water pump MERCEDES-BENZ ML320 1997 Complete User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 2610 of 4133

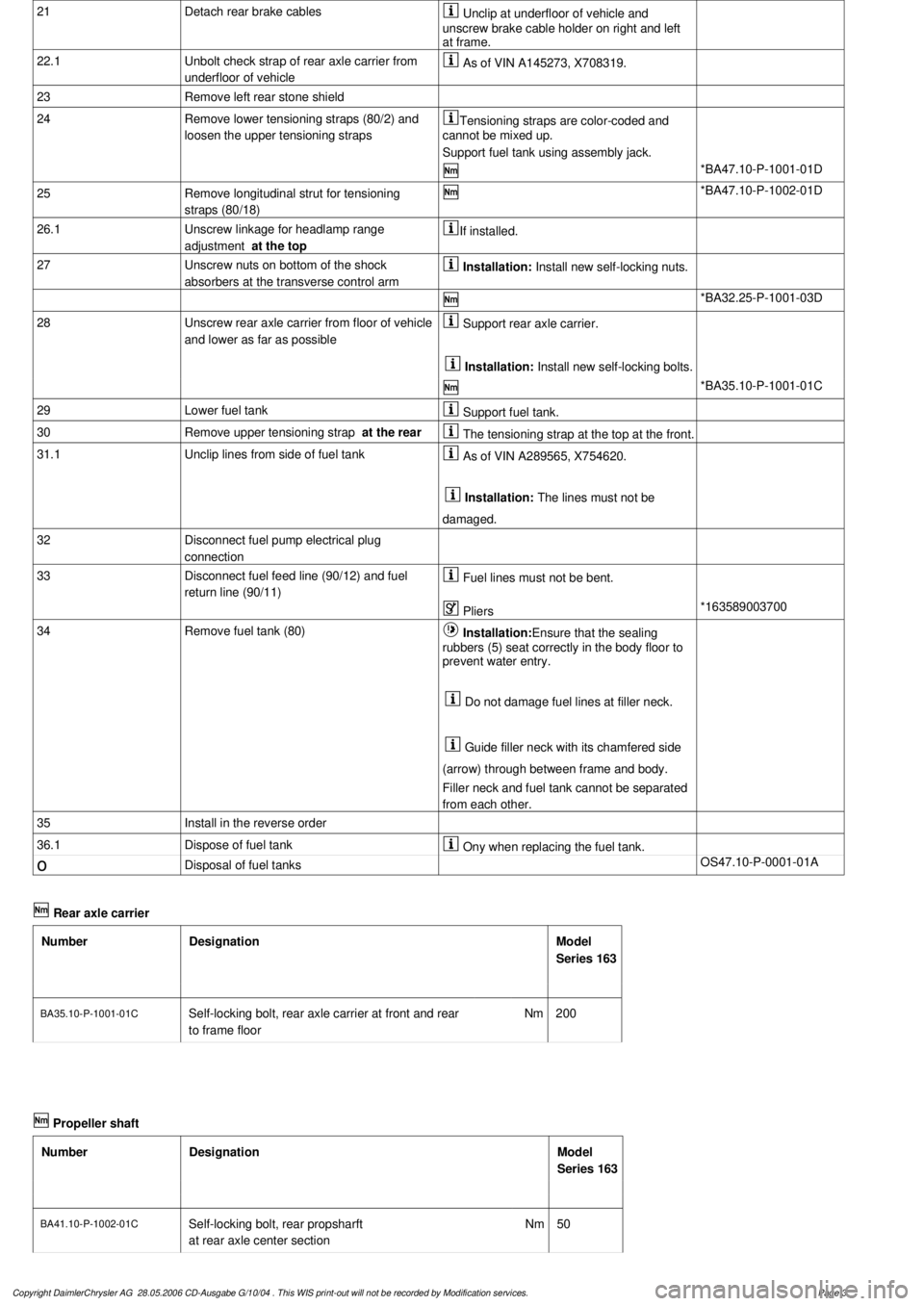

21

Detach rear brake cables

Unclip at underfloor of vehicle and

unscrew brake cable holder on right and left

at frame.

22.1

Unbolt check strap of rear axle carrier from

underfloor of vehicle

As of VIN A145273, X708319.

23

Remove left rear stone shield

24

Remove lower tensioning straps (80/2) and

loosen the upper tensioning straps

Tensioning straps are color-coded and

cannot be mixed up.

Support fuel tank using assembly jack.

*BA47.10-P-1001-01D

25

Remove longitudinal strut for tensioning

straps (80/18)

*BA47.10-P-1002-01D

26.1

Unscrew linkage for headlamp range

adjustment

at the top

If installed.

27

Unscrew nuts on bottom of the shock

absorbers at the transverse control arm

Installation:

Install new self-locking nuts.

*BA32.25-P-1001-03D

28

Unscrew rear axle carrier from floor of vehicle

and lower as far as possible

Support rear axle carrier.

