wheel bolt torque MERCEDES-BENZ ML320 1997 Complete User Guide

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 1145 of 4133

341 Index

Wear pattern (tires) 228

Weights 299

Wheel bolt wrench 258

Wheel change

Tightening torque 277

Wheels

Rotating 228

Window curtain airbags 64

Windows see Side windows

Windshield

Defogging 138

Refilling washer fluid 224

Replacing wiper blades 273

Washer fluid 224, 307

Washer system 307

Windshield washer fluid 307

Filler neck 224

Mixing ratio 307

Refilling 224

Wiping with 50Windshield washer system 307

Windshield wipers 49, 129

Intermittent 49

Interval wiping 130

Normal wiper speed 49

Rain sensor* 130

Rear window wiper/washer 51

Replacing wiper blades 273

Simultaneous wiping and washing 51

Single wipe 50

Switching on 49

Wiping with windshield washer

fluid 50

Winter driving

Snow chains 231

Tires 230

Winter driving instructions 198

Winter tires 230Wiper blades

Cleaning 237

Installing 273

Removing 273

Replacing 273

Wiper switch 49

Wiper/washer

Rear window 51

Wiping

And washing simultaneously 50

Intermittent 49, 130

With windshield washer fluid 50

Wiping and washing simultaneously 51

X

Xenon headlamps*

Bi-Xenon* 311

Page 1201 of 4133

Shift-Lock, Function

See SHIFT

-LOCK FUNCTION.

Park Pawl Interlock, Function

See PARK PAWL INTERLOCK, FUNCTION

.

Steering Lock Interlock, Function

See STEERING LOCK INTERLOCK, FUNCTION

.

Survey Of System Components, Automatic Transmission, Location/Task/Design/Function

See SURVEY OF SYSTEM COMPONENTS, AUTOMATIC TRANSMISSION,

LOCATION/TASK/DESIGN/FUNCTION.

Automatic Transmission, Function

Automatic transmission 722.6 is an electronically controlled 5-speed transmission with a lockup clutch in the

torque converter.

The ratios for the gear stages are achieved by three planetary gear sets. The 5th gear is designed with a step-up

ratio as an overdrive.

Shifting is initiated electronically. The gears are shifted by the corresponding combination of three

hydraulically actuated multi-disc clutches and two mechanical freewheels.

Basically automatic transmission 722.6 with electronic control offers the following advantages:

Reduced Fuel Consumption

Improved Shift Comfort

More Favorable Gear Steps As A Result Of 5 Gears

Enhanced Life And Reliability

Reduced Servicing Costs

The electrohydraulic control unit is bolted onto the bottom of the transmission housing. The end of the

transmission is formed by an oil pan made of sheet steel.

The oil pressure for the converter lockup clutch and center multiple-disc clutch is supplied via holes in the input

shaft. The oil pressure to the rear mulitiple-disc clutch is routed through the output shaft. The lubricating oil is

supplied and distributed by additional bore holes in both shafts. All bearing points of the gear sets as well as

freewheels and shift elements are supplied with lubricatin

g oil. NOTE: Transmission Without Touch Shift 722.6 In Model 163.

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:25 PMPage 32 © 2006 Mitchell Repair Information Company, LLC.

Page 1202 of 4133

The parking lock gear and drive flange are connected to the output shaft by gearing.

Freewheels F1 and F2 optimize shifting. The front freewheel (F1) rests against the stator shaft extension on the

transmission side and connects the sun gear of the front planetary gear set tot the transmission housing in the

locking direction.

The torque converter housing and transmission housing are made of a metal alloy. They are bolted together and

centered via the outer multiple-disc carrier of the multiple-disc brake B1. A coated intermediate panel seals the

two components.

The oil pump and outer multiple-disc carrier of the front multiple-disc brake are bolted to the converter housing.

The mechanical part consists of the propeller shaft, output shaft, a sun gear shaft and three planetary gearsets

which are coupled together.

