width MERCEDES-BENZ ML320 1997 Complete Owner's Manual

[x] Cancel search | Manufacturer: MERCEDES-BENZ, Model Year: 1997, Model line: ML320, Model: MERCEDES-BENZ ML320 1997Pages: 4133, PDF Size: 88.89 MB

Page 2353 of 4133

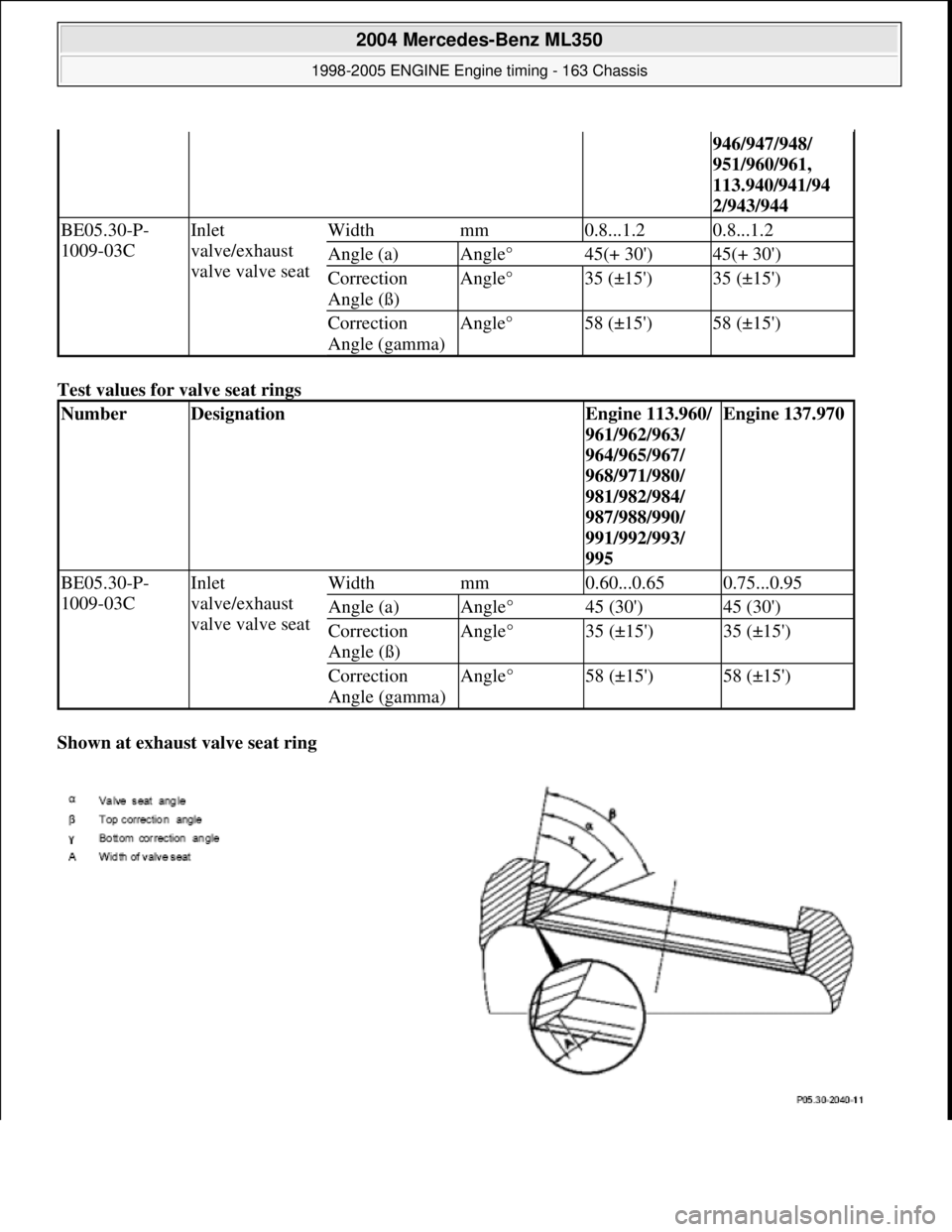

Test values for valve seat rings

Shown at exhaust valve seat ring

946/947/948/

951/960/961,

113.940/941/94

2/943/944

BE05.30-P-

1009-03CInlet

valve/exhaust

valve valve seatWidthmm0.8...1.20.8...1.2

Angle (a)Angle°45(+ 30')45(+ 30')

Correction

Angle (ß)Angle°35 (±15')35 (±15')

Correction

Angle (gamma)Angle°58 (±15')58 (±15')

NumberDesignationEngine 113.960/

961/962/963/

964/965/967/

968/971/980/

981/982/984/

987/988/990/

991/992/993/

995Engine 137.970

BE05.30-P-

1009-03CInlet

valve/exhaust

valve valve seatWidthmm0.60...0.650.75...0.95

Angle (a)Angle°45 (30')45 (30')

Correction

Angle (ß)Angle°35 (±15')35 (±15')

Correction

Angle (gamma)Angle°58 (±15')58 (±15')

2004 Mercedes-Benz ML350

1998-2005 ENGINE Engine timing - 163 Chassis

me

Saturday, October 02, 2010 3:39:39 PMPage 112 © 2006 Mitchell Repair Information Company, LLC.