Installation:

Install new self-locking bolts.

*BA35.10-P-1001-01C

29

Lower fuel tank

Support fuel tank.

30

Remove upper tensioning strap

at the rear

The tensioning strap at the top at the front.

31.1

Unclip lines from side of fuel tank

As of VIN A289565, X754620.

Installation:

The lines must not be

damaged.

32

Disconnect fuel pump electrical plug

connection

33

Disconnect fuel feed line (90/12) and fuel

return line (90/11)

Fuel lines must not be bent.

Pliers

*163589003700

34

Remove fuel tank (80)

Installation:

Ensure that the sealing

rubbers (5) seat correctly in the body floor to

prevent water entry.

Do not damage fuel lines at filler neck.

Guide filler neck with its chamfered side

(arrow) through between frame and body.

Filler neck and fuel tank cannot be separated

from each other.

35

Install in the reverse order

36.1

Dispose of fuel tank

Ony when replacing the fuel tank.

o

Disposal of fuel tanks

OS47.10-P-0001-01A

Rear axle carrier

Number

Designation

Model

Series 163

BA35.10-P-1001-01C

Self-locking bolt, rear axle carrier at front and rear

to frame floor

Nm

200

Propeller shaft

Number

Designation

Model

Series 163

BA41.10-P-1002-01C

Self-locking bolt, rear propsharft

at rear axle center section

Nm

50

Copyright DaimlerChrysler AG 28.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 3

Page 2665 of 4133

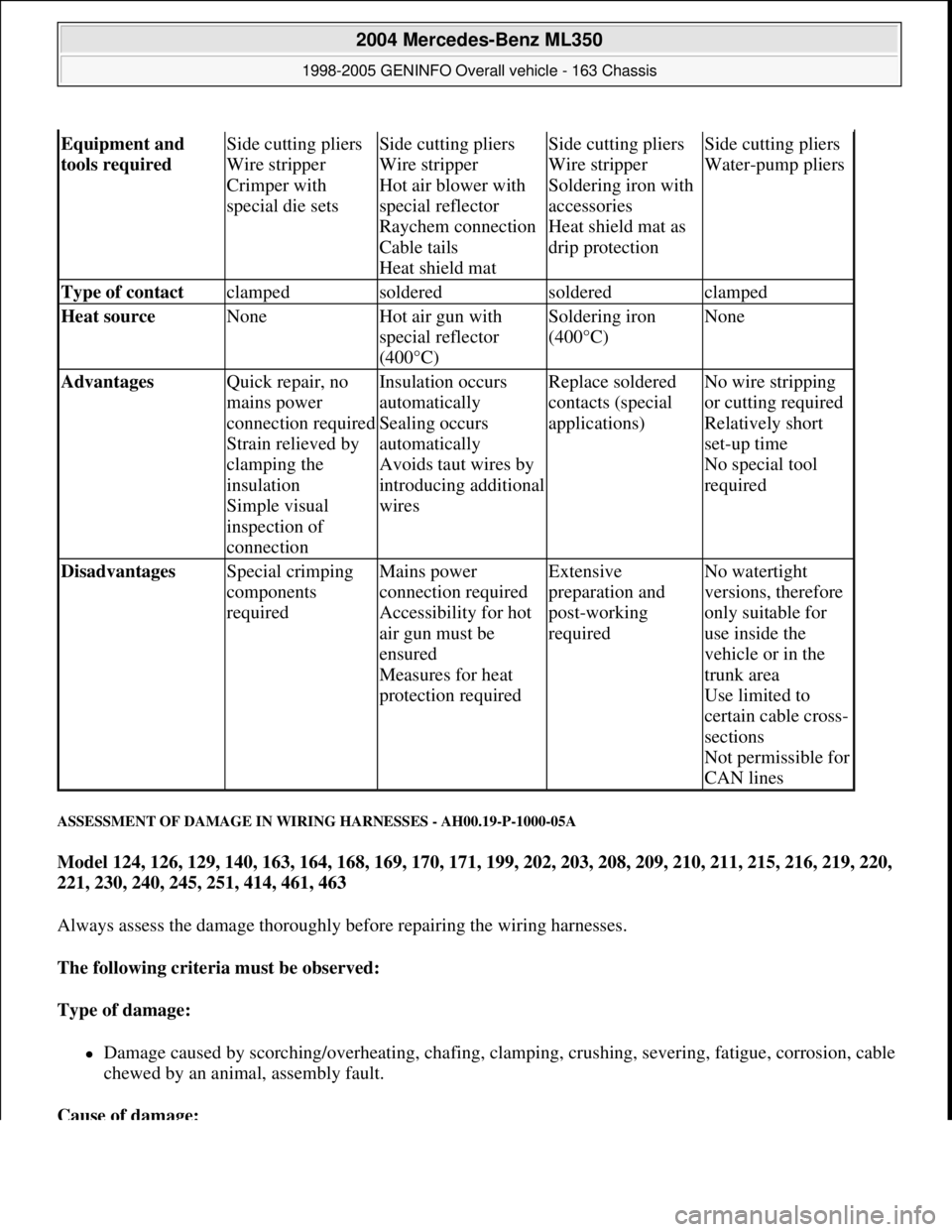

ASSESSMENT OF DAMAGE IN WIRING HARNESSES - AH00.19-P-1000-05A

Model 124, 126, 129, 140, 163, 164, 168, 169, 170, 171, 199, 202, 203, 208, 209, 210, 211, 215, 216, 219, 220,

