob

jects

CAUTION: On CL500, open doors before

disconnecting battery. Opening doors

allows windows to automa tically lower thus preventing roof seal damage.

WARNING: An undeployed air bag module or ET R should never be disposed of

without first being deplo yed. See SCRAPPED VEHICLE

. If deployment is

not possible, contact vehicle manuf acturer for further instructions.

WARNING: An undeployed air bag m odule and-or ETR seat belt CANNOT be disposed

of without first being de ployed. If this is not possible through procedures

outlined below, contact vehicle ma nufacturer for further instructions.

Perform remote deployment outdoors . Keep personnel at least 20 feet

away.

2001 Mercedes-Benz ML320

2000-01 ACCESSORIES/SAFETY EQUIPMENT Merc edes-Benz - Air Bag Restraint Systems

me

Saturday, October 02, 2010 3:44:45 PMPage 4 © 2006 Mitchell Repair Information Company, LLC.

Page 369 of 4133

from front seat. DO NOT allow anyone inside vehicle.

3. Disable air bag system. See DISABLING & ACTIVATING AIR BAG SYSTEM

. Connect Trigger

Device (126-589-00-90-00) and Adapter Cable (126 589 21 63 00) to SRS system connector (X29-9)

located at passenger footwell area. Move away from ve hicle as far as trigger device wiring will allow.

4. To deploy driver air bag and ETR, turn rotary knob on trigger device to position No. 1. Push battery

check push button and ignition push button simultane ously. Trigger light should illuminate indicating

driver air bag and ETR deployed. If trigger light is illuminated and driver air bag and-or ETR did not

deploy, driver air bag module and-or ETR is faulty. See UNDEPLOYED AIR BAG

-ETR .

5. To deploy passenger air bag detonator No. 1, turn ro tary knob on trigger device to position No. 2. Push

battery check push button and igni tion push button simultaneously. Tr igger light should illuminate

indicating passenger air bag detonator No. 1 deployed. If trigger light is illuminated and passenger air bag

detonator No. 1 did not deploy, passe nger air bag module is faulty. See UNDEPLOYED AIR BAG

-

ETR .

6. To deploy passenger air bag detonator No. 2, turn ro tary knob on trigger device to position No. 3. Push

battery check push button and igni tion push button simultaneously. Tr igger light should illuminate

indicating passenger air bag detonator No. 2 deployed. If trigger light is illuminated and passenger air bag

detonator No. 2 did not deploy, passe nger air bag module is faulty. See UNDEPLOYED AIR BAG

-

ETR .

UNDEPLOYED AIR BAG-ETR

After deploying procedures and-or diagnostic testing have confirmed air bag module and-or ETR is

undeployable, contact vehicle manufacture r for proper disposal instructions.

POST-COLLISION INSPECTION

When a vehicle has been involved in a collision, certain components of the passive restraint system must be

inspected or replaced. See AIR BAG/SRS COMPONENT INSPECTION & REPLACEMENT TABLES

article in the GENERAL INFORMATION section.

REMOVAL & INSTALLATION

CLOCKSPRING ASSEMBLY

Removal & Installation

1. Before proceeding, See AIR BAG SAFETY PRECAUTIONS . Disable air bag system. See

DISABLING & ACTIVATI NG AIR BAG SYSTEM

.

2. Remove driver air bag module. See DRIVER

-SIDE AIR BAG MODULE . Remove steering wheel bolt.

Using a puller, remove steering wheel. Disconnect lower clockspring connector. Turn 2 fixing screws

(locating on clockspring) countercl ockwise until clockspring cannot be rotated. Remove clockspring

mountin

g screws as necessary. Disconnect all necessary electrical connectors. Remove clockspring

WARNING:

Accidental air bag deployment is pos sible. Personal injury may result.

Read and follow all WARNINGS and AIR BAG SAFETY PRECAUTIONS

before working on ai r bag system or related components.

2001 Mercedes-Benz ML320

2000-01 ACCESSORIES/SAFETY EQUIPMENT Merc edes-Benz - Air Bag Restraint Systems

me

Saturday, October 02, 2010 3:44:45 PMPage 5 © 2006 Mitchell Repair Information Company, LLC.