Page 2355 of 4133

Commercially available tools

Workshop equipment

3Machin valve seat

ring in cylinder head

*WE58.40-Z-

1009-21A

*WE58.40-Z-

1010-21A

Observe tool manufacturer's operating instructions, maintain

dimensions in accordance with checking and machining

dimensions. ?

Checking and machining dime nsions for valve seatsAR05.30-P-

4510-01AV

If the measurements after machining are less than the

specification ?

Replace valve seat ring.AR05.30-P-

3831AV

Inspection

4Measure seat width Correct valve seat width if necessary.AR05.30-P-

4510-01AV

5Insert valve and

inspect for leaks Grind valve with valve grinding compound before

installation.

*WH58.30-Z-

1020-13A

6Measure valve set-

back to cylinder head

If measurement is less than minimum dimension no further

correct valve clearance compensation is possible; replace valve

seat ring or cylinder head ?AR05.30-P-

4100-01AV

Replace valve seat ring. ?

The valve must always be rep laced after installing a new

valve seat ring. AR05.30-P-

3831AV

Install

7Install valves AR05.30-P-

3511AV

NumberDesignation

WH58.30-Z-1020-13AVacuum testing unit

WE58.40-Z-1009-21AValve seat turning device

WE58.40-Z-1010-21AValve seat turning device

2004 Mercedes-Benz ML350

1998-2005 ENGINE Engine timing - 163 Chassis

me

Saturday, October 02, 2010 3:39:39 PMPage 114 © 2006 Mitchell Repair Information Company, LLC.

Page 2461 of 4133

1002-01M

*BA20.10-P-

1003-01C

*BA20.10-P-

1003-01M

*BA20.10-P-

1004-01C

*BA20.10-P-

1004-01M

*BA46.30-P-

1010-01A

*BA46.30-P-

1010-01C

Clean sealing surfaces, appl y sealant only to specified

surfaces in form of bead with height and width of 2.0 mm

± 0.5 mm. The sealant must be applied within 10 minutes!

The silicone bead must not be spread!*BR00.45-Z-

1013-01A

Notes on

application of

sealant to timing

case cover AH01.40-P-

1000-01B

Installation: If sealing compound enters the oil ducts,

this is carried by the oil flow and will clog the oil supply

bores.

Do not damage cylinder head gasket.

Replace seals on ti ming case (19).

Replace front crankshaft radial sealing ring: ?

Engine 112 in model 129

Engine 113 in model 129

Engine 113 in model 163, 202, 208, 210AR03.20-P-

3000B

Engine 112 in models 170, 202, 208, 210, 220

Engine 113 in model 215, 220

Engine 113.981 in model 163.174

Engine 113.963 in models 230.475

Engine 113.992 in model 230.474AR03.20-P-

3000BA

32Install in the

reverse order

Risk of accident

caused by vehicle

starting off by

itself when engine

is running. Risk

of injury caused

by contusions and

burns during

starting procedure

Secure vehicle to prevent it from moving by itself.

Wear closed and snug-fitting work clothes.

Do not grasp hot or rotating parts.AS00.00-Z-

0005-01A

2001 Mercedes-Benz ML320

1998-2005 ENGINE Complete engine - 163 Chassis

me

Saturday, October 02, 2010 3:17:57 PMPage 105 © 2006 Mitchell Repair Information Company, LLC.

Page 2842 of 4133

Fig. 318: Identifying Active Service System (ASSYST) Display

ACTIVE SERVICE SYSTEM (ASSYST) INFLUENCING PARAMETERS - GF00.20-P-0003-05A

The values of various influencing parameters are required by ASSYST for calculating the demand-based service

interval, and these are included in the calculation of the service interval as weighting factors . There are two

versions within ASSYST, the difference being in the oil level sensors fitted:

The familiar oil level indicator switch (S43) is fitted to engines (104, 111, 119, 120, 602.982, 604, 605,

606). In view of the fact that this is a switch, it is only possible to detect if the oil level drops below the

minimum level.

The oil sensor (oil level/temperature/quality, B40) is used on more recent engines (e.g. 112, 113, 166,

611, 668). This sensor consists of 2 capacitor systems with the engine oil as an insulator. If the water

content of the oil or the oil level changes, there is a change in the capacitance of the "capacitor".