221, 230, 240, 245, 251, 414, 461, 463

Always assess the damage thoroughly before repairing the wiring harnesses.

The following criteria must be observed:

Type of damage:

Damage caused by scorching/overheating, chafing, clamping, crushing, severing, fatigue, corrosion, cable

chewed by an animal, assembly fault.

Cause of damage:

Equipment and

tools required Side cutting pliers

Wire stripper

Crimper with

special die setsSide cutting pliers

Wire stripper

Hot air blower with

special reflector

Raychem connection

Cable tails

Heat shield matSide cutting pliers

Wire stripper

Soldering iron with

accessories

Heat shield mat as

drip protectionSide cutting pliers

Water-pump pliers

Type of contact clampedsolderedsolderedclamped

Heat source NoneHot air gun with

special reflector

(400°C)Soldering iron

(400°C)None

Advantages Quick repair, no

mains power

connection required

Strain relieved by

clamping the

insulation

Simple visual

inspection of

connectionInsulation occurs

automatically

Sealing occurs

automatically

Avoids taut wires by

introducing additional

wiresReplace soldered

contacts (special

applications)No wire stripping

or cutting required

Relatively short

set-up time

No special tool

required

Disadvantages Special crimping

components

requiredMains power

connection required

Accessibility for hot

air gun must be

ensured

Measures for heat

protection requiredExtensive

preparation and

post-working

requiredNo watertight

versions, therefore

only suitable for

use inside the

vehicle or in the

trunk area

Use limited to

certain cable cross-

sections

Not permissible for

CAN lines

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:44 PMPage 20 © 2006 Mitchell Repair Information Company, LLC.