In transmissions for powerful engines, the planetary gearsets have 4 planetary gears, while for less powerful

engines the front and rear planetary gear system has three planetary gear wheels. The stator shaft is pressed into

this and is secured against turning by a spline.

The rear freewheel (F2) connects the sun gear of the center planetary gear set to the sun gear of the rear

planetary gearset in the locking direction.

The electrohydraulic control unit consists of the shift plate made of light alloy for hydraulic control and an

electronic control unit.

The electrical control unit consists of a supporting body made of plastic in which the electrical components are

combined. The shell is screwed tot he shift plate. Conductor tracks which are integrated into the shell, connect

the electric components to a plug connector. This 13-pin plug connector forms the connection with the vehicle-

side wiring harness and with the ETC 5 (Electronic Transmission Control) control module (N15/5) via a

bayonet lock.

Automatic Transmission, Location Of Mechanical Parts

See AUTOMATIC TRANSMISSION, LOCATION OF MECHANICAL PARTS

.

Automatic Transmission, Location Of Electric/Electronic Components

See AUTOMATIC TRANSMISSION, LOCATION OF ELECTRIC/ELECTRONIC

COMPONENTS.

Automatic Transmission, Location Of Hydraulic Components

See AUTOMATIC TRANSMISSION, POSITION OF HYDRAULIC COMPONENTS

.

Automatic Transmission, Location Of Components, Floor Shift

See AUTOMATIC TRANSMISSION, LOCATION OF COMPONENTS, FLOOR SHIFT

.

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:26 PMPage 33 © 2006 Mitchell Repair Information Company, LLC.

Page 1352 of 4133

Fig. 106: Torque Converter Lockup Clutch, Function

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

Operation

When actuated by the ETC control module (N15/3), oil pressure controlled by the torque converter lockup

PWM solenoid Valve (Y3/6y6) is directed through the input shaft (1) to the pressure chamber behind the piston

(16d). See Fig. 106

. The piston presses the clutch pack (16c) together and allows torque to be transferred

directly between the impeller (P) and turbine wheel (T). The torque converter lockup clutch is activated in 5th,

4th and 3rd gears in relation to the engine speed and engine load.

AUTOMATIC TRANSMISSION, FUNCTION

Transmission without touch shift. 722.6 in MODEL 163, 170, 202, 208, 210.

Transmission 722.6 in MODEL 129, 140.

Automatic transmission 722.6 is an electronically controlled 5-speed transmission with a lockup clutch in the

torque converter.

The ratios for the gear stages are achieved by three planetary gear sets. The 5th gear is designed with a step-up

ratio as an overdrive.

Shifting is initiated electronically. The gears are shifted by the corresponding combination of three

hydraulically actuated multi-plate brakes, three hydraulically actuated multi-disc clutches and two mechanical

freewheels.

Basically automatic transmission 722.6 with electronic control offers the following advantages:

Reduced fuel consumption

Improved shift comfort

More favorable gear steps as a result of 5 gears

Enhanced life and reliability

Reduced servicing costs

The electrohydraulic control unit is bolted onto the bottom of the transmission housing. The end of the

transmission is formed by an oil pan made of sheet steel.

The oil pressure for the converter lockup clutch and center multiple disc clutch is supplied via holes in the input

shaft. The oil pressure to the rear multiple-disc clutch is routed through the output shaft. The lubricating oil is

supplied and distributed by additional bore holes in both shafts. All bearing points of the gear sets as well as

freewheels and shift elements are supplied with lubricating oil.

The parking lock gear and drive flange are connected to the output shaft by gearing.

Freewheels F1 and F2 optimize shiftin

g. The front freewheel (F1) rests against the stator shaft extension on the

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:28 PMPage 183 © 2006 Mitchell Repair Information Company, LLC.

Page 1353 of 4133

transmission side and connects the sun gear of the front planetary gear set to the transmission housing in the

locking direction.

The torque converter housing and transmission housing are made of a metal alloy. They are bolted together and

centered via the outer multiple-disc carrier of the multiple-disc brake B1. A coated intermediate panel seals the

two components.