The capacitance is thus a measure for the oil level.

In addition, the oil sensor (oil level/temperature/quality, B40) contains a temperature sensor which

detects the temperature of the engine oil.

All the signals are processed in the electronics integrated in the sensor to form a PWM (pulse width

modulated) signal, and passed to the engine control module (N3).

In addition to the weighting factors, which depend on reallife driving conditions, quality factors are also used

for calculating the demand-based service interval (remaining distance and remaining time).

Survey of ASSYST influencing parameters

Weighting factors (dependant on reallife driving conditions):

Load torque

Engine speed

Oil level

Engine oil temperature

Oil correction factor (is used as comparative value for determining oil level)

Coolant temperature

These data are supplied by the injection system control module (N3) to the service microprocessor over

the CAN.

The data relating to oil level, engine oil temperature and oil correction factor are supplied by the oil

sensor (oil level/temperature/quality, B40) through the injection system control module (N3), and are

therefore only available on engines fitted with this sensor.

Quality factors (these are factory-set to base values and can be changed with the HHT, if operating

conditions of the vehicle so necessitate; they influence the start distance):

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:47 PMPage 197 © 2006 Mitchell Repair Information Company, LLC.

Page 2853 of 4133

Warning threshold (in days)

With the HHT it is possible to set a warning threshold of between 5 and 30 days for the remaining time, with a

stepwidth of one day. The basic setting is 30 days.

Display of remaining time

The remaining time is always only displayed in those cases where the following condition is met:

Remaining time (in days) x 40 < remaining distance (in km), and the warning threshold is reached.

The remaining time is displayed in the following cases:

automatically, after 5 s start switch in position 2 or driving, if the warning threshold is reached:

The service symbol and the readout "SERVICE IN ... DAYS" appears for 10 seconds. (On vehicles not

fitted with multifunction display, the current remaining time, the service and the clock symbol appear.)

automatically, after 5 s start switch in position 2 or driving, if the remaining time is exceeded:

The service symbol and the readout "DAYS ... EXCEEDED" appears for 30 s (for 10 s up to mid-July

97). (On vehicles not fitted with multifunction display, the service and the clock symbol appear. The

"remaining time" is displayed with a negative sign (minus sign). The readout flashes in this case.)

After the display reaches the maximum readout of -730 days, the readout remains at this figure! The

readout is displayed with a resolution of 1 day.

As of approx. 06.97 a brief warning signal sounds in addition.

at driver request. The readout is then displayed, as above, for 10 s.

If a speed limit is set at the cruise control, this speed limit is displayed for a short moment before the

ASSYST display.

If certain measured values are not supplied to the ASSYST, e.g. because of failure of a sensor, it switches to

stored substitute values. An appropriate entry is then made in the fault memory of the particular control module.

If the power supply fails, the data are retained. The times without operating voltage (battery disconnected) are

not recorded, however! They can be retroactively included, however, with the HHT.

Active service system

(ASSYST) operating

informationEngine with oil sensor

(e.g. 112, 113, 611)GF00.20-P-0003-01A

Model 210 as of 01.03.97

with engines 111, 602,

604, 605, 606

Model 129, 140, 170, 202 GF00.20-P-0003-01B

2004 Mercedes-Benz ML350

1998-2005 GENINFO Overall vehicle - 163 Chassis

me

Saturday, October 02, 2010 3:47:47 PMPage 208 © 2006 Mitchell Repair Information Company, LLC.