Page 3287 of 4133

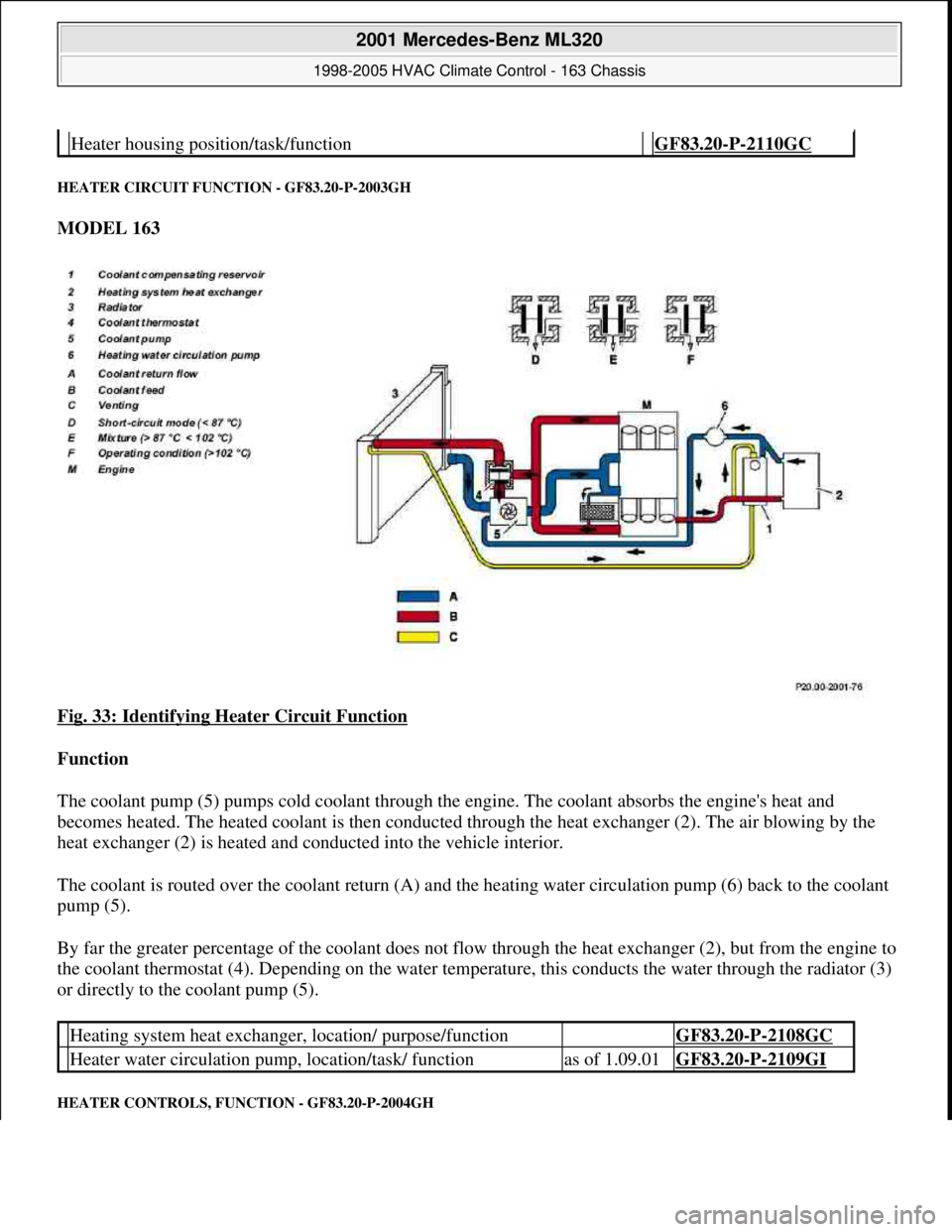

HEATER CIRCUIT FUNCTION - GF83.20-P-2003GH

MODEL 163

Fig. 33: Identifying Heater Circuit Function

Function

The coolant pump (5) pumps cold coolant through the engine. The coolant absorbs the engine's heat and

becomes heated. The heated coolant is then conducted through the heat exchanger (2). The air blowing by the

heat exchanger (2) is heated and conducted into the vehicle interior.

The coolant is routed over the coolant return (A) and the heating water circulation pump (6) back to the coolant

pump (5).

By far the greater percentage of the coolant does not flow through the heat exchanger (2), but from the engine to

the coolant thermostat (4). Depending on the water temperature, this conducts the water through the radiator (3)

or directly to the coolant pump (5).

HEATER CONTROLS, FUNCTION - GF83.20-P-2004GH

Heater housing position/task/function GF83.20-P-2110GC

Heating system heat exchanger, location/ purpose/function GF83.20-P-2108GC

Heater water circulation pump, location/task/ functionas of 1.09.01GF83.20-P-2109GI

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:15 PMPage 43 © 2006 Mitchell Repair Information Company, LLC.

Page 3289 of 4133

Fig. 35: Identifying Heater Core

HEATING WATER CIRCULATION PUMP FUNCTION - GF83.20-P-2102-01GI

Function

The quantity of coolant delivered to the heat exchanger when the engine is running is dependent on the coolant

pump. The heating water circulation pump ensures that a constant and bubble-free flow of water is present at

the heat exchanger during residual engine heat utilization, even at low engine speeds.

Initialization of the heating water circulation pump is carried out via the AAC push-button control module

(N22).

Switch-on conditions

Ignition ON

Stationary heater/ON

Enable conditions at residual engine heat complied with

Special conditions

At ambient temperatures of less than -20°C several starting attempts are made, in order to ensure that the

heating water circulation pump goes into operation.

To this end the heating water circulation pump is switched off in intervals of 1 minute for 5 seconds, until the

coolant or blow-out temperature is +20°C higher than the ambient temperature.

Switch-off conditions

Ignition OFF and overshoot time expired

Stationary heater OFF

Residual engine heat OFF and overshoot time expired

Enable conditions at residual engine heat no longer complied with

Enable conditions at residual engine heat

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:15 PMPage 45 © 2006 Mitchell Repair Information Company, LLC.

Page 3290 of 4133

The heating water circulation pump runs in any event 1 minute after starting residual engine heat operation. The

overshoot conditions at least will be fulfilled.

Overshoot conditions

Coolant temperature 100°C --> overshoot time 5 minutes

Coolant temperature >100°C --> overshoot time 10 minutes

HEATER HOUSING POSITION - GF83.20-P-2103-01GH

The heater housing (1) is located beneath the instrument panel.

Fig. 36: Identifying Heater Housing

HEATER BOX FUNCTION - GF83.20-P-2103-02GH

Operating condition: Heating

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:15 PMPage 46 © 2006 Mitchell Repair Information Company, LLC.

Page 3295 of 4133

The fresh air/recirculated air flap shuts off the supply of recirculated air.

Fresh air is drawn in.

Recirculation mode

The fresh air/recirculated air flap shuts off the supply of fresh air. Air is drawn in from the passenger

compartment.