The oil pump and outer multiple-disc carrier of the front multiple-disc brake are bolted to the converter housing.

The mechanical part consists of the propeller shaft, output shaft, a sun gear shaft and three planetary gearsets

which are coupled together.

In transmissions for powerful engines, the planetary gearsets have 4 planetary gears, while for less powerful

engines the front and rear planetary gear system has three planetary gear wheels. The stator shaft is pressed into

this and is secured against turning by a spline.

The rear freewheel (F2) connects the sun gear of the center planetary gear set to the sun gear of the rear

planetary gearset in the locking direction.

The electrohydraulic control unit consists of the shift plate made of light alloy for hydraulic control and an

electronic control unit.

The electrical control unit consists of a supporting body made of plastic in which the electrical components are

combined. The shell is screwed to the shift plate. Conductor tracks which are integrated into the shell, connect

the electric components to a plug connector. This 13-pin plug connector forms the connection with the vehicle-

side wiring harness and with the ETC 5 (electronic transmission control) control module (N15/5) via a bayonet

lock.

Automatic Transmission, Location Of Mechanical Components

See AUTOMATIC TRANSMISSION, LOCATION OF MECHANICAL PARTS

.

Automatic Transmission, Location Of Electrical/Electronic Components

See AUTOMATIC TRANSMISSION, LOCATION OF ELECTRIC/ELECTRONIC

COMPONENTS.

Automatic Transmission, Location Of Hydraulic Components

See AUTOMATIC TRANSMISSION, POSITION OF HYDRAULIC COMPONENTS

.

Automatic Transmission, Location of Components, Floor Shift

See AUTOMATIC TRANSMISSION, LOCATION OF COMPONENTS, FLOOR SHIFT

.

Automatic Transmission, Selector Lever Positions

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:28 PMPage 184 © 2006 Mitchell Repair Information Company, LLC.

Page 1358 of 4133

Fig. 108: Selector Lever Positions

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

AUTOMATIC TRANSMISSION, FUNCTION

Transmission With Touch Shift 722.6 In Model 163

Transmission 722.6 is an electronically controlled 5-speed transmission with a lockup clutch in the torque

converter.

The ratios for the gear stages are achieved by 3 planetary gearsets. The 5th gear is designed as a low-rev gear

with an overdrive ratio.

Shifting is initiated electronically. The gears are shifted by the corresponding combination of 3 hydraulically

actuated multi-disk brakes, 3 hydraulically actuated multi-disk clutches and 2 mechanical freewheels.

The oil pump as well as the external plate carrier of the front multi-disk brake are bolted to the torque converter

housing.

The mechanical part of the transmission 722.6 consists of a drive shaft, output shaft, a sun gear shaft and 3

planetary sets which are coupled to each other.

The electrohydraulic control unit is screwed onto the transmission housing from below. The end of the

transmission if formed by an oil pan made of sheet steel.

The oil pressure of the torque converter lockup clutch and center multi-disk clutch is supplied via bore holes in

the drive shaft. The oil pressure to the rear multi-disk clutch is supplied via the output shaft. The lubricating oil

is supplied and distributed by additional bore holes in both shafts. Oil is supplied to all bearing points of the

gearsets as well as to the freewheels and shifting elements.

The parking lock gear and drive flange are connected to the output shaft by gearing.

Basically transmission 722.6 with electronic control offers the following advantages:

Reduced fuel consumption.

Greater ease of shifting.

Favorable spacing by 5 gears.

Long service life and high reliability.

Low maintenance costs.

The torque converter housing and transmission housing consist of a light-metal alloy. Both housings are bolted

together and are centered via the external plate carrier of the multi-disk brake at the front. A coated intermediate

panel seals the two components.

Freewheels F1 and F2 optimize shifting. The front freewheel F1 is supported on the extension of the stator shaft

on the transmission end and connects in the lockin

g direction the sun gear of the front planetary gearset with the

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:28 PMPage 189 © 2006 Mitchell Repair Information Company, LLC.