Page 3742 of 4133

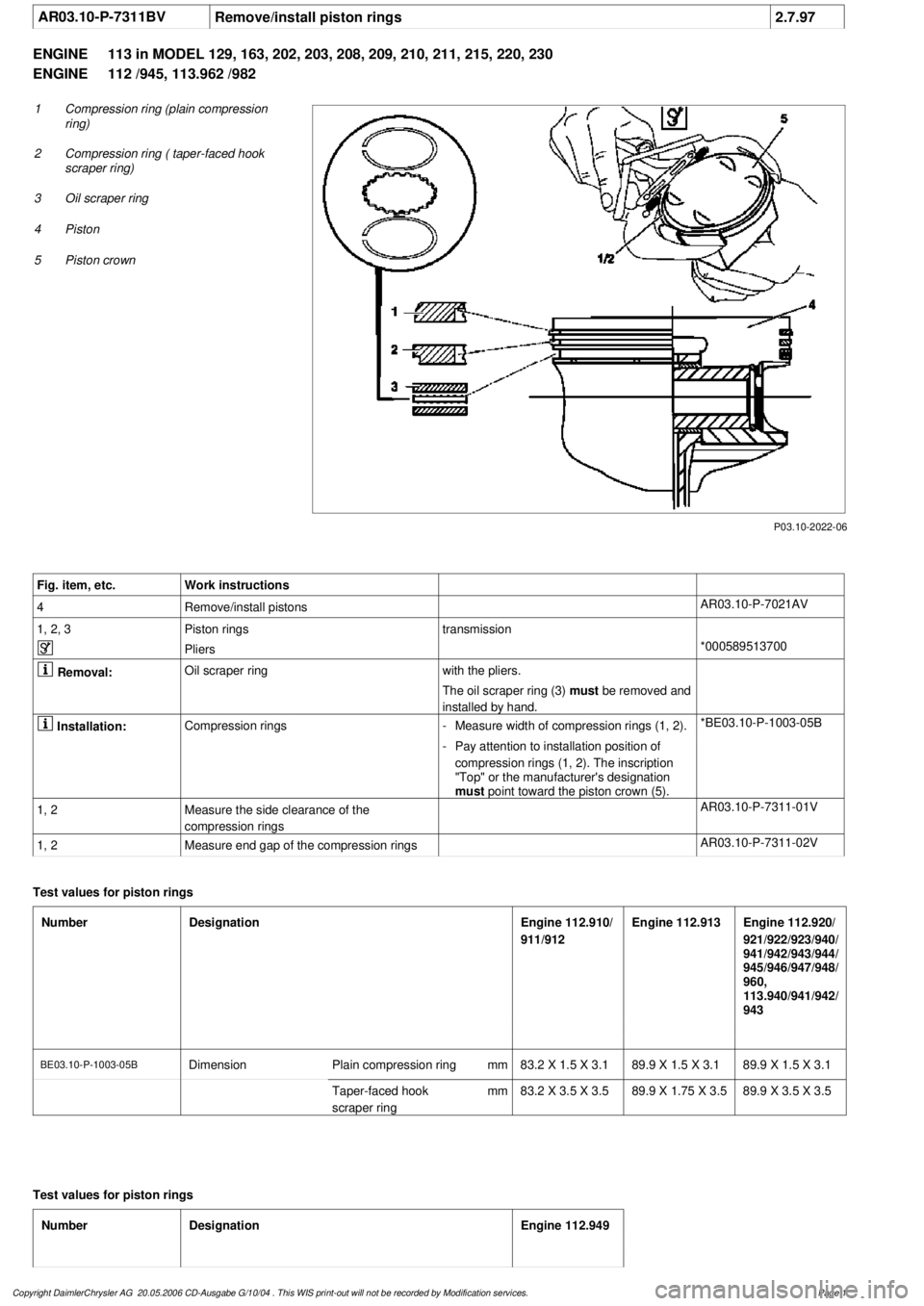

AR03.10-P-7311BV

Remove/install piston rings

2.7.97

ENGINE

113 in MODEL 129, 163, 202, 203, 208, 209, 210, 211, 215, 220, 230

ENGINE

112 /945, 113.962 /982

P03.10-2022-06

1

Compression ring (plain compression

ring)

2

Compression ring ( taper-faced hook

scraper ring)

3

Oil scraper ring

4

Piston

5

Piston crown

Fig. item, etc.

Work instructions

4

Remove/install pistons

AR03.10-P-7021AV

1, 2, 3

Piston rings

transmission

Pliers

*000589513700

Removal:

Oil scraper ring

with the pliers.

The oil scraper ring (3)

must be removed and

installed by hand.

Installation:

Compression rings

-

Measure width of compression rings (1, 2).

*BE03.10-P-1003-05B

-

Pay attention to installation position of

compression rings (1, 2). The inscription

"Top" or the manufacturer's designation

must

point toward the piston crown (5).

1, 2

Measure the side clearance of the

compression rings

AR03.10-P-7311-01V

1, 2

Measure end gap of the compression rings

AR03.10-P-7311-02V

Test values for piston rings

Number

Designation

Engine 112.910/

911/912

Engine 112.913

Engine 112.920/

921/922/923/940/

941/942/943/944/

945/946/947/948/

960,

113.940/941/942/

943

BE03.10-P-1003-05B

Dimension

Plain compression ring

mm

83.2 X 1.5 X 3.189.9 X 1.5 X 3.189.9 X 1.5 X 3.1

Taper-faced hook

scraper ring

mm

83.2 X 3.5 X 3.5

89.9 X 1.75 X 3.5

89.9 X 3.5 X 3.5

Test values for piston rings

Number

Designation

Engine 112.949

Copyright DaimlerChrysler AG 20.05.2006 CD-Ausgabe G/10/04 . This WIS print-out will not be recorde

d by Modification services.

Page 1