HEATER CORE, LOCATION/PURPOSE/FUNCTION - GF83.20-P-2108GC

MODEL 163, 168

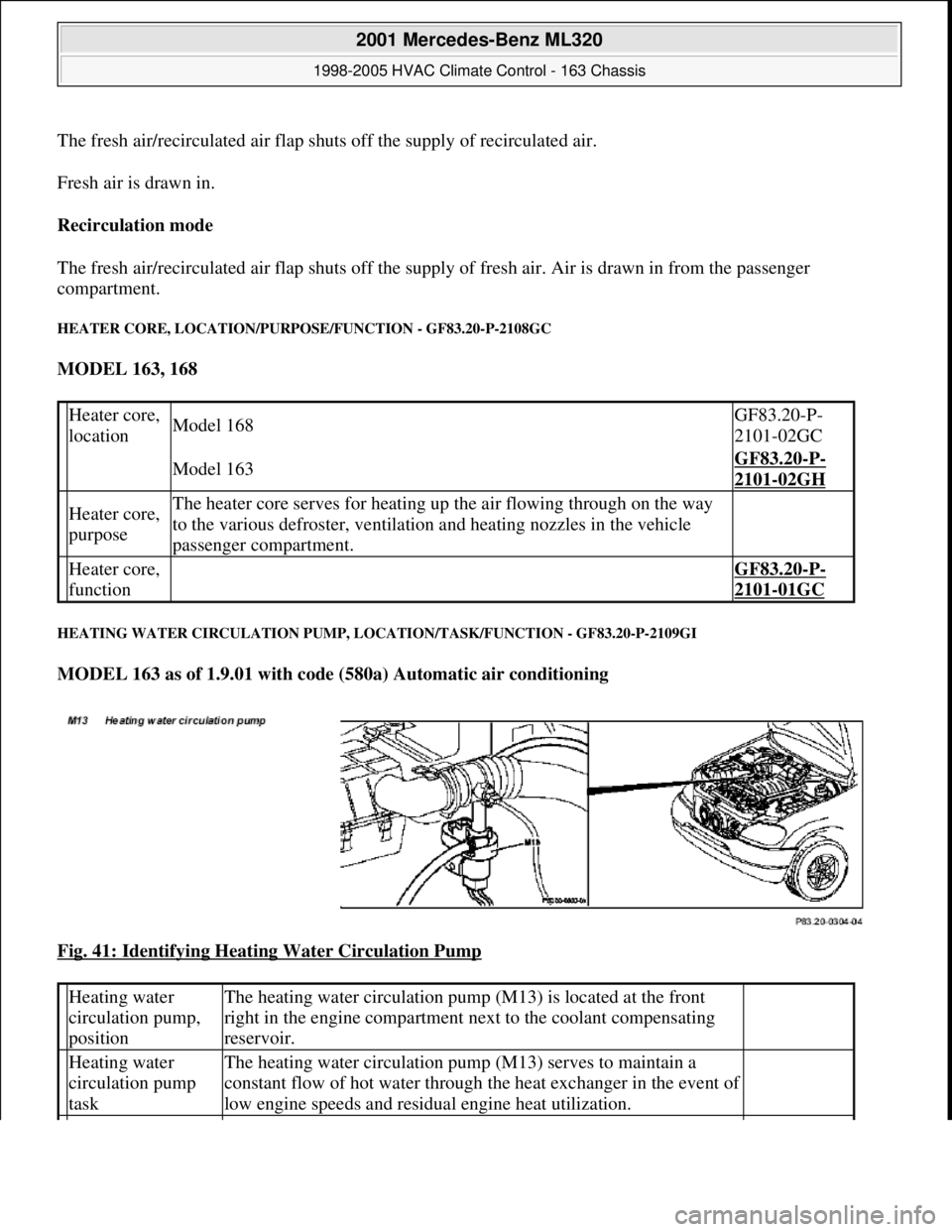

HEATING WATER CIRCULATION PUMP, LOCATION/TASK/FUNCTION - GF83.20-P-2109GI

MODEL 163 as of 1.9.01 with code (580a) Automatic air conditioning

Fig. 41: Identifying Heating Water Circulation Pump

Heater core,

locationModel 168GF83.20-P-

2101-02GC

Model 163GF83.20-P-

2101-02GH

Heater core,

purposeThe heater core serves for heating up the air flowing through on the way

to the various defroster, ventilation and heating nozzles in the vehicle

passenger compartment.

Heater core,

function GF83.20-P-

2101-01GC

Heating water

circulation pump,

positionThe heating water circulation pump (M13) is located at the front

right in the engine compartment next to the coolant compensating

reservoir.

Heating water

circulation pump

taskThe heating water circulation pump (M13) serves to maintain a

constant flow of hot water through the heat exchanger in the event of

low engine speeds and residual engine heat utilization.

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:15 PMPage 51 © 2006 Mitchell Repair Information Company, LLC.

Page 3296 of 4133

HEATER HOUSING POSITION/TASK/FUNCTION - GF83.20-P-2110GC

MODEL 163 up to 31.8.01

168 up to except CODE (580) Air conditioning or Tempmatic for USA

Shown on model 168 as of 1.03.01

Fig. 42: Identifying Heater Housing

- Shown On Model 168 As Of 1.03.01

FRESH AIR/RECIRCULATED AIR FLAP, LOCATION/PURPOSE/FUNCTION - GF83.20-P-2111GC

MODEL 163, 168

Heating water

circulation pump

function

GF83.20-P-

2102-01GI

Heater housing

positionThe heater housing (1) is located beneath the instrument

panel.