Page 1471 of 4133

Basically automatic transmission 722.6 with electronic control offers the following advantages:

Reduced Fuel Consumption

Improved Shift Comfort

More Favorable Gear Steps As A Result Of 5 Gears

Enhanced Life And Reliability

Reduced Servicing Costs

The electrohydraulic control unit is bolted onto the bottom of the transmission housing. The end of the

transmission is formed by an oil pan made of sheet steel.

The oil pressure for the converter lockup clutch and center multiple-disc clutch is supplied via holes in the input

shaft. The oil pressure to the rear multiple-disc clutch is routed through the output shaft. The lubricating oil is

supplied and distributed by additional bore holes in both shafts. All bearing points of the gear sets as well as

freewheels and shift elements are supplied with lubricating oil.

The parking lock gear and drive flange are connected to the output shaft by gearing.

Freewheels F1 and F2 optimize shifting. The front freewheel (F1) rests against the stator shaft extension on the

transmission side and connects the sun gear of the front planetary gear set to the transmission housing in the

locking direction.

The torque converter housing and transmission housing are made of a metal alloy. They are bolted together and

centered via the outer multiple-disc carrier of the multiple-disc brake B1. A coated intermediate panel seals the

two components.

The oil pump and outer multiple-disc carrier of the front multiple-disc brake are bolted to the converter housing.

The mechanical part consists of the propeller shaft, output shaft, a sun gear shaft and three planetary gearsets

which are coupled together.

In transmissions for powerful engines, the planetary gearsets have 4 planetary gears, while for less powerful

engines the front and rear planetary gear system has three planetary gear wheels. The stator shaft is pressed into

this and is secured against turning by a spline.

The rear freewheel F2 connects the sun gear of the center planetary gear set to the sun gear of the rear planetary

gearset in the locking direction.

The electrohydraulic control unit consists of the shift plate made of light alloy for hydraulic control and an

electronic control unit.

The electrical control unit consists of a supporting body made of plastic in which the electrical components are

combined. The shell is screwed to the shift plate. Conductor tracks which are integrated into the shell, connect

the electric components to a plug connector. This 13-pin plug connector forms the connection with the vehicle-

side wiring harness and with the ETC 5 (electronic transmission control) control module (N15/5) via a bayonet

lock.

2001 Mercedes-Benz ML320

1998-03 AUTOMATIC TRANSMISSIONS Complete Transmissions - ML 320 - 722.662

me

Saturday, October 02, 2010 3:15:30 PMPage 302 © 2006 Mitchell Repair Information Company, LLC.