Model 168 up to 28.02.01GF83.20-P-2103-

01GC

Model 163GF83.20-P-2103-

01GH

Heater housing task GF83.20-P-2103-

03GC

Heater housing

functionModel 168GF83.20-P-2103-

02GC

Model 163GF83.20-P-2103-

02GH

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:15 PMPage 52 © 2006 Mitchell Repair Information Company, LLC.

Page 3325 of 4133

The residual engine heat utilization system allows the vehicle to be heated even when the ignition is

switched OFF. To do so the system utilizes the residual heat from the engine and guides it via the

blower into the passenger compartment. The heating water circulation pump ensures that the

coolant is properly circulated.

Automatic air conditioning push-button control module

The automatic air conditioning can be operated by the driver using various tip switches. Apart from this

the push-

button control module reads in different sensor signals, processes them and controls components

in the automatic air conditioning.

Rear ventilation control panel

The operator can intervene in the automatic regulation of the rear ventilation through the automatic air

conditioning by using the rear ventilation control panel and adjust it accordingly to suit needs at any

given time. With the aid of the air distribution switch and blower switch the operator can accommodate

his/her own wishes. The correspondingly altered function is then no longer regulated by the automatic air

conditioning.

By pressing the automatic control button the manually initiated settings can be reset and thus regulated

again by the automatic air conditioning.

Regulation of the air quantity and air distribution ensues thus solely by way of the automatic air

conditioning push-button control module.

Heater circuit

Coolant is heated by the engine. Subsequently, the heated coolant is then routed through the heat exchanger,

where the heat is dissipated to the air in the passenger compartment. The heater return line, in which the heating

water circulation pump is located, takes the coolant back to the coolant pump.

The heating water circulation pump ensures that the coolant is properly circulated.

The coolant flows through the heat exchanger permanently.

Depending upon the desired in-car temperature, regulation is conducted over the blending air flaps, which are

operated by the blending air flap actuator motor.

Heater operation with heater booster in vehicles with OM 612.963

In vehicles equipped with direct-injection diesel engines, an electrical heater booster is additionally installed in

the evaporator housing downstream of the heat exchanger, in order to compensate the heater output deficit

which occurs in the case of certain operating conditions.

The 3 heating elements in the heater booster are supplied with current, as a result of which they are heated and

start to glow. As a result of the structural conditions, it is ensured that the drawn in fresh air flows directly past

the electric heater booster, and is therefore heated.

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:16 PMPage 81 © 2006 Mitchell Repair Information Company, LLC.