Page 2526 of 4133

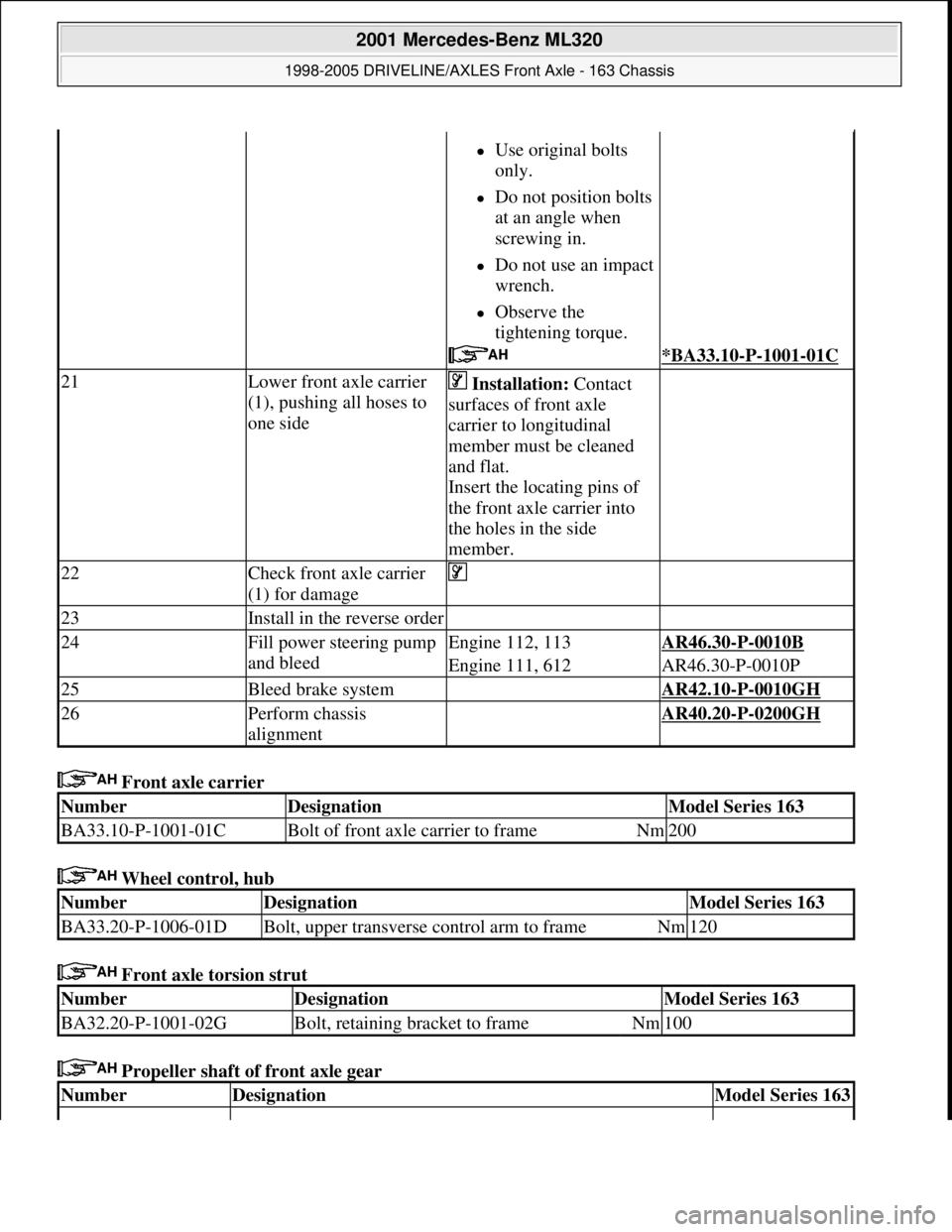

Front axle carrier

Wheel control, hub

Front axle torsion strut

Propeller shaft of front axle gear

Use original bolts

only.

Do not position bolts

at an angle when

screwing in.

Do not use an impact

wrench.

Observe the

tightening torque.

*BA33.10-P-1001-01C

21Lower front axle carrier

(1), pushing all hoses to

one side Installation: Contact

surfaces of front axle

carrier to longitudinal

member must be cleaned

and flat.

Insert the locating pins of

the front axle carrier into

the holes in the side

member.

22Check front axle carrier

(1) for damage

23Install in the reverse order

24Fill power steering pump

and bleedEngine 112, 113AR46.30-P-0010B

Engine 111, 612AR46.30-P-0010P

25Bleed brake system AR42.10-P-0010GH

26Perform chassis

alignment AR40.20-P-0200GH

NumberDesignationModel Series 163

BA33.10-P-1001-01CBolt of front axle carrier to frameNm200

NumberDesignationModel Series 163

BA33.20-P-1006-01DBolt, upper transverse control arm to frameNm120

NumberDesignationModel Series 163

BA32.20-P-1001-02GBolt, retaining bracket to frameNm100

NumberDesignationModel Series 163

2001 Mercedes-Benz ML320

1998-2005 DRIVELINE/AXLES Front Axle - 163 Chassis

me

Saturday, October 02, 2010 3:38:21 PMPage 7 © 2006 Mitchell Repair Information Company, LLC.

Page 3232 of 4133

Fig. 6: Removing Cooling Fans & Condenser

Courtesy of MERCEDES-BENZ OF NORTH AMERICA.

COOLING FANS

Removal & Installation

Remove headlight units. Remove upper frame crossmember, release hood release control cable and remove

crossmember. See Fig. 6

. Remove 2 cooling fans frame bolts on radiator. Disconnect cooling fan connector.