Page 3328 of 4133

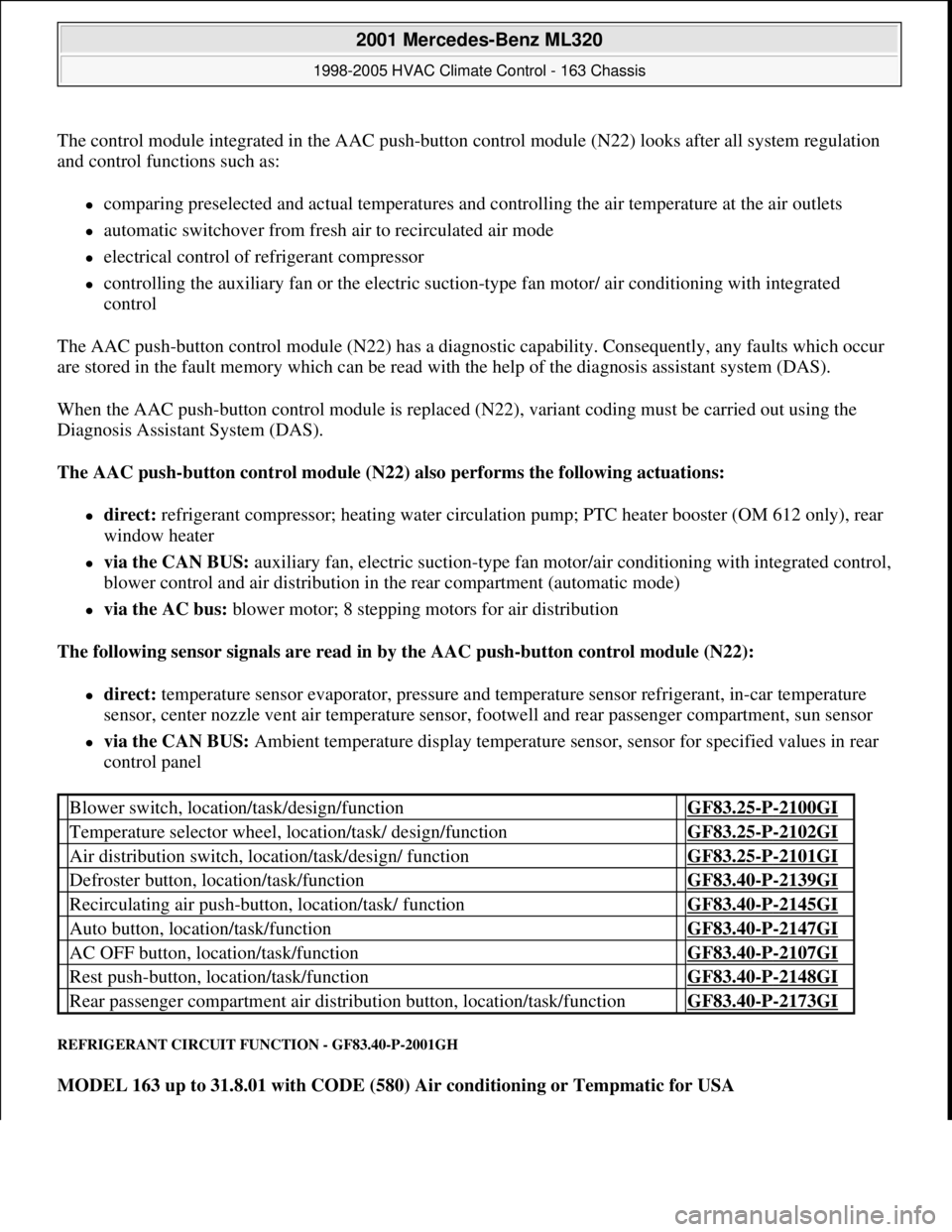

The control module integrated in the AAC push-button control module (N22) looks after all system regulation

and control functions such as:

comparing preselected and actual temperatures and controlling the air temperature at the air outlets

automatic switchover from fresh air to recirculated air mode

electrical control of refrigerant compressor

controlling the auxiliary fan or the electric suction-type fan motor/ air conditioning with integrated

control

The AAC push-button control module (N22) has a diagnostic capability. Consequently, any faults which occur

are stored in the fault memory which can be read with the help of the diagnosis assistant system (DAS).

When the AAC push-button control module is replaced (N22), variant coding must be carried out using the

Diagnosis Assistant System (DAS).

The AAC push-button control module (N22) also performs the following actuations:

direct: refrigerant compressor; heating water circulation pump; PTC heater booster (OM 612 only), rear

window heater

via the CAN BUS: auxiliary fan, electric suction-type fan motor/air conditioning with integrated control,

blower control and air distribution in the rear compartment (automatic mode)

via the AC bus: blower motor; 8 stepping motors for air distribution

The following sensor signals are read in by the AAC push-button control module (N22):

direct: temperature sensor evaporator, pressure and temperature sensor refrigerant, in-car temperature

sensor, center nozzle vent air temperature sensor, footwell and rear passenger compartment, sun sensor

via the CAN BUS: Ambient temperature display temperature sensor, sensor for specified values in rear

control panel

REFRIGERANT CIRCUIT FUNCTION - GF83.40-P-2001GH

MODEL 163 up to 31.8.01 with CODE (580) Air conditioning or Tempmatic for USA

Blower switch, location/task/design/function GF83.25-P-2100GI

Temperature selector wheel, location/task/ design/function GF83.25-P-2102GI

Air distribution switch, location/task/design/ function GF83.25-P-2101GI

Defroster button, location/task/function GF83.40-P-2139GI

Recirculating air push-button, location/task/ function GF83.40-P-2145GI

Auto button, location/task/function GF83.40-P-2147GI

AC OFF button, location/task/function GF83.40-P-2107GI

Rest push-button, location/task/function GF83.40-P-2148GI

Rear passenger compartment air distribution button, location/task/function GF83.40-P-2173GI

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:16 PMPage 84 © 2006 Mitchell Repair Information Company, LLC.