Release outside temperature sensor wiring harness. Pull up on cooling fan and remove. To install, reverse

removal procedure. Ensure cooling fan bottom guides are properly seated in lower mounts.

EVAPORATOR

Removal & Installation

Remove A/C housing unit. See A/C HOUSING UNIT . Remove expansion valve. See Fig. 5 . Discard "O"

rings. Disassemble A/C housing unit. Remove evaporator. Remove evaporator temperature sensor. To install,

reverse removal procedure. Use NEW "O" rings lubricated with refrigerant oil. If installing a new or repair

evaporator, add 1.35 ounces of NEW refrigerant oil to evaporator.

EXPANSION VALVE

Removal & Installation

1. Discharge A/C system, using approved refrigerant recovery/recycling equipment. Without disconnecting

coolant hoses, remove coolant expansion reservoir and set aside. Remove refrigerant line bracket and

loosen clamps. See Fig. 5

. Pull refrigerant lines out of expansion valve.

2. Remove expansion valve self-locking nut and discard. Remove expansion valve. Discard "O" rings. To

install, reverse removal procedure. Use NEW "O" rings lubricated with refrigerant oil. Tighten NEW self-

locking nut to specification. See TORQUE SPECIFICATIONS

.

INSTRUMENT PANEL & INSTRUMENT PANEL CARRIER

Removal & Installation

1. Secure vehicle against rolling. Set transmission selector to "D" position. Obtain radio security code.

Disconnect negative battery cable. Remove driver-side air bag.

2. Place match marks on steering wheel and steering shaft. Remove steering wheel, upper steering column

covers and combination switch. Remove instrument cluster cover frame. Remove one instrument panel

lower section bolt.

3. Remove screws in footwell from left side of instrument panel bottom section. Remove instrument panel

center section. Remove 4 A/C control panel screws and remove control panel. See Fig. 1

. Release pull

cables and disconnect connectors.

4. Remove screws from center section. Remove glove box. Remove screws in footwell from right side of

instrument panel bottom section. Remove entry courtesy lights. Remove end covers and screws.

5. Release 4 "A" clips between instrument panel bottom section and upper section. See Fig. 7

. Release

parkin

g brake release cable from handle. With assistance, remove instrument panel bottom section.

2001 Mercedes-Benz ML320

2000-01 MANUAL A/C-HEATER SYSTEMS ML 320, ML 430 & ML 55

me

Saturday, October 02, 2010 3:25:10 PMPage 21 © 2006 Mitchell Repair Information Company, LLC.

Page 3485 of 4133

Rims

D

When changing wheels, for instance, when replacing steel

wheels with light-alloy rims, ensure that the wheel bolts

required for the spare wheel are stored in a clearly visible

location.

D

Since December 1994 models 202 and 124 with special

equipment light alloy disk wheels, are supplied with a sheet

steel spare wheel instead of a light alloy spare wheel. The

necessary wheel bolts are included with the steel spare wheel.

D

Only use approved Mercedes-Benz rims of the same version.

D

Reinforced steel rims are identified by a sticker on the wheel

disc.

D

The wheel bolts on steel and light-alloy rims should always be

tightened to the specified tightening torque using a torque

wrench.

It is not necessary to retorque the lug bolts after approximately

100 to 500 km.

D

The seat for the tire bead must display no corrosion marks.

D

Before inserting a new rubber valve, clean the contact surfaces

on the disk wheel.

On sheet steel-disk wheel wheel trims must be fitted to support

the rubber valve.

Damaged or deformed rims must not be repaired.

Tire pressure monitor

D

Before replacing a tire, check the date of manufacturer of the

wheel sensor: wheel sensors which are more than 5 years old

must be replaced.

D

Use STAR DIAGNOSIS to read out the actual values of the tire

pressure monitor. Check the remaining life of the wheel sensor

battery, replace the wheel sensor if necessary.

Copyright DaimlerChrysler AG 06.07.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 2