Page 3362 of 4133

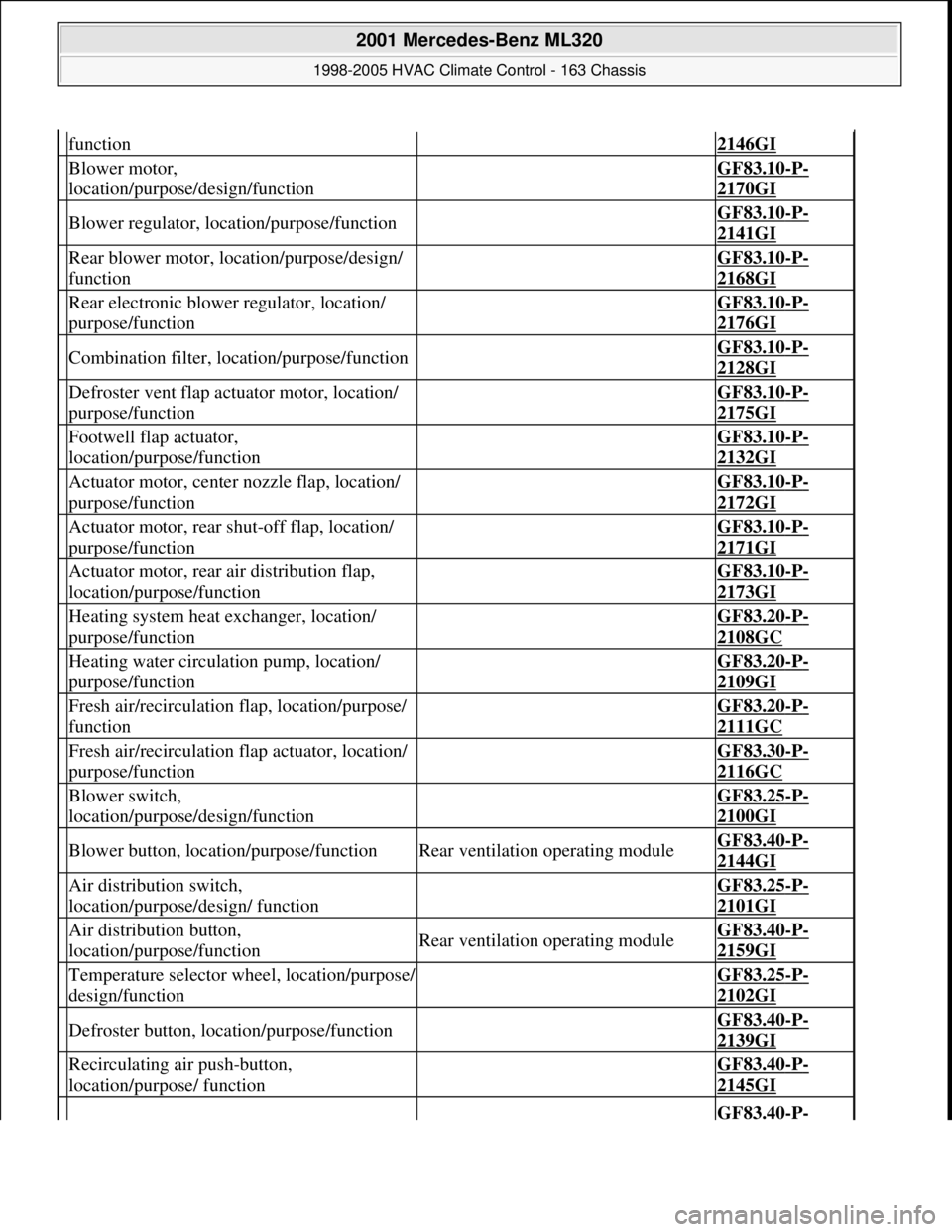

function 2146GI

Blower motor,

location/purpose/design/function GF83.10-P-

2170GI

Blower regulator, location/purpose/function GF83.10-P-

2141GI

Rear blower motor, location/purpose/design/

function GF83.10-P-

2168GI

Rear electronic blower regulator, location/

purpose/function GF83.10-P-

2176GI

Combination filter, location/purpose/function GF83.10-P-

2128GI

Defroster vent flap actuator motor, location/

purpose/function GF83.10-P-

2175GI

Footwell flap actuator,

location/purpose/function GF83.10-P-

2132GI

Actuator motor, center nozzle flap, location/

purpose/function GF83.10-P-

2172GI

Actuator motor, rear shut-off flap, location/

purpose/function GF83.10-P-

2171GI

Actuator motor, rear air distribution flap,

location/purpose/function GF83.10-P-

2173GI

Heating system heat exchanger, location/

purpose/function GF83.20-P-

2108GC

Heating water circulation pump, location/

purpose/function GF83.20-P-

2109GI

Fresh air/recirculation flap, location/purpose/

function GF83.20-P-

2111GC

Fresh air/recirculation flap actuator, location/

purpose/function GF83.30-P-

2116GC

Blower switch,

location/purpose/design/function GF83.25-P-

2100GI

Blower button, location/purpose/functionRear ventilation operating moduleGF83.40-P-

2144GI

Air distribution switch,

location/purpose/design/ function GF83.25-P-

2101GI

Air distribution button,

location/purpose/functionRear ventilation operating moduleGF83.40-P-

2159GI

Temperature selector wheel, location/purpose/

design/function GF83.25-P-

2102GI

Defroster button, location/purpose/function GF83.40-P-

2139GI

Recirculating air push-button,

location/purpose/ function GF83.40-P-

2145GI

GF83.40-P-

2001 Mercedes-Benz ML320

1998-2005 HVAC Climate Control - 163 Chassis

me

Saturday, October 02, 2010 3:23:16 PMPage 118 © 2006 Mitchell Repair Information Company, LLC.